DYNEX GP200MLS12 Datasheet

GP200MLS12

GP200MLS12

IGBT Chopper Module

Preliminary Information

DS5421-1.5 April 2001

FEATURES

■ Internally Configured With Lower Arm Controlled

■ Non Punch Through Silicon

■ Isolated Copper Baseplate

■ Low Inductance Internal Construction

APPLICATIONS

■ High Power Choppers

■ Motor Controllers

■ Induction Heating

■ Resonant Converters

■ Power Supplies

The Powerline range of high power modules includes half

bridge, dual and single switch configurations covering voltages

from 600V to 3300V and currents up to 2400A.

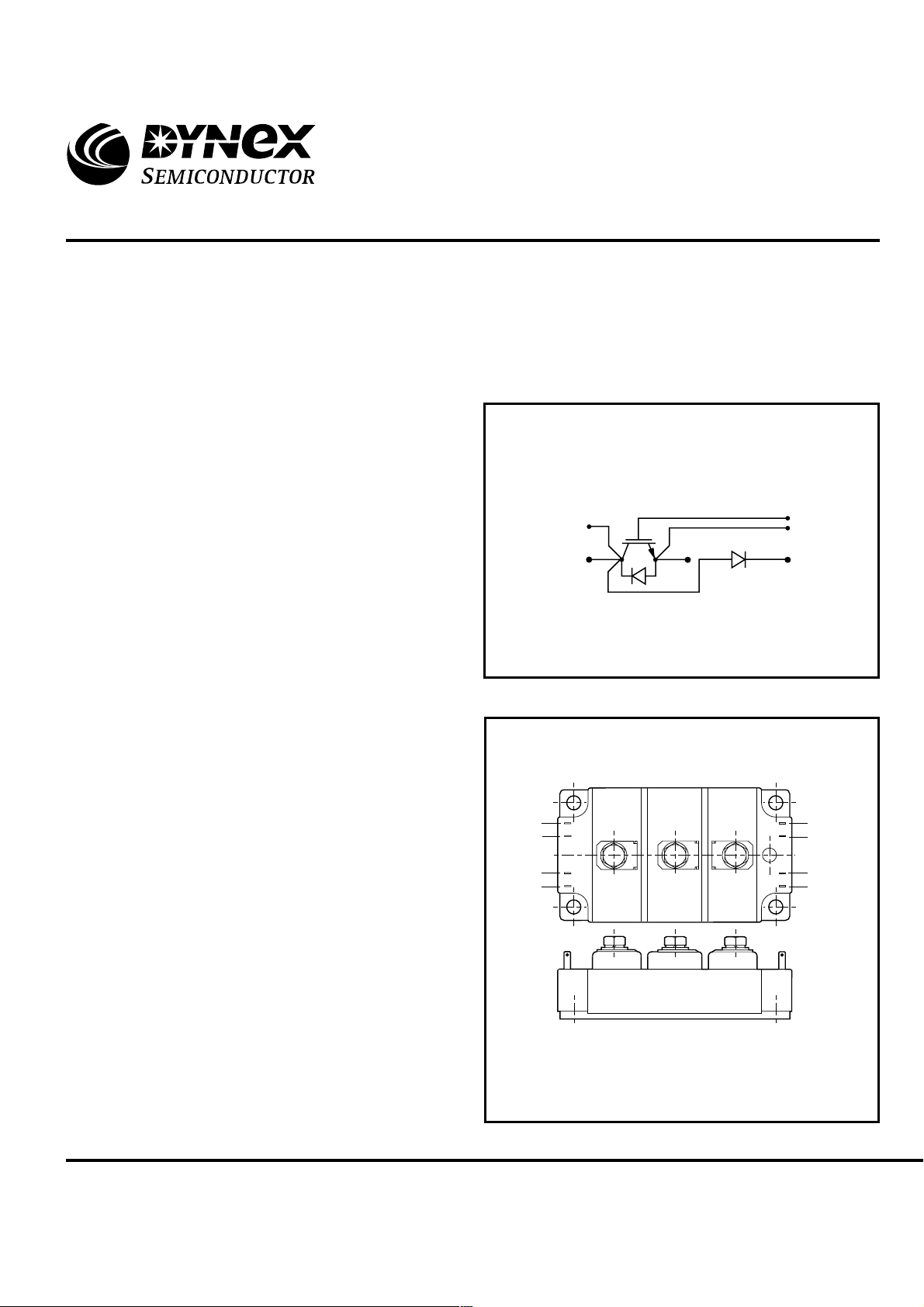

The GP200MLS12 is a 1200V, n channel enhancement

mode, insulated gate bipolar transistor (IGBT) chopper module

configured with the lower arm of the bridge controlled. The

module incoporates high current rated freewheel diodes. The

IGBT has a wide reverse bias safe operating area (RBSOA)

ensuring reliability in demanding applications.

