Dyna-Glo RMC-FA300DGD User Manual

Operating Instructions & Parts Manual RMC-FA300DGD

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and

others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

TM

Dyna-Glo

Delux

Propane Construction Heater

Description

Dyna-GloTM Delux Model RMC-FA300DGD heaters are 300,000 BTU/Hr construction

heaters. This heater uses propane gas for combustion, and electricity to run the

fan. It is primarily intended for temporary heating of well-ventilated buildings

under construction, alteration or repair. This heater should be utilized in sheltered,

well-ventilated areas, but never in occupied dwellings.

Specifications

Electrical Specifications

Model Electrical Input Amperage

RMC-FA300DGD 120 V, 60 Hz 0.65

ANS Z83.7-2011 CSA 2.14-2011 Construction Heater

C US

General Specifications

Output Rating Maximum Fuel Regulator

Model BTU/Hr Fuel Consumption Ignition Outlet Pressure

RMC-FA300DGD 300,000 Propane Vapor Only 13.9 lb/h Direct Spark, Interrupted 7-10 PSIG

Hot Air Output Minimum Supply Maximum Supply Size

Model Approx. (CFM) Motor Pressure to Regulator Pressure to Regulator L x W x H (Inches) RMC-RMC-

RMC-FA300DGD

FA300DGD 1800 0.085 HP 25 PSIG (For purposes Max Bottle Pressure 33.7 x 12.6 x 18.5

1,720 RPM of input adjustment)

(6.3 kg/h)

Figure 1 - Model RMC-FA300DGD

(85.6 x 32 x 47 cm)

Table of Contents Page

Description .......................1

Specifications......................1

Unpacking ....................... 1

General Safety Information ........1-3

Theory of Operation................3

Installation......................3-4

Ventilation........................4

Operation ......................4-5

Maintenance ....................5-6

Storage ..........................6

Wiring Diagram....................6

Repair Parts Illustration

and Parts List ....................7-8

Troubleshooting Chart ..............9

Warranty ........................11

Unpacking

1. Unpack all materials used to protect

the heater inside of carton. Retain

plastic caps attached to exposed

fittings for use during storage.

www.ghpgroupinc.com

2. Remove heater, accessories and all

hardware from carton.

3. Inspect all items for damage that may

have occurred during shipment.

WARNING

COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS

HEATER, CAN RESULT IN DEATH, SERIOUS

BODILY INJURY AND PROPERTY LOSS,

OR DAMAGE FROM THE HZARARDS OF

FIRE, EXPLOSION, BURN. ASPHYXIATION,

CARBON MONOXIDE POISONING, AND/

OR ELECTRIC SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND

AND FOLLOW THE INSTRUCTIONS

SHOULD USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER

INFORMATION SUCH AS AN INSTRUCTION

MANUAL, LABELS, ETCETERA, CONTACT

THE MANUFACTURER.

GENERAL HAZARD

WARNING

FAILURE TO

General Safety Information

IMPORTANT: Be sure to read and

understand all cautions and warnings,

Printed in China

before operating this heater. Keep

this instruction manual for future

reference, and use it as a guide to safe

and proper operation of the heater.

Various precautions appear throughout

this manual. Please review and pay

close attention to them. Below is an

explanation of the various levels of

caution required while operating this

heater.

DANGER

which, if not avoided, WILL result in death

or serious injury.

WARNING

which, if not avoided, COULD result in

death or serious injury.

CAUTION

which, if not avoided, MAY result in minor

or moderate injury.

WARNING

EXPLOSION HAZARD, KEEP SOLID

COMBUSTIBLES, SUCH AS BUILDING

Indicates an im minen tly

hazardous situation

Indicates a poten tially

hazardous situation

Indicates a poten tially

hazardous situa tion

FIRE, BURN,

INHALATION, AND

PROFESSIONAL GRADE

IMLPF300DGD - HBC

Dyna-GloTM Delux Operating Instructions and Parts Manual

RMC-FA300DGD

Dyna-Glo

TM

Propane Construction Heater

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

MATERIALS, PAPER OR CARDBOARD, A SAFE

DISTANCE AWAY FROM THE HEATER AS

RECOMMENDED BY THE INSTRUCTIONS.

NEVER USE THE HEATER IN SPACES WHICH

DO OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES, OR PRODUCTS

SUCH AS GASOLINE, SOLVENTS, PAINT

THINNERS, DUST PARTICLES OR UNKNOWN

CHEMICALS.

