Page 1

AIR PUMP TROUBLESHOOTING GUIDE

Warnings

The sensor and the copper sample tube are hot. Before touching

the sensor or the sample tube, make sure it has cooled.

To avoid the risk of electrical shock, do not disassemble the

pump housing. No user serviceable parts inside.

Before assembling the filter, lubricate the threads on the filter stem

and filter bowl using the grease provided with the replacement

filters or a similar grease. Do not use silicone. The filter stem may

break if not lubricated.

Keep the air pump upright. Tipping the pump

may result in damage to the sensor.

Running the pump with the filter clogged,

hose kinked, or filter removed will damage

the pump and void the warranty.

Always allow the air pump to run for five

minutes, after the dyno runs are complete, to

allow the air pump to cool.

The Air Pump Assembly has a 90 day warranty.

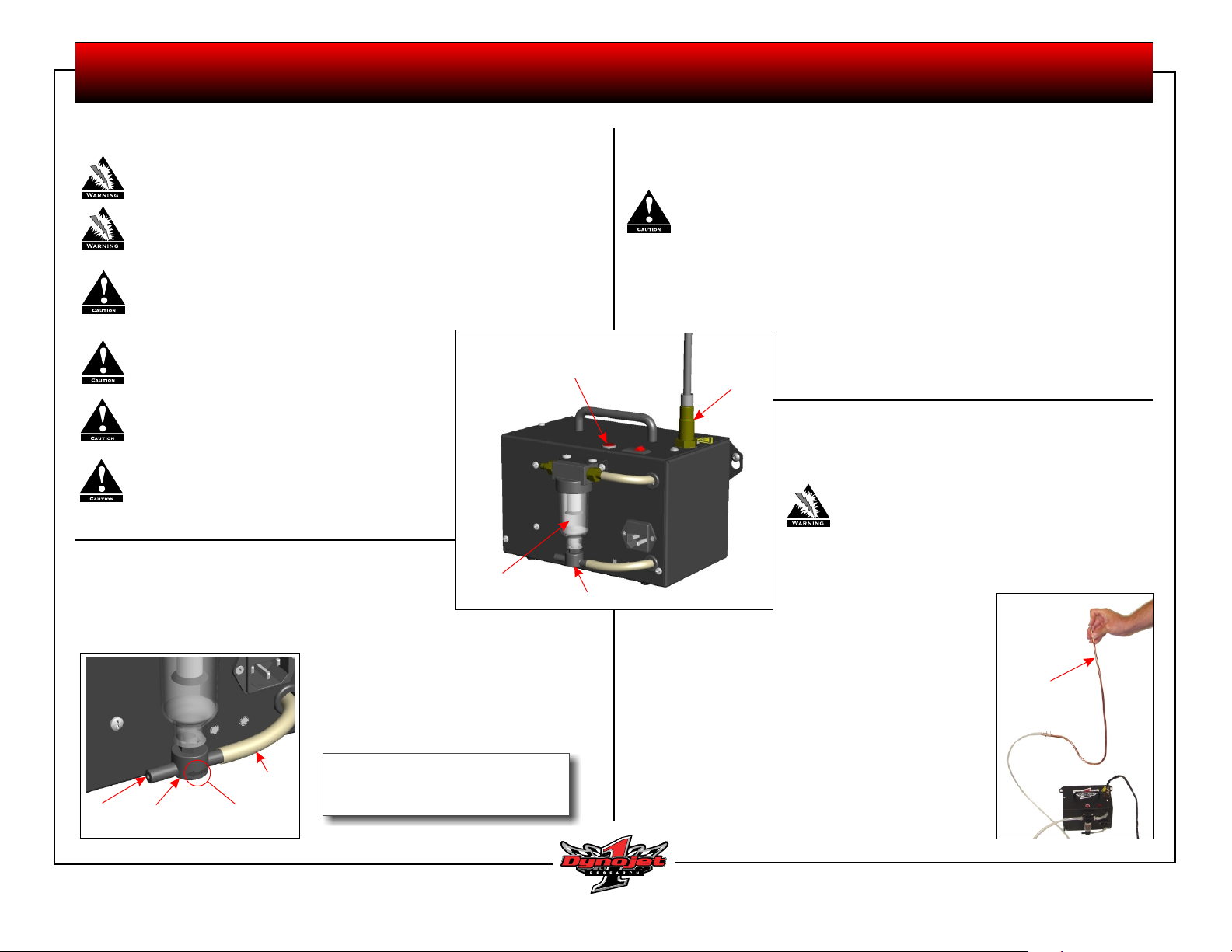

warning light

Water Aspirator

filter assembly

1. Verify the water aspirator is removing water from

the filter bowl during operation.

2. If water is collecting in the bowl and is not coming out of the aspirator

inlet

outlet

water

aspirator

direction

of flow

outlet, clean the aspirator.

3. Check for leaks in the aspirator. Refer to

the Air Fuel Ratio Module User Guide

for more information on finding and

fixing leaks.

Refer to the Air Fuel Ratio Module

User Guide on your WinPEP CD for more

information about the air pump.

water aspirator

Filter Assembly

Clean the filter daily or more often depending on usage.

DO NOT wait for the red warning light to come on.

Before assembling the filter, lubricate the threads on the filter stem and

filter bowl using the grease provided or a similar grease.

T The red warning light will come on when there is sufficient blockage in the

filter or if there is some other restriction in the system.

T If cleaning the filter does not result in free air flow, replace the filter. Be sure

to check for other restrictions in the system.

T Refer to the Air Fuel Ratio Module User Guide for

instructions on cleaning and replacing the filter.

sensor

T Refer to the back of this card for the filter assembly

replacement parts.

