Page 1

Page 2

©2007-2010 Dynojet Research, Inc. All Rights Reserved.

Compressed Air Air Fuel Ratio Module Installation and User Guide.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98200006 Version 05 (05/2010)

Page 3

T

ABLE OF

C

ONTENTS

Chapter 1 Air Fuel Ratio Module and

Compressed Air Pump Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Air Fuel Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Installing the Air Fuel Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Compressed Air Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Compressed Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Setting Up the Stand Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Installing the Pump Assembly on the Stand . . . . . . . . . . . . . . . . . . . . . . . .1-9

Connecting the Solenoid Power—i Series Dynos . . . . . . . . . . . . . . . . . . . 1-10

Connecting the Solenoid Power—Non i Series Dynos . . . . . . . . . . . . . . .1-10

Adjusting the Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Chapter 2 Using the Air Fuel Ratio Module

Module and Pump Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Sample and View Air Fuel Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Sampling Air Fuel Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Viewing and Graphing Air/Fuel Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Air Pump Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . .2-7

Sensor Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Correcting Lean Air Fuel Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Pump Maintenance—Stand Alone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Pump Maintenance—On Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Appendix A On-Board Dyno Installation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Compressed Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Installing the Pump Assembly on the Dyno . . . . . . . . . . . . . . . . . . . . . . . .A-2

Installing the Air Hose with the Air Brake . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Adjusting the Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Compressed Air Air Fuel Ratio Module Installation and User Guide

i

Page 4

Page 5

C HAPTER

1

AIR F

C

OMPRESSED

This document provides instructions for installing and using the Air Fuel Ratio

Module and the Compressed Air Pump Assembly with WinPEP 7. To ensure safety and

accuracy in the procedures, perform the procedures as they are described.

This manual will walk you through installation and set up procedures, sampling and

viewing air fuel ratios, and how to maintain your air pump.

Document Part Number: 98200006

Version 5

Last Updated: 05-18-10

This chapter is divided into the following categories:

•Introduction, page 1-2

• Air Fuel Module Installation, page 1-4

UEL

R

AIR P

ATIO

M

ODULE AND

UMP INSTALLATION

• Compressed Air Pump Assembly, page 1-8

Compressed Air Air Fuel Ratio Module Installation and User Guide

1-1

Page 6

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Air Fuel Ratio Module is designed to accurately sample air fuel ratios from

engines burning petroleum based fuels. Be sure to read and follow all warnings found

throughout this manual.

WARNINGS

The sensor and the copper sample tube are hot. Before touching the sensor or

the sample tube, make sure it has cooled.

Leaded racing fuels and two-stroke applications will contaminate the sensor

and dramatically shorten its service life.

The sensor is not covered by a warranty. Be sure to read and understand the

Compressed Air Air Fuel Ratio Module Installation and User manual.

Before turning the pump on, verify there is no water in the hose.

Warm up the vehicle before placing the copper sample tube in the exhaust to

avoid drawing excess water through the pump assembly.

Keep the air pump assembly upright. Tipping the pump assembly may result in

damage to the sensor.

Leaks in the system will result in erroneous readings. Verify there are no cracks

or holes in the hose. Verify the sensor is seated properly in the sensor block.

To ensure accurate readings, pump maintenance should be performed every

six months, or sooner, depending on usage. Refer to “Pump Maintenance—

Stand Alone” on page 2-8 and “Pump Maintenance—On Dyno” on page 2-9 for

more information.

1-2

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 7

AIR FUEL RATIO MODULE AND COMPRESSED AIR PUMP INSTALLATION

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

Introduction

Bold

!

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

Visit us on the World Wide Web at www.dynojet.com and www.winpep.com where

Dynojet provides state of the art technical support, on-line shopping, product images,

and press releases about our latest product line.

Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

“select File

then select the Open choice on the File menu.”

!

Open” means “select the File menu,

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

1-3

Page 8

CHAPTER 1

Air Fuel Module Installation

AIR FUEL MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes installation procedures for the Air Fuel Ratio Module.

