查询DCR1277SD供应商

DCR1277SD

DCR1277SD

Phase Control Thyristor

Replaces March 1998 version, DS4552-3.3 DS4552-4.0 January 2000

APPLICATIONS

■ High Power Drives.

■ High Voltage Power Supplies.

■ DC Motor Control.

FEATURES

■ Double Side Cooling.

■ High Surge Capability.

■ High Mean Current.

■ Fatigue Free.

VOLTAGE RATINGS

Type Number Repetitive Peak

Voltages

V

DRM VRRM

V

DCR1277SD36

DCR1277SD35

DCR1277SD34

DCR1277SD33

DCR1277SD32

Lower voltage grades available.

3600

3500

3400

3300

3200

Conditions

Tvj = 0˚ to 125˚C,

I

= I

, V

& V

& V

RRM

RRM tp

= 150mA,

= 10ms,

=

RSM

+ 100V

RRM

DRM

V

DRM

V

DSM

V

DRM

respectively

KEY PARAMETERS

V

DRM

I

T(AV)

I

TSM

dVdt* 300V/

dI/dt 150A/µs

*Higher dV/dt selections available

Outline type code: D.

See Package Details for further information.

3600V

1259A

23750A

µs

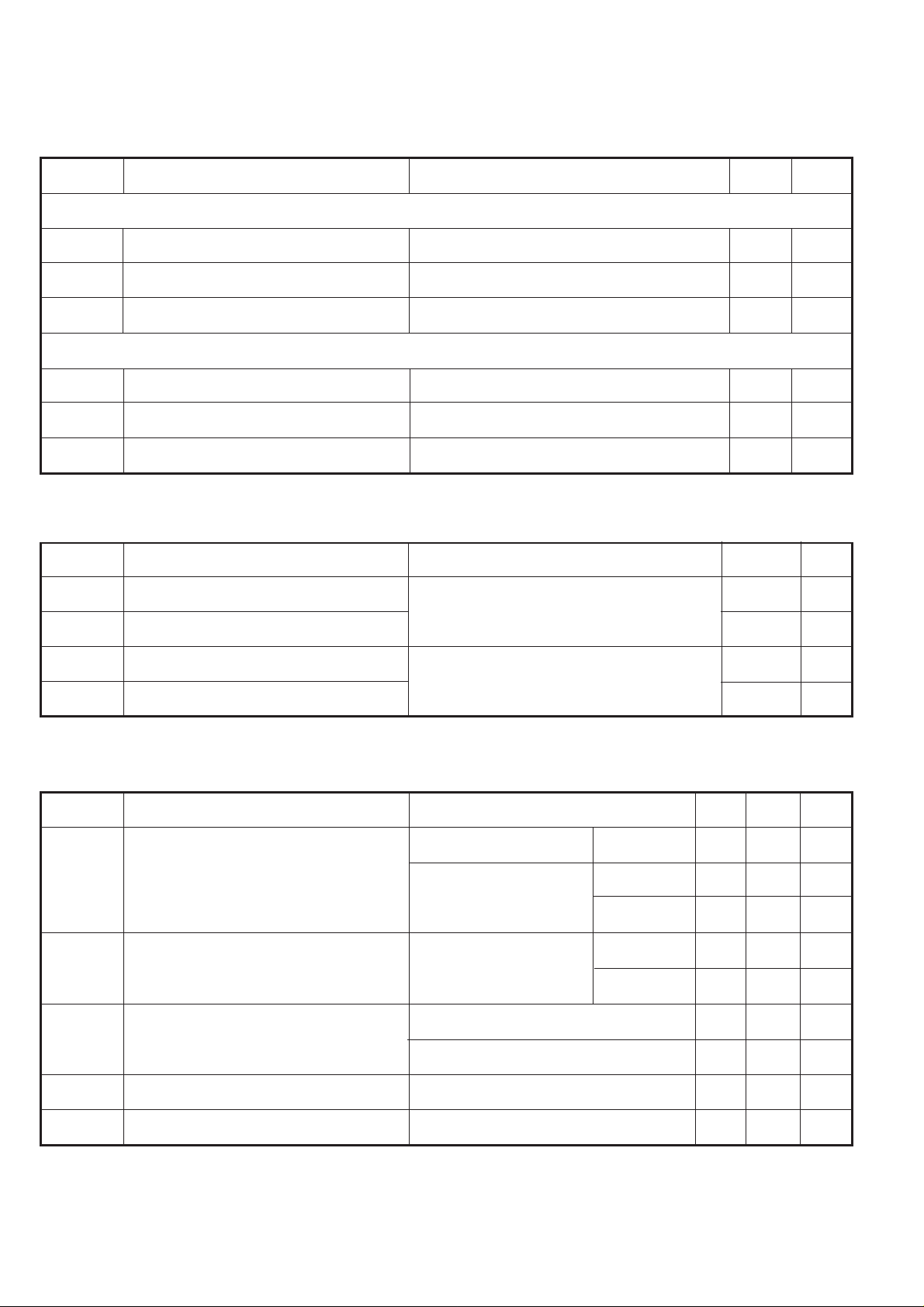

CURRENT RATINGS

T

= 60˚C unless stated otherwise.

