Page 1

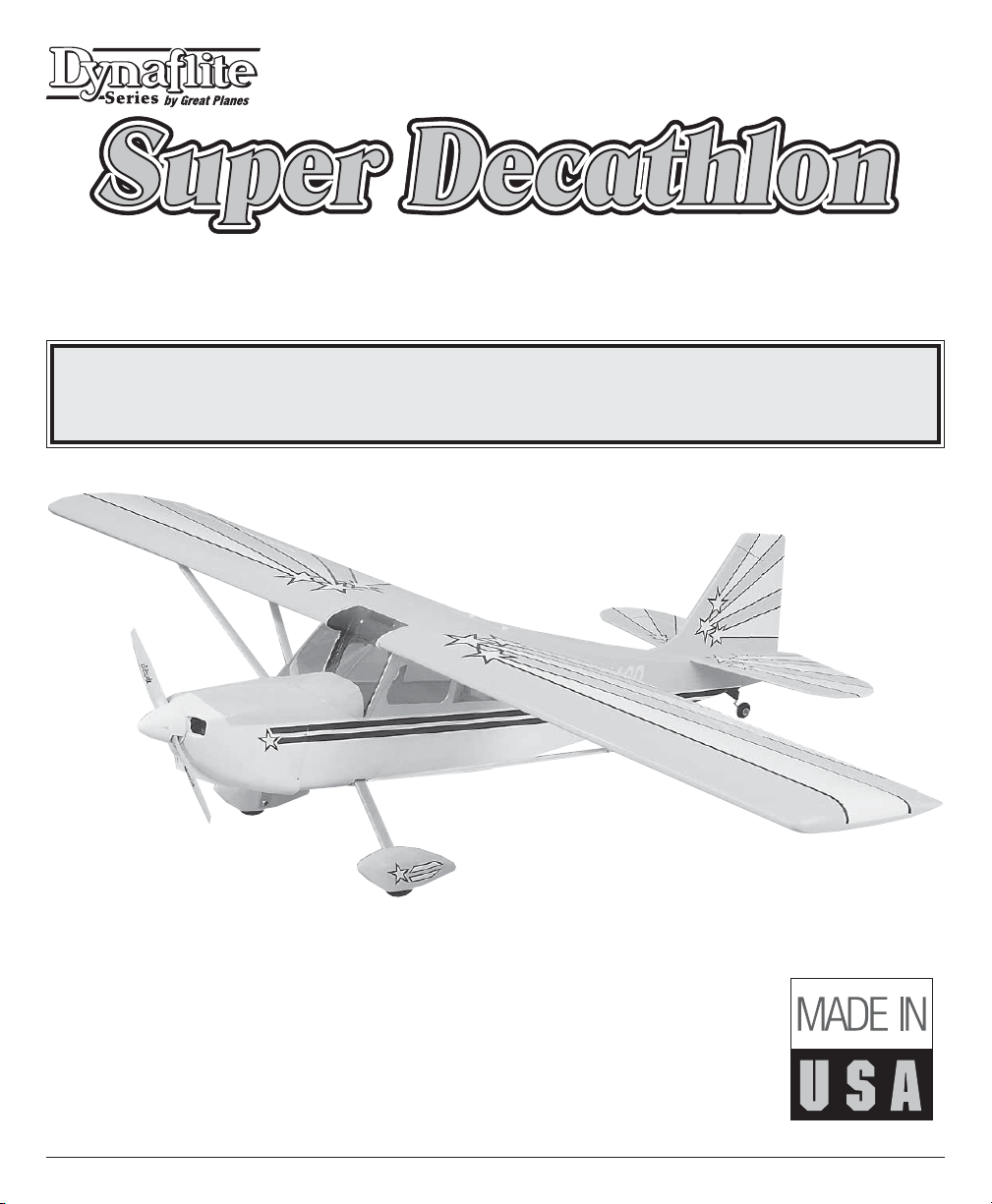

™

•89” IMAA-legal aerobatic trainer

•Selig 8036 semi-symmetrical airfoil for maneuverability & low-speed stability

•Performance excels with a wide range of engines

READ THROUGH THE PRELIMINARY INFORMATION BEFORE YOU START

BUILDING. IT CONTAINS IMPORTANT INSTRUCTIONS, WARNINGS, AND

INFORMATION CONCERNING THE BUILDING AND USE OF THIS MODEL.

Instruction Manual

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts damaged by use or modification.

In no case shall Dynaflite’s liability exceed the original cost of the purchased kit. Further, Dynaflite

reserves the right to change or modify this warranty without notice. In that Dynaflite has no control

over the final assembly or material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the final user-assembled product.

By the act of using the user-assembled product, the user accepts all resulting liability. If the buyer

is not prepared to accept the liability associated with the use of this product, return this kit

immediately in new and unused condition to the place of purchase.

DECGP04 Printed in USA

WARRANTY

1

© 2011 Hobbico®, Inc V:2.0

Page 2

TABLE OF CONTENTS

INTRODUCTION

INTRODUCTION .................................................2

PRECAUTIONS ...................................................3

PREPARATIONS .................................................3

Required accessories ...................................3

Suggested supplies .......................................4

Building notes ...............................................4

Types of wood ..............................................4

Metric conversions ........................................5

DIE PATTERNS ................................................... 5

BUILD THE TAIL SECTION ................................ 6

Build the fin and rudder ................................6

Build the stabilizer ......................................... 7

Build the elevators ........................................7

BUILD THE WING ............................................... 8

Sheet the top of the wing ............................11

Finish the wing ............................................13

Build the ailerons ........................................14

BUILD THE FUSELAGE ...................................15

Assemble the firewall ..................................15

Build the bulkheads and fuselage sides ............18

Assemble the fuselage ...............................19

Mount the wing ...........................................21

Sheet the top of the fuselage ......................23

Finish the bottom of the fuselage ............... 24

Mount the tail ..............................................26

Make and mount the wing struts ................. 28

Finish the windshield and cowl ................... 29

FINAL ASSEMBLY ...........................................30

Install the radio system ...............................30

Set the control throws .................................30

FINISHING ........................................................31

Finishing the struts ...................................... 31

Balance your model .................................... 31

PREFLIGHT ......................................................31

Balance your propellers .............................. 31

Charge your batteries .................................32

AT THE FLYING SITE .......................................32

Ground check your model ........................... 32

Range check your radio ..............................32

SAFETY PRECAUTIONS .................................32

FLIGHT .............................................................. 33

Takeoff ........................................................33

Flying ..........................................................33

Landing .......................................................34

Congratulations on your choice of this kit for your

next project. The Super Decathlon is a Fun Scale

model of a truly classic aerobatic aircraft. It has the

presence that only a big model can deliver. The

full-scale Super Decathlon is a basic aerobatic

aircraft capable of spins, loops, rolls, immelmanns,

split S’s, hammerheads and basic inverted flight.

Super Decathlons have been the choice for basic

aerobatics in the US for the past twenty-five years.

One of the things that made this plane so popular

was the fact that it was one of the easiest landing

taildraggers ever made. The Dynaflite Super

Decathlon has the great landing habits of the fullscale plane, with more aerobatic potential.

The two-piece wing means transporting this 89"

span model can be done in any vehicle which can

hold the manageable 67" fuselage. The big wing

and strong structure of the Dynaflite Super

Decathlon allows for an engine range from the

1.08 2-stroke all the way up to the 2.1 gas engines.

We do recommend flying wires on the tail if you are

using an engine at the larger end of the

recommended range.

At Dynaflite, we take pride in offering kits that are

simple and straightforward to build and provide

value for your modeling dollar. Because of the size

and cost of this model, we assume you have built

several models and have a general working

knowledge of modeling and its terms. If you HAVE

NOT built and flown several kits, we strongly

recommend you back up and get some experience

before beginning this kit.

Your Super Decathlon is not a toy, but a sophisticated

working model that functions like a full-size airplane.

Because of its performance, if you do not assemble

and operate the Super Decathlon correctly, you

could possibly injure yourself or spectators and

damage property. To make your R/C modeling

experience totally enjoyable, we recommend that

you get assistance with assembly and your first

flights from an experienced, knowledgeable

®

2

Page 3

modeler. Your local hobby shop has information

about flying clubs in your area whose membership

includes qualified instructors if needed.

If you are not already a member of the AMA,

please join! The AMA is the governing body of

model aviation and membership provides liability

insurance coverage, protects modelers’ rights and

interests and is required to fly at most R/C sites.

at: (217) 398-8970 or you may email us at

productsupport@dynaflite.com and we'll be

glad to help. If you are calling for replacement

parts, please look up the part numbers and have

them ready when calling.

PREPARATIONS

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can do to

preserve the radio controlled aircraft hobby are to

avoid flying near full-scale aircraft and avoid flying

near or over groups of people.

PRECAUTIONS

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable

model. In a few cases the instructions may differ

slightly from the photos or plan. In those instances,

follow the written instructions.

2. You must take the time to build straight, true

and strong.

3. You must install all R/C and other components

so that the model operates properly on the ground

and in the air.

4. You must test the operation of the model before

the first and each successive flight to insure that all

equipment operates correctly. You must also make

certain that the model has remained structurally

sound.

Please inventory and inspect all parts carefully

before starting to build! If any parts are missing,

broken or defective or if you have any questions

about building or flying this model, please call us

REQUIRED ITEMS

These are the items not included with your kit; you

will need to purchase them separately. Items in

parentheses (GPMQ4131) are suggested part

numbers recognized by distributors and hobby

shops and are listed for your ordering convenience.

GPM is the Great Planes® brand, TOP is the Top

Flite® brand and HCA is the Hobbico® brand.

❏ 4+ Channel radio w/6 servos (5 high torque)

❏ 2 18" Servo extension wires (ailerons)

❏ 2 “Y” Connectors (ailerons, elevators)

❏ Engine: 1.20 - 1.60 4-stroke,

1.08 - 1.8 2-stroke, or 1.5 - 2.1 gas

❏ Engine mount and mounting hardware

❏ 16 - 24 oz. Fuel tank

❏ Standard fuel tubing, glow (GPMQ4131)

❏ Tygon fuel tubing, gas (DUBQ0427)

❏ Gas stopper (DUBQ0675)

❏ 2 3-1/4" Main wheels (GPMQ4226)

❏ 1 1-1/2" Tail wheel (GPMQ4243)

❏ 4 5/32" Wheel collars (GPMQ4306)

❏ 2 1/8" Wheel collars (GPMQ4304)

❏ 2 3/16" Axles (GPMQ4278)

❏ 20 Giant Scale hinges

❏ 4 8-32 x 1" Socket head bolts (GPMQ3048)

❏ 4 8-32 Blind Nuts (GPMQ3328)

❏ Coverite™ Fabric or other covering

(approximately 5 rolls)

❏ Paint for fuelproofing, engine cowl and

windows

❏ 1/4" Latex Foam Rubber (HCAQ1000)

❏ 3" Spinner (GPMQ4530)

❏ 1 or 2 1/4 Scale pilot(s) (optional)

(DGAQ2110)

❏ Decathlon cockpit kit (optional) (DYFQ8115)

33

Page 4

SUGGESTED SUPPLIES

We recommend Great Planes Pro™ CA and Epoxy

❏ 4 oz. Thin CA Adhesive (GPMR5904)

❏ 4 oz. Medium CA+ Adhesive (GPMR5910)

❏ 2 oz. Thick CA- Adhesive (GPMR6015)

❏ Pro CA Applicator Tips (HCAR3780)

❏ Pro CA Accelerator w/pump (HCAR3750)

❏ 6-Minute Epoxy (GPMR6045)

❏ 30-Minute Epoxy (GPMR6047)

❏ 8 oz. Aliphatic Resin Wood Glue

(GPMR6163)

❏ 4 oz. Milled Fiberglass (GPMR6165)

❏ Microballoon Filler (TOPR1090)

J&Z Products RC/56 Canopy Glue (JOZR5007)

❏

❏ Great Planes Plan Protector (GPMR6167)

BUILDING NOTES

• When you see the term “cut and fit” in the

instructions, it means you should first position the

part on the assembly without using any glue.

