MODEL RCEM

PORTABLE FLEXIBLE VERSION

RECTIFIER MONITORING SYSTEM

Installation, Operation and Service Manual

Manual Item No. 043756

Rev. G

DynAmp, LLC 3735 Gantz Road Phone +1 614.871.6900 www.dynamp.com

Grove City, Ohio 43123 USA Fax +1 614.871.6910 help@dynamp.com

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page ii

43756 G

Installation, Operation and Service Manual RCEM

DynAmp, LLC WARRANTY

Items and components manufactured by Seller for permanent installation are warranted for

two (2) years from the date of shipment.

Items and components manufactured by Seller for portable and temporary use in more

than one location are warranted to be free from defects in material and workmanship for a

period of eighteen (18) months from the date of shipment.

Items and components not manufactured and resold by Seller are warranted by their

manufacturer.

Warranty repair shall be, at DynAmp's option, in the form of repair or replacement of the

defective items or components. Concerning warranty repairs, DynAmp will be responsible

for DynAmp provided time, material and transportation costs (shipping or travel). Actual

method of warranty repair / correction will be determined by DynAmp at DynAmp's sole

option. Such warranty repair shall constitute a fulfillment of all DynAmp, LLC liabilities in

respect to said items and components. In no event shall DynAmp, LLC be liable for

consequential damages.

Information in this document is subject to change without notice.

© 2001, 2003, 2004, 2006, 2011, 2012 DynAmp, LLC. All rights reserved.

Reproduction for purposes other than operation and service without written permission of DynAmp, LLC

is strictly forbidden.

This manual includes detailed drawings, installation, operation, service and maintenance. Users should

evaluate the information in the manual and their particular application. DynAmp assumes no liability for

any incidental, indirect, or consequential damages arising fro the use of this documentation.

While all information presented is believed to be reliable and in accordance with accepted engineering

practices, DynAmp makes no warranties as to the completeness of the information.

© 2012 DynAmp, LLC Page iii

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page iv

43756 G

Installation, Operation and Service Manual RCEM

VOLTAGE

INSTALLATION

Hazard Warning!

GENERAL

HAZARDOUS

Qualified technicians who are familiar with the warnings and instructions of

this manual must perform all installation, maintenance and service.

Disconnect power to the system before servicing or replacing fuses.

Use of the equipment in a manner not specified by the manufacturer can

impair the protection provided within.

DynAmp does not assume liability for the customer’s failure to comply with the

rules and requirements provided in this manual.

This equipment is designed to be connected to hazardous electric voltages.

Ignoring the installation precautions and warnings can result in severe

personal injury or equipment damage.

To avoid the risk of electrical shock or fire, the safety instructions and

guidelines in this manual must be followed. The electrical specifications must

not be exceeded and the unit must be installed according to directions

provided.

This equipment is intended for indoor use only. It should be mounted in a

well-ventilated area, away from high heat, dust, and corrosive atmosphere.

The ambient temperature must not exceed 55°C.

The laptop computer must be located well away from magnetic fields. Failure

to comply may result in damage to the computer.

For mounting considerations that fall outside the recommended specifications

provided in this manual, the factory should be contacted for approval.

This unit is rated for installation category III, 300V and pollution degree 2.

Symbol Identification:

General definitions of safety symbols used on equipment and manual.

© 2012 DynAmp, LLC Page v

43756 G

Caution/Warning: Refer to accompanying documents for instructions.

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page vi

43756 G

Installation, Operation and Service Manual RCEM

DynAmp, LLC Customer Support

For further assistance, contact DynAmp Customer Support at:

Americas:

Telephone: +1 614.871.6900 Fax: +1 614.871.6910

8:00 AM to 5:00 PM USA Eastern Time

From first Sunday in November to second Sunday in March – 13:00 GMT to 22:00 GMT

From second Sunday in March to first Sunday in November – 12:00 GMT to 21:00 GMT

Europe:

Telephone: +41 22.706.1446 Fax: +41 22.706.1311

8:30 AM to 5:00 PM Central European Time

From last Sunday in October to last Sunday in March – 7:30 GMT to 16:00 GMT

From last Sunday in March to last Sunday in October – 6:30 GMT to 15:00 GMT

After Hours Critical Service Emergency:

Telephone: +1 614.871.6906

5:00 PM to 8:00 AM USA Eastern Time

From first Sunday in November to second Sunday in March – 22:00 GMT to 13:00 GMT

From second Sunday in March to first Sunday in November – 21:00 GMT to 12:00 GMT

Central e-mail:

help@dynamp.com

DynAmp web:

www.dynamp.com

© 2012 DynAmp, LLC Page vii

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page viii

43756 G

Installation, Operation and Service Manual RCEM

Page

Rev

Reason For Revision

Date

All

NEW

06/01

23,

A

Add Integrator PC Board calibration procedure and Update

10/01

37

B

Revise Appendix B-2: Minimum Requirements for Laptop

10/03

45-54

C

ECO-3099 - Revise Appendix B: Add Devices/Leg

08/04

45-54

D

Update to DynAmp, LLC, ECO-3102 – Revise Appendix B:

12/04

v, 1, 27,

36

E

Update fuse precautions per ECR 1304

07/06

Intervals / New Manual Format

/Software requirments

REVISION PAGE

37-46

all F

35, 45 G

Appendix B to revised spreadsheets

Computer

Command Button

Add ANSI Rectifier Circuit select

PAR 10245 – Handling & Storage, ECR 1440- Calibration

ECR1683 - Revise Spare Parts List, Table 8.1, Computer

06/11

03/12

© 2012 DynAmp, LLC Page ix

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page x

43756 G

Installation, Operation and Service Manual RCEM

TABLE OF CONTENTS

Par. Title Page

1. SAFETY ____________________________________________________________ 1

1.1 O

VERVIEW ............................................................................................................................. 1

2. HANDLING AND STORAGE ____________________________________________ 3

3. DESCRIPTION _______________________________________________________ 5

3.1 G

3.2 D

3.3 D

3.4 L

3.5 F

3.6 M

ENERAL ............................................................................................................................... 5

EFINITIONS........................................................................................................................... 5

ATA ACQUISITION UNIT ......................................................................................................... 5

APTOP COMPUTER ................................................................................................................ 6

LEXIBLE CURRENT SENSORS ................................................................................................. 6

AGNETIC FIELD STATEMENT .................................................................................................. 6

4. SPECIFICATIONS ____________________________________________________ 7

5. TECHNICAL DESCRIPTION ____________________________________________ 9

5.1 G

5.2 B

5.3 A

5.4 B

5.5 P

5.6 A

5.7 I

5.8 R

5.9 T

5.10 P

5.11

5.12 D

ENERAL ............................................................................................................................... 9

ASIC THEORY OF OPERATION ............................................................................................... 9

NALOG CARD RACK .............................................................................................................. 9

ACKPLANE ......................................................................................................................... 10

OWER CIRCUITS ................................................................................................................. 10

NALOG INPUT CONNECTORS ............................................................................................... 11

NTEGRATOR CARDS ............................................................................................................. 11

ESET SYNC CARDS ............................................................................................................. 12

EST SIGNAL GENERATOR .................................................................................................... 13

ERSONAL DAQ/56 ............................................................................................................... 14

USB EXTENDER RECEIVER .................................................................................................. 15

IGITAL INTERFACE MODULE ................................................................................................. 15

6. PREPARATION FOR USE _____________________________________________ 17

6.1 S

6.2 R

6.3 S

6.4 I

YSTEM CHECKOUT AND PREPARATION ................................................................................. 17

ECTIFIER SHUTDOWN ......................................................................................................... 17

ENSOR MOUNTING AND CONNECTION CONSIDERATIONS ....................................................... 17

NSTALLATION INSTRUCTIONS ................................................................................................ 17

7. MAINTENANCE AND TROUBLESHOOTING ______________________________ 27

7.1 C

7.2 G

7.3 V

7.4 F

7.5 S

7.6 V

7.7 A

7.8 A

7.9 S

7.10 S

7.11 C

7.12 R

© 2012 DynAmp, LLC Page xi

43756 G

ALIBRATION INTERVALS ....................................................................................................... 27

ENERAL ............................................................................................................................. 27

ERIFYING PROPER OPERATION ............................................................................................ 27

USE REPLACEMENT ............................................................................................................ 28

TATIC PRECAUTIONS WHEN SERVICING ............................................................................... 28

ERIFYING PROPER INTEGRATOR RESET SYNCHRONIZATION .................................................. 29

DJUSTING THE SIGNAL GENERATOR ..................................................................................... 29

DJUSTING THE INTEGRATOR PC BOARDS....................................................................... 30

ENSOR TESTING (CONTINUITY METHOD) .............................................................................. 30

ENSOR DIELECTRIC TESTING - WINDINGS TO SURFACE ........................................................ 31

ONNECTOR CONTAMINATION (INTEGRATOR CARDS) .............................................................. 32

ESET SYNC ERROR OR INCORRECT DATA ............................................................................ 33

Installation, Operation and Service Manual RCEM

8. SERVICE, PARTS, AND DOCUMENTATION ______________________________ 35

8.1 SERVICE

8.2 S

8.3 S

PARE PARTS ORDERS - ROUTINE OR EMERGENCY ................................................................ 36

PARE PARTS ...................................................................................................................... 36

ASSISTANCE ..................................................................................................... 35

9. DRAWING LIST _____________________________________________________ 37

9.1

REQUIRED DRAWINGS ............................................................................................................. 37

APPENDIX A: ANSI RECTIFIER CIRCUITS __________________________________ 39

APPENDIX B: SOFTWARE _______________________________________________ 45

B.1 P

B.2 M

B.3 S

B.4 S

B.5 S

B.6 PROGRAMMING

B.7 SEL

B.8 A

B.9 S

B.10 A

B.11 STARTING

B.12 STOPPIN

B.13 V

B.14 R

B.15 CALIBRATE

B.16 P

ROVIDED SOFTWARE .......................................................................................................... 45

INIMUM REQUIREMENTS FOR LAPTOP COMPUTER ................................................................ 45

OFTWARE INSTALLATION ..................................................................................................... 45

TARTING THE DATA ACQUISITION PROGRAM ......................................................................... 46

PREADSHEET DESCRIPTION ................................................................................................ 47

THE NUMER OF DEVICES/LEG ............................................................ 48

ECTING THE ANSI RECTIFIER CIRCUIT NUMBER .................................................................. 48

CQUIRING A RECTIFIER DATA SET ........................................................................................ 49

AVING THE RECTIFIER DATA TO A DISK FILE ......................................................................... 49

CTIVATING THE TEST MODE OF OPERATION ......................................................................... 49

THE SCAN MODE OF OPERATION ................................................................ 49

G THE SCAN MODE OF OPERATION ....................................................................... 50

IEWING THE DIODE CURRENT BAR GRAPHS ........................................................................... 50

ECOVERING FROM DAQ ERRORS ......................................................................................... 50

WORKSHEET ................................................................................................ 51

RECAUTIONS ...................................................................................................................... 51

FIGURES

Figure # Title .................................................................................................. Page

Figure 5.1 Analog Card Rack ................................................................................................ 10

Figure 5.2 Reset Pulse Connector Location .......................................................................... 13

Figure 5.3 Reset Pulse Signal Location ................................................................................. 13

Figure 5.4 571A Test Signal Waveform................................................................................. 14

Figure 5.5 Personal Daq/56 .................................................................................................. 14

Figure 5.6 USB Extender Receiver ........................................................................................ 15

Figure 5.7 Digital Interface Module ........................................................................................ 15

Figure 6.1 Flexible Current Sensor Installation Detail ............................................................ 18

Figure 7.1 Device Current Waveform .................................................................................... 29

Figure 7.2 Reset Sync PC Board .......................................................................................... 30

Figure 7.3 Integrator PC Board ............................................................................................. 30

Figure 7.4 Hi-Pot Test Setup ................................................................................................. 32