KEY PARAMETERS

V

V

I

C

I

C(PK)

CES

CE(sat)

(typ) 2.7V

(max) 200A

(max) 400A

2

11(C

)

1(A

)

1C2

Fig. 1 Chopper circuit diagram

1200V

2(E2)

6(G

7(E

3(K1)

2

)

2

)

The module incorporates an electrically isolated base plate

and low inductance construction enabling circuit designers to

optimise circuit layouts and utilise earthed heat sinks for safety.

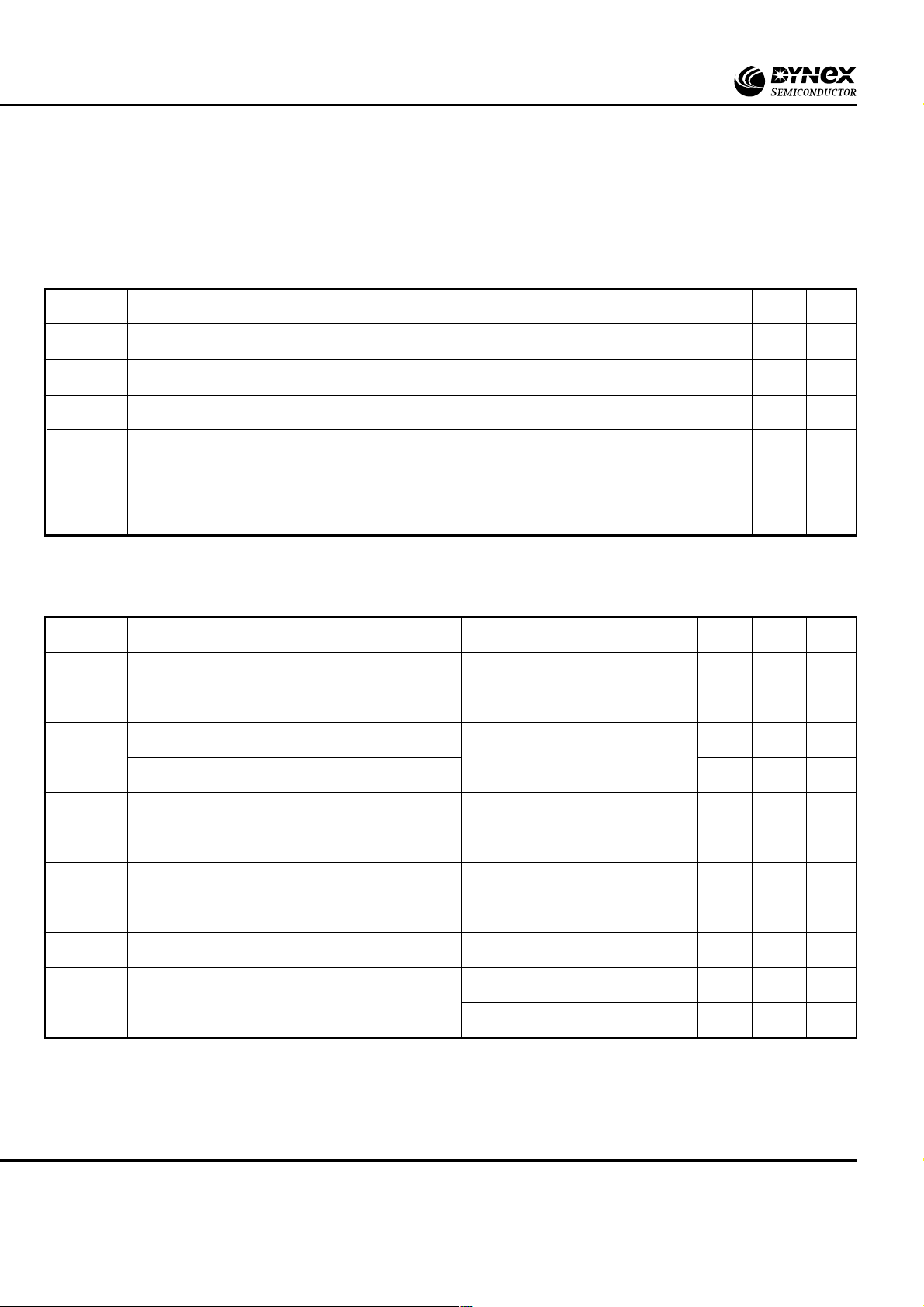

ORDERING INFORMATION

11

10

1

8

9

2

3

6

7

5

4

Order As:

GP200MLS12

Note: When ordering, please use the whole part number.

Outline type code: M

(See package details for further information)

Fig. 2 Electrical connections - (not to scale)

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures. 1/10

www.dynexsemi.com

GP200MLS12

ABSOLUTE MAXIMUM RATINGS - PER ARM

Stresses above those listed under 'Absolute Maximum Ratings' may cause permanent damage to the device. In extreme

conditions, as with all semiconductors, this may include potentially hazardous rupture of the package. Appropriate safety