Slightly modify or shape the part as necessary for

the best fit. Do not glue unless instructed to do so.

• Throughout the assembly of this model, thin CA

should be used unless the step calls for another

type of adhesive. If your parts do not fit well,

substitute medium or thick CA.

• Whenever just “epoxy” is called for, you may use

either 30-minute epoxy or 6-minute epoxy. When

30-minute epoxy is specified, it is highly

recommended that you use only 30-minute epoxy

because you will need either the working time or

the additional strength.

• CA accelerator causes CA glues to react

immediately, but residual accelerator can

prematurely cure CA on nearby joints even

hours later.

• During construction you will be using a number of

balsa sticks to frame various assemblies. Ample

material is included but you should study the

plans, then make an effort to cut the longest

pieces you will need first. Label the pieces for later

reference as you cut them. By doing this now, you

won't have to splice pieces together later.

• Do not throw away any leftover material until after

you have completed your model. Some small

pieces of leftover balsa or plywood are used

during construction.

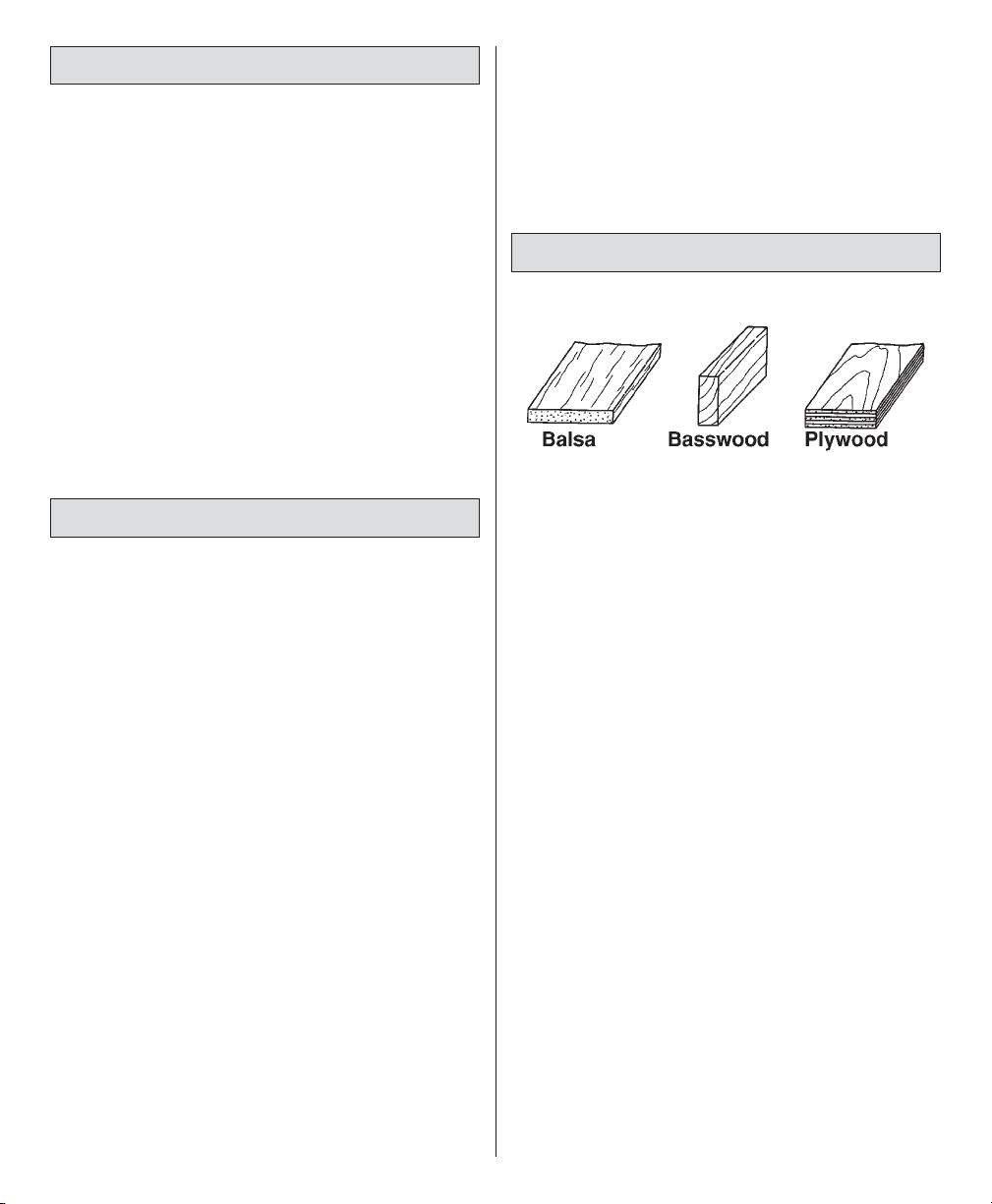

TYPES OF WOOD

4

Page 5

METRIC CONVERSIONS

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

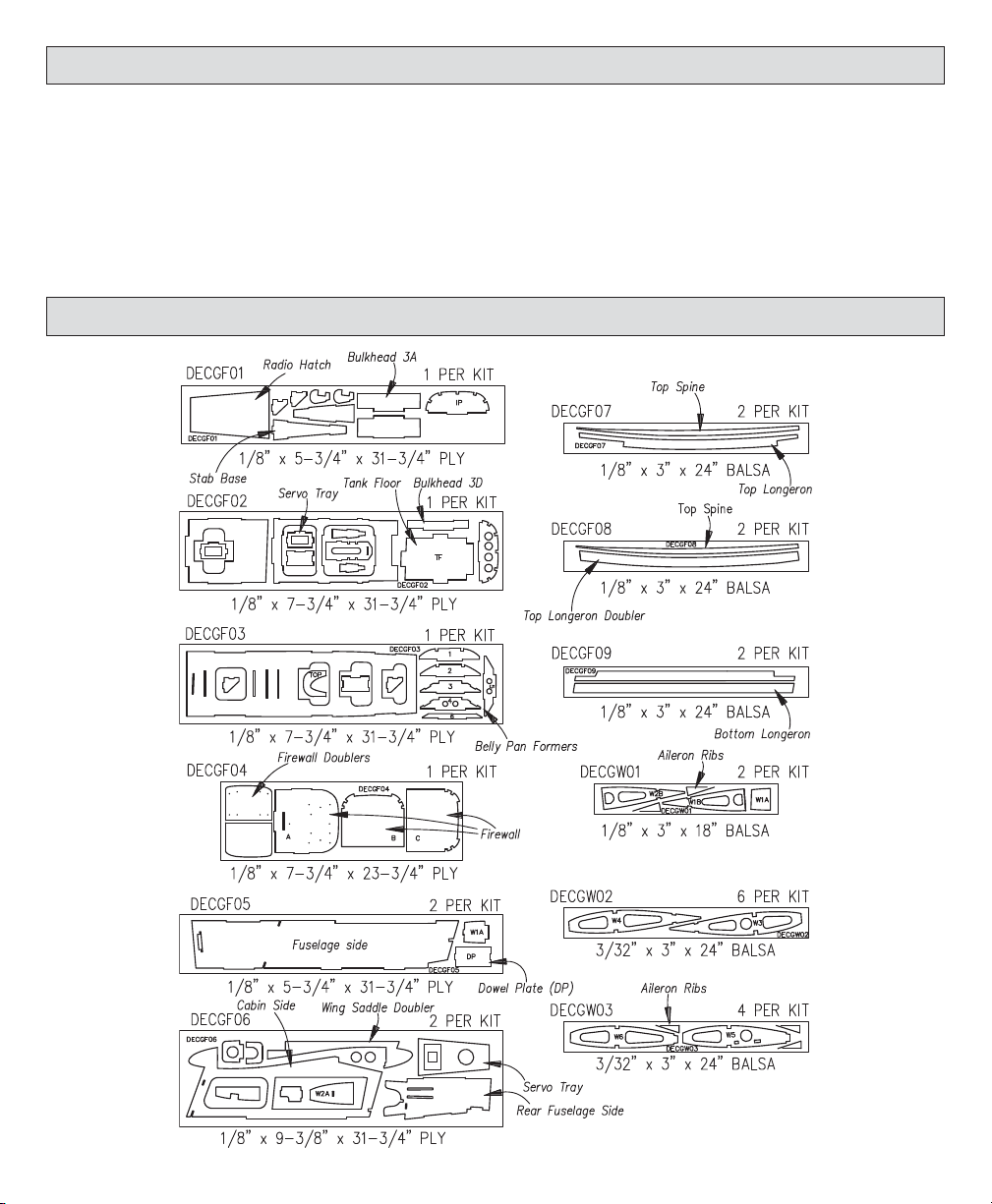

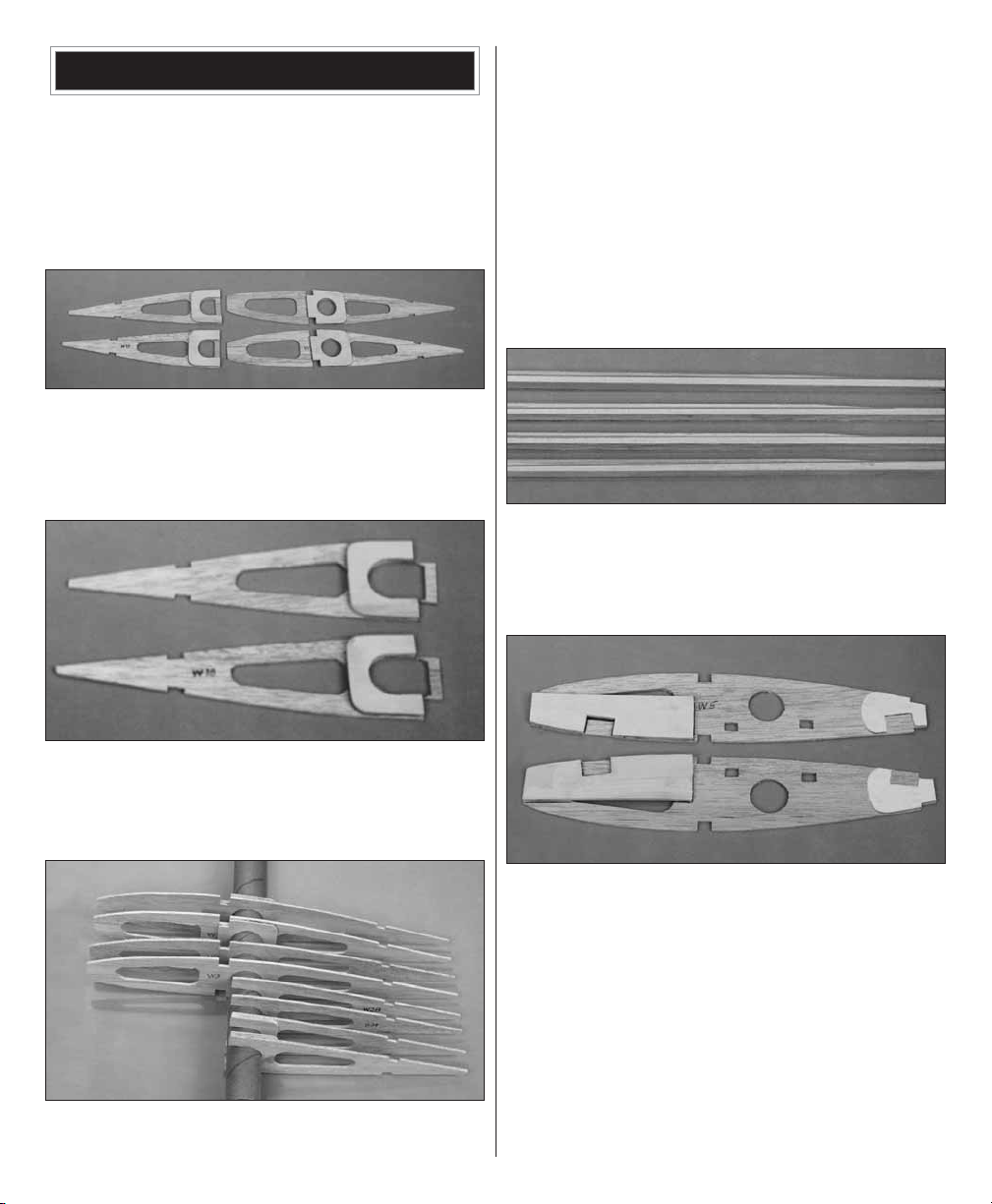

DIE PATTERNS

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

55

Page 6

BUILD THE TAIL SECTION

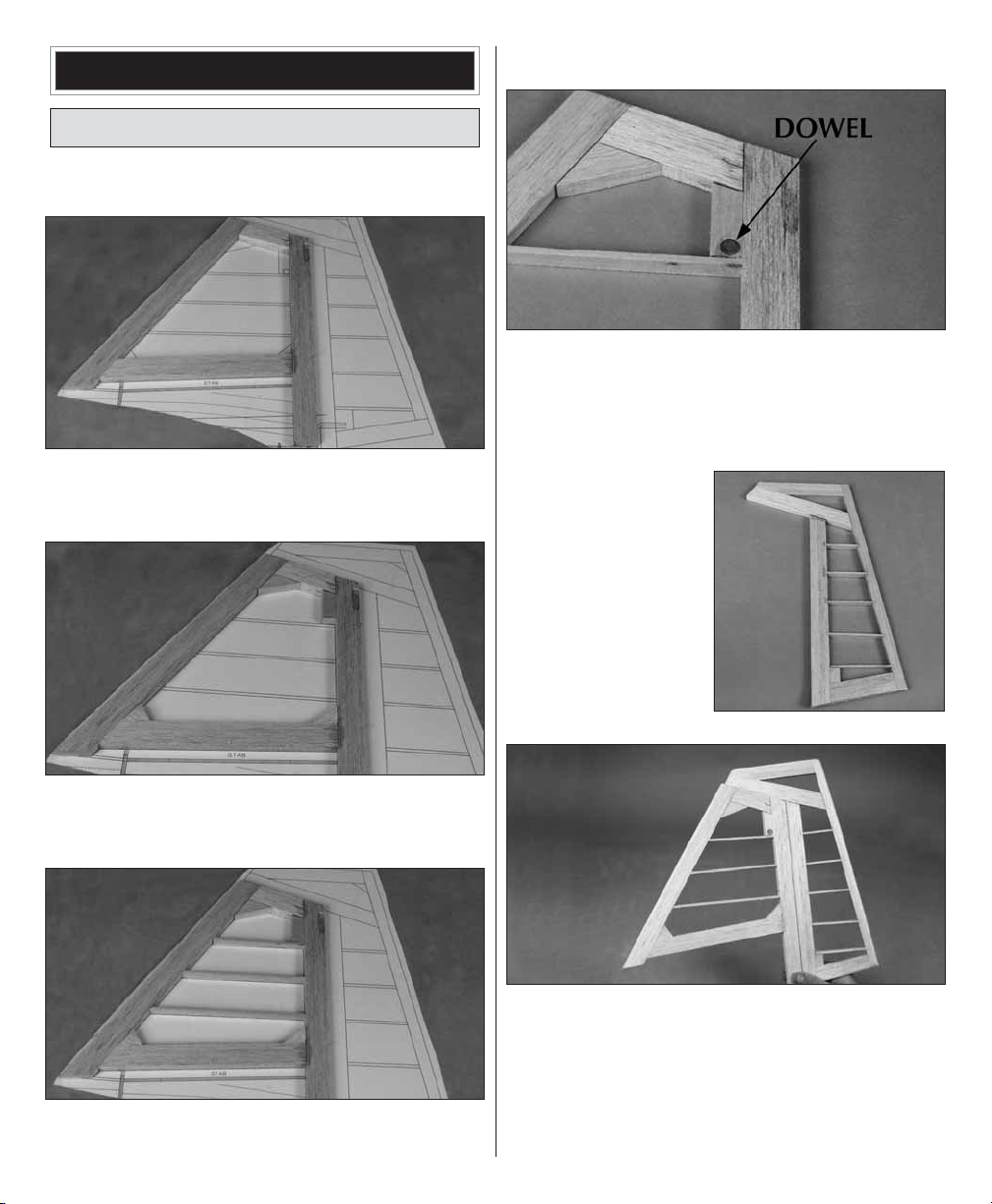

BUILD THE FIN AND RUDDER

❏ 1. Cover the FIN/RUDDER PLAN with Great

Planes Plan Protector or wax paper.

❏ 5. Remove the fin from the building board.

❏ 6. If you will be adding flying wires, drill a 5/16"

hole in the bottom of the upper rear gusset. Cut

3/8" off one of the 5/16" x 6-5/8" dowels. Using thin

CA, glue the 3/8" piece in the hole.

❏ 2. From two 3/8" x 15/16" x 24" balsa sticks, cut,