case

Symbol Parameter Conditions

Double Side Cooled

I

T(AV)

I

T(RMS)

I

T

Mean on-state current

RMS value

Continuous (direct) on-state current

Single Side Cooled (Anode side)

I

T(AV)

I

T(RMS)

I

T

Mean on-state current

RMS value

Continuous (direct) on-state current

Half wave resistive load 1259 A

Half wave resistive load 885 A

UnitsMax.

- 1977 A

- 1832 A

- 1390 A

- 1209 A

1/9

DCR1277SD

CURRENT RATINGS

T

= 80˚C unless stated otherwise.

case

Symbol Parameter Conditions

Double Side Cooled

I

T(AV)

I

T(RMS)

Mean on-state current

RMS value

I

T

Continuous (direct) on-state current

Half wave resistive load 995 A

Single Side Cooled (Anode side)

I

T(AV)

I

T(RMS)

Mean on-state current

RMS value

I

T

Continuous (direct) on-state current

Half wave resistive load 690 A

SURGE RATINGS

Symbol

I

TSM

2

tI

I

Parameter

Surge (non-repetitive) on-state current

2

t for fusing

10ms half sine; T

V

= 50% V

R

Conditions

- 1565 A

- 1420 A

- 1085 A

- 920 A

Max. Units

case

- 1/4 sine

RRM

= 125oC

19.0 kA

1.8 x 10

6

UnitsMax.

A2s

I

TSM

I2t

Surge (non-repetitive) on-state current

2

t for fusing 2.82 x 106A2s

I

THERMAL AND MECHANICAL DATA

Symbol

R

th(j-c)

R

th(c-h)

T

vj

T

stg

Thermal resistance - junction to case

Thermal resistance - case to heatsink

Virtual junction temperature

Storage temperature range

Parameter

10ms half sine; T

V

R

= 0

= 125oC

case

23.75 kA

Conditions Min. Max. Units

Double side cooled

dc

- 0.020

Single side cooled

Cathode dc - 0.044

Clamping force 22.0kN

with mounting compound

Double side

Single side

0.004

-

- 0.008

On-state (conducting) - 135

Reverse (blocking)