California Proposition 65 Warning:

Fuels used in gas or oil fired appliances

and the products of combustion of such

fuels, contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm. This

product contains chemicals, including lead

and lead compounds, known to the state

of California to cause cancer, birth defects

or other reproductive harm. Wash hands

after handling.

WARNING

requires that the heater is positioned

so that it is protected against any possible

damage by a moving vehicle, etc. It must be

positioned so that the base of the heater is

no less than 18 in (450 mm) above the

garage floor or 8 ft (2450 mm) in repair

garages. The heater must be placed on a

stable surface. Do not place it on a chair,

ladder, etc. Raising the heater will reduce

BUT NOT eliminate the possibility of lighting

the vapor of any flammable liquids which

may be improperly stored or accidentally

spilled. If the smell of gasoline is present,

DO NOT operate this heater until the area

has been properly ventilated.

WARNING

The heater is designed and approved

for use as a construction heater

under ANS Z83.7 CSA 2.14. It is hard

to anticipate every use which may

be made of this heater. CHECK WITH

YOUR LOCAL FIRE SAFETY AUTHORITY

IF YOU HAVE QUESTIONS ABOUT

APPLICATIONS.

Other standards govern the use of fuel

gases and heat producing products in

Using this heater in a

residential garage

Not for home or recreational vehicle use.

specific applications.

Your local authority can advise you

about these.

IMPORTANT: READ THIS USER’S

MANUAL CAREFULLY AND

COMPLETELY BEFORE TRYING TO

OPERATE OR SERVICE THIS HEATER.

IMPROPER USE OF THIS HEATER CAN

CAUSE SERIOUS INJURY OR DEATH

FROM FIRE, EXPLOSION AND CARBON

MONOXIDE POISONING.

This is a direct-fired forced air

construction heater for either indoor

construction or outdoor use. Its

intended use is primarily the temporary

heating of buildings or structures under

construction, alteration or repair. All

the products of combustion generated

by the heater are forced through the

heater and released into the area

being heated. This heater operates

at approximately 98%+ combustion

efficiency but still produces a small

amount of carbon monoxide. Humans

can tolerate small amounts of carbon

monoxide for short periods. Carbon

monoxide can build up in a heated

space and failure to provide adequate

ventilation could result in poisoning or

death.

CSA 2.14b-2009, ANS Z83.7b-2009.

IMPORTANT SAFETY INFORMATION

• Children should be carefully

supervised, when they are in the area.

• Always maintain proper clearance

from combustible materials. Minimum

clearance from combustibles:

Side - 24” (61cm); Top - 72” (1.8 m);

Front - 96” (2.4 m). Floor - combustible.

Not for use on finished floors.

• Heater must be placed on level and

stable surface.

• Never place anything including clothes

or other flammable items on the heater.

• The appliance area shall be kept clear

and free from combustible materials,

gasoline and other flammable

vapours and liquids.

• Do not modify or operate a heater

which has been modified.

• Adequate clearance for accessibility

and for combustion & ventilation air

supply must be maintained at all

times when the heater is operating.

• Service and repair should be done by

a qualified service person. The heater

should be inspected before each use

and at least annually by a qualified

person. More frequent cleaning may

be required as necessary. Do not service

while hot or operating.

• Never connect heater to an

unregulated gas supply.

• The heater is shipped from the

factory for LP(Propane) gas. This heater

is for use with propane gas only, do

not convert heater to any other gas.

Installation must conform to local

codes or, in the absence of local codes,

with the standard for the Storage and

Handling of Liquefied Petroleum Gases

ANSI/NFPA 58 and the Natural Gas and

Propane Installation Code CSA B149.1

• The minimum and maximum inlet

pressures to the regulator from the

gas tank are 5 psi and bottle pressure,

respectively. Use only the regulator

& hose assembly provided with the

heater. Inspect the regulator/hose

assembly prior to each use of the

heater. If there is excessive abrasion

or wear, or hose is cut, replace with

regulator/hose assembly listed on the

parts list prior to using this heater.

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

2

Dyna-Glo

TM

Delux Operating Instructions and Parts Manual

Models RMC-FA300DGD

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

• Gas supply connections should be

checked using a 50/50 solution of liquid

dish soap and never use a flame to

check for gas leaks.

• The electrical connection & grounding

must comply with National Electrical

Code. ANSI/NFPA 70 or in Canada CSA

C22.1, Canadian Electrical Code, Part 1.

Use only a properly grounded three (3)

prong receptacle.

• Do not restrict inlet or outlet by any

means. The flow of combustion and

ventilation air is not to be obstructed.