fit and glue the fin frame as shown in the photo.

Remember to save all leftover pieces.

❏ 3. From a 3/8" x 1/2" x 30" balsa stick, cut, fit and

glue the upper rear gusset. From leftover

15/16" balsa, cut, fit and glue the other 3

3/8" x

gussets.

❏ 7. Using a 3/8" x

15/16" x 24" balsa

stick, the 3/8" x 1/2" x

28-1/2" balsa stick

(leftover from the

upper rear gusset)

and a 1/8" x 3/8" x 30"

balsa stick, build the

rudder. Do not forget

the 3/8" x 1/2" gusset

in the lower corner.

❏ 8. Remove the rudder from the plan. Mark the

centerline the length of the fin trailing edge and the

rudder leading edge. Cut the hinge slots along the

centerlines where shown on the plan.

❏ 4. From the 1/8" x 3/8" x 30" balsa stick, cut, fit

and glue the 3 fin ribs in place.

❏ 9. Using the fuse plan top view as a reference,

sand the leading edge of the rudder to the “V”

6

Page 7

shape shown. Make sure the “V” is large enough to

allow for the specified left and right movement of

the rudder (see “SET THE CONTROL THROWS”,

page 30).

❏ 10. Round the leading edge of the fin and the top

and trailing edge of the rudder. Note: Check the

plans to see the location of the dorsal fin and do

not sand the leading edge of the fin in that area.

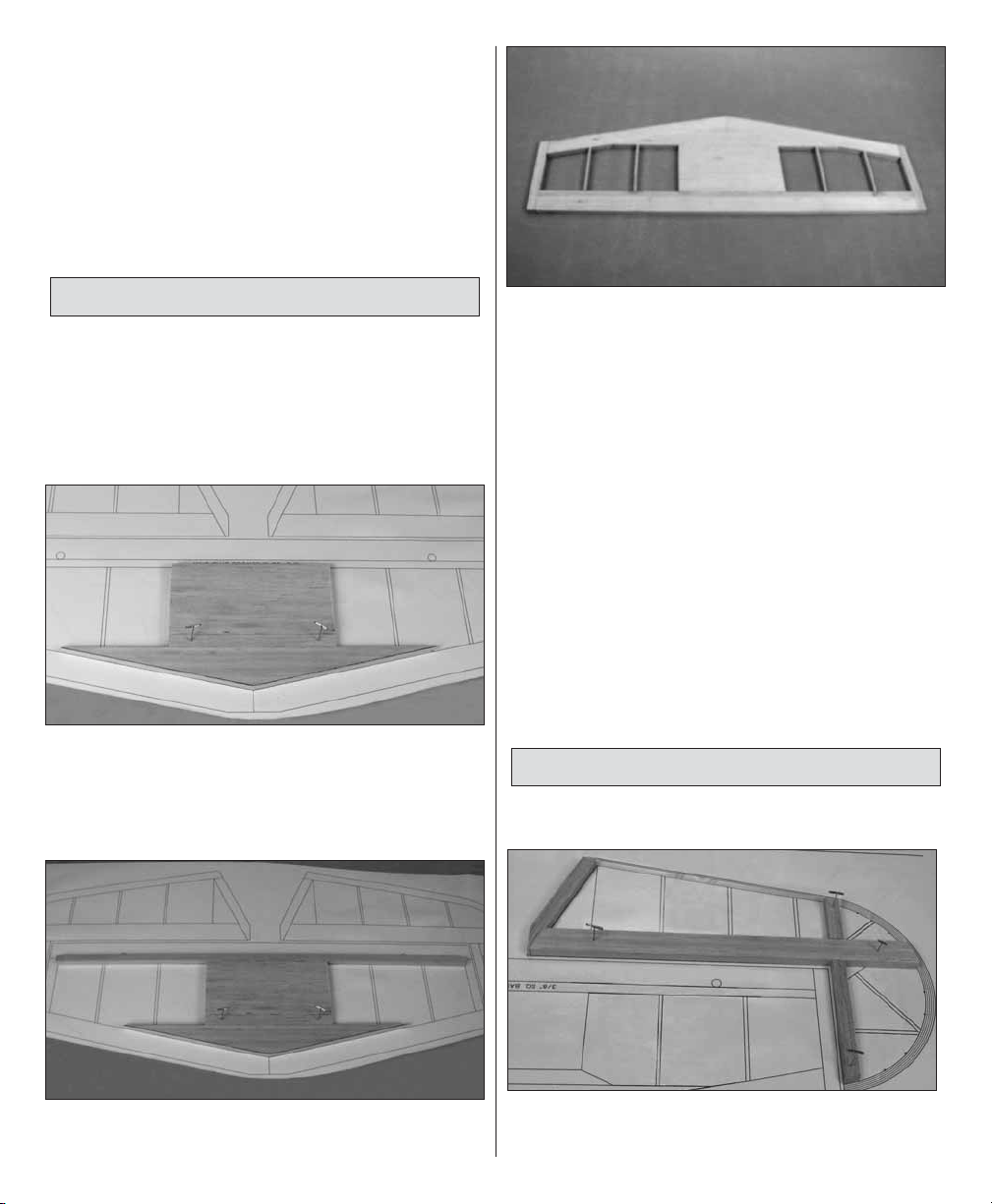

BUILD THE STABILIZER

❏ 1. Place the STABILIZER PLAN on your building

board. Cover the plan with Plan Protector.

❏ 2. From the 3/8" x 3" x 24" balsa sheet, cut a 6"

length, making the stab center. Using more of the

same sheet, make the leading edge joiner.

❏ 3. Cut 6" from a 3/8" x 1/2" x 30" balsa stick. Pin

it in front of the stab center on the plans.

❏ 4. Glue the stab center and stab leading edge

joiner to the 1/2" piece pinned to your plans.

❏ 6. Using two 3/8" x 15/16" x 24" balsa sticks,

fit and glue the leading edge and trailing edge.

❏ 7. From the leftover 3/8" x 1/2" balsa stick (used to

build the fin and rudder), cut, fit and glue the stab

tips.

