Page 1

INSTRUCTION MANUAL

sPIECE7INGFOR%ASY4RANSPORTATION

s3LOWAND&ORGIVING&LIGHT#HARACTERISTICS

s3IMPLEAND&AST!SSEMBLY

WARRANTY

Great Planes® guarantees this kit to be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts damaged by use or modification. In no

case shall Great Planes’ liability exceed the original cost of the purchased kit. Further, Great Planes

reserves the right to change or modify this warranty without notice. In that Great Planes has no control

over the final assembly or material used for final assembly, no liability shall be assumed nor accepted

for any damage resulting from the use by the user of the final user-assembled product. By the act of

using the user-assembled product, the user accepts all resulting liability. If the buyer is not prepared to

accept the liability associated with the use of this product, return this kit immediately in new and

unused condition to the place of purchase.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND

USE OF THIS MODEL.

™

Champaign, Illinois (217) 398-8970

®

Entire Contents © 2010 Hobbico,® Inc.

airsupport@greatplanes.com

GPMA00 90 Mnl 2.0

Page 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Accessories . . . . . . . . . . . . . . . . . . 3

Setting Up Shop . . . . . . . . . . . . . . . . . . . . . . 4

Required Supplies & Tools . . . . . . . . . . . . . . 4

Optional Accessories . . . . . . . . . . . . . . . . . . 4

Building Notes . . . . . . . . . . . . . . . . . . . . . . . . 5

Common Abbreviations. . . . . . . . . . . . . . . . . 5

Types of Wood . . . . . . . . . . . . . . . . . . . . . . . . 6

Cyanoacrylate Glue. . . . . . . . . . . . . . . . . . . . 6

Build The T ail Surfaces. . . . . . . . . . . . . . . . . . 6

Build The Fin . . . . . . . . . . . . . . . . . . . . . . . . . 6

Build The Rudder, Stab & Elevator . . . . . . . . 7

Finish The Tail Surfaces . . . . . . . . . . . . . . . . 8

Build The Wing . . . . . . . . . . . . . . . . . . . . . . . . 9

Build The Inner Wing Panels . . . . . . . . . . . . . 9

Build The Outer Wing Panels . . . . . . . . . . . 13

Join The Inner Panels . . . . . . . . . . . . . . . . . 15

Join The Outer & Inner Wing Panels . . . . . . 17

Finish The Wing. . . . . . . . . . . . . . . . . . . . . . 18

Build The Fuselage. . . . . . . . . . . . . . . . . . . . 19

Prepare The Fuse Sides . . . . . . . . . . . . . . . 19

Join The Fuselage Sides. . . . . . . . . . . . . . . 21

Sheet The Fuse Bottom . . . . . . . . . . . . . . . 22

Finish The Fuselage . . . . . . . . . . . . . . . . . . 22

Install The Servos . . . . . . . . . . . . . . . . . . . . 26

Align The Stab & Fin. . . . . . . . . . . . . . . . . . . 26

Align The Stab. . . . . . . . . . . . . . . . . . . . . . . 26

Align The Fin . . . . . . . . . . . . . . . . . . . . . . . . 27

Covering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Prepare For Covering . . . . . . . . . . . . . . . . . 28

Covering Sequence. . . . . . . . . . . . . . . . . . . 28

Covering Tips . . . . . . . . . . . . . . . . . . . . . . . 28

Join The T ail Surfaces . . . . . . . . . . . . . . . . . 31

Join The Stab, Fin & Fuse . . . . . . . . . . . . . . 31

Hinge The Control Surfaces . . . . . . . . . . . . 32

Fuelproofi ng . . . . . . . . . . . . . . . . . . . . . . . . . 33

Final Hook-Ups & Checks . . . . . . . . . . . . . . 33

Connect The Servos . . . . . . . . . . . . . . . . . . 33

Mount The Landing Gear . . . . . . . . . . . . . . 35

Finish Radio Installation . . . . . . . . . . . . . . . 35

Mount The Wing . . . . . . . . . . . . . . . . . . . . . 36

Balance Your Model. . . . . . . . . . . . . . . . . . . 36

Set The Control Throws. . . . . . . . . . . . . . . . 37

PreFlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

At Home . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

At The Flying Site . . . . . . . . . . . . . . . . . . . . 38

Engine Safety Precautions . . . . . . . . . . . . . 38

Flying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Find A Safe Place To Fly . . . . . . . . . . . . . . . 38