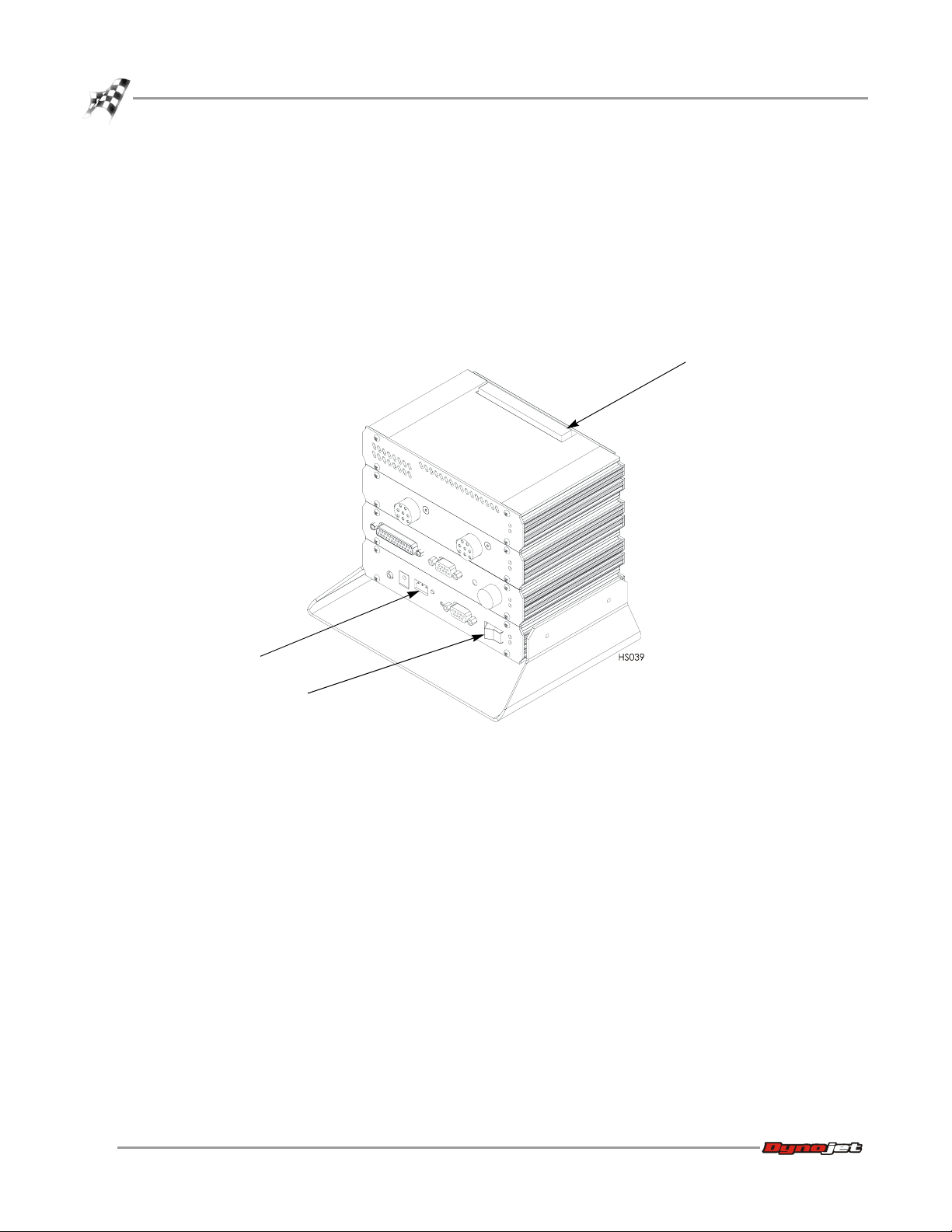

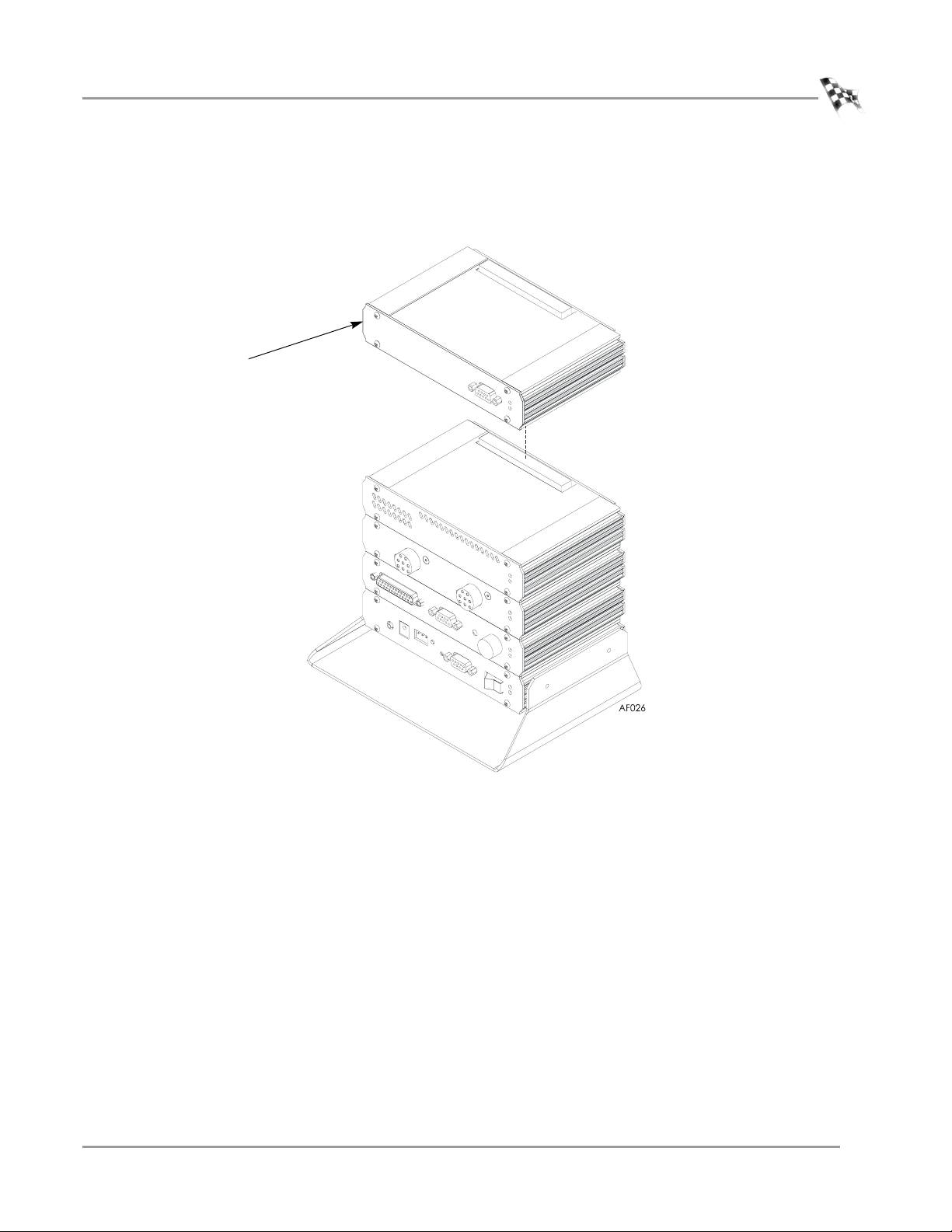

INSTALLING THE AIR FUEL MODULE

1 Verify the main dyno power is disconnected.

2 Turn off the main power switch on the CPU Module unplug the power cord.

3 Remove the dust cover from the existing top module.

dust cover

power cord input

power switch

Figure 1-1: Remove the Dust Cover

1-4

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 9

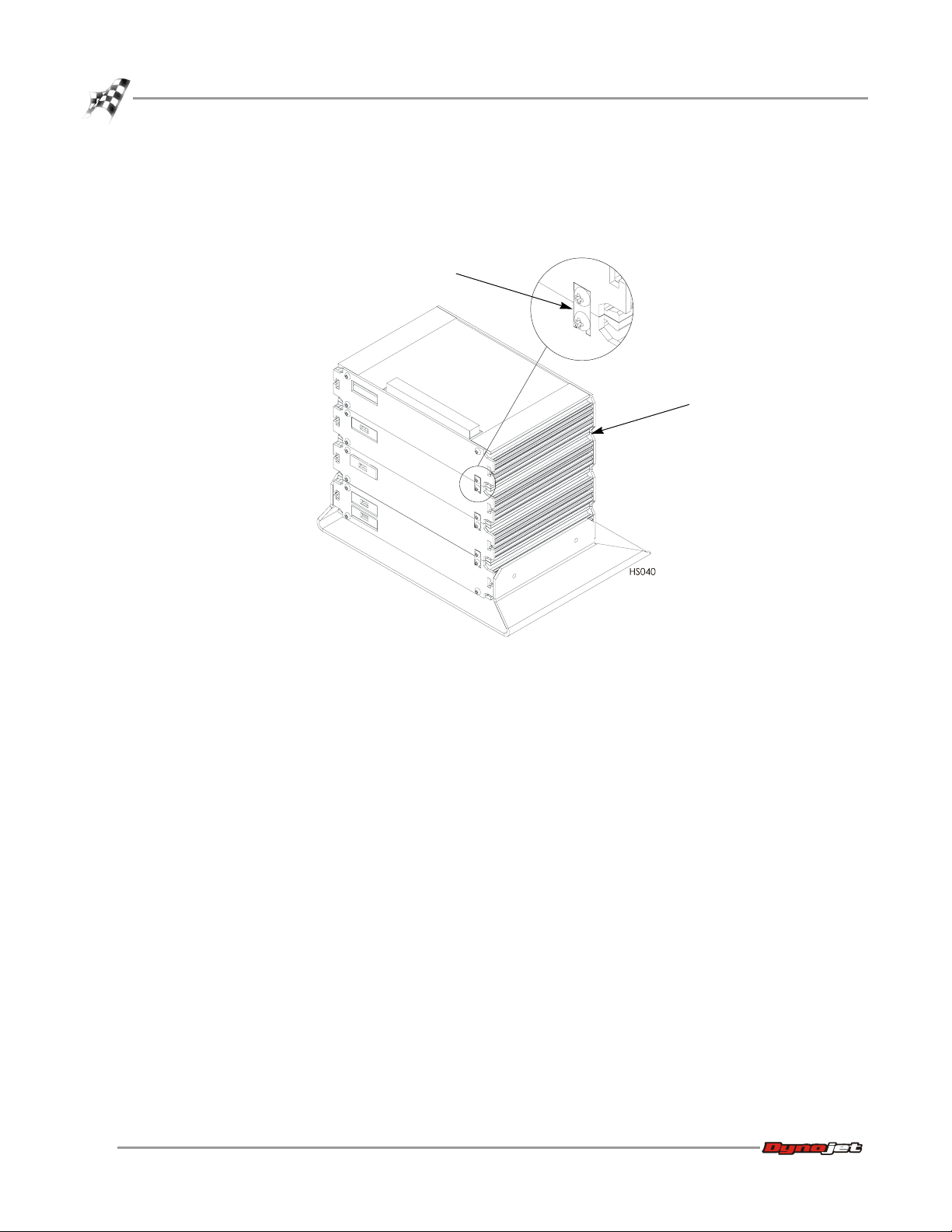

AIR FUEL RATIO MODULE AND COMPRESSED AIR PUMP INSTALLATION