Figure A.1 ANSI Rectifier Circuit 23 ...................................................................................... 39

Figure A.2 ANSI Rectifier Circuit 24 ...................................................................................... 39

Figure A.3 ANSI Rectifier Circuit 25 ...................................................................................... 40

Figure A.4 ANSI Rectifier Circuit 26 ...................................................................................... 40

Figure A.5 ANSI Rectifier Circuit 31 ...................................................................................... 41

Figure A.6 ANSI Rectifier Circuit 32 ...................................................................................... 41

Figure A.7 ANSI Rectifier Circuit 45 ...................................................................................... 42

Figure A.8 ANSI Rectifier Circuit 46 ...................................................................................... 42

Figure A.9 ANSI Rectifier Circuit 52 ...................................................................................... 43

Figure B.1 6Leg120Ch Spreadsheet ..................................................................................... 52

© 2012 DynAmp, LLC Page xii

43756 G

Installation, Operation and Service Manual RCEM

Figure B.2 M6Leg120Ch Spreadsheet ................................................................................... 52

Figure B.3 12Leg120Ch Spreadsheet ................................................................................... 53

Figure B.4 1Leg-20ch Spreadsheet ....................................................................................... 53

Figure B.5 Leg 1 Bar Chart ................................................................................................... 54

Figure B.6. Calibrate Worksheet ........................................................................................... 54

TABLES

Table # Title .................................................................................................. Page

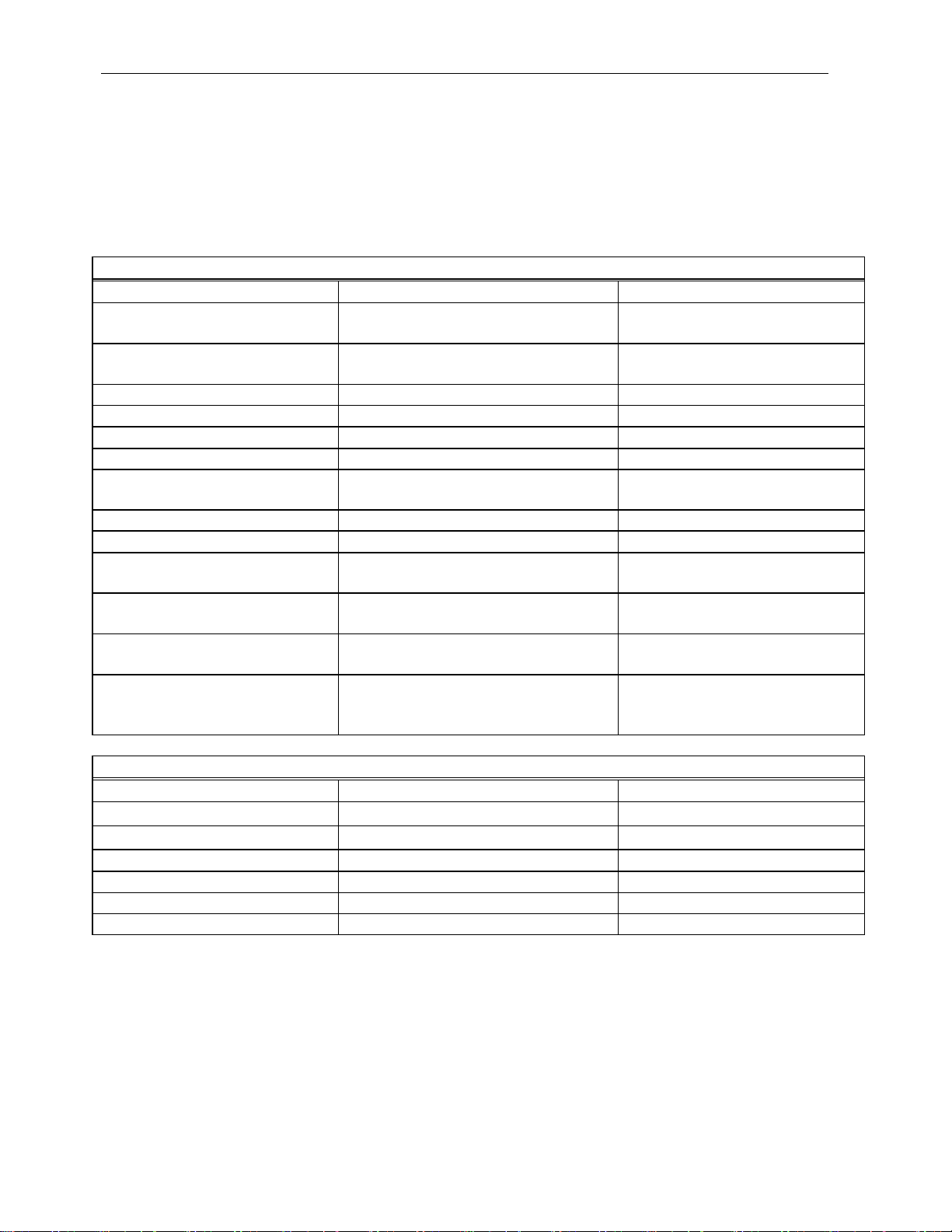

Table 4.1 Rectifier Condition Evaluation Monitor Specifications .............................................. 7

Table 4.1 Rectifier Condition Evaluation Monitor Specifications (Continued) ........................... 8

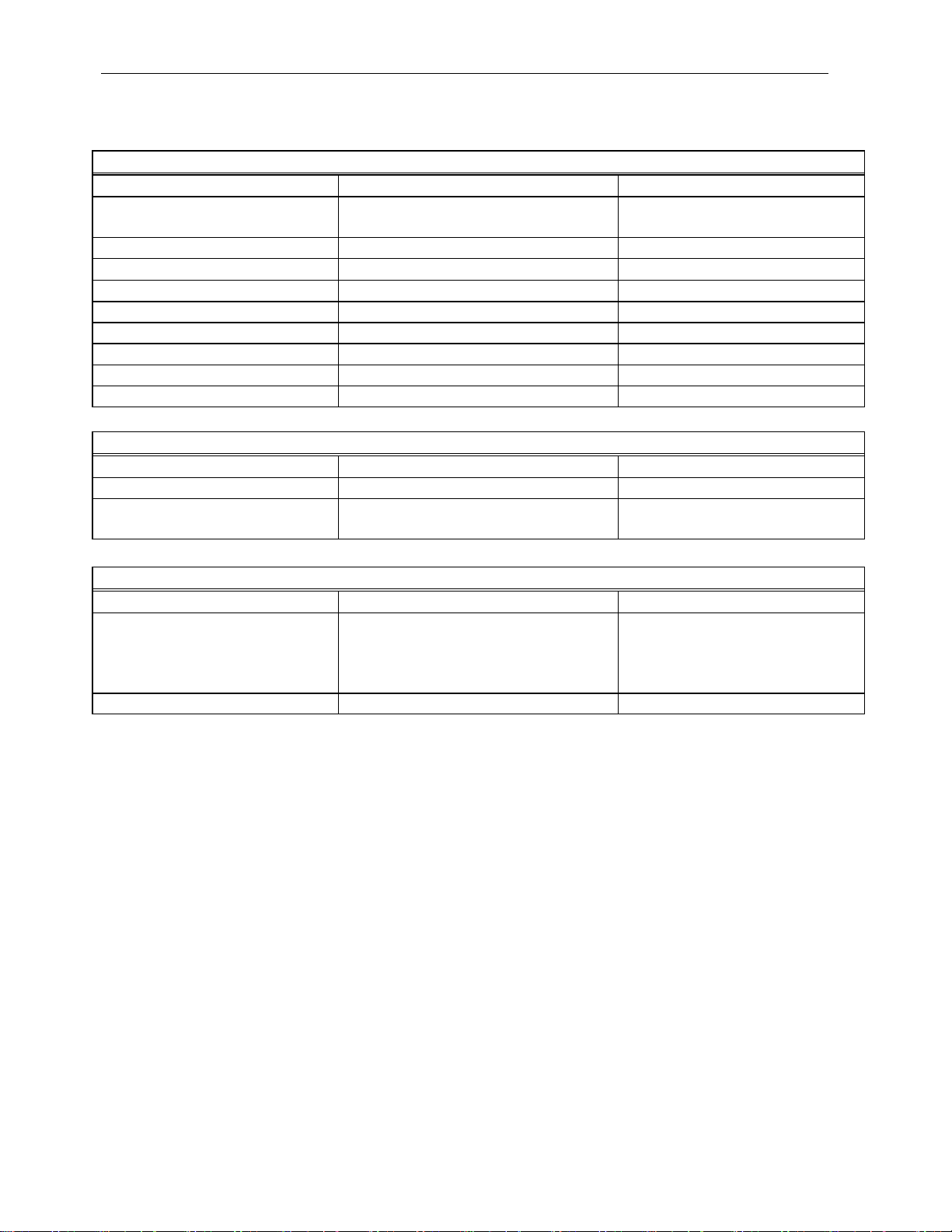

Table 6.1 Transducer Connections, 6-Leg Rectifier (20 Diodes Max.).................................... 19

Table 6.2 Transducer Connections, 6-Leg Rectifier (40 Diodes Max.)................................... 20

Table 6.3 Transducer Connections, Parallel 6-Leg Rectifier (10 Diodes Max) ........................ 21

Table 6.4 Transducer Connections, Parallel 6-Leg Rectifier (20 Diodes Max) ....................... 22

Table 6.5 Transducer Connections, 12-Leg Rectifier (10 Diodes Max.) ................................. 23

Table 6.6 Transducer Connections, 12-Leg Rectifier (20 Diodes Max.) ................................. 24

Table 6.7 Transducer Connections, 1-Leg of a Multi-Leg Rectifier ......................................... 25

Table 8.1 Spare Parts List ..................................................................................................... 36

Table 9.1 Drawing List ........................................................................................................... 37

© 2012 DynAmp, LLC Page xiii

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page xiv

43756 G

Installation, Operation and Service Manual RCEM

1. SAFETY

1.1 OVERVIEW

This equipment is designed to be connected to hazardous electric voltages. Ignoring the

installation precautions and warnings can result in severe personal injury or equipment

damage. The following are general guidelines that should be followed when installing,

operating and servicing the RCEM.

• Qualified technicians who are familiar with the warnings and instructions of this manual

must perform all installation, maintenance and service.

• Always follow all local and plant safety procedures.

• The equipment covers should remain closed at all times during operation to ensure

safety of personnel. Only authorized personnel or technicians should be allowed to

open and service the equipment.

• Cover #3 (PC Board Cover) may be removed if the operator needs access to the diode

waveform connectors. Use caution whenever the cover is removed.

• Only qualified technicians should perform Service. If use of an oscilloscope becomes

necessary during operation or servicing, either the scope must be floating or

ungrounded, or differential probe(s) must be used. The equipment is isolated from the

mains via the power transformers. If a grounded scope is used, a hazardous condition

is created since current will flow through the probe to ground.

• Replace fuses with correct type, size and value. Refer to the servicing instructions or

spare parts list for more information on replacement fuses. Do not bypass the fuses or

modify the electronics. Disconnect power to the system before replacing fuses. Failure

to follow these instructions will result in intermittent operation and premature failure and

will void the warranty.

• The equipment is not intrinsically safe. Do not place in explosive atmospheres.

• The Current Transducers are double insulated to protect the operator from possible

hazardous voltage potentials of the rectifier. The transducers are also protected from

heat by a protective sheath.

• Make sure the transducer cables and interconnection cables are kept well away from

hazardous voltage potentials and heat sources inside the rectifier.

• Keep the electronics enclosure as far as possible away from the hazardous voltage

potentials of the rectifier.

• Use of the equipment in a manner not specified by the manufacturer can impair the

protection provided.

DynAmp does not assume liability for the customer’s failure to comply with the rules and

requirements provided in this manual.