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Introduction

Congratulations and thank you for purchasing

the Dynafl ite Butterfl y. The Butterfl y is a “powered

sailplane” or “motor glider” and is an ideal model for

learning to fl y radio controlled models – especially

if you are not able to locate an experienced fl ight

instructor and must try it on your own. Because

of its large wingspan and light wing loading, the

Butterfl y is a gentle model that will give you plenty

of time to think and react. Because of its size and

light weight however, you must reserve fi rst fl ight

attempts for a calm day – more on that in the “Flying”

section at the end of the manual. The Butterfl y does

not require a powerful engine. Any .10 to .15 cu.

in. 2-stroke will do the job – all the engine has to

do is provide a little thrust and the large wing will

do the rest!

The way you fl y the Butterfl y is to let it climb (it will

do that almost by itself with just a little guidance from

you), then throttle back and fl y it around rather like

a sailplane. When you need more altitude just apply

throttle. This doesn’t sound like much action but

don’t worry, if you’re a beginner you’ll be busy. Most

important, you’ll develop the hand-eye coordination

required to fl y traditional “40-size” sport/trainers.

Enough said. Please thoroughly read the rest of

the preliminary information, then let’s get started!

2

Page 3

Protect Your Model, Yourself

and Others... Follow This

Important Safety Precaution

Your Butterfl y is not a toy, but a sophisticated

working model that functions like a full-size

airplane. Because of its performance, if you do

not assemble and operate the Butterfl y correctly,

you could possibly injure yourself or spectators

and damage property.

2. You must take time to build straight, true and

strong.

3. You must install all R/C and other components

so that the model operates properly on the ground

and in the air.

4. You must test the operation of the model before

the fi rst and each successive fl ight to insure

that all equipment operates correctly. You must

also make certain that the model has remained

structurally sound.

To make your R/C modeling experience

totally enjoyable, we recommend that you get

assistance with assembly and your fi rst fl ights

from an experienced, kno wledgeable modeler.

You’ll learn faster and avoid risk to your model

before you’re truly ready to solo. Your local hobby

shop has information about fl ying clubs in your area

whose membership includes qualifi ed instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,500

chartered clubs across the country. We recommend

you join the AMA which will provide you with

insurance coverage at AMA club sites and events.

AMA Membership is required at chartered club

fi elds where qualifi ed fl ight instructors are available.

Contact the AMA at the address or toll-free phone

number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

(800) 435-9262

Fax (765) 741-0057

or via the internet at: www.modelaircraft.org

Precautions

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unfl yable model.

In a few cases the instructions may differ slightly

from the photos or plan. In those instances the text

should be taken as correct.

NOTE: We, as the kit manufacturer, can provide

you with a quality kit and great instructions, but

ultimately the quality and fl yability of your fi nished

model depends on how you assemble it; therefore,

we cannot in any way guarantee the performance

of your completed model and no representations

are expressed or implied as to the performance

or safety of your completed model.

Please inventory and inspect all parts carefully

before starting to build! If any parts are missing,

broken or defective or if you ha ve any questions

about building or fl ying this model, please call

us at (217) 398-8970 and we’ll be glad to help.

If you are calling for replacement parts, please

look up the part numbers and have them ready

when calling. Visit our web site at:

www.dynafl ite.com

Preparations

Required Accessories

These are the items “not included” with your kit,

that you will need to purchase separately. Items

in parentheses (OSMG2691) are suggested part

numbers recognized by distributors and hobby

shops and are listed for your ordering convenience.