• This heater should not be directed

toward any propane-gas container

within 20 ft (6 m). The heater must be

located at least 6 ft. (1.83 m) in the U.S.;

or (ii) 10 ft. (3 m) in Canada, from any

propane gas container.

• The propane cylinder supply system

must be arranged to provide for vapour

withdrawal from the operating cylinder.

• This heater is not to be used with

external thermostats, timers or other

devices that control or alter electrical

supply to the heater.

Ignitor

Clean Heated

Air Out (Front)

Combustion Chamber

PCB Control

Air For Heating Air For Combustion

Figure 2 – Cross Section Operational View

WARNING

during operation and at shutdown, in order

to prevent a flame-out condition which

could result in personal injury or property

damage.

Motor and fan must be

running before lighting,

• Do not adjust regulator below 7 PSIG

or above 10 PSIG

Theory of Operation

FUEL SYSTEM

The hose/regulator assembly runs from

the propane supply to the heater itself.

After the gas runs through the hose

and regulator, it passes through the

solenoid valve and out the nozzle into

the combustion chamber.

AIR SYSTEM

The internal motor turns the fan, which

pushes air around and through the

combustion chamber. Here the air is

heated and provides a constant stream

of warmth.

IGNITION SYSTEM

The spark module sends voltage to the

ignitor. The ignitor ignites the fuel and

air mixture.

Motor

Fan

Cool Air In (Back)

On/Off Switch

Power Cord

Nozzle

Solenoid Valve

Hose / Regulator

Assembly

Spark Module (Spark Ignitor)

SAFETY CONTROL SYSTEM

This system shuts the heater down

if the flame is extinguished. The fan

and motor will continue to operate,

butthere will not be any heat.

PROPANE SUPPLY

All propane gas and tanks are to be

provided by the user.

This heater should only be used with

a tank that has a vapor withdrawal

system. Refer to the Standard of

Storage and Handling of Liquefied

Petroleum Gas, ANSI/NFPA 58, Chapter

5. Your local fire department or library

will have this information.

Two factors will dictate how much

propane is used from each tank:

1. The amount of gas in each tank.

2. The surrounding air temperature at

each tank.

The chart below shows how many tanks

should be used at a given tempera ture.

This heater should not be operated with

a tank smaller than 100 pounds.

As the tempera ture drops, less gas is

Average

Temperature

at Tank Location

°F

40

32

40

20

32

10

20

0

10

-10

0

-20

-10

-20

°C

4.44

0

-6.67

-12.22

-17.78

-23.33

-28.89

Number

of Tanks

3

Use larger tank

Use larger tank

Use larger tank

Use larger tank

Use larger tank

Use larger tank

Use larger tank

vaporized, so a larger tank may be

necessary in very cold weather. Never

operate this heater with a tank smaller

than 100 pounds. Your local propane

dealer can help you select the proper

tank size and configuration.

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

3

supplied with the heater.

ProFitter

TM

& Dyna-GloTMOperating Instructions and Parts Manual

ProFitterTM& Dyna-Glo

TM

RMC-FA300PF/DG/DGD

Dyna-GloTM Delux Operating Instructions and Parts Manual

RMC-FA300DGD

Dyna-Glo

TM

Propane Construction Heater

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

Installation

Installation

warnings in the Safety Information

warnings in the Safety Information

Section on pages 1–3. They are required to

Section on pages 1–3. They are required

operate this heater safely. Follow all local

to operate this heater safely. Follow all

and state codes when operating this

local and state codes when operating

heater.

this heater.

making the proper connections, be sure

making the proper connections, be sure

to check for leaks. Apply a 50/50

to check for leaks. Apply a 50/50

mix ture of dish soap and water to

mixture of dish soap and water to

all connections. Bubbles forming are

all connections. Bubbles forming are

evidence of a leak. Be sure to correct

evidence of a leak. Be sure to correct

all leaks at once!

all leaks at once!