© 2012 DynAmp, LLC Page 1

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 2

43756 G

Installation, Operation and Service Manual RCEM

2. HANDLING AND STORAGE

DynAmp products are engineered and manufactured for use in industrial environments.

However, they contain sensitive electronic and mechanical components which may be

damaged and fail if not handled and stored properly. All products must be handled and

stored with the same care as any precision measurement instrument. Severe bumps or

jolts may damage internal parts and cause malfunction or premature failure. DynAmp

products are designed and assembled with conformal coating, shock mounting, and

environmental seals, when appropriate or when specified. However, this protection

requires that the product must be properly installed and operational before the protection is

fully functional. Therefore, adequate protection from humidity, shock, and temperature

must be provided during handling and storage prior to installation.

The handling and storage of equipment must be sufficient to meet the storage temperature

and humidity specifications of the product and to prevent any condensation or contact with

water or any other liquid. The storage location and container or crate must provide

adequate protection from precipitation (rain, snow, ice) and direct water contact. Adequate

shelter must be provided to prevent the accumulation of precipitation (rain, snow, ice) and

water which can lead to the deterioration or failure of shipping containers or crates and

cause water ingress. Storage in coastal or industrial areas subject to salt-laden or

corrosive air or areas of wind-driven sand or other abrasive dust must be adequate to

prevent the deterioration or failure of shipping containers or crates and cause ingress.

Frequent inspection of storage areas and storage containers or crates is required to ensure

proper storage conditions are being maintained.

If the shipping container or crate is opened and/or the equipment is removed for inspection

prior to installation, the equipment must be repackaged in the original undamaged

container or crate in the same manner as it was shipped to prevent environmental damage

or placed in a storage location that meets the required environmental and storage

conditions.

General product storage temperature and humidity requirements:

Storage Temperature: -40 to 70°C

-40 to 158°F

Storage Humidity: 85%, non-condensing

DynAmp, LLC does not assume liability for the customer’s failure to comply with handling

and storage requirements.

For further assistance, contact DynAmp customer support.

© 2012 DynAmp, LLC Page 3

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 4

43756 G

Installation, Operation and Service Manual RCEM

Channel

Flexible Current Sensor and associated electronic circuitry

DAU

Abbreviation for Data Acquisition Unit; rectifier monitoring system

Device

Rectifier semiconductor device (such as a diode or thyristor).

Current Sensor

DynAmp Flexible Current Sensor

I/O

Input/Output device.

Laptop Computer

Portable computer used to display the rectifier data

Leg

Group of rectifier devices connected in parallel. Symbolically

Multiplexer

The binary address that selects one-of-six integrator card leg

USB

Universal Serial Bus

RCEM

DynAmp Rectifier Condition Evaluation Monitor

RMS

root mean square – Effective value of a waveform

3. DESCRIPTION

3.1 GENERAL

The DynAmp RECTIFIER MONITORING SYSTEM Model RCEM is designed for isolated

measurement of device currents in multiple path power rectifiers.

Model RCEM is a monitoring system composed of a 120 Channel Data Acquisition Unit, a

laptop computer, Flexible Current Sensors, and the interconnection cables.

A 240 Channel RCEM is also available. This system consists of two 120 Channel Data

Acquisition Units, a laptop computer, LEM~flex Current Transducers, and interconnection

cables.

3.2 DEFINITIONS

The following terms are used extensively in this manual:

Address

active electronics hardware

referred to as R or S in ANSI circuit diagrams

output signals.

3.3 DATA ACQUISITION UNIT

The Data Acquisition Unit contains the following elements:

1.) Analog Card Rack containing:

© 2012 DynAmp, LLC Page 5

43756 G

Installation, Operation and Service Manual RCEM

2.) Backplane

3.) Reset Sync Cards

4.) Integrator Cards

5.) Personal Daq/56 – USB Data Acquisition Module

6.) USB Extender Receiver

7.) Digital Interface Module

3.4 LAPTOP COMPUTER

The laptop computer is connected to the Data Acquisition Unit via the USB Extender

Sender and RJ-45 cable. The laptop computer provides a means of displaying the rectifier

data. It also allows access to the internal test signal generator. The data is displayed on a

spreadsheet program.

3.5 FLEXIBLE CURRENT SENSORS

The 3.625 ID Flexible Current Sensor is the standard sensor supplied with the RCEM.

Other Flexible Current Sensor sizes are available from DynAmp, if required. Presently they

include inside diameter (I.D.) sizes of 1.000", 1.500", 2.750", 4.250", and 2.875” x 5.500”

models. All Flexible Current Sensors have the same output, so they may be interchanged.

3.6 MAGNETIC FIELD STATEMENT

The magnetic field from a high current DC bus may damage or destroy the laptop

computer hard disk drive, or floppy disks. To avoid damage the laptop and floppy disks

should be kept as far from the DC bus as practicable. Protect floppy disks in a

magnetic shielded case. This warning applies at all times.

The destructive effect of a magnetic field on a hard disk drive depends on the orientation of

the laptop computer within the field, and the degree of magnetic shielding provided by the

hard disk enclosure. Laptop computer and hard disk manufacturers do not provide

specifications for maximum magnetic field outside the hard disk enclosure.

It is difficult to accurately specify a maximum safe Gauss level for laptop computer disk

drives. Our best estimate is a maximum ambient magnetic field strength of 25 to 50 Gauss

for safe laptop computer operation.

This manual provides recommended guidelines for use of the rectifier monitoring system.

It is the sole responsibility of the customer to assure safety of equipment and personnel

when using this product.

© 2012 DynAmp, LLC Page 6

43756 G

Installation, Operation and Service Manual RCEM

Physical

Dimensions

Comments:

Data Acquisition Unit

22”W x 23”H x 13.75”D

(559 x 584 x 349) mm

Flexible Current Sensor

3.625 ID (92 mm)

Standard Size (other sizes are

available)

Sensor cable length

4.5 ft. (1.37 m)

Weight

Data Acquisition Unit

55 lbs. (20.5 kg)

Flexible Current Sensor

0.76 lbs. (0.28 kg)

3.625 ID Flexible Current

Sensor

Interconnection Cable

Length

33 ft (10 m)

Data Acquisition Unit(s) to

Flexible Current Sensor

USB Cable Length

15 ft (5 m)

Computer to USB Extender

Sender

Serial Data Cable Length

(Type Category 5E)

150 ft (45.7 m)

USB Extender Sender to Data

Acquisition Unit

USB Cable Length

15 ft (5 m)

Data Acquisition Unit #1 to

Channel Systems)

Environmental

Temperature

Comments:

Data Acquisition Unit

0°C to 50°C

Flexible Current Sensor

-20°C to +150°C

Humidity

Data Acquisition Unit

85% RH non-condensing

Flexible Current Sensor

85% RH non-condensing

4. SPECIFICATIONS

The specifications for the Rectifier Condition Evaluation Monitor are listed in Table 4.1.

TABLE 4.1

RECTIFIER CONDITION EVALUATION MONITOR SPECIFICATIONS

Data Acquisition Unit #2 (240

© 2012 DynAmp, LLC Page 7

43756 G

Installation, Operation and Service Manual RCEM

Electrical

AC Supply

Comments:

Voltage

90 – 135 Vac

175 – 264 Vac

Automatic Selection

Frequency

50/60 Hz

Basic Accuracy

3%

Flexible Current Sensors

Measuring Range

Flexible Current Sensor

0…2000A

Data Acquisition Unit

10 to 100%

Output

Analog Output

1V/1kA

Waveform Connectors

Serial Data

USB Port

Laptop Computer

Safety

Isolation

Comments:

Flexible Current Sensor

3000 VAC, 1 Minute @ 60 Hz

Data Acquisition Unit

Output to line

Installation Category III @ 300

Volts

Other

Visual Indicators

Comments:

Data Acquisition Unit

+24V LED

TEST A0 – TEST A1 LEDs

Personal Daq/56 Update Rate

4 seconds for 120 channels

TABLE 4.1

RECTIFIER CONDITION EVALUATION MONITOR SPECIFICATIONS (CONTINUED)

MUX A0 – MUX A2 LEDs

TEST MODE LED

© 2012 DynAmp, LLC Page 8

43756 G

Installation, Operation and Service Manual RCEM

DAU Data I/O Connector Variations

DAU Version

Data Port

USB Port

120 Channel

Installed

N/A

240 Channel DAU #1

Installed

USB “A”

240 Channel DAU #2

N/A

USB “B”

5. TECHNICAL DESCRIPTION

5.1 GENERAL

The Data Acquisition Unit (DAU) contains one analog card rack with backplane, reset sync

cards, and integrator cards. The Data Acquisition Unit also contains the Personal Daq/56

USB Data Acquisition Module, the USB Extender Receiver, and two power supplies. The

Personal Daq/56 accepts a maximum of 120 device data channels. The Data Acquisition

Unit #2 in a 240 Channel system does not contain an USB Extender Receiver.

5.2 BASIC THEORY OF OPERATION

Each current sensor is associated with the measurement channel for a specific rectifier

element. The signal from each current sensor is conducted to the DAU via an individual 2conductor cable and a wire pair within the interconnection cable.

The output from a current sensor is a voltage waveform corresponding to the

instantaneous change of current in the rectifier device associated with that current sensor.

Integrating the output signal of the current sensor returns it to the current waveform being

conducted by the rectifier device. The current waveform is converted to a DC voltage

proportional to the RMS value of the integrated signal.

The analog card rack contains multiplexer circuits to switch the DC voltage signals into the

twenty analog input channels located in the Personal Daq/56. The digital I/O in the

Personal Daq/56 controls the multiplexer. The multiplexing scheme can be described as a

6-leg by 20-channel matrix. One of six integrator channels ("legs") is addressed on all 20

integrator cards.

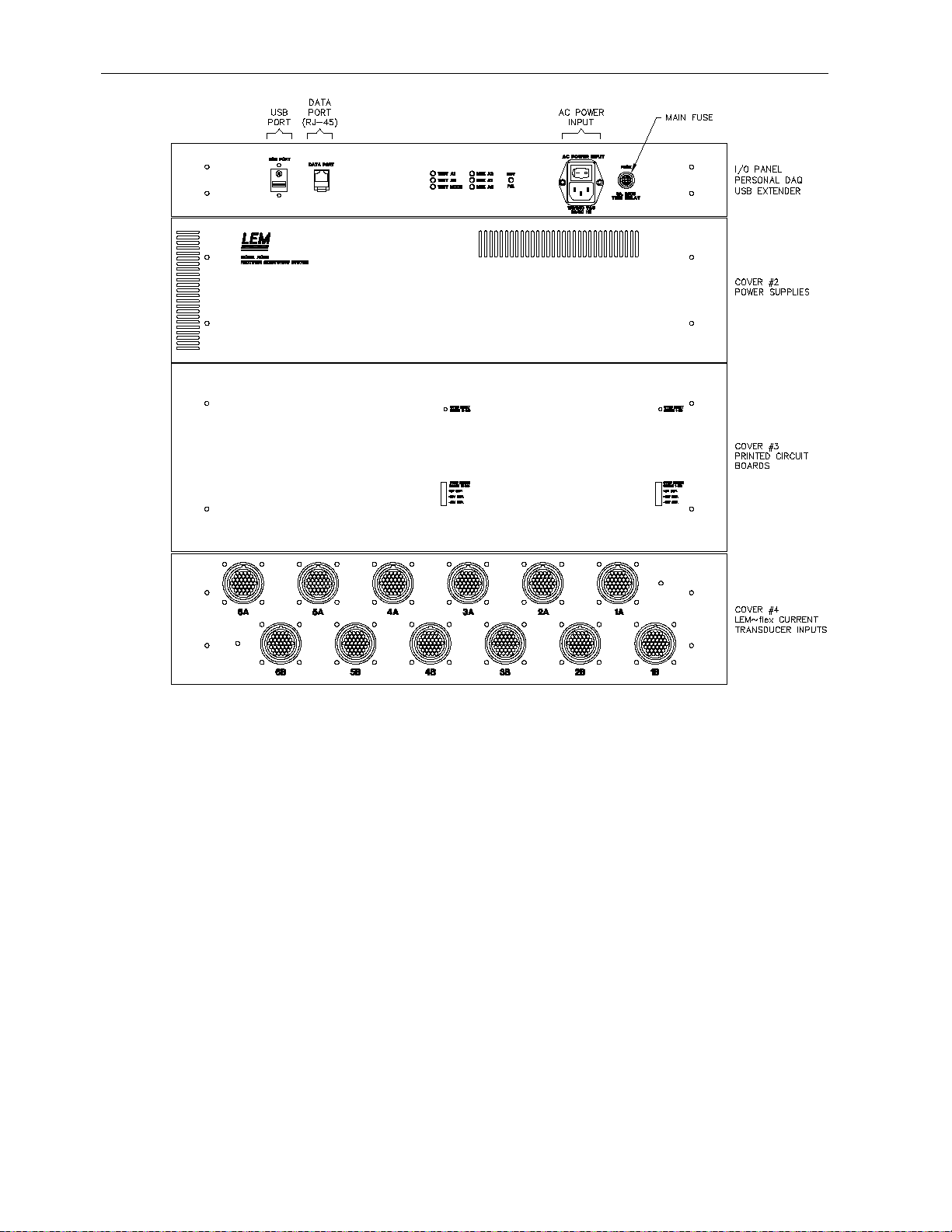

5.3 ANALOG CARD RACK

The analog card rack contains the following elements: one backplane, two reset sync

cards, and twenty integrator cards. See Figure 5.1.