Air Fuel Module Installation

4 Loosen the top right screw on the back of the existing top module.

5 Install the Air Fuel Module into the existing top module. Place the dust cover,

removed in step 3, on the Air Fuel Module.

air fuel module

Figure 1-2: Install the Air Fuel Module

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

1-5

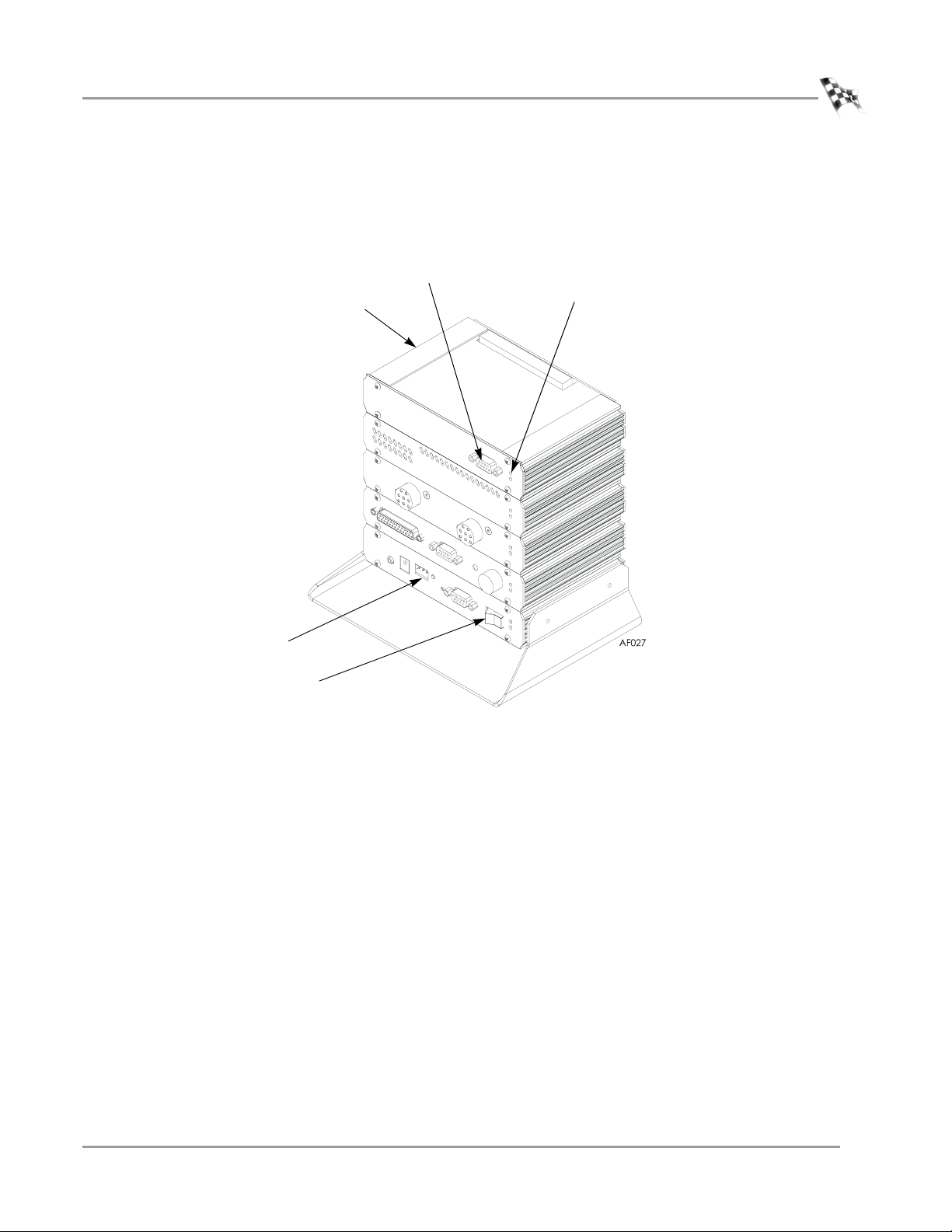

Page 10

CHAPTER 1

Air Fuel Module Installation

6 Secure the grounding strap on the back of the Air Fuel Module to the existing top

module.