GPM is the Great Planes® brand, TOP is the Top

®

Flite

brand and HCA is the Hobbico

❍ 4-Channel Aircraft Radio with three

standard servos

®

brand.

3

Page 4

❍ O.S.® 10LA (OSMG0011) or O.S. 15LA

(OSMG0016)

❍ Engine Mount (Hayes 006-AS15 short

mount for O.S. LA engines) HAYG0006

❍ Propellers; Refer to your engine’s

instructions for proper size

❍ Approximately 2 rolls Top Flite MonoKote

covering; See Covering Tips (page 31)

❍ Medium Fuel Tubing (3’, GPMQ4131)

❍ 1/4" Latex Rubber Padding (HCAQ1000)

❍ 1/16" Foam Wing Seating Tape

(GPMQ4422)

❍ 4 oz. Fuel Tank

❍ (2) 2-1/4" Wheels (GPMQ4222)

❍ (4) 4-40 x 1/2" screws to secure engine

mount (GPMQ3012)

❍ (4) 4-40 blind nuts for engine mount

screws (GPMQ3324)

❍ #64 Rubber Bands (1/4 lb box –

HCAQ2020)

❍ (4) 5/32" Wheel Collars (GPMQ4306)

❍ #4 x 1/2" Screw for mounting engine to

engine mount

Required Supplies and Tools

These are the building tools and adhesives that

you will need to build your Butterfl y.

We recommend Great Planes Pro™ CA and Epoxy

❍ 2 oz. Thin CA Adhesive - (GPMR6003)

®

❍ 2 oz. Medium CA+ (GPMR6009)

❍ CA Activator - (GPMR6035)

❍ 30-Minute Epoxy - (GPMR6047)

❍ #1 Hobby Knife Handle (XACR4305)

❍ #11 Blades (Qty. 100 – HCAR0311) or (Qty.

5 – XACR2911)

❍ X-Acto® (or similar) Building Square

(XACR7726) or Building Triangle

(XACR7725)

❍ Medium T-pins (HCAR5150)

❍ Wax Paper

❍ Electric Drill

❍ Drill Bits: 1/16", 5/64", 3/32", 3/16", 11/64"

or 5/32", 15/64" or 1/4"

❍ String for aligning the stabilizer

❍ Screwdrivers (Phillips and Flat Blade)

❍ Top Flite Covering Iron (TOPR2100)

❍ A building board that you can stick pins

into (see “Setting Up Shop”)

Setting Up Shop

If this is your fi rst model there are a few supplies

and tools that you should gather before you begin.

The most important item is a fl at table that you can

build your models on. You can turn a solid core door

into a building table, but avoid hollow core doors

because they warp easily. If possible, locate your

building table in an area that is not in the way of

other projects or household activities. Cover your

building table with a board that you can stick pins

into. The back of a 2’ x 4’ ceiling tile works well or

you can cut a piece to fi t your table from a 4’ x 8’

sheet of Celotex insulation board available from a

home improvement store.

Optional Accessories

You can build your Butterfl y without these items

but they will make the job much easier and provide

you with better results. These are things you will

accumulate as your building “career” progresses

anyway.

❍ Razor Plane (MASR1510)

❍ Single-Edge Razor Blades (100,

HCAR0312)

❍ CA Applicator Tips (HCAR3780)

❍ Hot Sock™ (for your covering iron,

TOPR2175)

4

Page 5

❍ 6-Minute Pro™ Epoxy (GPMR6045)

❍ Trim Seal Tool™ (TOPR2200)

❍ Heat Gun (TOPR2000)

❍ Straightedge (Fourmost Non-Slip,

FORR2149)

❍ Denatured or Isopropyl Alcohol (for epoxy

clean-up)

❍ Spare Glow Plugs (O.S. #8 for most

2-stroke engines, OSMG2691)

™

❍ HobbyLite

Balsa Filler (HCAR3401)

❍ Epoxy Brushes (GPMR8060)

❍ CA Debonder (GPMR6039)

❍ Powered hand tool with Sanding Drum and

Cut-off Wheel

❍ Bar Sander or Sanding Block and

Sandpaper (coarse, medium, fi ne grit)*

12’ Roll of adhesive-backed sandpaper,

80-grit (GPMR6180)

150-grit (GPMR6183)

220-grit (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

Building Notes

● There are two types of screws used in this kit:

Sheet metal screws are

designated by a number

and a length.