System Check

Perform a system check before and after every

tuning session to ensure accurate readings.

The copper sample tube is hot. Before touching

the sample tube, make sure it has cooled.

1. Cover the end of the copper sample tube with your

finger. The red warning light should come on in less

than three seconds.

2. If the warning light does not come on, there may

be a leak in the system.

Refer to the Air Fuel Ratio Module User Guide

for more information on finding and fixing leaks.

3. If the warning light stays on after removing your

finger (allowing air flow to resume), clean the filter.

4. Repeat steps 1-3 to confirm the warning light comes

on when you cover the copper sample tube with

your finger and turns off when you remove

your finger.

copper

sample tube

P/N 98199104 • Version 4

For assistance, call Dynojet Technical Support at 1-800-992-3525, visit www.dynojet.com, or write to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

© Copyright 2001-2002 Dynojet Research, Inc. All Rights Reserved. 051502SD

Page 2

AIR PUMP TROUBLESHOOTING GUIDE

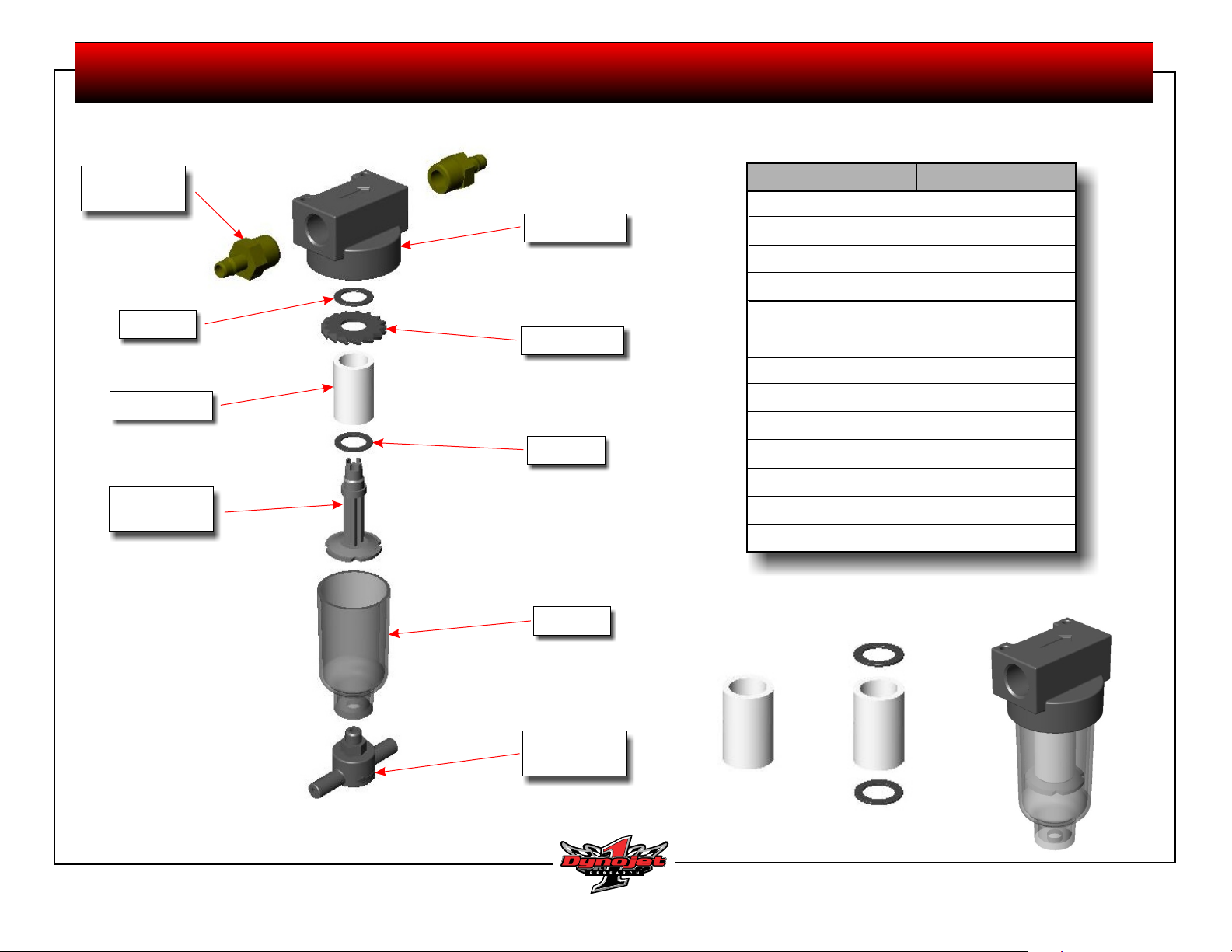

Filter Assembly Replacement Parts

fitting

(P/N 34111220)

seal

filter element

filter stem

(P/N 34492000)

filter housing

deflector

seal

filter bowl

part number

The following parts are common replacements:

29909000

29909001

34491000

34491001

34310002

34492000

11108800

24730300

The following parts are included in P/N 34420001:

• filter housing

• filter stem

• filter bowl (poly)

description

filter bowl

(metal)

filter bowl

()poly carbonate

filter element kit

(includes seals and grease)

filter element

water aspirator

filter stem

silicone tube

(not shown)

copper sample tube

(not shown)

• filter element

• seal (2)

• deflector

P/N 34420001

P/N 34491000

P/N 98199104 • Version 4

For assistance, call Dynojet Technical Support at 1-800-992-3525, visit www.dynojet.com, or write to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

P/N 34491001

water aspirator

(P/N 34310002)

© Copyright 2001-2002 Dynojet Research, Inc. All Rights Reserved. 051502SD

Loading...

Loading...