❏ 8. Using a 1/8" x 3/8" x 30" balsa stick, cut, fit

and glue the other four stab ribs in place. After the

glue has dried, remove the stab from your work

surface.

❏ 9. If you will be installing flying wires, drill two

5/16" holes in the balsa trailing edge in the

locations shown on the plan. Cut two 3/8" long

pieces off the 5/16" dowel. With thin CA, glue the

3/8" pieces in the holes.

cut,

BUILD THE ELEVATORS

❏ 1. Cover the elevator plans with Plan Protector.

❏ 5. From the 3/8" x 3/8" x 22" basswood stick, cut,

fit and glue the stab spar to the stab center.

❏ ❏ 2. From a 3/8" x 15/16" x 24" balsa stick, cut,

fit and pin one elevator leading edge to the plans.

77

Page 8

❏ ❏ 3. From a 3/8" x 1/2" x 30" balsa stick, cut, fit

and glue the 1/2" elevator ribs and corner gusset to

the leading edge. Note: It is important that the

edge of the ribs align accurately with the plans.

❏ ❏ 4. From a 1/8" x 3/8" x 30" balsa stick, cut, fit

and glue the 1/8" elevator ribs to the leading edge.

❏ ❏ 5. From leftover 3/8" x 3" balsa (from the stab

center), cut, fit and glue the control horn mount to

the back of the leading edge and also to the

inboard elevator rib.

trailing

❏ ❏ 8. One at a time, install the remaining four

1/16" x 3/8" x 24" balsa sticks as you did the first,

using medium CA to glue each successive stick to

the one applied before it and pressing it in

until the CA dries. Note: Leave some

on both ends to be trimmed off later.

❏ ❏ 9. Remove the elevator from the plan.

❏ ❏ 10. Trim the laminated sticks off flush with the

elevator ribs.

❏ 11. Repeat steps 2-10, to build the second

elevator.

balsa overhang

position

❏ ❏ 6. Push the six T-pins in place as indicated on

the plans, ensuring that they are vertical and firmly

in place.

❏ ❏ 7. Wet one of the 1/16" faces of a 1/16" x 3/8"

x 24" balsa stick. Glue the stick to the aft end of the

ribs with the wet side facing out. Pull the stick

around the tip, gluing it to the ends of the leading

edge and tip ribs as you go. Note: Pull the stick just

enough to touch the pins, but do not move

them.

❏ 12. Mark the centerline of the trailing edge of the

stab and of the leading edges of the elevators. Cut

the hinge slots along the centerlines as shown on

the plan.

❏ 13. Using the fuse plan side view as a reference,

sand the leading edge of the elevator to the “V”

shape shown. Make sure the “V” is large enough to

allow for the specified up and down movement of

the elevators (see “SET THE CONTROL THROWS”,

page 30).

❏ 14. Sand the stab LE and the outside edges of

the elevators to a rounded shape.

8

Page 9

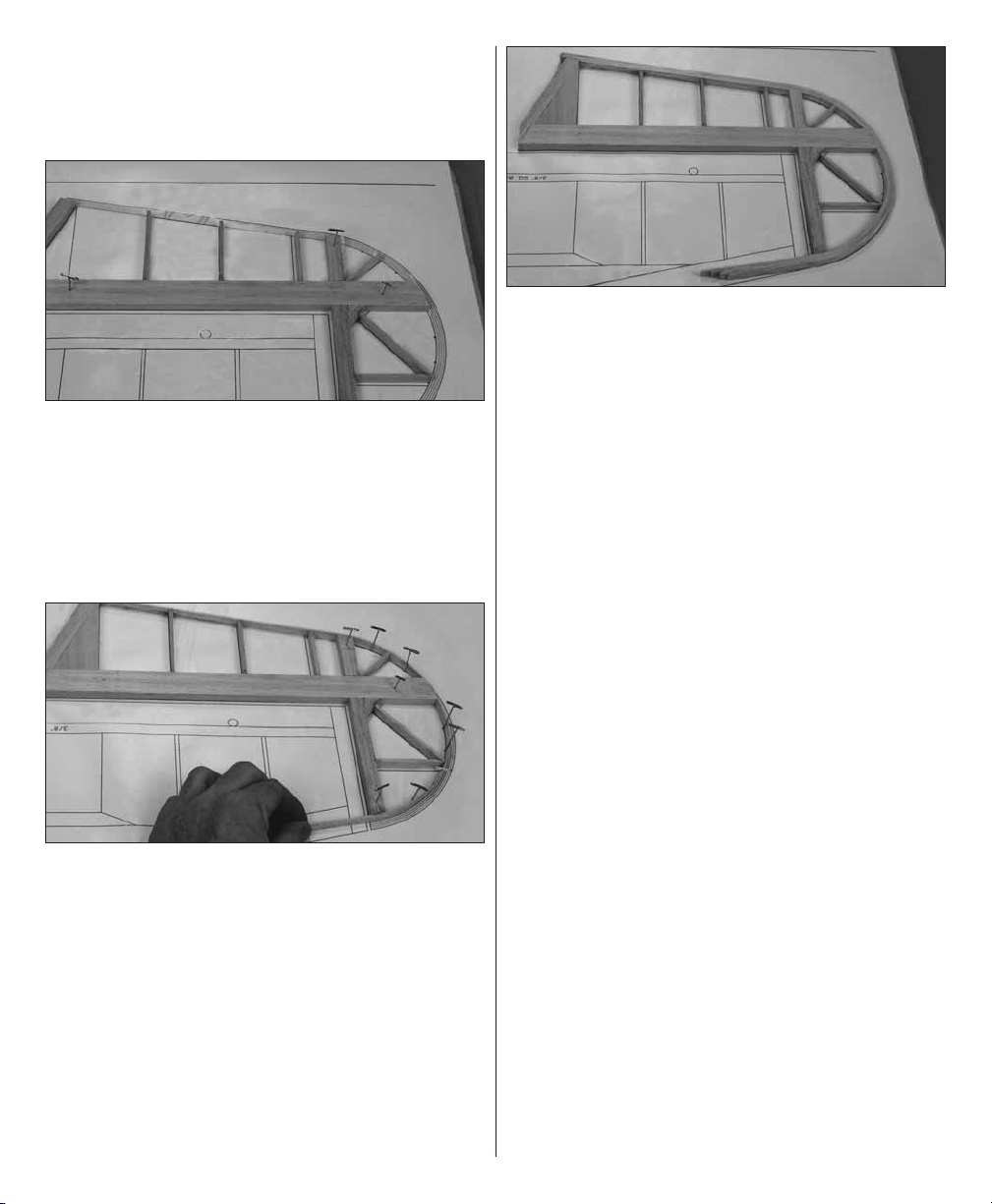

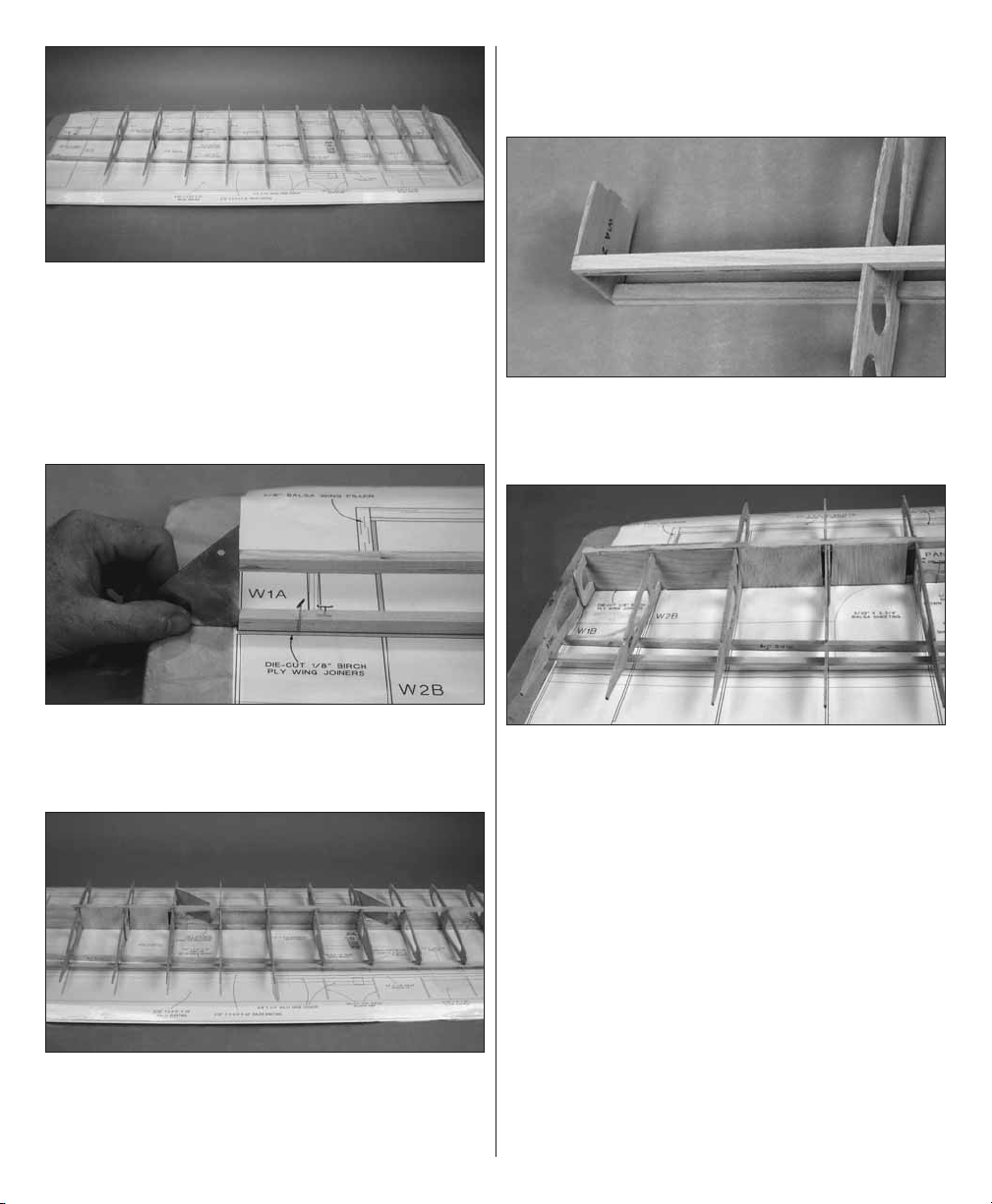

BUILD THE WING

Note: The airfoil used on this plane is semi-

symmetrical. We positioned the embossed labels

on the die-cut 3/32" balsa ribs so that they are

right-side up when the wing is right-side up. This is

the easiest way to reference the top and bottom of

the ribs.

❏ 1. Glue the two die-cut 1/8" ply W1 doublers to

the two W1B ribs. Glue the two die-cut 1/8" ply W3

doublers to two of the W3 ribs as shown. Note:

These parts mirror each other.

W3s (including the two with the doublers) to the

paper wing tube. Use your rotary tool to enlarge

the holes in the ribs as necessary. When satisfied

with the fit, remove the ribs from the tubes and set

the tubes aside.

❏ 5. Cut the two 1/8" x 2-1/8" x 14-5/8" birch ply

sheets in half, making four 1/8" x 2-1/8" x 7-5/16"

shear webs.

❏ 6. Sand a taper on the last two inches of the four

1/8" x 3/8" x 18" basswood spar doublers.

❏ 7. Glue the four spar doublers to the four 1/4" x

3/8" x 42" basswood spars with the non-tapered

end of the doublers aligned with one end of each

spar. These assemblies are now known as spars.

❏ 2. Trim W1B to match the opening in the doubler

as shown in the photo.