© 2012 DynAmp, LLC Page 9

43756 G

Installation, Operation and Service Manual RCEM

5.4 BACKPLANE

The digital interface circuits to/from the Personal Daq/56 are located on the Data

Acquisition Unit backplane. The backplane also contains the reset sync cards connectors,

the integrator card connectors, the signal input connectors from the current sensors, and

the power circuits.

The backplane also contains the ac zero-crossing detector circuit. This circuit supplies the

ac zero-crossing timing pulse to the reset sync pulse generator and the test signal

generator circuits located on the Reset Sync Cards.

5.5 POWER CIRCUITS

The power circuits in the Data Acquisition Unit consist of the ac power input circuit, the

regulated quad output power supply, the +12V power supply, the + 5V power supply, and

the dc power input circuits.

Figure 5.1

Analog Card Rack

© 2012 DynAmp, LLC Page 10

43756 G

Installation, Operation and Service Manual RCEM

The ac power input circuit contains varistors used to clamp transient voltages and a filter

module to reduce line-transmitted noise. The fuses are used to protect the power supply

and the ac zero-crossing detector.

The regulated power supply has 4 output voltages. They are +5VDC, ±15VDC, and

+24VDC. The regulated voltages all have a common ground circuit. The power supply is

mounted on card rack side panel. This power supply may be accessed by removing Cover

#2.

The power supply outputs are connected to the backplane. LC filters located on the

backplane filter the regulated voltages. The +24VDC is connected to the digital interface

module as well as powering the rectifier/test relays on the integrator cards.

The isolated +12V and the +5V power supplies are also mounted on the card rack side

panel. The +12V power supply is used to power the Personal Daq/56 while the +5V power

supply provides power to the USB Extender Receiver. All three power supplies have a

universal ac power input circuit rated at 100-240VAC, 50/60Hz.

5.6 ANALOG INPUT CONNECTORS

There are twenty analog input connectors located to the bottom edge of the backplane.

The current sensors are connected to these connectors via twelve circular connectors

located on the analog input panel. The backplane connects the current sensor output

signals to the integrator inputs. Each integrator card has an associated 12-position

waveform output connector.

5.7 INTEGRATOR CARDS

Each integrator card provides electronic circuitry for six channels. Each integrator includes

the following:

1. rectifier/test DPDT relays

2. active integrator circuits

3. RMS-to-dc converters

4. (1) 6-to-1 analog multiplexer

The circuits found on each integrator card are discussed below.

1.) Rectifier/Test DPDT Relay.

Each of the test signal DPDT relays is used to switch the input source for two

integrator circuits. The normally closed relay contacts connect the integrator inputs

to the current sensor signals. Energizing the ganged relay coils selects the test

signal as the input source for all integrator circuits. A digital I/O channel in the

Personal Daq/56 controls the relays.

2.) Active Integrator Circuits.

Each integrator card contains six active integrator circuits. Each integrator circuit

uses a CMOS analog switch to reset the integrating capacitor. Integrator reset

pulses are buffered by CMOS digital buffers.

Integrator resets are synchronized to the ac line supplying power to the DAU.

Reset synchronization is established by the Reset Sync Cards during its

© 2012 DynAmp, LLC Page 11

43756 G

Installation, Operation and Service Manual RCEM

initialization sequence upon power-up. A “RCEM RESET” command from the

spreadsheet program will also cause the integrator resets to synchronize to the ac

line.

To work properly, each integrator must be reset when the associated rectifier device

is not conducting current during the commutation cycle. In a full-wave, three leg

rectifier, the reset pulse will occur at a different instant for each integrator on the

integrator card. The six integrator channels on each integrator card are referred to

as Leg 1, Leg 2, Leg 3, Leg 4, Leg 5, and Leg 6.

The integrator circuit outputs are scaled to 1V/1kA. The output of each integrator

circuit is available at the 12-position waveform output connector located on the top

edge of each integrator card. The integrator circuit outputs are also connected to

the pc board edge connector. These outputs are used by the reset sync cards to

generate the reset pulses. The final connection is to the RMS-to-dc converters.

This is the output signal path.

3.) RMS-TO-DC Converter.

The RMS-to-dc converters are used to convert the device current waveform to a dc

voltage. The outputs of the RMS-to-dc converters are connected to the 6-to-1

multiplexer.

4.) 6-to-1 Analog Multiplexer Circuit.

The multiplexer used is an eight input, one output CMOS analog multiplexer. Inputs

S1 through S6 are connected to the six RMS-to-dc converter outputs. Inputs S7

and S8 are not used. The output of the 6-to-1 multiplexer is connected to a noninverting amplifier with a gain of 5. This output is routed to the Personal Daq/56 via

the backplane and a wiring harness.

5.8 RESET SYNC CARDS

This circuit generates the reset pulses required to control the analog integrator circuits.

The device waveform signal from the integrator card is applied to a window comparator.

The outputs of the window comparators are connected to a microcontroller. The

microcontroller uses the ac zero-crossing signal from the backplane and the outputs from

the window comparators to generate the reset signals.

The first Reset Sync Card generates the reset signals for the first ten Integrator Cards

while the second Reset Sync Card generates the resets for the second group of ten

Integrator Cards. The reset signals are available on connectors P23 and P24 located on

the backplane. See Figure 5.2 for the Reset Pulse Connector Location and Figure 5.3 for

Reset Pulse Signal Location.

© 2012 DynAmp, LLC Page 12

43756 G

Installation, Operation and Service Manual RCEM

PIN NO.

Reset Pulse

1

1 2 Commo

n

Reset Pulse

2

3 4 Commo

n

Reset Pulse

3

5 6 Commo

n

Reset Pulse

4

7 8 Commo

n

Reset Pulse

5

9

10

Commo

n

Reset Pulse

6

11

12

Common Zero-

crossing

13

14

Commo

n

10

20

Figure 5.2

Reset Pulse Connector Location

5.9 TEST SIGNAL GENERATOR

© 2012 DynAmp, LLC Page 13

43756 G

Notes:

1) P23: Channels 1 –

2) P24: Channels 11 –

Figure 5.3

Reset Pulse Signal Location

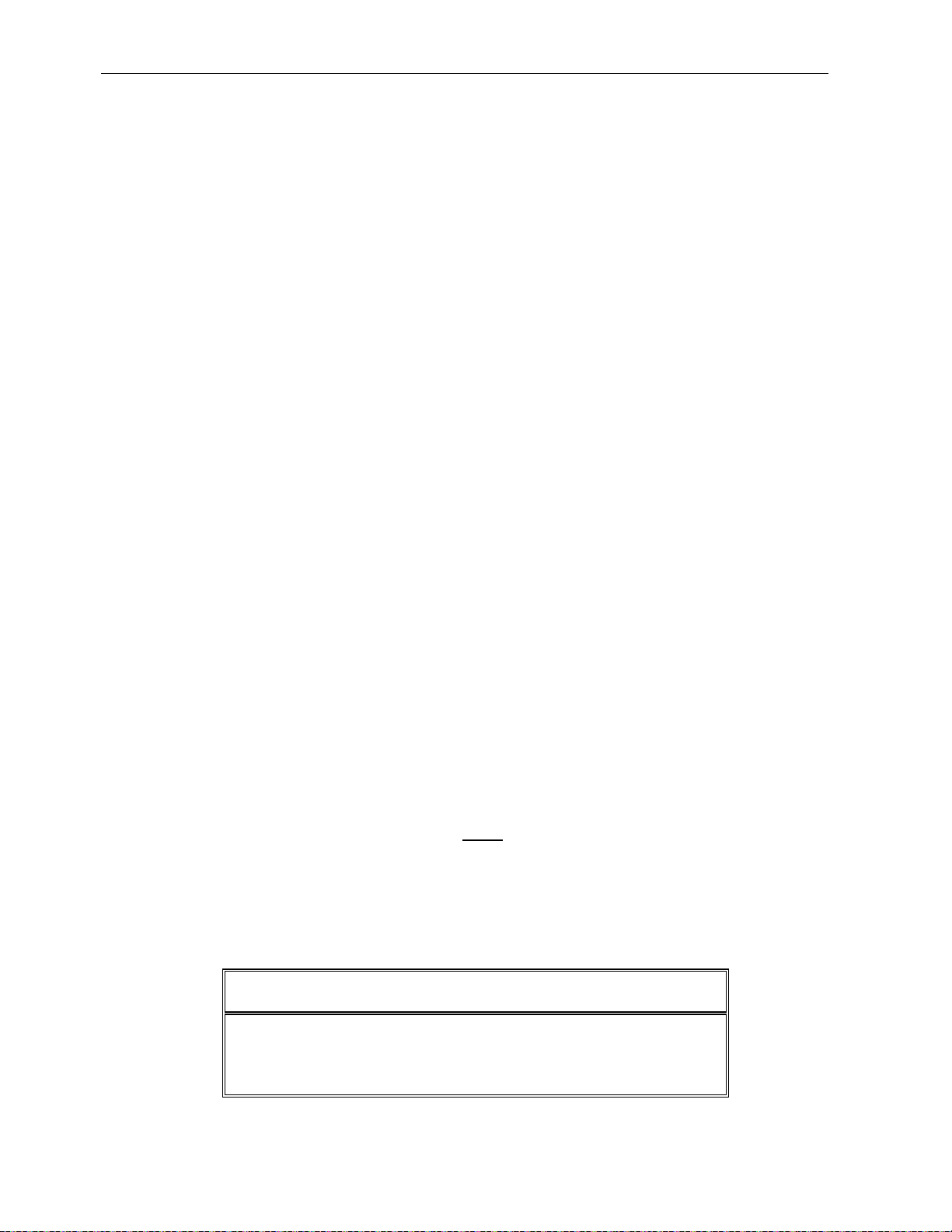

The reset sync card also contains the test signal generator. A second microcontroller is

used to generate the test pattern. This microcontroller also uses the ac zero-crossing

circuit to generate the pattern. The timing signals from the microcontroller is connected to

the signal generator consisting of op amps U11 and U14, analog switch U9, and a

reference voltage produced by U12. The test signal waveform for the 571A test signal is

shown in Figure 5.4.