precautions should always be followed. Exposure to Absolute Maximum Ratings may affect device reliability.

= 25˚C unless stated otherwise

T

case

Symbol

V

CES

V

GES

I

C

I

C(PK)

P

max

V

isol

Collector-emitter voltage

Gate-emitter voltage

Collector current

Peak collector current

Max. transistor power dissipation

Isolation voltage

Parameter

THERMAL AND MECHANICAL RATINGS

Symbol

R

th(j-c)

R

th(j-c)

Thermal resistance - transistor (per arm)

Thermal resistance - antiparallel diode

Parameter

Test Conditions

= 0V

V

GE

-

DC, T

1ms, T

T

= 72˚C

case

= 72˚C

case

= 25˚C, Tj = 150˚C

case

Commoned terminals to base plate. AC RMS, 1 min, 50Hz

Test Conditions

Continuous dissipation -

junction to case

Continuous dissipation

Min.

-

-

Max.

1200

±20

200

400

1490

2500

Max.

84

160

Units

V

V

A

A

W

V

Units

˚C/kW

˚C/kW

R

th(c-h)

Thermal resistance - freewheel diode

Thermal resistance - case to heatsink (per module)

Mounting torque 5Nm

-

-

80

15

˚C/kW

˚C/kW

(with mounting grease)