❏ 3. Select a W2B rib and trim it to match W1B.

❏ 4. Insert the aluminum wing tube into the paper

wing tube. Fit the two W1Bs, two W2Bs and four

❏ 8. Glue the die-cut 1/8" ply forward and rear strut

braces to two of the W5 ribs as shown.

❏ ❏ 9. Cover your right wing panel with Plan

Protector. Cross-pin the bottom spar in place on

the plan, aligning the inboard end with the centerline

of the wing, with the spar doubler facing up.

❏ ❏ 10. Pin the 1/4" x 3/8" x 42" balsa wing jig to

the plans, with the 1/4" edge against the plans.

Notice how the jig is skewed to provide the required

wing twist (washout).

9

9

Page 10

❏ ❏ 11. Select two of the four W3 ribs you fitted to

the wing tube. Position them in the two W3

locations where the wing tube installs. Glue those

two W3 ribs, one W3 (which was not fitted to the

tube), three W4 and two W6 ribs vertically to the

bottom spar. Glue one W5 with a strut brace and

one W5 without a strut brace in the locations

shown.

❏ ❏ 14. Glue the 1/8" x 3/8" x 42" basswood

bottom aft spar in place, being careful to keep the

ribs straight over the plans.

❏ ❏ 15. Glue the die-cut 1/8" ply W1A in place at

the root of the wing with the spars firmly set in the

notches.

❏ ❏ 12. Using a square to make sure the top spar

aligns with the bottom spar, fit and glue the top

spar in place.

❏ ❏ 13. Using the 3/32" x 4" x 24" balsa, cut, fit and

glue the shear webs in place. Note: You will install

the remaining balsa shear webs in the bays that

have pins in them after the wing is turned over.

❏ ❏ 16. Remove the T-pins at the root of the spar.

Using 6-minute epoxy, fit and glue the ply shear

webs (you cut earlier) in place.

❏ ❏ 17. Glue W1B and W2B in place over the

plans.

❏ ❏ 18. Glue the top 1/8" x 3/8" x 42" basswood aft

spar in place.

10

Page 11

❏ ❏ 19. Cut the paper wing tube in half. Insert the

aluminum tube inside the paper tube. Using medium

CA, glue the paper tube to the four ribs and the ply

shear web, aligning the end with the root rib.

Remove the aluminum tube from the paper tube.

❏ ❏ 20. Fit and glue the die-cut 1/8" ply tube plug

in the outboard end of the paper tube.

❏ ❏ 21. Glue the die-cut 1/8" ply W2A rib in place.

❏ ❏ 24. Using a razor plane and/or sanding bar,

shape the top of the sub leading edge to the

contour of the ribs. Trim the sub leading edge flush

with the wing tip rib and the root rib.

❏ ❏ 25. From a 1/4" x 1" x 24" balsa stick, fit and

glue the trailing edge in place in the aileron bay.

Sand the top to the shape of the ribs.

❏ ❏ 26. From a 3/8" x 3/4" x 24" balsa stick, cut

and glue the four hinge doublers in place.

❏ ❏ 22. Glue the die-cut 1/8" ply dowel plate (DP)

in place.

❏ ❏ 23. Glue the 1/8" x 1" x 42" balsa sub leading

edge to the ribs, centering it vertically on the front

of the ribs.

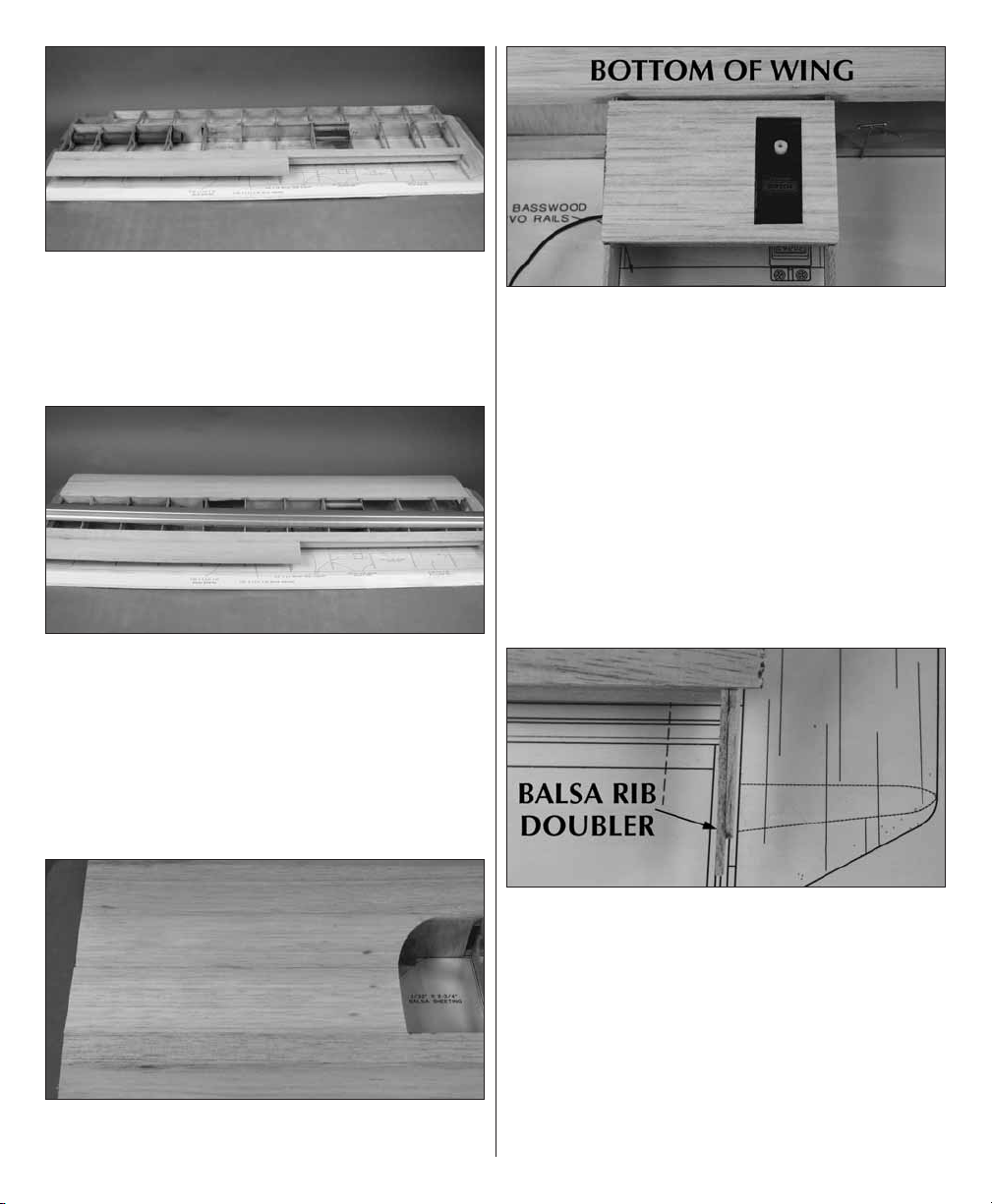

SHEET THE WING

❏ ❏ ❏ ❏ 1. Cut a 1" x 42" strip from a 3/32" x 3" x

42" balsa sheet.

❏ ❏ ❏ ❏ 2. Edge glue the 1" strip to a 3/32" x 3" x

24" balsa sheet as shown in the photo.

11

11

Page 12

❏ ❏ ❏ ❏ 3. Using a square to properly align the

sheeting with the trailing edge of the wing as

shown on the plans, position the sheeting and glue

it in place. DO NOT align with the trailing

the ribs. (See the cross section of the

❏ ❏ ❏ ❏ 4. Edge glue the 3/32" x 3" x 42" balsa

sheet to the 3/32" x 2" x 42" balsa sheet (leftover

from the trailing edge sheet), making the leading

edge sheeting. Align the trailing edge with the

center of the spar and glue the sheeting in place.

Note: Be sure to hold the ribs down on the jig and

hold the spar against your flat work surface to

create the correct washout in your wing.

edge of

plans.)

❏ ❏ 6. If this is your second or fourth time

this section, complete the following

❏ ❏ 6a) Cut the 1/4" x 3/8" x 8" basswood stick in

half, making two 4" long aileron servo rails.

Glue one servo rail in the forward square

holes in the W5 ribs.

❏ ❏ 6b) Slip the rear 4" servo rail in place. Fit your

servo on the rails, sliding the aft rail forward

until the spacing between the rails is correct

for the servo. Glue the aft rail in place.

❏ ❏ 6c) Using leftover center sheeting, sheet

the servo bay. Cut an opening for the servo.

steps:

through

over

❏ ❏ ❏ ❏ 5. Use a piece of 3/32" x 3" x 30" balsa

to sheet the center section of the wing.

❏ ❏ 7. If this is your first or third time through this

section, glue the die-cut 3/32" balsa rib doubler to

the inboard edge of the tip rib.

❏ ❏ ❏ ❏ 8. Using 3/32" x 1/4" x 24" balsa stick, cut

and glue cap strips to all of the exposed ribs,

including the trailing edge of the tip rib and its

doubler.

❏ ❏ ❏ ❏ 9. Trim the sheeting flush with the root rib,

tip rib, sub leading edge and the aileron bay.

12

Page 13

❏ ❏ 10. Lift the wing off your work surface. If this is

your second time through this section, go back to

the start of “BUILD THE WING” and build the other

wing half. If this is your fourth time through this

section, go to “FINISH THE WING”.

❏ ❏ 11. Flip your wing over, aligning the spar over

the spar on the plans. Notice how you did not have

to move your wing jig -- it still sets the washout for

your wing.

❏ ❏ 12. From the 1" x 3" x 7-7/8" balsa block, cut

and fit the filler block between ribs W1 and W2.

Sand the block to the shape of the ribs. When

satisfied with the fit, glue it in place.

❏ ❏ 13. Glue two 1/2" x 3/4" x 3/4" basswood strut

blocks into the forward and rear strut braces and to

W5.

❏ ❏ 15. Sand the trailing edge sheeting as

in the cross section on the plans and in the photo.

❏ ❏ 16. Glue the remaining balsa shear webs in

place, as shown on the plans.

❏ ❏ 17. Sand the 1/8" sub leading edge and the

1/4" trailing edge to match the contour of the ribs.

❏ ❏ 18. Trim the leading edge sheeting flush with

the sub leading edge, W2A, DP, W1A and the tip

rib.

❏ ❏ 19. Sand the sheeting flush with the root rib.

❏ ❏ 20. Glue the die-cut 3/32" balsa W4 rib doubler

in place at the root end of the aileron bay, then trim

the sheeting flush with the outside of the doubler.

❏ ❏ 21. Go back to step one of “SHEET THE

WING” and sheet the bottom of this wing panel.

shown

FINISH THE WING

❏ ❏ 14. Using a piece of leftover 3/32" balsa, fit

glue a cap onto the bottom of the rear strut block.

and

❏ ❏ 1. Glue the 1/2" x 1-3/8" x 42" balsa leading

edge to the front of the wing.

13

13

Page 14

❏ ❏ 2. Using the plans and the leading edge

gauge as a reference, razor plane and sand the

leading edge to shape.

❏ ❏ 3. Hold the 2-1/2" x 2-3/4" x 14-7/8" balsa wing

tip onto the wing tip rib and trace the tip rib onto the

wing tip with a pen. Cut the block on the line you

drew.

BUILD THE AILERONS

❏ ❏ 1. From two 3/32" x 3" x 42" balsa sheets, cut

two aileron sheets 18-9/16" long. Pin one in place

over the aileron section on the plan.