Installation, Operation and Service Manual RCEM

Figure 5.4

571A Test Signal Waveform

5.10 PERSONAL DAQ/56

The Personal Daq/56 is a self-contained USB data acquisition module with twenty analog

input channels and 16 digital I/O channels. The Personal Daq/56 is located on the top end

panel of the Data Acquisition Unit. See Figure 5.5.

Figure 5.5

Personal Daq/56

© 2012 DynAmp, LLC Page 14

43756 G

Installation, Operation and Service Manual RCEM

5.11 USB EXTENDER RECEIVER

The USB specification severely limits the distance of an USB peripheral from the computer.

The USB Extender allows that distance to be increased to a maximum distance of about

300 feet. The USB Extender Receiver is located near the Personal Daq/56 on the top end

panel of the Data Acquisition Unit. See Figure 5.6. The receiver is powered by an isolated

+5V power supply.

Figure 5.6

USB Extender Receiver

5.12 DIGITAL INTERFACE MODULE

The digital interface module connects the 5V digital outputs of the Personal Daq/56 to the

24V digital inputs required by the backplane. This module consists of an input terminal

strip, an interface integrated circuit, and an output terminal strip. The module is located

adjacent to the Personal Daq/56 Data Acquisition Module. See Figure 5.7.

Figure 5.7

Digital Interface Module

© 2012 DynAmp, LLC Page 15

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 16

43756 G

Installation, Operation and Service Manual RCEM

IMPORTANT

WARNING

6. PREPARATION FOR USE

6.1 SYSTEM CHECKOUT AND PREPARATION

Make a system checkout when the equipment is received.

When unpacking or handling the current sensor assemblies,

treat them very gently; do not handle in such a manner as to

place strain on the current sensors. The current sensors

should ALWAYS be treated as delicate measurement

instruments.

6.2 RECTIFIER SHUTDOWN

Disconnect the input side of the rectifier from the AC power

supply and disconnect the output side of the rectifier from the

load, or use your approved disconnect procedure to ensure

that no AC input is present and that cell-effect voltages from

the electrochemical process are not present during installation

of current sensors.

6.3 SENSOR MOUNTING AND CONNECTION CONSIDERATIONS

Once the rectifier has been safely taken off line, a current sensor may be safely placed

around each device (or related fuse or pigtail as circumstances dictate).

6.4 INSTALLATION INSTRUCTIONS

Make sure the current sensors and their output cables are clean before installing them in

the rectifier. If the current sensors and cables are not clean, the contaminants on them

may provide a conductive path for a high-voltage breakdown. Section 6 describes how to

check for such paths.

The Flexible Current Sensors are factory calibrated to DynAmp’s standard Flexible Current

Sensor circuit. All Flexible Current Sensors are interchangeable regardless of the physical

size.

To install current sensors in a rectifier:

© 2012 DynAmp, LLC Page 17

43756 G

a.) Place current sensors on device paths in the proper direction (conventional plus-to-

minus current flowing into the polarity dot). Proper Flexible Current Sensor mounting is

shown in Figure 6.1.

Installation, Operation and Service Manual RCEM

Figure 6.1

Flexible Current Sensor Installation Detail

b.) To install the Flexible Current Sensor, separate the Velcro fasteners and separate the

ends. Then encircle the conductor and secure the Velcro fasteners.

c.) Connect each current sensor cable to mating half of extension cable (refer to the

enclosed interconnection drawings). Table 6.1 through Table 6.7 summarizes the

connections for various rectifier configurations on 120 channel systems and 240

channel systems. The cable connectors are keyed for proper polarity.

d.) Connect the Data Acquisition Unit to the appropriate ac power.

e.) Turn ON the Data Acquisition Unit using the power switch located on the I/O Panel.

f.) Put the rectifier back on-line and bring it up to load.

The RCEM may be tested, using its built-in test signal generator, during rectifier testing.

Use the procedure in Appendix B.9 whenever the RCEM measurements indicate a problem

in a rectifier, before taking the rectifier off-line. Use caution when disconnecting the current

sensor cables, since hazardous voltages may exist when the current sensors are installed

on live rectifier circuits.

© 2012 DynAmp, LLC Page 18

43756 G

Installation, Operation and Service Manual RCEM

Leg 1

Leg 2

Leg 3

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

11

1B-1

11

2B-1

11

3B-1

20

1B-10

20

2B-10

20

3B-10

Leg 4

Leg 5

Leg 6

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

11

4B-1

11

5B-1

11

6B-1

20

4B-10

20

5B-10

20

6B-10

Notes:

TABLE 6.1

TRANSDUCER CONNECTIONS, 6-LEG RECTIFIER (20 DIODES MAX.)

1) This chart applies to a 120 Channel RCEM

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connect to Data Acquisition Unit

connectors 1A through 6B

© 2012 DynAmp, LLC Page 19

43756 G

Installation, Operation and Service Manual RCEM

Leg 1

Leg 2

Leg 3

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

11

1B-1

11

2B-1

11

3B-1

20

1B-10

20

2B-10

20

3B-10

21

1C-1

21

2C-1

21

3C-1

30

1C-10

30

2C-10

30

3C-10

31

1D-1

31

2D-1

31

3D-1

40

1D-10

40

2D-10

40

3D-10

Leg 4

Leg 5

Leg 6

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

11

4B-1

11

5B-1

11

6B-1

20

4B-10

20

5B-10

20

6B-10

21

4C-1

21

5C-1

21

6C-1

30

4C-10

30

5C-10

30

6C-10

31

4D-1

31

5D-1

31

6D-1

40

4D-10

40

5D-10

40

6D-10

TABLE 6.2

TRANSDUCER CONNECTIONS, 6-LEG RECTIFIER (40 DIODES MAX.)

Notes:

1) This chart applies to a 240 Channel RCEM

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connect to Data Acquisition Unit #1 connectors 1A through 6B

4) Cables 1C through 6D connect to Data Acquisition Unit #2 connectors 1A through 6B

© 2012 DynAmp, LLC Page 20

43756 G

Installation, Operation and Service Manual RCEM

Leg 1A

Leg 2A

Leg 3A

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

Leg 4A

Leg 5A

Leg 6A

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

Leg 1B

Leg 2B

Leg 3B

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1B-1

1

2B-1

1

3B-1

10

1B-10

10

2B-10

10

3B-10

Leg 4B

Leg 5B

Leg 6B

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4B-1

1

5B-1

1

6B-1

10

4B-10

10

5B-10

10

6B-10

TABLE 6.3

TRANSDUCER CONNECTIONS, PARALLEL 6-LEG RECTIFIER (10 DIODES MAX)

Notes: 1) This chart applies to a 120 Channel RCEM

© 2012 DynAmp, LLC Page 21

43756 G

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connect to Data Acquisition Unit connectors 1A through 6B

Installation, Operation and Service Manual RCEM

Leg 1A

Leg 2A

Leg 3A

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

11

1B-1

11

2B-1

11

3B-1

20

1B-10

20

2B-10

20

3B-10

Leg 4A

Leg 5A

Leg 6A

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

11

4B-1

11

5B-1

11

6B-1

20

4B-10

20

5B-10

20

6B-10

Leg 1B

Leg 2B

Leg 3B

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1C-1

1

2C-1

1

3C-1

10

1C-10

10

2C-10

10

3C-10

11

1D-1

11

2D-1

11

3D-1

20

1D-10

20

2D-10

20

3D-10

Leg 4B

Leg 5B

Leg 6B

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4C-1

1

5C-1

1

6C-1

10

4C-10

10

5C-10

10

6C-10

11

4D-1

11

5D-1

11

6D-1

20

4D-10

20

5D-10

20

6D-10

TABLE 6.4

TRANSDUCER CONNECTIONS, PARALLEL 6-LEG RECTIFIER (20 DIODES MAX)

Notes: 1) This chart applies to a 240 Channel RCEM

© 2012 DynAmp, LLC Page 22

43756 G

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connect to Data Acquisition Unit #1 connectors 1A through 6B

4) Cables 1C through 6D connect to Data Acquisition Unit #2 connectors 1A through 6B

Installation, Operation and Service Manual RCEM

Leg 1

Leg 2

Leg 3

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

Leg 4

Leg 5

Leg 6

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

Leg 7

Leg 8

Leg 9

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1B-1

1

2B-1

1

3B-1

10

1B-10

10

2B-10

10

3B-10

Leg 10

Leg 11

Leg 12

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4B-1

1

5B-1

1

6B-1

10

4B-10

10

5B-10

10

6B-10

TABLE 6.5

TRANSDUCER CONNECTIONS, 12-LEG RECTIFIER (10 DIODES MAX.)

Notes: 1) This chart applies to a 120 Channel RCEM

© 2012 DynAmp, LLC Page 23

43756 G

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connects to Data Acquisition Unit connectors 1A through 6B

Installation, Operation and Service Manual RCEM

Leg 1

Leg 2

Leg 3

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

1

2A-1

1

3A-1

10

1A-10

10

2A-10

10

3A-10

11

1B-1

11

2B-1

11

3B-1

20

1B-10

20

2B-10

20

3B-10

Leg 4

Leg 5

Leg 6

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4A-1

1

5A-1

1

6A-1

10

4A-10

10

5A-10

10

6A-10

11

4B-1

11

5B-1

11

6B-1

20

4B-10

20

5B-10

20

6B-10

Leg 7

Leg 8

Leg 9

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1C-1

1

2C-1

1

3C-1

10

1C-10

10

2C-10

10

3C-10

11

1D-1

11

2D-1

11

3D-1

20

1D-10

20

2D-10

20

3D-10

Leg 10

Leg 11

Leg 12

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

4C-1

1

5C-1

1

6C-1

10

4C-10

10

5C-10

10

6C-10

11

4D-1

11

5D-1

11

6D-1

20

4D-10

20

5D-10

20

6D-10

TABLE 6.6

TRANSDUCER CONNECTIONS, 12-LEG RECTIFIER (20 DIODES MAX.)

Notes: 1) This chart applies to a 240 Channel RCEM

© 2012 DynAmp, LLC Page 24

43756 G

2) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

3) Cables 1A through 6B connects to Data Acquisition Unit #1 connectors 1A through 6B

4) Cables 1C through 6D connects to Data Acquisition Unit #2 connectors 1A through 6B

Installation, Operation and Service Manual RCEM

Leg “n”

Leg “n”

Leg “n”

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

1

1A-1

6

2A-1

11

3A-1

2

1A-2

7

2A-2

12

3A-2

3

1A-3

8

2A-3

13

3A-3

4

1A-4

9

2A-4

14

3A-4

5

1A-5

10

2A-5

15

3A-5

Leg “n”

Leg “n”

Leg “n”

Diode No.

Cable No.

Diode No.

Cable No.

Diode No.

Cable No.

16

4A-1

21

5A-1

26

6A-1

17

4A-2

22

5A-2

27

6A-2

18

4A-3

23

5A-3

28

6A-3

19

4A-4

24

5A-4

29

6A-4

20

4A-5

25

5A-5

30

6A-5

TABLE 6.7

TRANSDUCER CONNECTIONS, 1-LEG OF A MULTI-LEG RECTIFIER

Notes: 1) Rectifier must have at least 3 legs

2) This table shows connections for 30 diodes/leg

3) 1A-1 = Leg cable “1A”, Current Transducer connector “1”

4) Cables 1A through 6A connects to Data Acquisition Unit connectors 1A through 6A

© 2012 DynAmp, LLC Page 25

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 26

43756 G

Installation, Operation and Service Manual RCEM

7. MAINTENANCE AND TROUBLESHOOTING

7.1 CALIBRATION INTERVALS

DynAmp does not specify required intervals of calibration for its products.