7 Secure the Air Fuel Module to the dyno electronics with the plastic tie straps (one

on each side).

grounding strap

plastic tie strap

Figure 1-3: Secure the Grounding Strap

1-6

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 11

AIR FUEL RATIO MODULE AND COMPRESSED AIR PUMP INSTALLATION

Air Fuel Module Installation

8 Attach the 15-pin connector on the sensor cable to the front of the Air Fuel

Module and tighten down the screws.

9 Attach the power cord to the dyno electronics and turn the power switch on.

The green LED light on the Air Fuel Module should now be on.

sensor cable and port

green LED light

air fuel module

power cord input

power switch

Figure 1-4: Attach the Sensor Cable

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

1-7

Page 12

CHAPTER 1

Compressed Air Pump Assembly

COMPRESSED AIR PUMP ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to set up the compressed air pump assembly. Refer to

Appendix A for on-board dyno installation instructions.

COMPRESSED AIR REQUIREMENTS

The following requirements are needed for the compressed air pump assembly:

• Clean and dry air, 100 psi or greater, 5 CFM or better flow

• 1/4-inch NPT pipe thread connector (to attach air to the solenoid or pump ball

valve)

• optional air regulator

SETTING UP THE STAND ASSEMBLY

Secure the upright to the base using three 1/4-20 x 5/8-inch pan-head torx screws.

upright

screw

base

Figure 1-5: Stand Assembly

1-8

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 13

AIR FUEL RATIO MODULE AND COMPRESSED AIR PUMP INSTALLATION

INSTALLING THE PUMP ASSEMBLY ON THE STAND

Use the following instructions to install the pump assembly on the stand. Refer to

Appendix A for on-board dyno installation instructions.

1 Open the toggle clamp and slide the pump assembly on the upright.

2 Close the toggle clamp to secure the pump in place.

3 Secure the sensor(s) to the pump assembly.

Note: Make sure the sensor is on top.

4 Attach the compressed air line to the solenoid.

Note: The compressed air must be clean and dry, 100 psi or greater.

5 Attach the silicone tube(s) to the sensor block.

Note: The length of the silicone tube can be adjusted for your application.