❏ ❏ 2. From a 3/8" x 7/8" x 24" balsa stick, fit and

glue the aileron leading edge to the sheeting.

❏ ❏ 4. Glue the wing tip in place on the tip rib.

Using the plans as a reference, razor plane and

sand the tip to shape.

❏ ❏ 5. Cut a 1/2" servo lead hole in the bottom

sheeting near the root rib of the wing.

❏ 6. Go back to step 9 on page 9 and build the other

wing half.

❏ ❏ 3. Position the two end ribs flush with the inboard

and outboard ends of the aileron sheeting. Glue in

place to the sheeting and to the aileron leading edge.

Glue the remaining four aileron ribs in place, using

the location of the main ribs as a guide.

❏ ❏ 4. From a 3/8" x 3/4" x 24" balsa stick, fit and

glue the four hinge doublers and the one control

horn support.

14

Page 15

❏ ❏ 5. Shape the leading edge, hinge doublers and

the control horn support to the shape of the ribs.

❏ ❏ 6. Sand the trailing edge of the sheeting to the

same angle as the top of the ribs.

❏ ❏ 7. Glue the other 3/32" x 3" x 18-9/16" balsa

aileron sheet in place. Note: Align the trailing edge

of the sheeting as shown in the photo.

BUILD THE FUSELAGE

ASSEMBLE THE FIREWALL

We tested our prototype Super Decathlons with an

®

O.S.

1.20 4-stroke and with a 25cc US Engine™.

From this point forward when we refer to a glow

installation, we are referring specifically to the

steps we took to install the O.S. 1.20 4-stroke.

Similarly, when we refer to gas installation, we are

referring specifically to the steps we took to install

the US 25. If you are installing a gas or glow

engine other than those listed above, you may

need to modify these steps somewhat to

accommodate your particular engine.

Note: The pieces used to assemble the engine

mount for the gasoline engines are also utilized as

engine mount spacers to position the glow engine

sufficiently forward from the firewall. For clarity, we

will refer to this assembly as “engine mount spacer”

in the glow sections; however, please note that it is

the same piece as the gasoline engine mount.

❏ ❏ 8. Position and trace around the die-cut 1/8"

ply control horn mount on the bottom of the aileron.

Remove the control horn mount. Cut and remove

the 3/32" sheeting from the area you traced. Glue

the control horn mount in place and sand it flush

with the aileron sheeting.

❏ ❏ 9. Sand the leading edge to a V-shape, using

the cross section at W5 on the plans as a guide.

❏ 10. Repeat steps 1-9 for the other aileron.

GLOW ENGINE INSTALLATION

The following 13 steps are for glow installation.

Skip these steps if you are using a gas engine.

❏ 1. Select the three die-cut 1/8" ply firewall pieces

A, B and C. With the embossed labels toward the

desk top, laminate B onto A then C onto B, all with

6-minute epoxy. This assembly is now known as

the firewall.

15

15

Page 16

❏ 2. Turn over the firewall and draw two straight

lines from the outer punch marks. Note: These

lines are used for locating the engine on the

❏ 3. Drill four 7/32" holes at the punch marks.

firewall.

❏ 8. Loosely mount the Great Planes 60 - 120

engine mount to the engine mount

with four 8-32 x 1-1/4" socket head cap screws and

#8 washers. Slide the mount halves to the widest

position, then tighten the mount to the firewall.

❏ 9. Position the engine on the engine mount so

that the spinner backplate is 6-7/8" from the

firewall. Note: Do not confuse the engine mount

spacer with the firewall.

❏ 10. Mount the engine to the mount with 8-32 x

3/4" socket head cap screws, confirming the 6-7/8"

measurement from the firewall to the spinner

backplate.

spacer/firewall

❏ 4. Laminate the two die-cut 1/8" ply engine

mounts, creating the engine mount spacer.

❏ 5. Glue the engine mount spacer to the firewall,

centering it on the lines you made on the firewall.

❏ 6. Drill four 7/32" holes through the engine

spacer, using the holes in the firewall as a guide.

❏ 7. Using a hammer, gently tap the 8-32 blind

nuts into the back of the firewall. Glue the blind

nuts in the firewall with thin CA.

mount

❏ 11. Make a mark on the firewall for the throttle

pushrod. Also make marks for the fuel line holes.

❏ 12. Remove the engine mount from the firewall.

Drill 1/4" fuel line holes and a 3/16" hole for the

throttle pushrod.

❏ 13. Go to the “ASSEMBLE THE FUSELAGE”

section.

16

Page 17

GAS ENGINE INSTALLATION

The following steps are for a gas engine

Skip these 10 steps if you are using a glow

❏ 1. Select the three die-cut 1/8" ply firewall pieces

A, B and C. With the embossed labels toward the

desk top, laminate B onto A then C onto B, all with

6-minute epoxy. This assembly is now known as

the firewall.

❏ 2. Laminate the two die-cut 1/8" ply engine

installation.

engine.

mounts.

❏ 4. Using a hammer, gently tap four 1/4-20 blind

nuts into the back of the firewall. Glue in place with

thin CA.

❏ 5. Using four 1/4-20 x 3/4" bolts, attach the

engine mount to the engine. Note: Make sure the

embossed letters are facing the engine when the

engine is bolted to the engine mount.

❏ 3. Drill eight 1/4" holes in the laminated engine

mount at the punch marks. Drill four 9/32" holes in

the firewall at the outermost punch marks as

shown in the photo.

❏ 6. Using four 1/4-20 x 1" bolts and washers,

attach the engine mount (with engine preto the firewall. Note: Tighten the bolts just enough

so that the bolts going into the back of the engine

imprint the firewall.

17

17

installed)

Page 18

BUILD THE BULKHEADS

AND THE FUSELAGE SIDES

❏ 7. Remove the engine and mount from the

firewall. Using your rotary tool, make clearance

holes in the firewall for the engine mounting bolts

and washers.

❏ 8. Re-attach the engine and mount to the

firewall.

❏ 9. Make a mark on the engine mount for the

pushrod. Also make marks for the fuel line holes.

throttle

❏ 1. Place the FUSELAGE PLAN on your

and cover the bulkheads with Plan Protector.

Note: For clarity, our photos show the fuse

components off of the plan, but you should build

over the plans.

❏ 2. Using 1/4" x 1/2" x 30" and 1/4" x 1/4" x 30"

balsa sticks, build the bulkheads 4, 5 and 6. Note:

Use the ends of two different 1/4" x 1/4" x 30"

sticks for the cross-trussing. Save the leftover long

sections of 1/4" x 1/4" stick for the fuse sides.

❏ 3. Notch the outer framework of bulkhead 4 to

allow clearance for the side windows, using the

plans and the plastic windows as a guide.

workbench

❏ 10. Remove the engine mount from the firewall

and the engine mount from the engine. Drill 1/4"

holes for the fuel lines and a 3/16" hole for the

throttle pushrod.

❏ 4. Glue the die-cut 1/8" ply cabin side to the diecut 1/8" ply forward fuse side. Repeat this step to

make the other fuse side.

❏ 5. After covering the fuse plan with Plan

Protector, pin one fuse side in place on the plans.

This is now your right fuse side. Lightly write the

word “right” on the fuse side for easy reference.

18

Page 19

❏ 6. Glue the die-cut 1/8" balsa top longeron and

die-cut 1/8" balsa bottom longeron to the fuse

❏ 7. Glue the die-cut 1/8" ply rear fuse side to the

top and bottom longerons.

❏ 8. Remove the pins from the fuse side and cover

the fuse side with Plan Protector.

sides.

❏ 10. Lift the left fuse side off the right side and lay

it down mirrored to the right fuse side. Write “left”

on the inside for clarity. Remove both fuse sides

from your work surface. Sand the glue joints

smooth on both sides of each fuse side.

❏ 11.Glue the die-cut 1/8" ply wing saddle doubler

and the two die-cut 1/8" balsa longeron doublers to

the inside of both fuse sides. Note: Make sure you

built a left and a right fuse side.

❏ 12. From the two leftover 1/4" x 1/4" balsa sticks

(from making the bulkheads) and two 1/4" x 1/4" x

30" balsa sticks, fit and glue the side stringers in

place.

❏ 9. Align the second fuse side over the first and

pin it in place. Glue the longerons and the rear

side in place, making the other fuse side

These assemblies are now known as fuse sides.

Note: It is very important that the fuse sides be the

same. Take your time aligning these pieces so that

the second fuse side matches the first.

fuse

assembly.

19

19

Page 20

ASSEMBLE THE FUSELAGE

❏ 1. Pin the die-cut 1/8" ply fuse bottom in place

on the top view plans. Note: Make sure the slot in

the front of the fuse bottom matches the plan. This

slot helps set the right thrust.

❏ 2. Fit the fuse sides, bulkhead 3A and bulkhead

4 in place. Use a square to check that the fuse

are perpendicular to your work surface at 3A. Glue

3A to the fuse sides and fuse bottom. Note: The

top of bulkhead 3A has a slight taper towards the

inside, so there should be a slight gap between

your square and the fuse side at the top.

❏ 3. Glue bulkhead 4 to the sides and bottom,

again making sure the fuse sides are perpendicular

to your work bench.

sides

❏ 7. Laminate the two die-cut 1/8" ply tail gear

❏ 8. Fit bulkhead 7, the tail gear mounts, the aft

fuse bottom and the stab base to the fuse. Using

your square, check that the fuse sides are

perpendicular to your work surface and glue

bulkhead 7 to the fuse sides.

❏ 9. Glue the aft fuse bottom to the fuse sides.

❏ 10. Epoxy the tail gear mounts and the stab

base to the fuse sides.

❏ 11. Laminate the two die-cut 1/8" ply servo

mounts.

mounts.

❏ 4. Epoxy the firewall in place, again using your

square to make sure the fuse sides are perpendicular

to your work surface.

❏ 5. Glue the fuse bottom to the fuse sides.

❏ 6. Unpin the fuse bottom from your work

surface.

❏ 12. Using the plans to determine positioning and

the servo tray to gain the proper spacing, fit and

glue bulkheads 5 and 6. Note: The bulkheads

extend past the fuse top and bottom at this stage.

20

Page 21

❏ 13. Sand bulkheads 4, 5 and 6 flush with the top

of the fuse.

❏ 14. Turn the fuse upside-down. Glue the servo

tray to bulkheads 5 and 6.

❏ 15. Sand bulkheads 5 and 6 flush with the

bottom of the fuse.

❏ 16. Fit the servo hatch in place, trimming as

necessary. Note: The hatch is made oversize to

allow for any deviations in building.

❏ 17. Mount the hatch to the fuse with four #2 x

3/8" flat head screws.

❏ 19. Turn the fuse right-side up. Laminate the diecut 1/8" ply bulkheads 3B and 3C with medium CA,

aligning the bottom corners.

❏ 20. Glue the die-cut 1/8" ply 3D bulkhead

support in place.

❏ 18. Using 3/32" x 3" x 30" balsa, sheet the

bottom of the fuse with the grain running across

the fuse bottom, NOT along the length of the fuse.

Note: Be careful not to glue the hatch to the fuse.

Save the leftover sheeting for the front deck.

❏ 21. Epoxy the laminated 3B and 3C in place.

21

21

Page 22

❏ 22. Fit and epoxy the 1/4" x 1-3/4" x 5-3/4" ply

wing bolt plate.

bulkheads, then the first front ply shear web. DO

NOT drill through the second shear web.

❏ 3. From the 5/16" dowel, cut two 3" pieces. Fit

the 5/16" dowel through the hole you drilled.

❏ 4. Drill the second hole the same as the first,

making sure the wing halves are still tight against

each other.