The end user of the product is responsible for identifying the appropriate interval between

calibrations. The intervals should be determined based on the following factors:

• Requirements of a Quality Management System

• Accuracy and permissible limits of errors

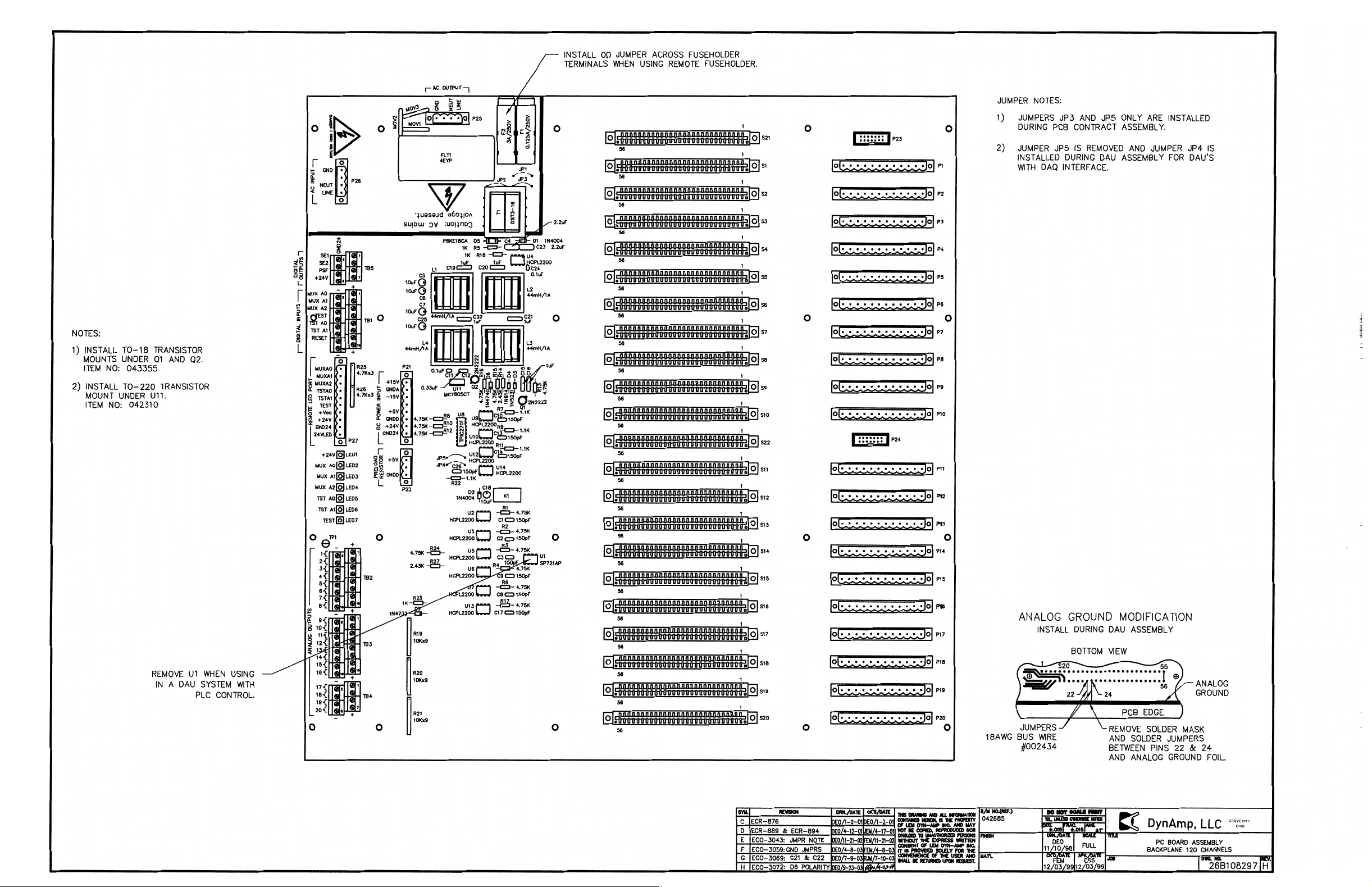

• Purpose and usage

• Experience with similar products

• Manufacturer's recommendations

• Stability of the product

• Past history

• Other characteristics of the product

Reference: "ISO/IEC 17025:2005, General requirements for the competence of testing and

calibration laboratories" and Laboratory Accreditation Bureau "Guidance for Documenting

and Implementing ISO/IEC 17025:2005 and Laboratory Guidance."

As a guideline, DynAmp recommends a 24-month interval of calibration for all permanently

installed products and a 12-month interval of calibration for all products used in portable

applications.

7.2 GENERAL

The RCEM electronics will not operate until the communications link is

established with the laptop computer.

This section contains some specialized tests of the electronics and current sensors of the

RCEM, as well as some preventive maintenance procedures. The output of the built-in

signal generator provides a test signal for testing the overall operation of the RCEM as well

as its accuracy.

IMPORTANT

7.3 VERIFYING PROPER OPERATION

Data acquired from the test signal generator should be within ±1.5% of the selected test

signal level. If data acquired from the test signal generator is within specified accuracy, the

© 2012 DynAmp, LLC Page 27

43756 G

Installation, Operation and Service Manual RCEM

problem is not likely to be a DAU hardware problem. If data acquired from the test signal

generator is not within specified accuracy, continue with the steps in this section.

7.4 FUSE REPLACEMENT

Replace DAU fuse(s) with the specified type and current rating. The main fuse is located

on the I/O Panel. The ac zero-crossing fuse is located on the end of the analog card rack.

Disconnect power to the system before servicing or replacing fuses.

1. Turn the DAU power switch off.

2. Remove the fuseholder cap. You may use the blade of a small screwdriver, if

desired.

3. Remove the blown fuse from the fuse clip PC board. Replace with MDL1 slow blow

fuse. Be sure to insert the replacement fuse in the proper location for the

appropriate line voltage.

7.5 STATIC PRECAUTIONS WHEN SERVICING

Qualified personnel only should perform servicing, following procedures described herein.

If troubleshooting indicates a need to replace a component on a printed circuit board or to

replace the entire board, measures to prevent electrostatic discharge (ESD) damage must

be taken, as follows:

a. ALWAYS wear a wrist strap connected to ground through a 1-megohm resistor

when working on printed circuit boards.

b. Use a soldering iron with a grounded tip.

c. Use a non-static generating de-soldering pump (metallic) or solder removal braid.

d. Transport static sensitive components in static shielding bags or rails. A new

printed circuit board should be treated as a static sensitive device. The fact that a

part is installed on a board does not make the part static safe.

e. If possible, perform printed circuit board maintenance at a workstation that has a

conductive covering that is grounded through a 1-megohm resistor. If a conductive

tabletop cover is not available, a clean steel tabletop is an excellent substitute.

f. Keep plastic, vinyl, Styrofoam and other non-conductive materials away from

printed circuit boards. They are good static generators that do not give up their

charge easily.

g. Return goods to DynAmp in static safe packaging. This will limit further component

damage from ESD.

CAUTION

Do not touch any printed circuit board unless you are wearing

a grounded wrist strap, as circuit damage may occur.

© 2012 DynAmp, LLC Page 28

43756 G

Installation, Operation and Service Manual RCEM

7.6 VERIFYING PROPER INTEGRATOR RESET SYNCHRONIZATION

One possible source of incorrect device data is improper integrator reset synchronization.

Check any suspect channels with an oscilloscope. The waveform should look similar to

Figure 7.1

Figure 7.1

Device Current Waveform

The device current waveforms should be present anytime the rectifier is ON. Proper

integrator reset synchronization is indicated by 0 volts when rectifier device is not

conducting during the commutation cycle. That is, the device current "humps" should rise

from, and return to a level of zero volts (no dc offset voltage present).

If a dc offset voltage is present in the device current waveform, the integrators are not

being reset at the proper time. In this case, check the suspect integrator card as follows:

1. Make sure that all integrator cards are properly seated in the card rack.

2. Connect the oscilloscope to the questionable waveform test points. See Figure 7.2.

3. With the laptop computer connected to the Personal Daq/56, click on the “RCEM

RESET” button on the spreadsheet.

4. If the problem persists, remove the integrator card, and substitute a known good

integrator card. Be sure to observe static precautions.

5. Repeat steps 3 through 4.

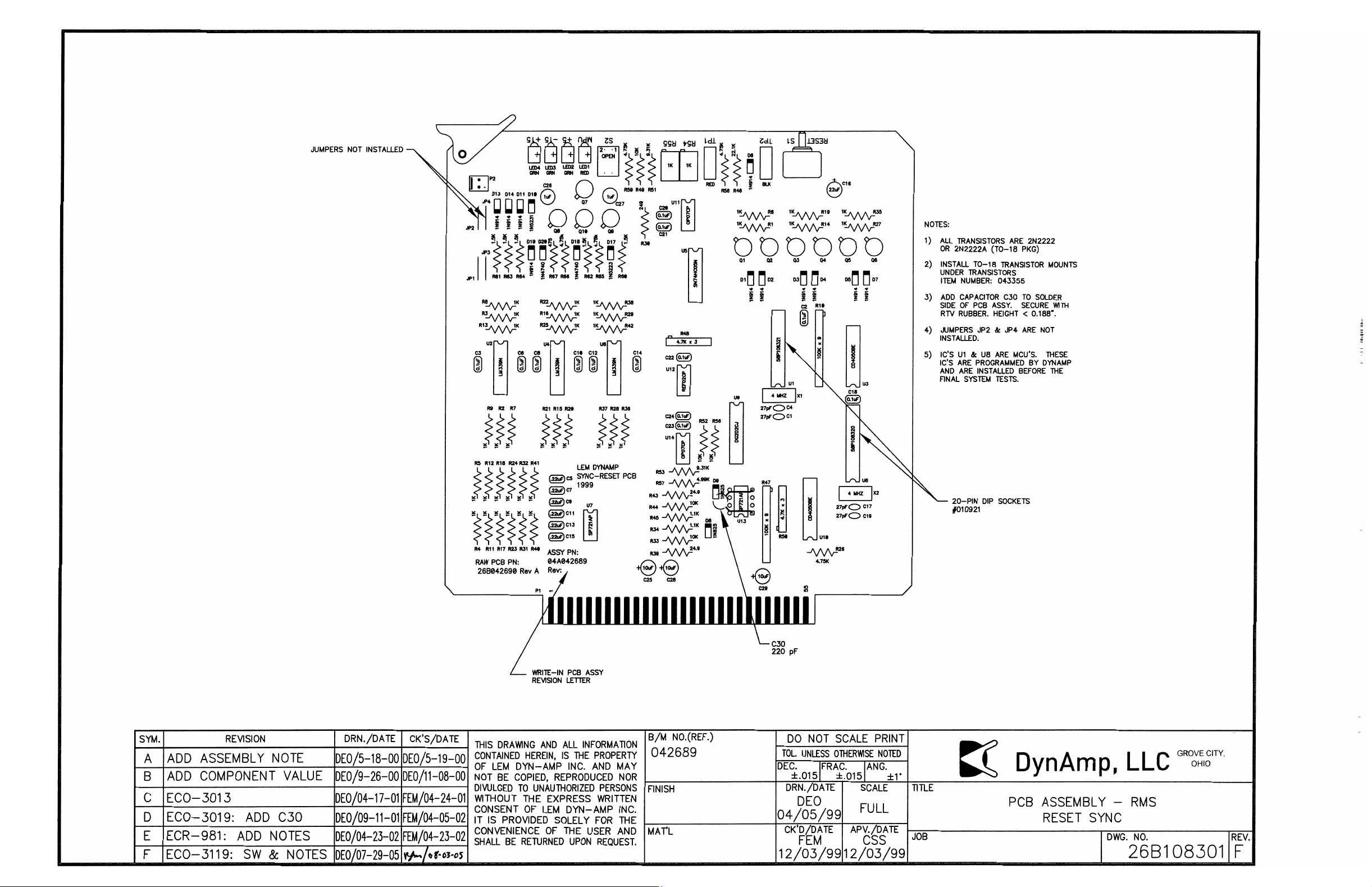

7.7 ADJUSTING THE SIGNAL GENERATOR

To adjust the signal generator, refer to Figure 7.2 and proceed as follows:

a. Connect a DMM between TP1 (+) and TP2 (COM). Place switch SW2 Position 2 in

the MANUAL position (switch lever down).

b. Place switch SW2 Position 1 in the V- position (switch lever down).

c. Adjust potentiometer R54 for a reading of -10.000 Vdc.

d. Place switch SW2 Position 1 in the V+ position (switch lever up).