For example #6 x 3/4"

Machine screws are

designated by a number,

threads per inch and a

length.

For example 6-32 x 3/4"

● When you see the term “test fi t” in the instructions,

it means you should fi rst position the part on the

assembly without using any glue, then slightly

modify or “custom fi t” the part as necessary for

the best fi t.

*A fl at, durable, easy-to-handle sanding tool is

a necessity for building model airplanes. Great

Planes makes a complete range of Easy-Touch™

Bar Sanders and replaceable Easy-Touch

adhesive-backed sandpaper. For the Butterfl y all

that is required is the short 5-1/2" Bar Sander

(GPMR6169) and two assortment packages of

adhesive-backed sandpaper (GPMR6189).

For future reference, here’s a list of Easy-Touch

Bar Sanders and adhesive-backed sandpaper:

5-1/2" Bar Sander (GPMR6169)

11" Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

● Whenever just “epoxy” is specifi ed you may

use either 30-minute epoxy or 6-minute epoxy.

When 30-minute epoxy is specifi ed it is highly

recommended that you use only 30-minute epoxy

because you will need either the working time

and/or the additional strength.

Common Abbreviations

Fuse = Fuselage

Stab = Horizontal Stabilizer

LE = Leading edge (front)

TE = Trailing edge (rear)

Ply = Plywood

" = Inches

5

Page 6

Types Of Wood

Balsa Basswood Plywood

Cyanoacrylate Glue

The most popular type of glue modelers use for

general construction of R/C models is Cyanoacrylate

or CA glues. Modelers build with CA because

it cures fast (immediately in some cases) and

the pieces do not have to be clamped or pinned

together as they do with traditional adhesives.

CA’s do, however have their own set of special

procedures and precautions that you should follow.

Always use CA in a well ventilated area. Open some

windows or place a fan in the room to circulate the

air. Do not lean directly over your work when you

use CA and look away while it cures or “sets off.”

CA can cure immediately upon contact with skin

so if you accidentally bond your fi ngers, do not

use vigorous motion to separate them. Use CA

Debonder (GPMR6039) or acetone (nail polish

remover) or soak your fi ngers in warm water for

a few minutes. Never point the tip of a CA bottle

toward your face and be especially careful when

you unclog a CA tip. Hobbico CA Applicator Tips

(HCAR3780) are highly recommended and will

help keep the bottle from clogging. Keep paper

towels or tissues close by to immediately absorb

excess CA dropped on your model or work area.

Read all the warning labels on your CA bottle.

other conditions that require one or the other types

of CA. For the Butterfl y all you really need is thin

and medium CA.

CA Accelerator is a chemical that you can spray

over uncured CA to make it cure immediately. A

mist spray of accelerator will do the job. Do not

inhale the vapors! Some modelers “preprime” the

parts to be glued with accelerator, join them, then

add the CA. This way the CA is guaranteed to cure

immediately. This prepriming is especially handy

when you use thin CA because it will cure before all

of the glue soaks into the wood away from the glue

joint. We do not recommend you build your entire

model with this method and use accelerator only

when necessary. Often, overspray from accelerator

used hours or even days earlier on nearby glue

joints will cause the CA you use on the next step to

cure prematurely and unexpectedly – so be careful!

