Page 1

Page 2

©2005 Dynojet Research, Inc. All Rights Reserved.

Analog Module Installation and User Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98198118 Version 01 (08/2005)

Page 3

T

ABLE OF

C

ONTENTS

Chapter 1 Analog Module Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Analog Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Connecting and Disconnecting Power to the Dyno . . . . . . . . . . . . . . . . . .1-3

Accessing the Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Installing the Analog Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Routing the Analog Module Cable Assembly . . . . . . . . . . . . . . . . . . . . . . .1-6

Connecting the Sensor Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Chapter 2 Analog Channel Configuration and Viewing Data

Analog Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Configuring the Analog Channel(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Customizing Sensor Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Saving and Loading Sensor Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Editing a Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Configuring the Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Analog Module Installation and User Guide

i

Page 4

Page 5

A

NALOG

M

C HAPTER

1

ODULE INSTALLATION

This document provides instructions for installing and using the Analog Module with

WinPEP 7. To ensure safety and accuracy in the procedures, perform the procedures

as they are described.

This chapter will walk you through installing the Analog Module, routing the Analog

Module cable assembly, and connecting the sensor cables. Chapter two will walk you

through configuring your Analog Module and viewing the data.

Document Part Number: 98198118

Version 0 1

Last Updated: 08-31-05

This chapter is divided into the following categories:

•Introduction, page 1-2

• Analog Module Installation, page 1-3

• Routing the Analog Module Cable Assembly, page 1-6

• Connecting Sensor Cables, page 1-7

Analog Module Installation and User Guide

1-1

Page 6

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Analog Module, when added to Dynojet's market leading inertia dynamometer,

results in a complete vehicle performance test.

The Analog Module is capable of measuring any 0-5 volt signal on a vehicle and comes

with an unterminated cable to allow you to hook up your own sensors. Additional

sensors and cables are available from Dynojet.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

part number description quantity

66104002 Analog Module Sub-Assembly 1

76950818 Cable, 4 Channel Auxiliary Input Module 1

76950416 Cable, Sensor-Unterminated 1

The following sensors are optional:

76199007 0-100 PSI Gage (Relative) Sensor and Cable

76199006 0-50 PSI Absolute Sensor and Cable

Bold

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

PARTS LIST

The following table lists all of the parts included in the Analog Module installation kit

(P/N 66104002). Check your kit against the parts listed to make sure you have

received all of the parts. If any part is missing, contact Dynojet Technical Support.

Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

“select File

then select the Open choice on the File menu.”

Open” means “select the File menu,

1-2

Analog Module Installation and User Guide

Page 7

ANALOG MODULE INSTALLATION

ANALOG MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to access the dyno electronics, install the Analog Module,

route the Analog Module cable assembly, and connect the sensor cables.

CONNECTING AND DISCONNECTING POWER TO THE DYNO

Always disconnect the power before beginning any installation procedures.

Refer to your dyno installation manual for more information on disconnecting the

power to your specific dyno.