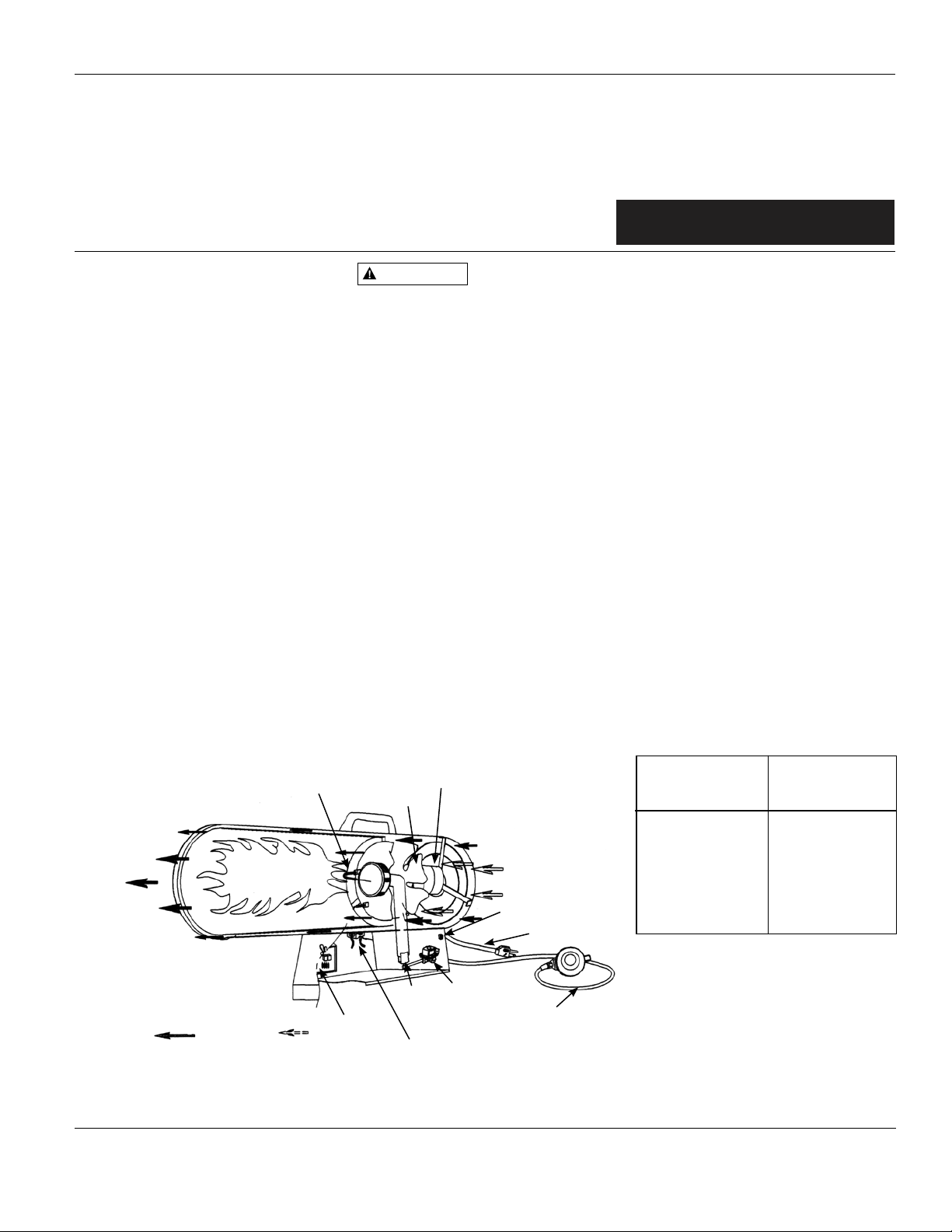

1. Provide propane supply system as

1. Provide propane supply system as

outlined above.

outlined above.

2. Connect POL fitting on hose/regulator

2. Connect POL fitting on hose/regulator

assembly to propane tank(s) by turn ing

assembly to propane tank(s) by turn-

the fitting COUNTER CLOCKWISE

ing the fitting COUNTERCLOCKWISE

into the threads on the valve on top of

into the threads on the valve on top

the tank. Finish by tightening firmly,

of the tank. Finish by tightening

using 7/8” (22.2 mm) wrench.

firmly, using 7/8” wrench.

IMPORTANT: To protect the regulator

IMPORTANT: To protect the regulator

from weather damage, tighten the

from weather damage, tighten the

fitting with the black adjustment knob

fitting with the black adjustment knob

pointing down.

pointing down.