© 2012 DynAmp, LLC Page 29

43756 G

Installation, Operation and Service Manual RCEM

e. Adjust potentiometer R55 for a reading of +10.000 Vdc.

f. Place switch SW2 Position 2 in the AUTO position (switch lever up).

Figure 7.2

Reset Sync PC Board

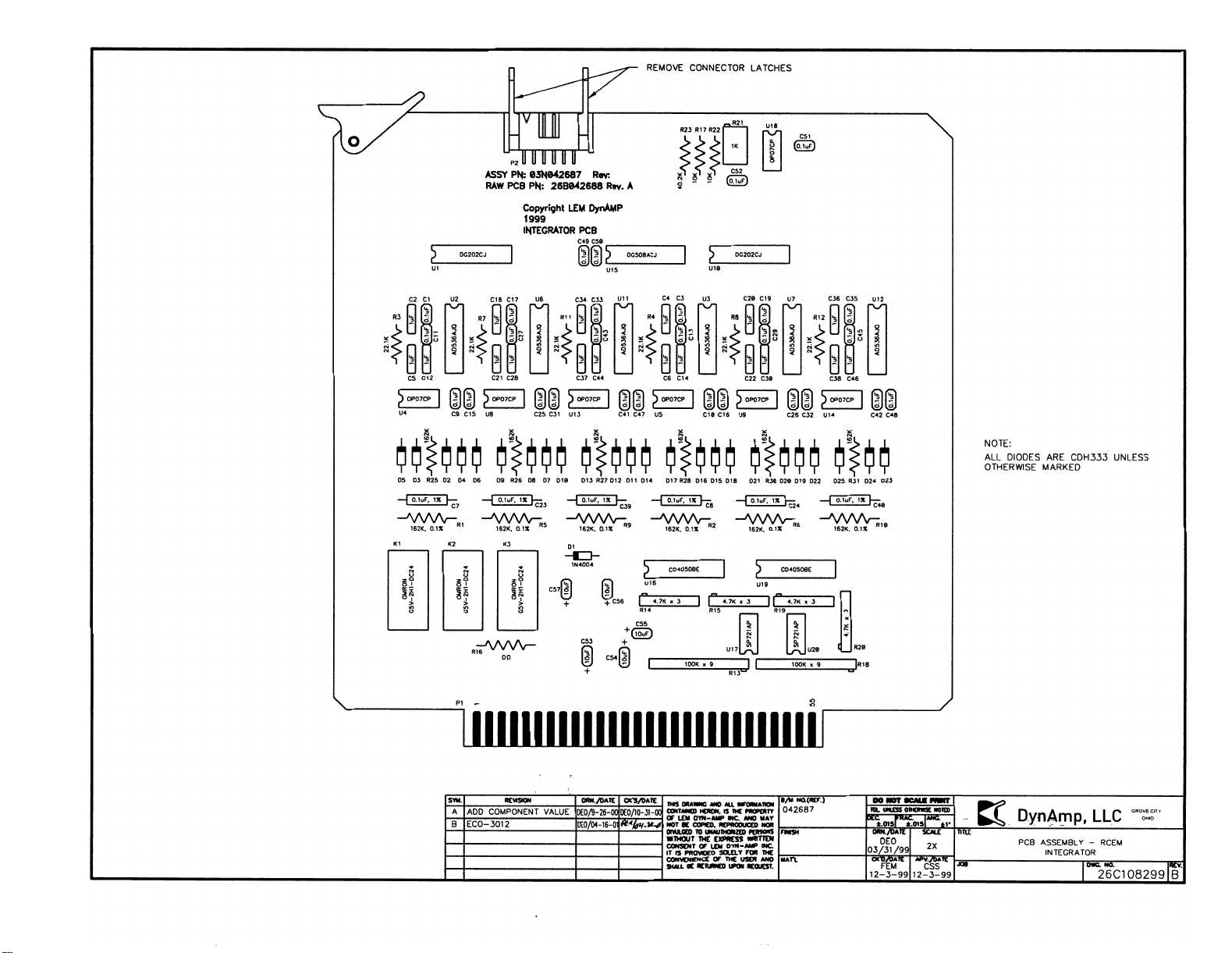

7.8 ADJUSTING THE INTEGRATOR PC BOARDS

To adjust the Integrator PC Boards, refer to Figure 7.3 and proceed as follows:

Figure 7.3

Integrator PC Board

1. Adjust the signal generator as described in the proceeding section. The accuracy

of the Integrator PC Boards depends on the accuracy of the signal generator.

2. Activate the “Calibrate Worksheet” as described in Appendix B.14.

3. Adjust potentiometer R21 on the first Integrator PC Board while watching the

average of Diode 1 on the “Calibrate Worksheet”. Adjust the potentiometer for a

reading of 571 amps, ±1 amp.

4. Repeat for Integrator PC Boards 2 through 20 (“Calibrate Worksheet”, Diodes 2

through 20).

7.9 SENSOR TESTING (CONTINUITY METHOD)

The current sensor continuity test (described below) is made when the RCEM is first

installed and will also prove useful in troubleshooting. The dielectric test, paragraph 7.9, is

another useful preventive maintenance and diagnostic tool.

1. Make sure that the rectifier system in which the current sensors are connected is

off-line (not powered).

2. Disconnect the input connectors “1A” through “6B” on the I/O Panel of the DAU.

Measure the continuity of each current sensor with a DMM.

© 2012 DynAmp, LLC Page 30

43756 G

Installation, Operation and Service Manual RCEM

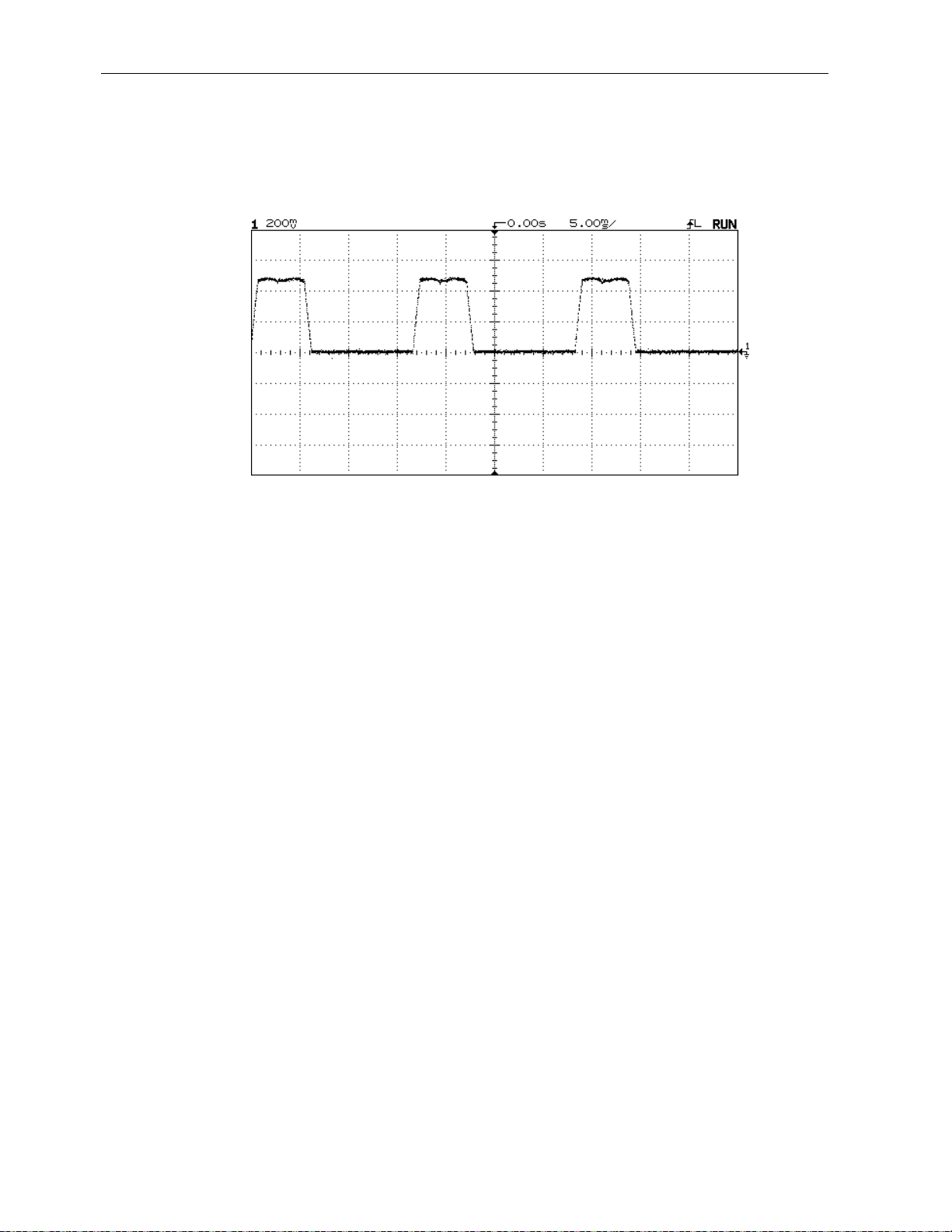

Current

Sensor

Pins

1

16 & 13

2

10 & 4

3

17 & 8

4

23 & 9

5

24 & 14

6

29 & 15

7

34 & 21

8

30 & 22

9

17 & 18

10

19 & 20

3. Replace any defective current sensor(s) and repeat the test.

7.10 SENSOR DIELECTRIC TESTING - WINDINGS TO SURFACE

Dielectric withstand-voltage tests of the current sensors can be useful in preventive

maintenance and troubleshooting of the RCEM.

WARNING

DANGER HIGH VOLTAGE exists while performing Hipot

tests. Qualified trained personnel should perform Hipot

tests. Refer to test equipment users guide for equipment

operating instructions.

CAUTION

1. Hipot testing produces ozone gas through electrolysis

that in high concentrated levels (0.12 PPM) can be

toxic as a strong irritant through inhalation. The

presence of high concentrated levels of ozone gas

will be noticeable by a strong pungent odor.

2. All Hipot tests should be performed in an open area

with air movement to disperse ozone gas. The use of

a portable fan may be necessary to disperse

concentrated levels of ozone gas.

3. All Hipot Testing should be halted if a high level of

ozone gas is suspected until the Safety Director has

reviewed the application.