6 Attach the copper sample tube(s) to the silicone tube(s).

Compressed Air Pump Assembly

upright

sensor

attach compressed air

toggle clamp

copper sample tube

silicone tube

attach power cable

Figure 1-6: Installing the Pump Assembly on the Stand

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

1-9

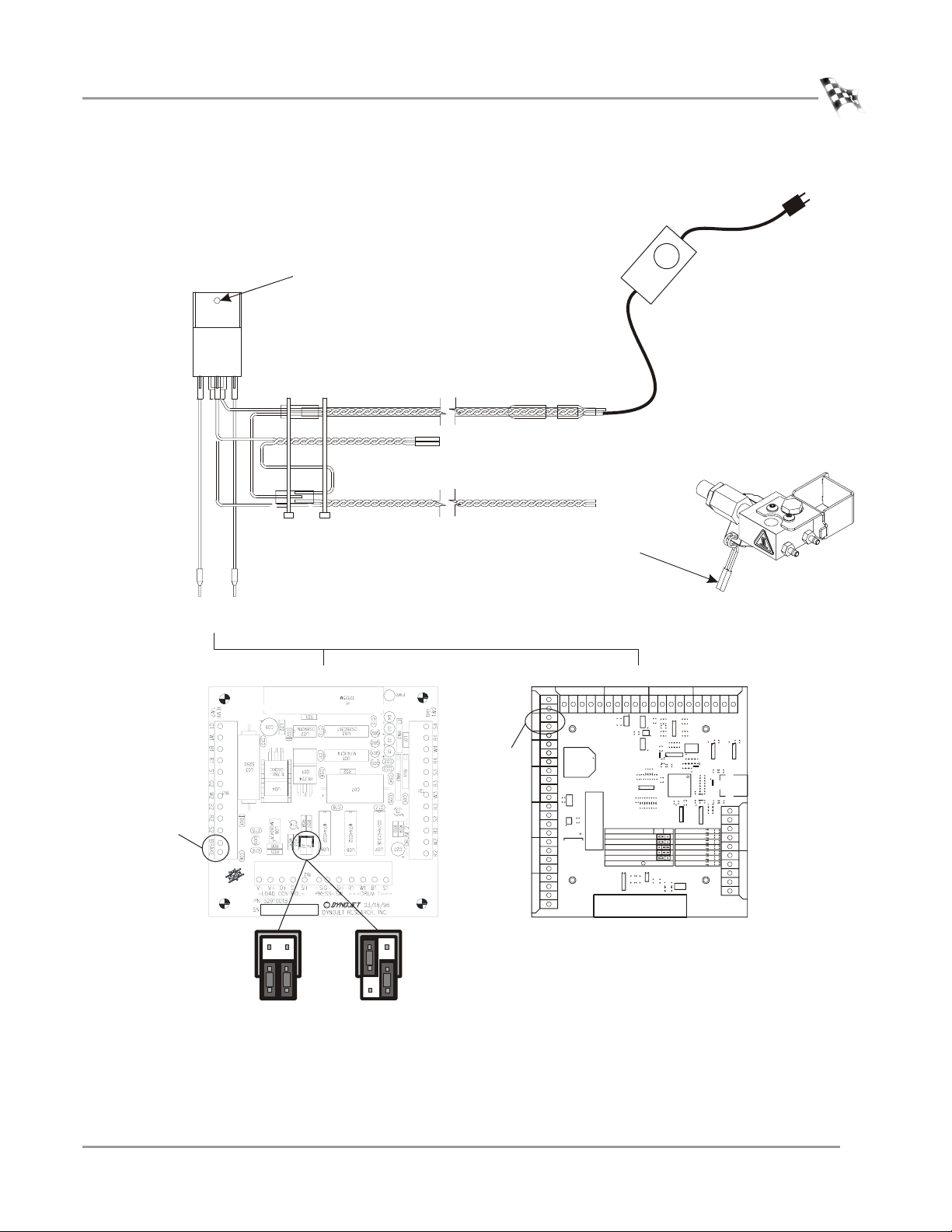

Page 14

CHAPTER 1

Compressed Air Pump Assembly

CONNECTING THE SOLENOID POWER—I SERIES DYNOS

Attach the power cable (P/N 71950403) from PII in the CPI to the solenoid on the

compressed air pump assembly.

CONNECTING THE SOLENOID POWER—NON I SERIES DYNOS

Use the Stand Alone Breakout Board Controlled Compressed Air Pump Remote Kit

(P/N 76493010) to control the air pump assembly using the dyno brakes. When the

dyno brakes are released, the compressed air pump will activate; when the dyno

brake are applied, the compressed air pump will deactivate.

Note: In order for the AFR pump to operate as expected, the jumper settings

must be set to digital brake or eddy current brake and digital brake. Refer to

Figure 1-7 on page 1-11. If these jumper settings are not appropriate for your

dyno application, you must use the manual ball valve (P/N 24300000).

If you use the Dynojet model 248 chassis dyno with Proportional air brake,

unfortunately the kit (P/N 76493010) will not work with the required jumpers

settings so you must use the manual ball valve (P/N 24300000).

1 Using an existing screw on the Breakout board/Advanced Breakout board, secure

the relay to the board.

2 Remove the brake wires from the Breakout board/Advanced Breakout board.

3 Attach the two butt connectors on the relay cable (P/N 76950186) to the brake

solenoid wires. Refer to Figure 1-7 on page 1-11.

4 Attach the two wires on the relay cable (P/N 76950186) to the solenoid wire

butt connectors on the compressed air pump assembly. Refer to Figure 1-7 on

page 1-11.

5 Attach the two ferrules on the relay cable (P/N 76950186) to the BRAKE terminal

on the Breakout board/Advanced Breakout board.

6 Verify your jumper settings. Refer to Figure 1-7 on page 1-11.

7 Plug the power supply into a 110/220V outlet.

1-10

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 15

AIR FUEL RATIO MODULE AND COMPRESSED AIR PUMP INSTALLATION

A

Compressed Air Pump Assembly

secure the relay to one of the

screws on the Breakout

board/Advanced Breakout board

connect to the dyno

brake solenoid wires

connect to the

compressed air

pump assembly

solenoid wires

connect to the BRAKE terminals on the

Breakout board/Advanced Breakout board

Breakout board

brake

J2 J1

eddy current brake

and digital brake

dvanced Breakout board

BRA

brake

c

AP117

J1J2

digital brake

only

Figure 1-7: Routing Cables and Wiring the Breakout Board

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

1-11

Page 16

CHAPTER 1

Compressed Air Pump Assembly

ADJUSTING THE AIR FLOW

To ensure accurate readings, adjust the air flow as necessary to maintain 35L/min. If

you are unable to adjust the air flow to 35L/min., clean the pump then try to adjust

the air flow again. Refer to “Pump Maintenance—Stand Alone” on page 2-8 for more

information.

Adjust the air flow at the end of each exhaust probe to 35 L/min.

1 Attach six inches of the silicon tubing from the top port on the flow meter to the

copper sample tube.

2 Loosen the lock nut.

3 Turn the ball valve to the open position or turn on the air pump using the control

panel.

4 Rotate the vacuum generator exhaust port until the flow meter reads

35 L/min.

5 Tighten the lock nut.

Note: Make sure not to rotate the vacuum generator exhaust port when

tightening the lock nut.

6 Remove air flow meter and the six inches of silicon tube.

Note: Periodically check the air flow and adjust as necessary to maintain 35 L/min.

vacuum generator

exhaust port

sensor

copper sample

tube

lock nut

silicon tube

flow meter

Figure 1-8: Adjusting the Air Flow—Stand Alone

1-12

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 17

U

SING THE

AIR F

UEL

R

ATIO

C HAPTER

2

M

ODULE

This chapter will walk you through the set up procedures, sampling and viewing air

fuel ratios, and how to maintain and troubleshoot your pump assembly. To ensure

safety and accuracy in the procedures, perform the procedures as they are described.

This chapter is divided into the following categories:

•Module and Pump Set Up, page 2-2

• Sample and View Air Fuel Ratios, page 2-3

• Air Pump Maintenance and Troubleshooting, page 2-7

Compressed Air Air Fuel Ratio Module Installation and User Guide

2-1

Page 18

CHAPTER 2

Module and Pump Set Up

MODULE AND PUMP SET UP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes the set up procedures for the Air Fuel Ratio Module and

compressed air pump assembly.

1 Run the vehicle and allow the vehicle to warm up. Excess condensed water is

produced during warm up which can damage the air pump assembly. Allowing

the vehicle to warm up removes this excess water.

2 Place the copper sample tube(s) in the exhaust pipe(s) of the test vehicle.

copper sample

tube

Figure 2-1: Sample Tube Placement

3 Turn on the dyno electronics power. Verify the Air Fuel Ratio Module power

light is on.

4 Turn on the compressed air to the pump assembly.

2-2

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 19

USING THE AIR FUEL RATIO MODULE

Sample and View Air Fuel Ratios

SAMPLE AND VIEW AIR FUEL RATIOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes the procedures to sample and view air fuel ratios using

WinPEP 7.

Note: Allow the sensor to preheat before making a run. An orange LED light on

the Air Fuel Ratio Module will light up continuously and the Air/Fuel gauge on the

MakeRun screen will read 18 when the sensor is ready to make a run.

SAMPLING AIR FUEL RATIOS

1 Verify you are in the MakeRun screen.

2Click the MakeRun Configuration button .

3 In the MakeRun Configuration dialog box, verify the Air/Fuel Heater is on and

click OK.