1 Use the main breaker to turn power on and off to the dyno.

2 Disconnect the power plug to ensure all power has been removed from the dyno.

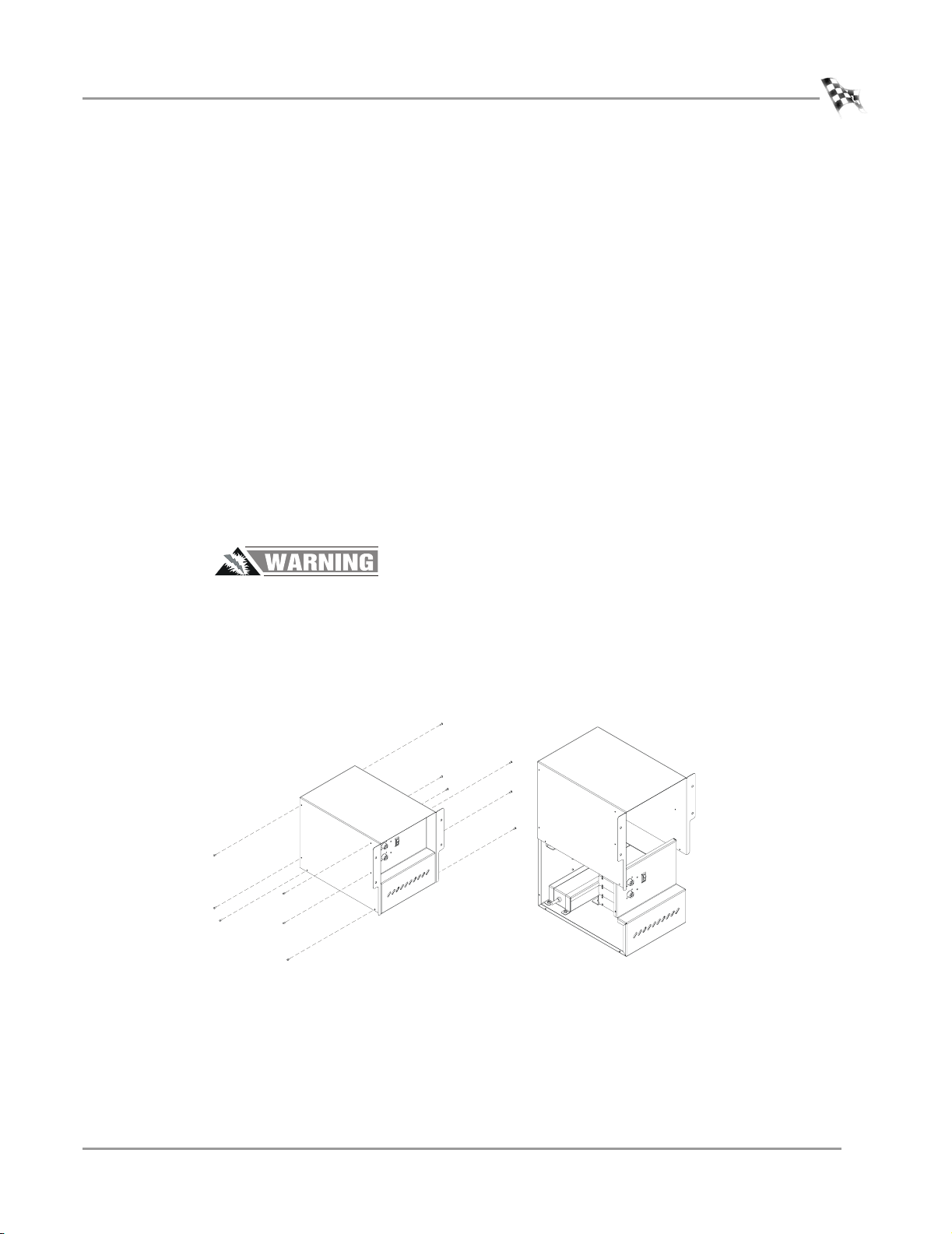

ACCESSING THE DYNO ELECTRONICS

You will need to access your dyno electronics in order to add the Analog Module. Use

the following steps to access the dyno electronics.

1 Turn off the main power to the dyno.

Analog Module Installation

To prevent possible injury always disconnect all power to the dyno.

2 Locate the dyno electronics enclosure.

Refer to your dyno installation manual for more information on locating and

accessing the dyno electronics encloser.

3 Remove the twelve screws securing the cover and lift the cover off.

Figure 1-1: Remove Electronics Enclosure Cover

Vers ion 1 Analog Module Installation and User Guide

1-3

Page 8

CHAPTER 1

Analog Module Installation

4 Add the Analog Module to the top of the dyno electronics. Refer to “Installing the

Analog Module” on page 1-5.