© 2012 DynAmp, LLC Page 31

43756 G

Installation, Operation and Service Manual RCEM

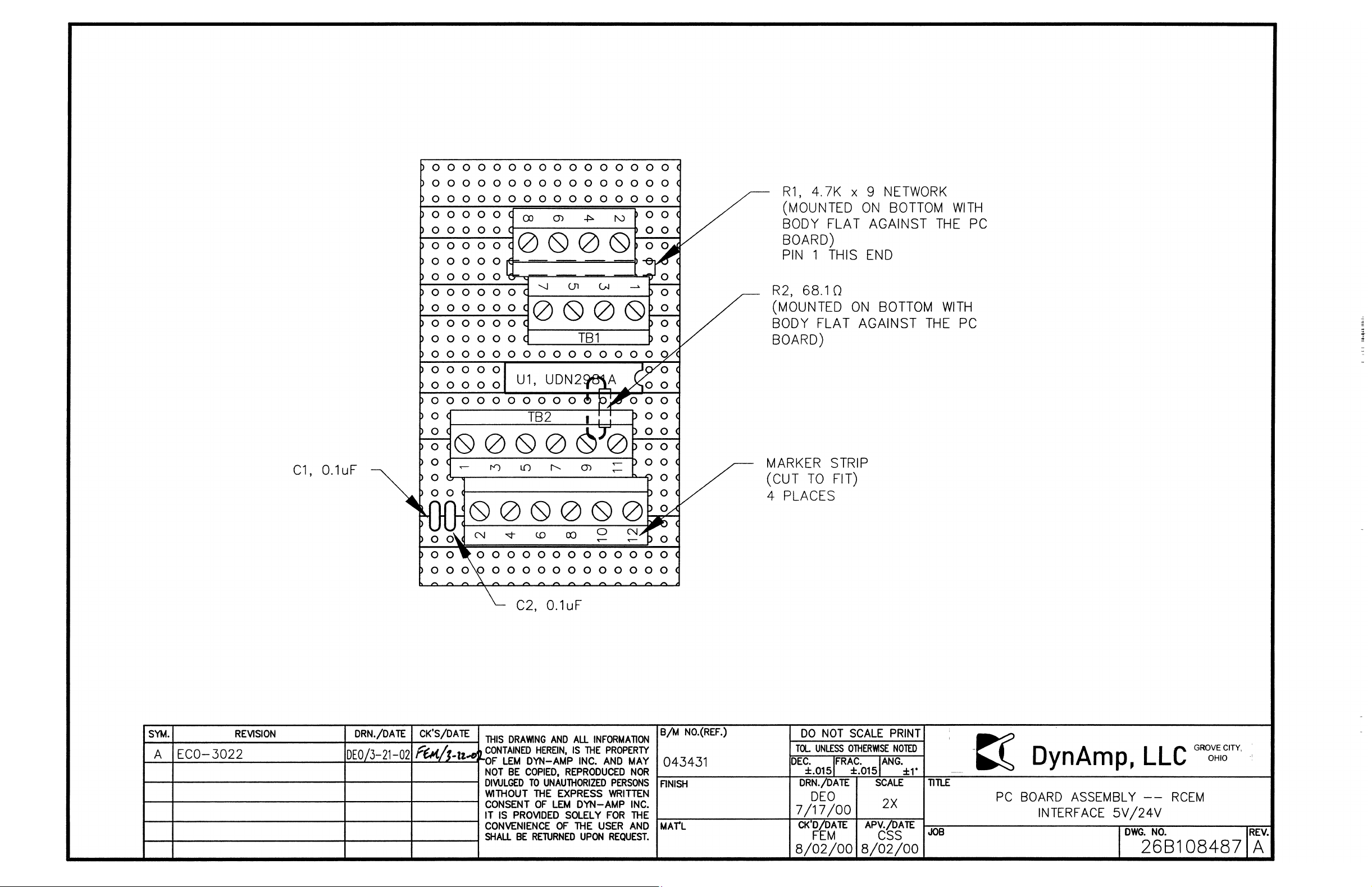

Place current sensor in test ground plane (metal container containing loose hardware).

Submerge current sensor below loose hardware. Use metallic hardware, preferably ball

bearings (no sharp edges). Keep the output cable outside the test ground plane. See

Figure 6.4 for a typical Hi-Pot Test Setup.

Short current sensor connector pins 1 and 2 together. Connect Hipot between connector

pins and metal container. Gradually apply 3000 Vac and maintain for 1 minute.

As the high-voltage source, we suggest the use of a commercial high-potential tester such

as the Junior Hy-Pot from Associated Research, Inc. (8221 N. Kimball Ave., Skokie, IL).

Connect the test apparatus to the ac terminals of the tester and set the tester's AC/DC

switch to the AC position.

Note that the tester has two neon lamp indicators - BREAKDOWN and LEAKAGE. Once

the connections are made, slowly increase the voltage output of the tester and look for an

indication from the lamps. It should be possible to run the voltage up to 3000 Vac without

breakdown occurring. If a LEAKAGE indication is obtained before this point, it may be

necessary to adjust the threshold of the tester's leakage test circuit (by means of a

potentiometer on the tester). Capacitive effects cause (Leakage.) A breakdown will be

indicated by the tester's BREAKDOWN lamp.

Figure 7.4

Hi-Pot Test Setup

7.11 CONNECTOR CONTAMINATION (INTEGRATOR CARDS)

In the process of daily operation or during vibration in shipment, the DAU integrator card

connectors may get contaminated. This may also happen from airborne contaminants that

may enter the DAU from normal factory use. This action may cause abnormal operation of

the RCEM.

© 2012 DynAmp, LLC Page 32

43756 G

Installation, Operation and Service Manual RCEM

NOTE

ADHERE TO ALL STATIC PROTECTION WARNINGS IN

SECTION 7.5!

The cure for this symptom is simple. Turn off the DAU using the power switch. Remove

the protective cover on the DAU analog card rack. This is done by removing four screws.

Remove the integrator cards from the DAU. Clean the connector pins on the integrator

cards and the connectors inside the DAU. Suitable solvent would be isopropyl alcohol

(99% pure, no glycerin added), trichlorethylene, or any other DynAmp, LLC approved

connector cleaner. Reinstall all integrator cards in the appropriate slots. Reinstall the front

cover and reapply ac to the unit.

7.12 RESET SYNC ERROR OR INCORRECT DATA

If a Reset Sync error occurs, this means that the DAU is not synchronized to the rectifier.

Incorrect data will result if the DAU is not properly synchronized. When the DAU is turned

on, it automatically goes through its synchronization routine. In order for the DAU to

synchronize properly, the rectifier needs to be conducting current when the DAU is

powered up. The value of this current should be approximately 100 amps per device or

greater. If the DAU is powered up and the rectifier is not in the above stated condition, the

DAU may not establish correct reset pulse locations. The DAU will automatically adjust the

reset pulse locations when the rectifier is conducting adequate current. However, all reset

pulses may not be in the optimum location. A scanner reset will assure optimum reset

pulse location.

The “RCEM RESET” command button will also cause the Data Acquisition Unit to

synchronize to the rectifier. This may be accomplished by turning the DAU power off then

on, or by clicking on the “RCEM RESET” command button located on the laptop computer

spreadsheet.

© 2012 DynAmp, LLC Page 33

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 34

43756 G

Installation, Operation and Service Manual RCEM

8. SERVICE, PARTS, AND DOCUMENTATION

8.1 SERVICE ASSISTANCE

For further assistance, contact DynAmp Customer Support at:

Americas:

Telephone: +1 614.871.6900 Fax: +1 614.871.6910

8:00 AM to 5:00 PM USA Eastern Time

From first Sunday in November to second Sunday in March – 13:00 GMT to 22:00 GMT

From second Sunday in March to first Sunday in November – 12:00 GMT to 21:00 GMT

Europe:

Telephone: +41 22.706.1446 Fax: +41 22.706.1311

8:30 AM to 5:00 PM Central European Time

From last Sunday in October to last Sunday in March – 7:30 GMT to 16:00 GMT

From last Sunday in March to last Sunday in October – 6:30 GMT to 15:00 GMT

After Hours Critical Service Emergency:

Telephone: +1 614.871.6906

5:00 PM to 8:00 AM USA Eastern Time

From first Sunday in November to second Sunday in March – 22:00 GMT to 13:00 GMT

From second Sunday in March to first Sunday in November – 21:00 GMT to 12:00 GMT

Central e-mail:

help@dynamp.com

DynAmp web:

www.dynamp.com

© 2012 DynAmp, LLC Page 35

43756 G

Installation, Operation and Service Manual RCEM

Fuses, 0.125A, 250V, MDA-1/8 (5 per box)

3529

1 box

Fuses, 3A, 250V, MDA-3 (5 per box)

12591

1 box

COP, 3.625 ID Flexible

14063

5

PCB Assembly, RCEM Integrator

42687

2

PCB Assembly, RCEM Reset Sync

44521

1

Cable Assembly, BNC Male-to-Male 5 Ft

42814

2

Adapter, BNC Female to 0.025 x 0.025 Socket

42815

2

8.2 SPARE PARTS ORDERS - ROUTINE OR EMERGENCY

Requests for spare parts, either in an emergency or for a routine order, should be directed

to "Inside Sales" at DynAmp during normal hours, if possible, or via any method shown

above for off-hours. When contacting us, please present as much information as possible the related equipment Model Number and Serial Number; the required part name and its

DynAmp item number (and other identifying or vendor number(s); and your time needs. An

approved Purchase Order Number should be given with your order.

8.3 SPARE PARTS

The following table lists recommended quantities of spare parts for the RCEM. As spares

are used, replacements should be ordered to insure continuous operation of the

equipment.

TABLE 8.1

SPARE PARTS LIST

DESCRIPTION ITEM NO. QUAN

Disconnect power to the system before servicing or replacing fuses.

© 2012 DynAmp, LLC Page 36

43756 G

Installation, Operation and Service Manual RCEM

DRAWING TITLE

NUMBER

9. DRAWING LIST

9.1 REQUIRED DRAWINGS

The drawings in table 8.1 are to be considered as part of (although not necessarily included

in) this manual. Drawings should be kept with the manual at all times.

TABLE 9.1

DRAWING LIST

Interconnection Diagram: RCEM 120 Channel COP (6-Pulse) 02D108554

Interconnection Diagram: RCEM 120 Channel COP (12-Pulse) 02D108555

Outline and Mounting: RCEM DAU 120 Channel 02D108504

Outline and Mounting: COP 3.625 ID Flexible 02B104835

PCB Assembly: RCEM Backplane 26D108297

PCB Assembly: RCEM Integrator 26C108299

PCB Assembly: RCEM Reset Sync 26B108301

PCB Assembly: RCEM Digital Interface 5V/24V 26B108487

Schematic: RCEM System 120 Channel 05D108502

© 2012 DynAmp, LLC Page 37

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 38

43756 G

Installation, Operation and Service Manual RCEM

APPENDIX A: ANSI RECTIFIER CIRCUITS

Figure A.1

ANSI Rectifier Circuit 23

Figure A.2

ANSI Rectifier Circuit 24

© 2012 DynAmp, LLC Page 39

43756 G

Installation, Operation and Service Manual RCEM

Figure A.3

ANSI Rectifier Circuit 25

Figure A.4

ANSI Rectifier Circuit 26

© 2012 DynAmp, LLC Page 40

43756 G

Installation, Operation and Service Manual RCEM

Figure A.5

ANSI Rectifier Circuit 31

Figure A.6

ANSI Rectifier Circuit 32

© 2012 DynAmp, LLC Page 41

43756 G

Installation, Operation and Service Manual RCEM

Figure A.7

ANSI Rectifier Circuit 45

Figure A.8

ANSI Rectifier Circuit 46

© 2012 DynAmp, LLC Page 42

43756 G

Installation, Operation and Service Manual RCEM

Figure A.9

ANSI Rectifier Circuit 52

© 2012 DynAmp, LLC Page 43

43756 G

Installation, Operation and Service Manual RCEM

This Page is Intentionally Blank

© 2012 DynAmp, LLC Page 44

43756 G

Installation, Operation and Service Manual RCEM

APPENDIX B: SOFTWARE

B.1 PROVIDED SOFTWARE

All software and drivers associated with this product are supplied on CD-ROMs. The

contents of the DynAmp CD-ROM are as follows:

• DynAmp spreadsheet(s)

• Personal Daq/56 configuration file: “RCEM.cfg”

• A copy of this manual “043526x.pdf” (x = manual revision)

• Applicable manuals addendums

The Personal Daq/56 software is supplied on the manufacturer’s CD-ROM.

The above software is already installed on the laptop computer supplied with the product.

However, in case of a problem, please follow the instructions below for reinstalling the

software.

B.2 MINIMUM REQUIREMENTS FOR LAPTOP COMPUTER

The following is a list of the minimum requirements for the laptop computer:

1. Windows 2000 operating system. Software is compatible with Vista (32 bit) and

Windows 7 (32 bit).

2. Microsoft Office Small Business

3. USB High-power Compliant Port

4. USB Mass Storage Device

5. CD-ROM Drive