The Air/Fuel Heater will be on by default when the Air Fuel Ratio Module is added

to the dyno electronics.

Note: To ensure repeatable and accurate measurements, the Air/Fuel Heater must

be allowed to heat up to temperature. An orange LED light on the Air Fuel Ratio

Module will light up continuously when the sensor is ready to make a run.

4 Select the Air/Fuel Type from the drop down list.

Figure 2-2: MakeRun Configuration Window—Air/Fuel Heater

air/fuel heater

must be on

select air/fuel type

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

2-3

Page 20

CHAPTER 2

Sample and View Air Fuel Ratios

5 Verify the air pump assembly is on.

6 Press the green sample button on the pendent to begin recording data.

Note: For more information on how to make a run, refer to the WinPEP 7 User

Guide (on your WinPEP CD or at www.dynojet.com) or the WinPEP 7 Online

Help.

7 Press the sample button a second time to stop sampling.

air/fuel gauge

Figure 2-3: MakeRun Screen—Sampling

Be sure to turn the Air Fuel Heater off when not in use for long periods of time.

2-4

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 21

browse

directories

VIEWING AND GRAPHING AIR/FUEL RUNS

For more information about graph functions and displays, refer to the WinPEP 7 User

Guide (on your WinPEP CD or at www.dynojet.com) or the WinPEP 7 Online Help.

1 Verify you are in the Graph screen.

2Select File

3 Browse the directory and select a run file. You may also select multiple run files.

A preview of the graph will appear. The graph preview is configurable but not

required to open the run file.

4 Once you have found the run and configured the graph preview (optional),

click Open.

!

Open.

USING THE AIR FUEL RATIO MODULE

Sample and View Air Fuel Ratios

run file

graph preview

Figure 2-4: Graph Screen—Open Dialog Box

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

2-5

Page 22

CHAPTER 2

Sample and View Air Fuel Ratios

The run information is displayed in the ListView along with a graph of the run.

5 Click on the axis channel label and choose Air/Fuel from the list.

Note: Available channels may differ depending on your dyno model and

configuration.

The graph will now display the run with air/fuel readings.

axis channel

label

choose air/fuel from

the list of options

Figure 2-5: Main Graph Display with Air/Fuel

2-6

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 23

USING THE AIR FUEL RATIO MODULE

Air Pump Maintenance and Troubleshooting

AIR PUMP MAINTENANCE AND TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section contains sensor information and describes the procedures for

maintaining and troubleshooting the pump assembly.

Make sure you are aware of the following items:

• Keep the air pump upright. Tipping the pump may result in damage to the sensor.

• Leaks in the system will result in erroneous readings. Verify there are no cracks or

holes in the hoses. Verify the sensor is seated properly in the sensor block.

SENSOR INFORMATION

Under optimal conditions, the sensor life can exceed 1500 hours. When using leaded

race fuel, 2.5 grams of lead per gallon of fuel will reduce the expected life of the

sensor to less than 100 hours.

The sensor is not covered by a warranty. Be sure to read and understand the

Compressed Air Air Fuel Ratio Module Installation and User manual.

CORRECTING LEAN AIR FUEL READINGS

Refer to the instructions below if you are experiencing air fuel ratio readings that are

leaner than you expected.

1 Verify the pump is on.

2 Check the system for restrictions in the air flow such as a kinked hose or dirty

pump.

3 Verify the copper sample tube is not kinked or clogged and is inserted into the

exhaust as far as possible. Refer to Figure 2-1.

4 Check for leaks in the system.

4a Verify all hoses are securely attached to the fittings.

4b Verify there are no cracks or holes in the hoses.

4c Verify the sensor is seated properly in the sensor block.

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

2-7

Page 24

CHAPTER 2

Air Pump Maintenance and Troubleshooting

PUMP MAINTENANCE—STAND ALONE

To ensure accurate readings, pump maintenance should be performed every six

months, or sooner, depending on usage. Periodically check the air flow and adjust as

necessary to maintain 35 L/min for each sample tube. If you are unable to adjust the

air flow to 35 L/min, clean the pump. Use a solvent to clean all pump pieces very

carefully.

1 Remove the ball valve or solenoid (for pumps using the control pod).

2 Loosen the lock nut.

3 Remove the vacuum generator exhaust port.

4 Remove the venturi body.

5 Remove the sensor(s) from the sensor block.

6 Remove the two screws securing the sensor block to the toggle clamp.

7 Use a solvent to carefully clean the vacuum generator exhaust port, venturi body,

and sensor block.

Note: Be careful not to damage the internal structure of the venturi body.

8 Install the sensor block using the two screws removed earlier.

9 Install the venturi body, vacuum generator exhaust port, and ball valve or

solenoid.

10 Install the sensor(s).

11 Replace the silicon and copper tubing if necessary.

12 Re-calibrate the pump using the flow meter. Refer to page 1-12 for more

information.

vacuum generator

exhaust port

lock nut

venturi body

toggle clamp

sensor block

solenoid

Figure 2-6: Pump Maintenance—Stand Alone Pump

sensor

copper sample

tube

silicon tube

2-8

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 25

PUMP MAINTENANCE—ON DYNO

To ensure accurate readings, pump maintenance should be performed every six

months, or sooner, depending on usage. Periodically check the air flow and adjust as

necessary to maintain 35 L/min for each sample tube. If you are unable to adjust the

air flow to 35 L/min, clean the pump. Use a solvent to clean all pump pieces very

carefully.

1 Remove the eight screws securing the drum module panel to the dyno. Set the

screws and the panel aside. For more information on removing the panel, refer to

your dyno installation guide.

2 Remove the hose connecting the sensor block and the venturi body.

3 Remove the two screws securing the sensor block to the pump housing.

USING THE AIR FUEL RATIO MODULE

Air Pump Maintenance and Troubleshooting

pump housing

sensor block screws

sensor block

(not visible from this view)

venturi body

hose

Figure 2-7: Remove the Screws Securing the Sensor Block

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

2-9

Page 26

CHAPTER 2

Air Pump Maintenance and Troubleshooting

4 Remove the sensor(s) from the sensor block.

5 Remove the sensor block.

6 Remove the silicon tube from the sensor block.

7 Loosen the vacuum generator lock nut.

8 Remove the vacuum generator exhaust port and venturi body.

9 Unscrew the venturi body from the solenoid.

10 Use a solvent to carefully clean the vacuum generator exhaust port, venturi body,

and sensor block.