125

-

-55 125

o

C/W

o

C/W- 0.036Anode dc

o

C/W

o

C/W

o

C/W

o

o

o

C

C

C

2/9

-

Clamping force

20.0 24.0 kN

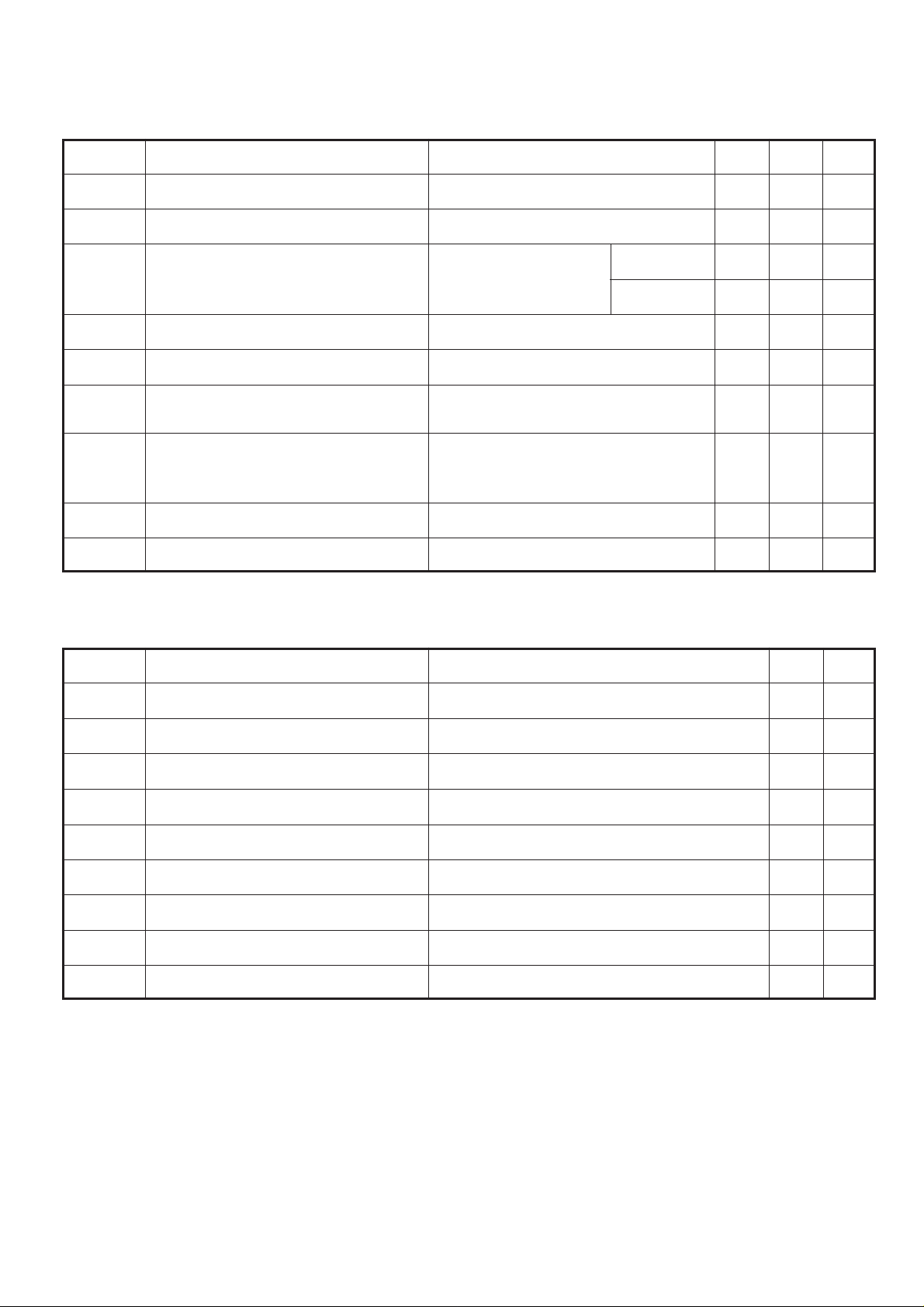

DYNAMIC CHARACTERISTICS

DCR1277SD

Symbol

I

RRM/IDRM

Peak reverse and off-state current At V

Parameter

RRM/VDRM

dV/dt Maximum linear rate of rise of off-state voltage To 67% V

From 67% V

dI/dt

Rate of rise of on-state current

Gate source 10V, 5Ω

tr ≤ 0.5µs, Tj = 125oC

V

T(TO)

r

T

t

gd

q

I

L

I

H

Threshold voltage At Tvj = 125oC

On-state slope resistance At Tvj = 125oC

Delay time

VD = 67% V

tr = 0.5µs, Tj = 25oC

I

= 2000A, tp = 1ms, Tj = 125˚C,

T

V

= 50V, dIRR/dt = 5A/µs,

R

VDR = 67% V

Latching current Tj = 25oC, VD = 5V

Holding current Tj = 25oC, R

Conditions Typ. Max. Units

- 150 mA

- 300 V/µs

- 100 A/µs

- 150 A/µs

DRM Tj

, T

case

= 125oC.

to 1000A

DRM

= 125oC

Repetitive 50Hz

Non-repetitive

- 0.45 mΩ

, Gate source 30V, 15Ω

DRM

, dVDR/dt = 20V/µs linear

DRM

- 2.5 µs

700 1000 mA

g-k

= ∞

200 500 mA

0.95-V

µs650500Turn-off timet

GATE TRIGGER CHARACTERISTICS AND RATINGS

V

GT

I

GT

V

GD

V

FGM

V

FGN

V

RGM

I

FGM

P

GM

P

G(AV)

Gate trigger voltage V

Gate trigger current

Gate non-trigger voltage At V

DRM

V

DRM

= 5V, T

= 5V, T

DRM Tcase

Peak forward gate voltage Anode positive with respect to cathode

Peak forward gate voltage Anode negative with respect to cathode

Peak reverse gate voltage

Peak forward gate current Anode positive with respect to cathode

Peak gate power See table, fig.4

Mean gate power

= 25oC

case

= 25oC

case

= 125oC

ConditionsParameterSymbol

Max. Units

4.0 V

400 mA

0.25 V

30 V

0.25 V

5V

10 A

150 W

5W

3/9

DCR1277SD

CURVES

3000

2500

2000

- (A)

T

1500

Measured under pulse conditions

Tj = 125˚C

Instantaneous on-state current I

1000

500

0

0.5 1.0 1.5 2.0

Instantaneous on-state voltage V

Fig.1 Maximum (limit) on-state characteristics

2.5

- (V)

4/9

4000

DCR1277SD

3000

2000

Mean power dissipation - (W)

1000

6 phase

d.c.