5 Leave the dyno electronics enclosure out. You will need to route any sensor

cables to the Analog Module as they are installed.

dyno electronics

Figure 1-2: Inside the Electronics Enclosure

1-4

Analog Module Installation and User Guide

Page 9

INSTALLING THE ANALOG MODULE

1 Verify the main dyno power is disconnected.

2 Turn off the main power switch on the CPU Module and unplug the power cord.

3 Remove the dust cover from the existing top module.

ANALOG MODULE INSTALLATION

Analog Module Installation

dust cover

power cord

input

power switch

Figure 1-3: Remove Dust Cover

4 Loosen the top right screw on the back of the existing top module.

5 Plug the Analog Module into the existing top module. Place the dust cover,

removed in step 3, on the Analog Module.

6 Secure the grounding strap on the back of the Analog Module to the existing top

module.

7 Secure the Analog Module to the dyno electronics with the plastic tie straps (one

on each side).

grounding strap

Figure 1-4: Secure Grounding Strap

plastic tie strap

Vers ion 1 Analog Module Installation and User Guide

1-5

Page 10

CHAPTER 1

Analog Module Installation

ROUTING THE ANALOG MODULE CABLE ASSEMBLY

1 Route the Analog Module cable assembly through the cable clamp on the back of

the dyno electronics enclosure.

1a Loosen the two screws and lift the clamp up to slide the analog cable

through.

1b Secure the clamp with the two screws.

2 Attach the connector on the Analog Module cable assembly to the front of the

Analog Module.

cable clamp

analog module

cable assembly

analog module

Figure 1-5: Attach the Analog Module Cable Assembly to the Analog Module

1-6

Analog Module Installation and User Guide

Page 11

CONNECTING THE SENSOR CABLES

1 Attach the sensor cable(s) to the Analog Module cable assembly. The two types of

sensor cables are described below and shown in Figure 1-6.

• An unterminated sensor cable, included with your Analog Module, is designed

to connect directly to or “tap into” the vehicle’s existing sensors. Wire the

cable as follows:

•Red is 5 VDC

• Green is sensor output

•Black is GND

• A terminated sensor cable is designed with a specific sensor attached for

measuring a specific pressure.

2 Once the sensor cable is connected to the analog cable, you will need to route the

sensor cable to the appropriate location on your vehicle for the pressure you are

measuring.

connect to

analog module

analog module cable assembly

ANALOG MODULE INSTALLATION

Analog Module Installation

terminated sensor cable

unterminated sensor cable

red

green

black

Figure 1-6: Attach the Sensor Cable(s) to the Analog Module Cable Assembly

3 Attach the power cord to the CPU Module and turn the dyno electronics power

switch on.

4 Connect all power to the dyno.

5 The green LED light on the Analog Module should now be on.

6 Replace the dyno electronics cover. Refer to Figure 1-1 on page 1-3.

Vers ion 1 Analog Module Installation and User Guide

1-7

Page 12

Page 13

A

NALOG

C

HANNEL

C HAPTER

C

ONFIGURATION

2

AND

This chapter provides instructions for configuring the Analog Module and viewing the

data with WinPEP 7. To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

This chapter is divided into the following categories:

• Analog Channel Configuration, page 2-2

•Viewing Data, page 2-7

V

IEWING

D

ATA

Analog Module Installation and User Guide

2-1

Page 14

CHAPTER 2

Analog Channel Configuration

ANALOG CHANNEL CONFIGURATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

You can configure up to four different analog channels. Use the following instructions

to configure the analog channel(s).

CONFIGURING THE ANALOG CHANNEL(S)

1 Verify you are in the MakeRun screen.

2 Verify you are connected to the dyno electronics.

Note: You must be connected to the dyno electronics and the Analog Module

must be installed for the analog channels to be available.

Note: For more information on connecting to the dyno electronics, refer to the

WinPEP 7 User Guide (on your WinPEP CD or at

www.dynojet.com/manuals.shtml) or the WinPEP 7 Online Help.

3Select Too ls

4 Select the desired analog channel tab.

5Click the Enable logging on this channel check box.

6Click Sensor Helper.