Note: Be careful not to damage the internal structure of the venturi body.

11 Secure the solenoid to the venturi body.

12 Install the vacuum generator exhaust port to the venturi body.

13 Secure the sensor block to the pump housing using the two screws removed

earlier.

14 Install the sensor(s).

15 Replace the silicon tube between the sensor block and the venturi body.

16 Replace the silicon tube to the sensor block.

17 Re-calibrate the pump using the flow meter. Refer to page A-5 for more

information.

sensor

silicon tube

sensor block

Figure 2-8: Pump Maintenance—On Dyno Pump

2-10

Compressed Air Air Fuel Ratio Module Installation and User Guide

vacuum generator

exhaust port

venturi body

solenoid

lock nut

Page 27

A PPENDIX

A

ON-B

This appendix provides instructions for installing the compressed air pump on your

motorcycle dynamometer. To ensure safety and accuracy in the procedures, perform

the procedures as they are described.

OARD

D

YNO INSTALLATION

Compressed Air Air Fuel Ratio Module Installation and User Guide

A-1

Page 28

APPENDIX A

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to install the compressed air pump assembly on your

motorcycle dynamometer.

COMPRESSED AIR REQUIREMENTS

The following requirements are needed for the on-board compressed air pump

assembly:

• Clean and dry air, 100 psi or greater, 5 CFM or better flow

• Fittings to hook your air system to a 3/8-inch inside diameter hose (if no air brake is

present)

• optional air regulator

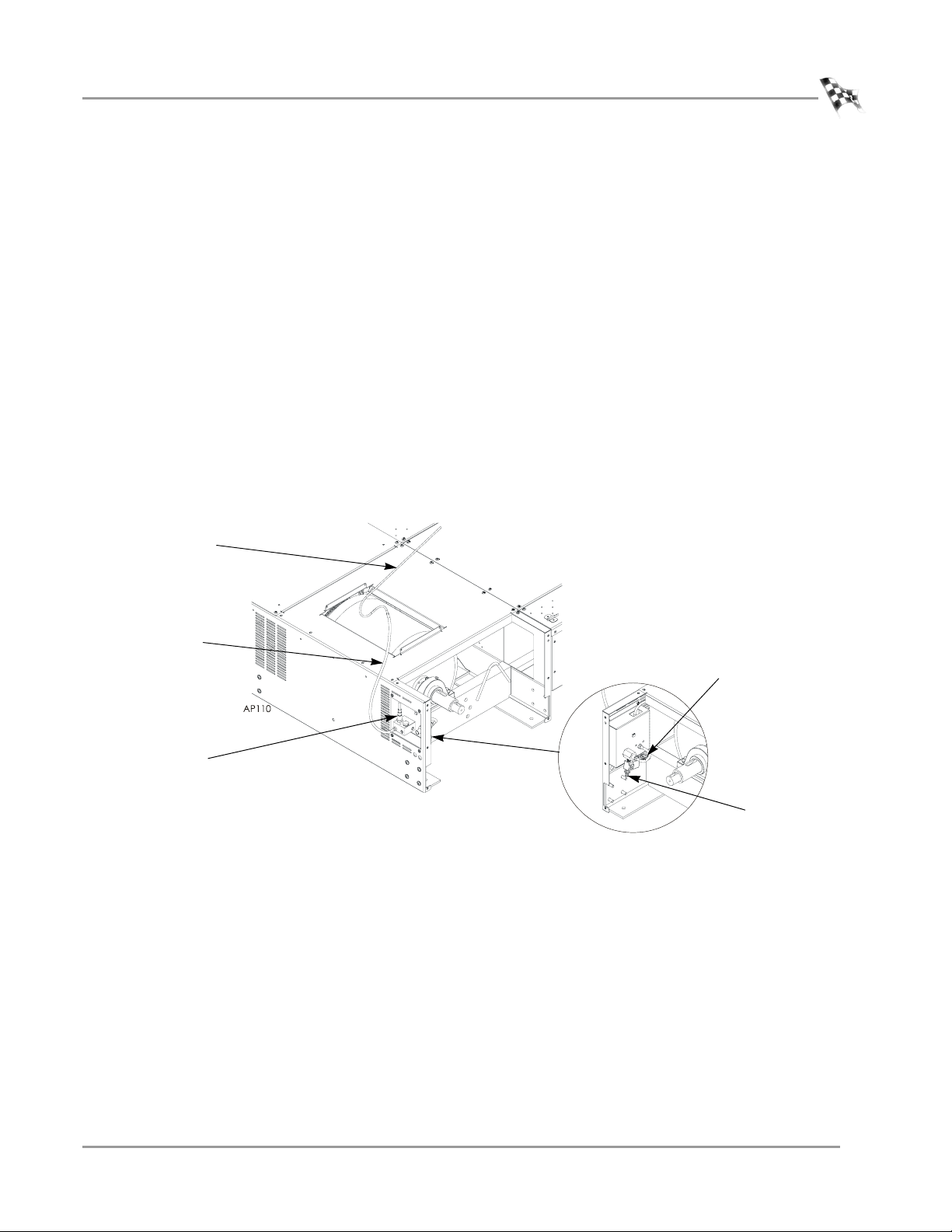

INSTALLING THE PUMP ASSEMBLY ON THE DYNO

1 Remove the eight screws securing the drum module panel to the dyno. Set the

screws and the panel aside. For more information on removing the panel, refer to

your dyno installation guide.

2 Secure the pump housing to the dyno using four 1/4-20 torx screws.

pump housing

Figure A-1: Install the Pump Housing

A-2

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 29

ON-BOARD DYNO INSTALLATION

Installation

3 Run the provided air hose from the air pump assembly to the front of your dyno.

If you have an air brake, refer to “Installing the Air Hose with the Air Brake” on

page A-4.

You will need to remove the carriage assembly and top center cover to route the

air hose. Refer to your dyno installation guide for instruction on removing the top

cover.

4 Route the air hose through the air access holes in the front of the dyno.

5 Attach the hose to your air supply.

6 Attach the sensor.

7 Attach the silicone hose and copper sample tube to the sensor block.

8 Attach the sensor cable to the corresponding cable from the inside back panel of

the dyno.