POL Fitting

POL Fitting

Supply

Supply

Valve

Valve

Propane/LP

Propane/LP

Tank

Tank

Figure 3 – Regulator with Vent Pointing

Figure 3 – Regulator with Vent Pointing

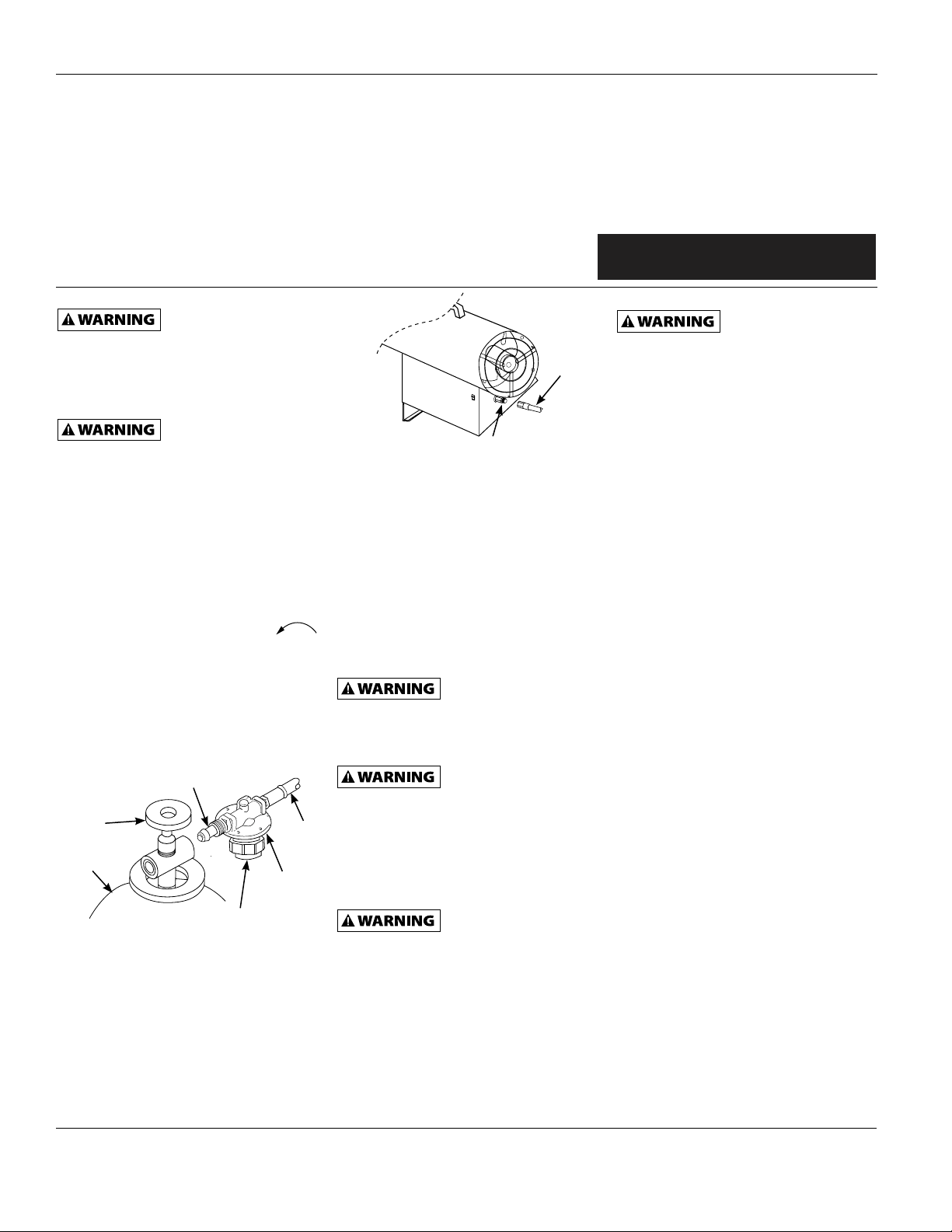

3. Connect female end of hose to the

3. Connect female end of hose to the

inlet connector of the heater, and

inlet connector of the heater, and

tighten firmly with a wrench.

tighten firmly with a wrench.

IMPORTANT: Use extra piping or hose

IMPORTANT: Use extr

if necessary to connect the heater to the

if necessary to connect the heater to the

gas supply, but always use the regulator

gas supply, but always use the regulator

supplied with the heater.

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Down

Down

Review and under-

Review and under-

stand all of the

stand all of the

After installing

After installing

all gas piping, and

all gas piping, and

Regulator

Regulator

Adjustment Knob

Adjustment Knob

(Pointing Down)

(Pointing Down)

a piping or hose

Hose

Hose

Inlet Connector

Inlet Connector

Figure 4 – Hose and Inlet Connector

Figure 4 – Hose and Inlet Connector

4. Open supply valve on propane tank(s)

4. Open supply valve on propane tank(s)

SLOWLY.

SLOWLY.