T

Junction temperature

j

Transistor

Diode

T

stg

-

Storage temperature range

Screw torque

Mounting - M6

-

Electrical connections - M6

-

-

–40

-

-

150

125

125

5

5

˚C

˚C

˚C

Nm

Nm

2/10 Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

www.dynexsemi.com

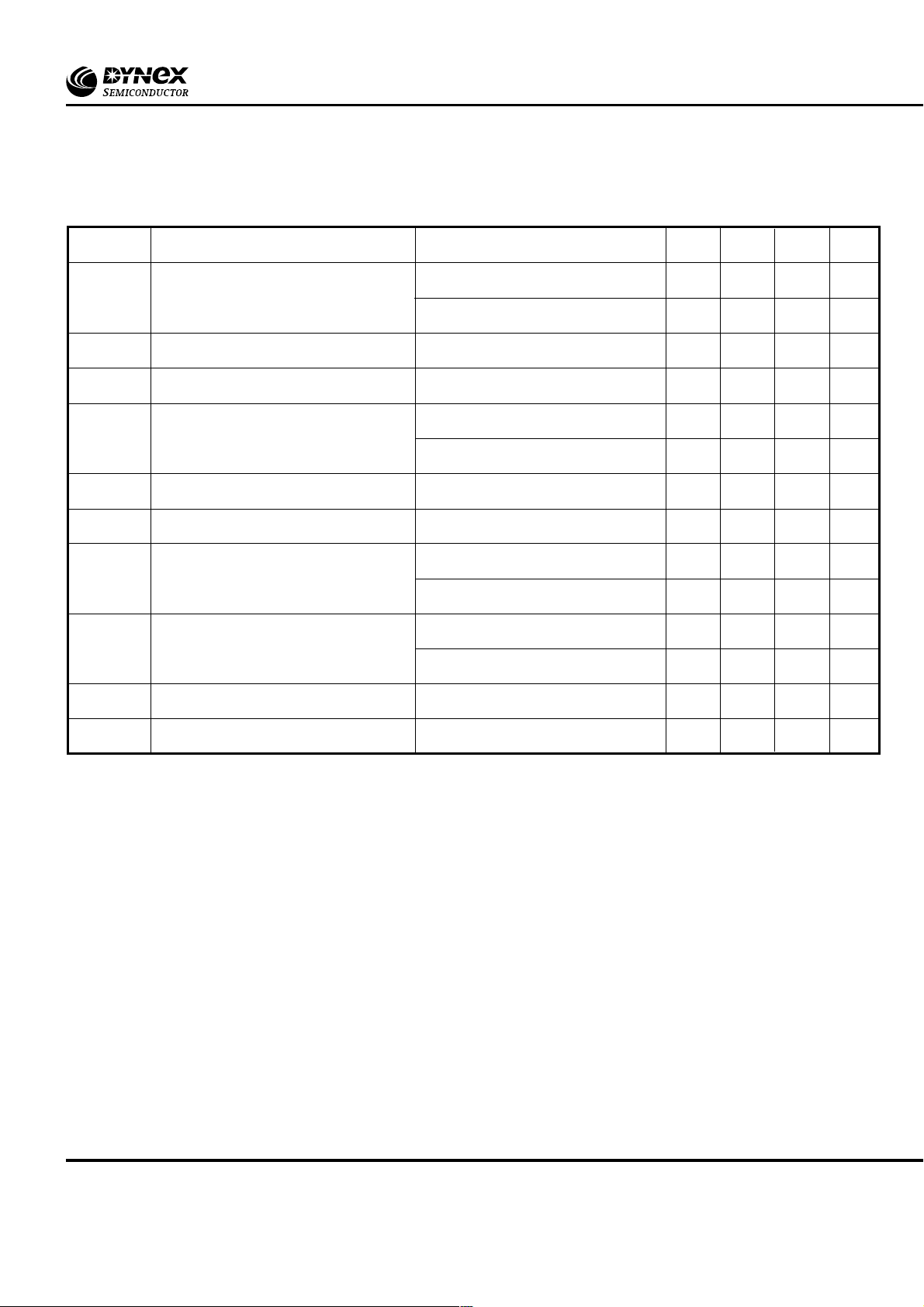

ELECTRICAL CHARACTERISTICS

T

= 25˚C unless stated otherwise.

case

GP200MLS12

Symbol

I

CES

I

GES

V

GE(TH)

V

CE(sat)

I

F

I

FM

V

F

Parameter

Collector cut-off current

Gate leakage current

Gate threshold voltage

Collector-emitter saturation voltage

Diode forward current

Diode maximum forward current

Diode forward voltage - antiparallel diode

Diode forward voltage - freewheel diode

Test Conditions

= 0V, VCE = V

V

GE

VGE = 0V, VCE = V

= ±20V, VCE = 0V

V

GE

I

= 10mA, VGE = V

C

CES

CES

VGE = 15V, IC = 200A

= 15V, IC = 200A, , T

V

GE

DC

= 1ms

t

p

= 200A

I

F

= 200A, T

I

F

= 200A

I

F

= 200A, T

I

F

= 125˚C

case

= 125˚C

case

CE

, T

= 125˚C

case

case

= 125˚C

Min.

-

-

-

4.5

-

-

-

-

-

-

-

-

Typ.

-

-

-

-

2.7

3.2

-

-

2.2

2.3

1.7

1.7

Max.

1

12

±1

6.5

3.5

4.0

200

400

2.4

2.5

2.1

2.2

Units

mA

mA

µA

V

V

V

A

A

V

V

V

V

C

ies

L

M

Input capacitance

Module inductance

= 25V, VGE = 0V, f = 1MHz

V

CE

-

25

30

nF

-

nH

-

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures. 3/10

www.dynexsemi.com

Loading...

Loading...