9 Attach the connector from the pump solenoid to the cable on the inside back

panel of the dyno.

10 Replace the top center cover and carriage assembly.

11 Replace the drum module panel using the screws removed earlier.

copper sample

tube

silicon tube

sensor

solenoid connector

attach air

Figure A-2: Installing the Sensor and Copper Sample Tube

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

A-3

Page 30

APPENDIX A

Installation

INSTALLING THE AIR HOSE WITH THE AIR BRAKE

Use the following instructions to install the air hose when the air brake is installed.

1 Install the tee.

1a Cut the hose running from the air brake as shown in Figure A-3.

1b Slide a hose clamp over each piece of hose.

1c Insert the tee.

1d Secure the hose clamps.

2 Measure the distance from the tee to the air pump assembly and cut a piece of

hose.

3 Attach the hose to the air pump assembly. This connection does not require a

hose clamp.

4 Slide a hose clamp over the hose.

Note: The hose clamp is only needed on the tee end.

5 Slide the hose over the tee.

6 Secure the hose clamp.

AP115

air hose to the pump

air hose to the brake

air hose to the brake

cut here

tee

air hose to the pump

Figure A-3: Installing the Air Hose with the Air Brake

A-4

Compressed Air Air Fuel Ratio Module Installation and User Guide

Page 31

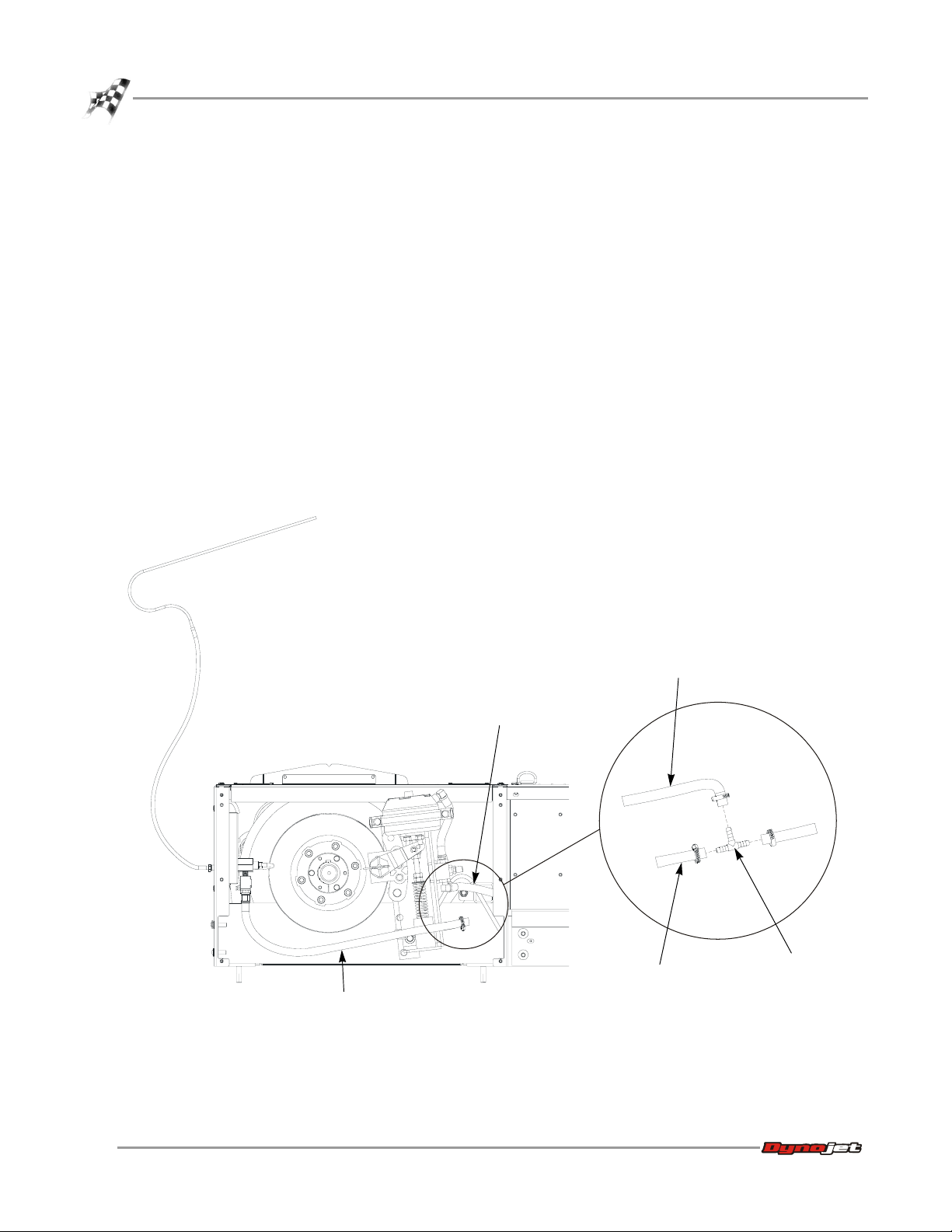

ADJUSTING THE AIR FLOW

To ensure accurate readings, adjust the air flow as necessary to maintain 35L/min. If

you are unable to adjust the air flow to 35L/min. for each sample tube, clean the

pump then try to adjust the air flow again. Refer to “Pump Maintenance—On Dyno”

on page 2-9 for more information.

Adjust the air flow at the end of the exhaust probe to 35 L/min.

1 Attach six inches of the silicon tubing from the top port on the flow meter to the

copper sample tube.

2 Loosen the lock nut.

3 Turn on the air pump with the control panel.

4 Rotate the vacuum generator exhaust port until the flow meter reads

35 L/min.

5 Tighten the lock nut.

Note: Make sure not to rotate the vacuum generator exhaust port when

tightening the lock nut.

6 Remove the air flow meter and the six inches of silicon tube.

Note: Periodically check the air flow and adjust as necessary to maintain 35 L/min.

copper sample

tube

ON-BOARD DYNO INSTALLATION

Installation

silicon tube

sensor

vacuum generator exhaust port

and lock nut

flow meter

Figure A-4: Adjusting the Air Flow—On Dyno

Version 5 Compressed Air Air Fuel Ratio Module Installation and User Guide

A-5

Page 32

Page 33

Loading...

Loading...