Half wave

3 phase

0

0 500 1000 1500 2000

Mean on-state current I

T(AV)

- (A)

Fig.2 Dissipation curves

5/9

DCR1277SD

100

V

- (V)

GT

- (µC)

S

10000

Conditions:

T

= 125˚C

j

Q

is total integral stored

S

charge

1000

Total stored charge Q

100

0.1 1.0 10 100

Rate of decay of on-state current dI/dt - (A/µs)

Table gives pulse power PGM in Watts

Pulse frequency Hz

100

50

150

150

150

150

150

150

100

150

20

FGM

10

Pulse width

µs

100

200

500

1ms

10ms

Fig.3 Stored charge

400

150

125

100

25

-

-

t

p

dI/dt

2W

IT = 2000A

IT = 1000A

I

T

10W

5W

Q

I

RM

20W

S

100W

50W

6/9

1

Gate trigger voltage V

0.1

Tj = 25˚C

Tj = 125˚C

Upper limit 99%

Lower limit 1%

Gate trigger current I

Fig.4 Gate characteristics

GT

- (A)

Tj = -40˚C

I

1010.10.010.001

FGM

1.0

Conduction

Effective thermal resistance

Double side

d.c.

Halfwave

3 phase 120˚

6 phase 60˚

0.1

0.01

Thermal impedance - (˚C/W)

Junction to case ˚C/W

Anode side

0.020

0.022

0.024

0.027

0.036

0.038

0.040

0.043

DCR1277SD

Anode side cooled

Double side cooled

0.001

Time - (s)

Fig.5 Maximum (limit) transient thermal impedance - junction to case

50

VR = 0

V

= 50% V

R

RRM

I2t = Î2 x t

2

40

30

20

10

Peak half sine wave on-state current - (kA)

I2t

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

1010.10.010.001

I

2

t value - (A

2

s x 10

6

)

0

11012345

ms Cycles at 50Hz

Duration

Fig.6 Surge (non-repetitive) on-state current vs time at T

case

0.6

50

125˚C

7/9

DCR1277SD

PACKAGE DETAILS

For further package information, please contact your local Customer Service Centre. All dimensions in mm, unless stated otherwise.

DO NOT SCALE.

2 holes Ø3.6 x 2.1 deep (One each side)

Cathode tab

Cathode

Ø76 max

Ø48 nom

Ø2.8

27.0

Gate

25.4

Ø48 nom

Nominal weight: 500g

Clamping force: 22kN ±10%

Lead length: 420mm

Lead terminal connector: M4 ring

Package outine type code: D

Anode

ASSOCIATED PUBLICATIONS

Title Application Note

Number

Calculating the junction temperature or power semiconductors AN4506

Gate triggering and the use of gate characteristics AN4840

Recommendations for clamping power semiconductors AN4839

The effect of temperature on thyristor performance AN4870

Thyristor and diode measurement with a multi-meter AN4853

Turn-on performance of thyristors in parallel AN4999

Use of V

, rT on-state characteristic AN5001

TO

8/9

DCR1277SD

POWER ASSEMBLY CAPABILITY

The Power Assembly group was set up to provide a support service for those customers requiring more than the basic semiconductor, and has developed a flexible range of heatsink / clamping systems in line with advances in device types and the voltage and

current capability of our semiconductors.

We offer an extensive range of air and liquid cooled assemblies covering the full range of circuit designs in general use today. The

Assembly group continues to offer high quality engineering support dedicated to designing new units to satisfy the growing needs of

our customers.

Using the up to date CAD methods our team of design and applications engineers aim to provide the Power Assembly Complete

solution (PACs).

DEVICE CLAMPS

Disc devices require the correct clamping force to ensure their safe operation. The PACs range offers a varied selection of preloaded clamps to suit all of our manufactured devices. This include cube clamps for single side cooling of ‘T’ 22mm

Clamps are available for single or double side cooling, with high insulation versions for high voltage assemblies.

Please refer to our application note on device clamping, AN4839

HEATSINKS

Power Assembly has it’s own proprietary range of extruded aluminium heatsinks. They have been designed to optimise the

performance or our semiconductors. Data with respect to air natural, forced air and liquid cooling (with flow rates) is available on

request.

For further information on device clamps, heatsinks and assemblies, please contact your nearest Sales Representative or the

factory.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded as

a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company reserves

the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such

methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication

or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS4552-4 Issue No. 4.0 January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

9/9

Loading...

Loading...