❏ 23. From a 1" x 1-3/4" x 6" balsa block, shape and

glue the filler block to the top of the wing bolt plate.

MOUNT THE WING

❏ 1. Slide the wing halves together on the aluminum

tube and center the wing on the fuse. Note: Be sure

the wing halves are slid all the way onto the tube.

❏ 2. Using a 5/16" drill bit, drill one hole through

bulkheads 3A, 3B, 3C, the dowel plates and the

front ply shear web. Note: Only drill through the

❏ 5. Remove the wings from the fuse and the

tube. Round one end of each 5/16" x 3"

a wing dowel in place in each wing half, with 1/2”

of the rounded end protruding. Allow the epoxy to

cure completely before continuing.

❏ 6. Cut the 1/16" x 2" x 7" birch ply sheet in half,

making two 3-1/2" wing bolt plates. Glue one wing

bolt plate to each wing half as shown.

22

dowel. Epoxy

wing

Page 23

❏ 7. On each of the wing bolt plates make a mark

from the trailing edge and 2" from the root of the

❏ 8. Put the wing halves back on the wing tube and

the wing back on the fuse. Align the wing squarely

on the fuselage. This is easily done using a piece

of string as a guide. Put a pin in the tail of the

fuselage at the centerline. Tie a loop in the end of

the string and place it over the pin. Move the other

end of the string to one wing tip and put some

masking tape around the string. Draw an arrow on

the tape where it reaches the wing tip. Now swing

the string over to the other wing tip. If the tip aligns

with the arrow, the wing is properly aligned. If not,

adjust the wing’s position and try again. Continue

to adjust the wing until both wing tips are aligned

with the arrow on the tape. Secure the wing in its

squared position.

1"

wing.

❏ 9. Drill two 13/64" tap holes at the marks you

on the wing bolt plates through the wing bolt plate.

❏ 10. Remove the wing from the fuselage. Tap

threads into the holes in the ply plates in the fuse

with a 1/4-20 tap. Apply thin CA to the tapped

threads to harden them. Re-tap the threads after

the CA has hardened. Hint: Your drill, triggered at

a slow speed, works well as a tap driver.

❏ 11. Enlarge the holes in the wings to 1/4".

made

23

23

Page 24

SHEET THE TOP

LINE UP WITH THE WING

❏ 3. Glue the tank floor, with the tank attached, in

place in the fuse.

❏ 4. Attach the fuel lines to your tank and route

them through the firewall. Note: You may have go

up through the front deck plate with the carburetor

line. If so, run the line now, then cut the deck plate

as needed during its installation to allow for the

fuel line.

❏ 1. Mount the wing to the fuse. Using 3/32" x 3" x

30" balsa sheeting, sheet the top of the fuse with

the grain running ACROSS the fuse, not lengthwise.

Note: Do not glue the wing to the fuse. Save the

leftover sheeting for the front deck.

❏ 2. Assemble the fuel tank. Mount the tank to the

die-cut 1/8" ply tank floor with foam and rubber

bands. Note: The front of the tank floor has the

right thrust in it to match the firewall, so make sure

to mount the tank on the correct side of the tray.

❏ 5. Glue the die-cut 1/8" ply front deck plate in

❏ 6. Glue the die-cut 1/8" ply bulkhead 2 and the

die-cut 1/8" ply instrument panel (IP)

to the front deck plate.

24

perpendicular

place.

Page 25

❏ 7. Using two 1/4" x 1/4" x 30" balsa sticks, fit and

glue the seven front deck stringers in place.

❏ 8. Using the two leftover pieces of 3/32" x 3"

balsa (from the rear top and bottom of the fuse),

sheet the front deck. Note: You may need to wet

the outside of the sheeting with an

mix to bend it without cracking.

ammonia/water

❏ 2. From a 1/4" x 1/4" x 30" balsa stick, cut and

glue the four belly pan stringers in place.

❏ 3. Sand the side stringers to the shape of the

sub-formers.

❏ 4. From each of three 1/8" x 3" x 24" balsa sheets,

cut a 6-1/4" long piece. Edge glue the three 6-1/4"

pieces together, making one 9" x 6-1/4" sheet. Save

the three leftover 17-3/4" sheets for step 9.

FINISH THE BOTTOM

OF THE FUSELAGE

❏ 1. Glue the two die-cut 1/8" ply sub-formers 1

and 2 perpendicular to the fuse bottom.

❏ 5. Glue the sheeting to the sub-formers and

stringers, wetting with an ammonia/water mix if

needed.

❏ 6. Sand the sheeting to the shape shown on the

front view of sub-former 4 on the plan.

2525

Page 26

❏ 7. Glue the die-cut 1/8" ply sub-formers 3, 4, 5

and 6 in place perpendicular to the fuse bottom.

Glue the two die-cut 1/8" ply sub-former braces to

sub-formers 3 and 4.

❏ 8. Glue the four 1/4" x 1/4" x 30" balsa stringers

in place. Sand the stringers to the shape of the

sub-formers. Note: The photo shows you how the

right side stringers are sanded to match the shape

of the sub-formers. Sand both sets of stringers to

match the sub-formers.

❏ 10. Sand a taper on one 6" end of the sheet so

that when the sheet is positioned on sub-formers 5

and 6 the tapered end of the sheet fits flat against

the fuselage bottom.

❏ 9. From three 1/8" x 3" x 17-1/2" balsa sheets

(leftover from the front of the belly pan), cut three

7-5/8" sheets. Edge glue two pieces, making a 7-5/8"

x 6" sheet. Save the third piece for the sides of the

belly pan. Set the remaining 9-7/8" pieces aside for

step 14.

❏ 11. Glue the sheeting in place, aligning it with

the center of sub-former 5 (front to back, not left

to right).

26

Page 27

❏ 12. Trim the sheeting and sand the edge to the

angle of the sub-formers.

❏ 13. Glue the third 1/8" x 3" x 7-5/8" sheet to the

side of the sub-formers and to the center of subformer 5 (front to back). Trim this sheeting flush

with the bottom sheeting. Use the leftover piece to

sheet the other side.

❏ 15. Round the edges of the belly pan sheeting

to shape.

❏ 16. Epoxy the 1/8" x 3-1/8" x 7-1/2" ply landing

gear plate in place inside the fuse.

❏ 14. Using the remaining three 9-7/8" balsa

sheets, sheet the last section, covering the middle

first, then the sides.

❏ 17. Drill four 3/16" holes through the fuse bottom

and the landing gear plate, using the landing gear

as a guide. Remove the gear and enlarge these

holes to 13/64".

27

27

Page 28

❏ 18. Using four 8-32 x 3/4" bolts, pull four 8-32

blind nuts into the landing gear plate. Glue them in

place with thin CA.

MOUNT THE TAIL

❏ 1. Sand a flat on the leading edge of the stab so

the stab fits flush against bulkhead 7.

horizontally as well. When satisfied with the fit and

alignment, glue the stab to the fuselage with

30-minute epoxy.

❏ 3. Cut the 1/2" x 12" balsa triangle stock in half,

making two 6" pieces. Glue them to the fuse and

the bottom of the stab.

❏ 4. Using a 90 degree triangle, align the fin

vertically. Be sure that the fin is also aligned with

the centerline of the fuselage. Glue the fin in place

with 30-minute epoxy.

❏ 2. Place the stab on the fuselage and align it with

the wing and centerline of the fuselage. Use the

same string technique that you used for aligning

the wing. Be sure that the stab aligns with the wing

❏ 5. Using the template provided on the plans, cut

the dorsal fin from leftover 3/8" balsa. Round the

leading edge of the dorsal fin. Glue it in place.

28

Page 29

MAKE AND MOUNT

THE WING STRUTS

❏ 6. Laminate two of the die-cut 1/8" balsa top

spines, making a 1/4" spine. Laminate the other

two, making a second 1/4" spine. Glue the spines

to the top sheeting, with the forward edges 1-1/4"

from the fuse side and the rear edges against the

fin and the forward edge of bulkhead 7.

❏ 1. Drill an 1/8" hole which is 3/4" deep in one

of each of the four shaped basswood wing struts.

❏ 2. Thread four 6-32 x 1-1/2" studs into the struts

until 3/4" of the stud is protruding from the end of

the strut. Do not glue at this time. Note: You will

permanently secure the studs to the struts after the

model is completely covered and all measurements

and alignments have been checked.

❏ 3. Using the wing plans as a reference, drill four

1/8" holes through the bottom sheeting and through

the four basswood strut blocks.

end

❏ 7. Sand the front of the spines to the shape

shown on the plans. Fill in around the dorsal fin

and the spines with leftover 3/8" x 1/2" balsa stick

and filler.

❏ ❏ 4. Screw one of the nylon strut ends onto one

strut. This is now your front strut.

❏ ❏ 5. Cut the belly pan sheeting behind subformer 3 until you can fit the nylon strut end in the

slot. Drill a 1/8" hole for the strut mounting screw.

Mount the front strut to the fuse with a #8 x 3/4"

truss head screw.

29

29

Page 30

❏ ❏ 6. Mount the wing to the fuselage. Screw one

of the 6-32 x 1-1/2" studs all the way into one of the

nylon strut ends. Mount the strut end (and stud) in

the forward hole in the wing.

❏ ❏ 7. Align the strut overlapping the strut end.

Make a mark on the strut at the position of the end

of the strut end as shown in the photo. Remove the

strut. Cut the strut at the mark you made. Drill a 1/8"

hole in the end of the strut. Remove the strut end

from the wing and thread the 6-32 stud into the hole

until the strut end is flush against the strut. Do not

glue at this time.

❏ ❏ 9. Screw a nylon end onto a second strut,

making your rear strut. Mount the rear strut to the

wing. Align the rear edge of the rear strut at the

rear edge of the forward strut as shown in the

photo. Extend the line on the front strut onto the

rear strut. Make a line on the front strut along the

rear strut’s leading edge as shown on the photo.

❏ ❏ 8. Beginning at the trailing edge of the

fuselage end of the forward strut, make a mark

1/4" into the airfoil (toward the leading edge).

Measure 5" down the length of the strut and again

make a mark 1/4" forward of the trailing edge as

shown in the sketch. Draw a line between these

two marks, which indicates where the two struts

will join. Mount the forward strut.

❏ ❏ 10. Using the lines you drew and the sketch

before step 8 as references, cut the marked area

out of the trailing edge of the forward strut, making

a good mating joint for the rear strut. Cut the rear

strut along the diagonal line you drew. Glue the two

struts together.

❏ ❏ 11. Remove the strut assembly from the

model. Blend the base of the struts together with a

mixture of epoxy and microballoons or milled

fiberglass resin. For additional strength, we strongly

recommend wrapping the assembly with glass

cloth or carbon tow.

❏ 12. Repeat steps 4-11 to mount the struts on the

other side. Label each strut assembly.

30

Page 31

FINISH THE WINDSHIELD

AND COWL

to the two rear halves and test fit it over the front of

the fuse. After all the fitting is done, glue all joints

with thin CA.

❏ 7. Cut the holes in the cowl for the engine,

carburetor, air inlets and air exit. If you go slowly

and remove a little material each time, you will be

rewarded with a tight-fitting and good-looking

❏ 8. Mount the cowl with four #6 x 1/2" sheet metal

screws and washers. Reinforce seams inside the

cowl and the mounting holes with 1" wide fiberglass

cloth.

cowl.

❏ 1. Trim the windshield along the cut-lines and

test fit it to the cabin. Trim where necessary for a

good fit. Tack glue the windshield in place. Note:

The windshield will be permanently attached to the

fuse after the model is covered.

❏ 2. Mount the wing to the fuse. Using a 3/8" x 3"

x 7-1/2" balsa sheet, fit and glue the wing root filler

blocks to ribs W2A, leaving a 1/16" gap between

the windshield and the filler blocks.