NOTE: If this valve is not opened slowly,

NOTE: If this valve is not opened slowly,

the excess flow check valve on the tank

the excess flow check valve on the

will interrupt the gas flow. If this

tank will interrupt the gas flow. If this

happens, close the supply valve and

happens, close the supply valve and

reopen slowly.

reopen slowly.

5. Adjust the regulator to between 7

5. Adjust the regulator to between 7

and 10 PSIG.

and 10 PSIG.

PSIG or below 7 PSIG, or the heater may

PSIG or below 7 PSIG, or the heater may

not operate properly.

not operate properly.

6. Check all connections for leaks.

6. Check all connections for leaks.

leaks. Apply a 50/50 solution of liquid

leaks. Apply a 50/50 solution of liquid

dish soap a

dish soap and water to check all

connections. Correct all leaks

connections. Correct all leaks

immediately.

immediately.

7. Close propane supply valve.

7. Close propane supply valv

nd water to check all

Do not adjust the

Do not adjust the

regulator above 10

regulator above 10

Never use an open

Never use an open

flame to check for

flame to check for

e.

Ventilation

Ventilation

ventilation requirements. If these

ventilation requirements. If these

guidelines are not followed, carbon

guidelines are not followed, carbon

monoxide poisoning can occur. Always

monoxide poisoning can occur. Always

provide proper amounts of fresh air

provide proper amounts of fresh air

before operating this heater.

before operating this heater.

Provide at least three square feet of

Provide at least three square feet (0.28 m²)

fresh, outside air for each 100,000

of fresh, outside air for each 100,000 BTU/

BTU/Hr of rating. This heater requires

Hr of rating. This heater requires

a fresh air opening of at least 11.25

a fresh air opening of at least 11.25 square

squ

are feet. Provide extra fresh air if

feet (1.05 m²). Provide extra fresh air if

more heaters are being used.

more heaters are being used.

Always follow the

Always follow the

minimum fresh air

minimum fresh air

Hose

Hose

Operation

Operation

warnings in the Safety Information

warnings in the Safety Information

Section, on pages 1–3. They are required

Section, on pages 1–3. They are required

to operate this heater safely. Follow all

to operate this heater safely. Follow all

local and state codes when operating this

local and state codes when operating

heater.

this heater.

TO START HEATER

TO START HEATER

1. Follow all safety, installation and

1. Follow all safety, installation and

ventilation instructions in this

ventilation instructions in this

manual.

manual.

2. Position the heater on a stable and

2. Position the heater on a stable and

level surface, and be sure that no

level surface, and be sure that no

drafts blow into the inlet or outlet

drafts blow into the inlet or out

of the heater.

of the heater.

3. Plug the power cord of the heater

3. Plug the power cord of the heater

into a three hole grounded extension

into a three hole grounded extension

cord. Be sure that the extension cord

cord. Be sure that the extension cord

is at least 6 feet long, and is UL listed.

is at least 6 feet long, and is UL listed.

EXTENSION CORD SIZE

EXTENSION CORD SIZE

REQUIREMENT

REQUIREMENT

• Up to 50 feet (15.2 m) long, use 18

• Up to 50 feet long, use 18 AWG

AWG rated cord.

rated cord.

• 51 to 100 feet (15.5 - 30.5 m) long,

• 51 to 100 feet long, use 16 AWG

use 16 AWG rated cord.

rated cord.

• 101 to 200 feet (130.8 - 61 m) long,

• 101 to 200 feet long, use 14 AWG

use 14 AWG rated cord.

rated cord.

4. Plug extension cord into a 120 volt/60

4. Plug extension cord into a 120 volt/60

hertz, three hole grounded outlet.

hertz, three hole grounded outlet.

5. Open supply valve on propane tank(s)

5. Open supply valve on propane tank(s)

SLOWLY.

SLOWLY.

NOTE: If this valve is not opened slowly,

NOTE: If this valve is not ope

the excess flow check valve on the

the excess flow check valve on the tank

tank will interrupt the gas flow. If this

will interrupt the gas flow. If this

happens, close the supply valve and

happens, close the supply valve and

reopen slowly.

reopen slowly.

6. Adjust the regulator to between 7

6. Adjust the regulator to between 7

and 10 PSIG.

and 10 PSIG.

NOTE: The higher regulator setting

NOTE: The higher regulator setting

will enable the heater to produce

will enable the heater to produce

more heat.

more heat.

Review and under-

Review and under-

stand all of the

stand all of the

let

ned slowly,

4

Loading...

Loading...