MakeRun Options Analog Configuration.

analog channel tabs

check box

sensor helper

Figure 2-1: Analog Configuration Window—Select Desired Channel

2-2

Analog Module Installation and User Guide

Page 15

ANALOG CHANNEL CONFIGURATION AND VIEWING DATA

7 Choose a sensor from the drop down list.

8Click OK.

Figure 2-2: Analog Sensor Helper Window—Choose a Sensor

Analog Channel Configuration

sensor drop

down list

9 Enter the analog channel name in the Display Name field.

10 Click OK to enter these changes or click Cancel to abort the changes and return

to the MakeRun screen.

display name

field

Figure 2-3: Analog Configuration Window—Enter the Display Name

Vers ion 1 Analog Module Installation and User Guide

2-3

Page 16

CHAPTER 2

Analog Channel Configuration

CUSTOMIZING SENSOR TABLES

Some sensors may require additional rows. You may customize your sensor table by

adding or removing rows.

1 Right click on the table.

2 Choose Add Row or Remove Row to customize your table.

add row

Figure 2-4: Analog Configuration Window—Customize the Sensor Table

2-4

Analog Module Installation and User Guide

Page 17

ANALOG CHANNEL CONFIGURATION AND VIEWING DATA

SAVING AND LOADING SENSOR TABLES

Commonly used sensor tables may be saved to a file allowing you to load and use

them later.

1Click Save Sensor Table to save the sensor table to a file.

2 Choose a location and click Save.

3Click Load Sensor Table to load a saved sensor table.

4Click OK to load the sensor table or click Cancel to abort the changes and return

to the MakeRun screen.

load sensor

table

Analog Channel Configuration

save sensor

table

Figure 2-5: Analog Configuration Window—Save and Load Sensor Tables

Vers ion 1 Analog Module Installation and User Guide

2-5

Page 18

CHAPTER 2

Analog Channel Configuration

EDITING A GAUGE

You will need to either create a new gauge or edit an existing gauge to represent your

analog channel. For this example, we will edit an existing gauge.

For more detailed information on creating a gauge, refer to the WinPEP 7 manual.

1 Verify you are in Advanced Mode. To change the user level click

To ol s

2 If you are not already there, go to the MakeRun screen. Click the Make Run

button . The last template used is automatically loaded.

3Click the Edit Mode button . You cannot edit gauges unless you are in Edit

Mode.

4 Right click on the gauge and choose Gauge Properties.

5 The Gauge Property Editor dialog box will appear.

Each type of gauge has a slightly different dialog box, but most share the same

properties.

6 Select the analog channel you created earlier from the Data Channel drop down

list.

The analog channel selected automatically appears in the Upper Title and on the

gauge.

Note: You must be connected to the dyno electronics and the Analog Module

must be installed for the list of analog channels to be available.

7Click OK to enter these changes or click Cancel to abort the changes and return

to the MakeRun screen.

Environment Options and click on the General tab.

upper title

2-6

Analog Module Installation and User Guide

data channel

drop down list

Figure 2-6: Gauge Property Editor Dialog Box

Page 19

ANALOG CHANNEL CONFIGURATION AND VIEWING DATA

VIEWING DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Once the analog channel is configured, the information will automatically be

recorded when you make a run.

1 Make your dyno run. Refer to the dyno installation and WinPEP 7 manuals for

more detailed information on making a run.

2 By default, a graph of your run will appear. In order to view the analog channel

data recorded, you will need to configure your graph to show the analog channel.

Viewing Data

CONFIGURING THE GRAPH

Once the run is graphed, you can configure the graph to show the analog channel(s)

using the axis selection buttons.

For more detailed information on configuring graphs, refer to your WinPEP 7 user

guide.

1 Click on any of the three axis channel labels.

Note: Available channels may differ depending on your dyno model and

configuration.

2 Choose the analog channel from the list.

axis channel

label

axis channel

options-analog

channels

Figure 2-7: Configuring the Graph Screen

Vers ion 1 Analog Module Installation and User Guide

2-7

Page 20

Page 21

Loading...

Loading...