❏ 3. Remove the wing and sand the filler blocks to

the shape of the airfoil.

❏ 4. Mount your engine to the fuselage.

❏ 9. Fill the joints with Bondo or a similar filler.

Sand smooth.

❏ 10. Mount the tail gear to the fuse with three #4

x 1/2" sheet metal screws. Drill a hole in the

leading edge of the rudder for the tail gear wire.

FINAL ASSEMBLY

INSTALL THE RADIO SYSTEM

Our radio installation consisted of the following:

A. One high-torque servo for each aileron.

B. One high-torque servo for each elevator, with

separate pushrods.

C. One high-torque servo for the rudder.

D. One standard servo for the throttle.

E. One 1200 mAh battery pack to support the

additional servo drain.

❏ 1. Fit and install the elevator and rudder servos

into the servo tray. Install a control horn on each

elevator and on the rudder. Install the pushrods.

Connect the linkages to the servos.

❏ 5. Round the bottom corners of the fuselage

sides to match the cowl shape as shown on the

❏ 6. Trim the three cowl sections along the trim

lines. Tape the rear top and rear bottom sections

together with masking tape. Tape the front section

plans.

❏ 2. Install one aileron servo and its control horn,

pushrod, and linkage with a 28" servo lead in each

wing half.

31

31

Page 32

❏ 3. Glue the four die-cut 1/8" ply servo mount

pieces together for the throttle servo. Mount the

servo in the mount. Glue the servo mount to the

fuse side in a location that does not bind your

throttle linkage. Note: There is another set of diecut 1/8" ply servo mount pieces which can either

be used for a kill switch or a smoke switch or valve,

or not used at all.

FINISHING

❏ 1. Finish the cockpit. The cockpit area was

designed to be structure-free so that you could add

as much detail as desired. Add neat details such

as seats and scale instrument panel by installing

the cockpit kit (available separately).

❏ 2. Cover the model. If you prefer iron-on

coverings that do not require painting, this type of

model lends itself very well to 21st Century Fabric®.

This material has a painted appearance with a

fabric texture. It will make your Super Decathlon

look like it has been covered with fabric and

painted, just like the real Super Decathlons were

when they came off the assembly line! Your

Dynaflite Super Decathlon will require two fifteenfoot rolls of covering.

❏ 3. Finish the hinge installation.

SET THE CONTROL THROWS

❏ 1. Measuring at the widest part of the trailing

edge of the rudder, ailerons and elevator, set the

control throws as listed below. After a few flights

you may want to change the throws to suit your

own flying style.

Set your control throws as follows:

High Rate Low Rate

Ailerons: 1-1/4” up 5/8” up

1-1/4” down 5/8” down

Elevator: 1-1/2” up 1” up

1-1/2” down 1” down

Rudder: 1-1/2” left 1” left

1-1/2” right 1” right

❏ 4. Position and glue the windshield to the fuse

with special canopy glue such as RC/56 Canopy

Glue. Paint the cabin and window frames. Trim the

plastic sheets to fit behind the window openings

and glue trim in place with canopy glue. Note: Test

spray your paint on a small, leftover piece of your

butyrate windshield and allow to dry for at least

48 hours to ensure compatibility prior to painting

your windshield.

FINISHING THE STRUTS

❏ 1. Attach the wing to the fuselage and the struts

to the wings. Place the aircraft upside-down and

support as necessary so that the wing incidence

measured at the fuselage is zero.

❏ 2. Use an incidence meter to confirm the 2° of

washout at the wing tips. Remove the struts and

epoxy the strut studs into the struts at the exact

length which gave you the proper washout.

32

Page 33

BALANCE THE MODEL

LATERALLY

Do not confuse this procedure with “checking

the C.G.” which will be discussed later in the

manual.

Now that the model is covered and nearly

completed, this is the time to balance it laterally

(side-to-side). Here’s how:

❏ 1. With the wing level and attached to the model

(and the engine and muffler installed), lift the

model by the propeller shaft and the fin. This may

require an assistant. Do this several times.

PREFLIGHT

BALANCE YOUR PROPELLERS

Many problems are the result of vibration caused

by an unbalanced propeller. Nuts and bolts can

vibrate loose. Vibration can damage delicate radio

components and even damage the delicate glow

plug element, resulting in an engine that is difficult

or impossible to start. Purchase a Top Flite Precision

Magnetic Balancer

Prop Balancer to accurately balance your

propellers.

™

or a Great Planes Fingertip

❏ 2. The wing that consistently drops indicates the

heavy side. Balance the model by adding weight to

the other wing tip.

An airplane that is laterally balanced will track

better during aerobatic maneuvers.

BALANCE YOUR MODEL

This section is important and must not be omitted.

A model that is not properly balanced will be

unstable and possibly unflyable. Note: You must

check the balance point with all components

installed in the model and the fuel tank empty.

❏ 1. Attach the wing and struts to the fuselage.

Then, accurately mark the balance point on the

bottom of both wing halves next to the fuselage.

Check and set the CG as shown on the plan at

3-3/8" aft of the leading edge. After your first flights,

the CG can be adjusted fore or aft up to 1/2" from

the optimum CG to fit your flying style.

CHARGE YOUR BATTERIES

Follow the battery charging instructions in the

instruction manual that came with your radio

control system. You should always charge your

batteries the night before you fly.

AT THE FLYING SITE

GROUND CHECK

YOUR MODEL

Inspect all nuts, screws and wheel collars. Make

sure that you installed the screws that hold the

servo arms onto the servos and that the servo

wires are securely connected to the receiver. If you

are not thoroughly familiar with R/C models, ask an

experienced modeler to inspect your radio

installation and make sure the control surfaces

respond correctly. The engine must be “broken-in”

according to the engine manufacturer's

recommendations for break-in. Refer to the Safety

Precautions on this page before you start your

engine. After you run the engine on the model,

make sure all screws remain tight, the hinges are

secure and the prop is on tight.

33

33

Page 34

RANGE CHECK

YOUR RADIO

Check the operational range of the radio before the

first flight. Before you turn your radio on, the first

thing you always must do is make sure no one else

is on your frequency (channel). Most model flying

fields utilize frequency control so familiarize

yourself with their system. Collapse your transmitter

antenna and turn on the transmitter, then the

receiver (the receiver should never be on by itself).

You should be able to walk at least 100 feet away

from the model and still have control. Have an

assistant stand by your model and tell you what the

control surfaces are doing while you operate them

from the transmitter. Repeat this test with an

assistant holding the model and running the engine

at various speeds. If the control surfaces do not

always respond correctly, don't fly! Find and correct

the problem first. Look for loose servo connections

or corrosion, loose fasteners that may cause

vibration, a defective on/off switch, low battery

voltage or a defective cell, a damaged receiver

antenna or a receiver crystal that may have been

damaged from a previous crash.

SAFETY PRECAUTIONS

Note: Failure to follow these safety precautions

may cause severe injury to yourself and others.

Store model fuel in a safe place away from high

heat, sparks or flames. Do not smoke near the

engine or fuel as it is very flammable. Engine

exhaust gives off a great deal of deadly carbon

monoxide, so do not run the engine in a closed

room or garage.

Get help from an experienced modeler if you are

not confident operating r/c engines.

Use safety glasses when you operate model

engines. Do not run the engine near loose gravel

or sand; the propeller may throw loose material in

your face or eyes.

When you start and run the engine, keep your face

and body as well as all spectators away from the

plane of rotation of the propeller.

Keep loose clothing, shirt sleeves, ties, scarfs, long

hair or loose objects away from the prop. Be

conscious of pencils, screwdrivers or other objects

that may fall out of your shirt or jacket pockets.

Use a “chicken stick” or electric starter and follow

the instructions to start your engine.

Ask an assistant to hold the model from the rear

while you start the engine and operate the

controls.

Make all engine adjustments from behind the

rotating propeller.

The engine gets hot! Do not touch the engine

during or immediately after you operate it. Make

sure fuel lines are in good condition so fuel will not

leak onto a hot engine and cause a fire.

To stop the engine, close the carburetor barrel

(rotor) or pinch the fuel line to discontinue the fuel

flow. Do not use your hands, fingers or any body

part to stop the engine. Never throw anything into

the prop of a running engine.

The best place to fly your R/C model is at an AMA

(Academy of Model Aeronautics) chartered club

field. Ask your hobby dealer or the AMA if there is

a club in your area and join it (the address and

telephone number for the AMA is listed on page 3

of this instruction book). Club fields exist to make

your R/C flying safe and enjoyable. We recommend

that you join the AMA and a local club so you may

have a safe place to fly and insurance in case of a

flying accident.

If a club flying site is not available, find a large,

grassy area at least 6 miles away from houses,

buildings, streets and other R/C activity like boats

and cars. Avoid flying R/C models near traffic or

areas such as parks, school yards, office building

lawns, etc, which may seem inviting but are much

too small to fly safely.

If you are not an experienced modeler who has

flown aircraft such as this, we highly recommend

that you get an experienced modeler to assist you

with your first flights. An experienced modeler can

34

Page 35

take your Super Decathlon up for the first time and

make sure it performs correctly, then give you

valuable flight instruction. He can hand you the

transmitter when the Super Decathlon has climbed

to a safe altitude or connect your transmitter to his

if both of your systems have a trainer cord or

“buddy box” capability. Assistance from an

experienced modeler will make your modeling

“career” progress faster (and cheaper).

FLIGHT

TAKEOFF

First flight attempts should be reserved for calm

days when the wind speed is less than five mph.

Always takeoff (and land) into the wind. Check the

operation of all controls just before takeoff. This will

eliminate the possibility of overlooking reversed or

disconnected controls (it happens).

As you apply power on takeoff, you will need to

apply a slight amount of right rudder to compensate

for engine torque and propeller “P” effect. The tail will

rise almost immediately, indicating that the tail

surfaces have gained effectiveness. Allow the model

to continue to accelerate until it has reached flying

speed. Use as much of the available runway as you

can. Then, gently apply some up elevator. Your

Super Decathlon should slowly lift from the runway.

Continue straight ahead until you have accelerated

to a safe flying speed.

the same basic flying characteristics. Your Dynaflite

Super Decathlon faithfully duplicates these same

characteristics.

To fly your Super Decathlon in a scale-like manner,

you should work on coordinating your turns by

using a little rudder in addition to the ailerons. You

can do this manually or use a computer radio to

mix-in some rudder with ailerons.

LANDING

Before attempting your first landing you should first

try some slow flight and stalls at higher altitudes to

become familiar with the Super Decathlon's slow

speed characteristics. You will probably find the

model slows down quicker and requires more

power than you are used to. Remember that

aircraft of the Super Decathlon's era had high drag

and limited low speed control effectiveness,

especially for the ailerons. The rudder is very

effective, however. Continue to carry approximately

1/4 power and speed until you initiate the flare,

then reduce power and allow the model to gently

settle to the ground. If you must go around, add

power and accelerate straight ahead. Do not

attempt to climb or turn until you have accelerated

to a safe flying speed.

We hope you enjoy the realistic looks and

performance of your Super Decathlon.

FLYING

As an aerobatic trainer, the full-scale Decathlon is

used to teach takeoffs, landings, turns, stalls,

spins and gentle aerobatics. Being relatively lowpowered, it does not have a high rate of climb and

has poor vertical performance. To gain speed for a

loop, it is necessary to dive for a brief period.

Barrel rolls are slow, teaching rudder/elevator

coordination. While the Super Decathlon is a more

powerful and advanced model, it still has most of

35

Page 36

TWO VIEW DRAWING

Use copies of this page to plan your trim scheme

Loading...

Loading...