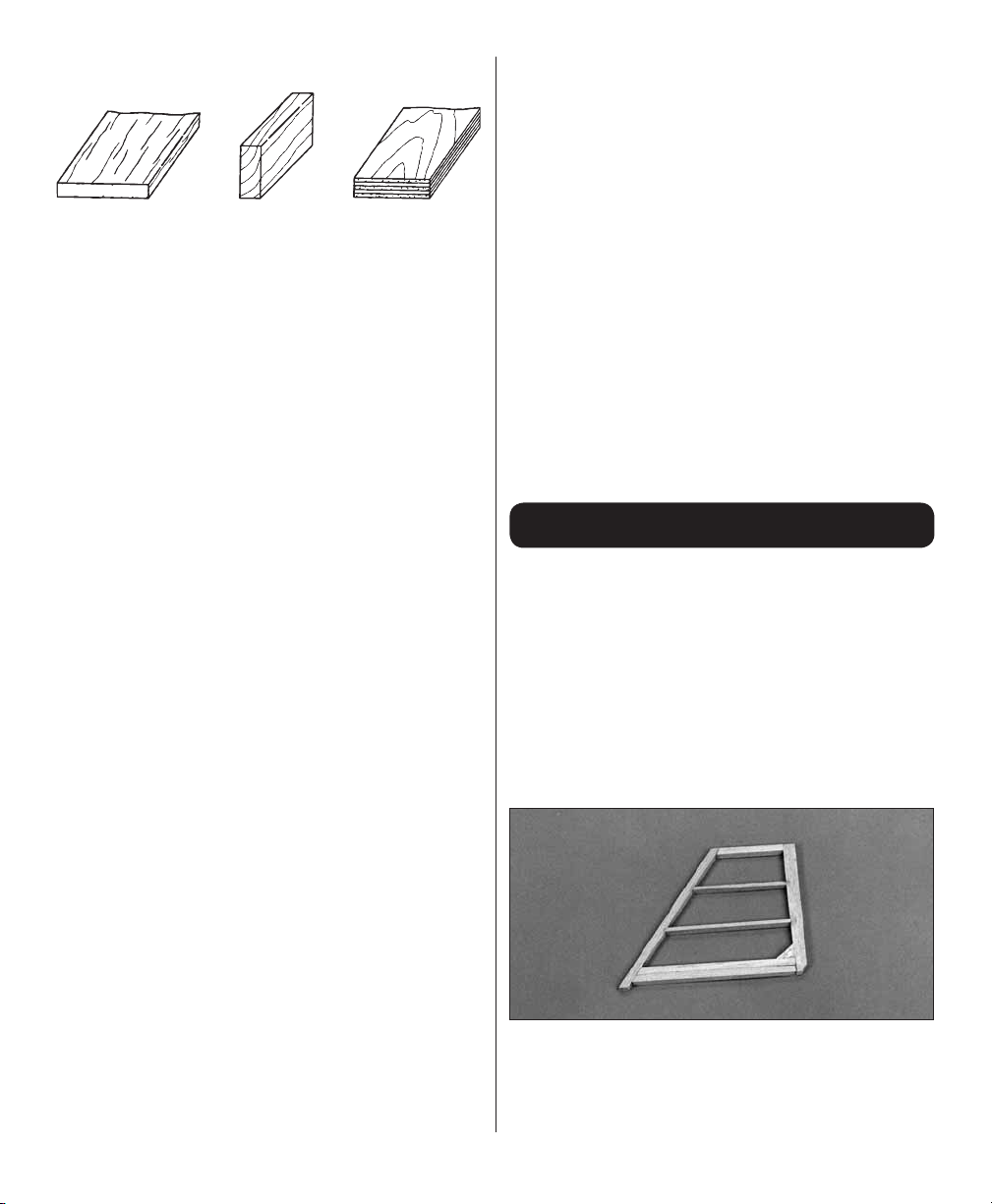

Build the Tail Surfaces

Build the Fin

Place your building board on top of your fl at building

table. Position the plan sheet so the rudder and

fi n drawing is over your fl at building board. (Reroll

the plan sheet inside out to make it lie fl at or use

weights or tape to hold it down.) You may separate

the wing portion from the plan or fold the plan in

half to make it easier to work with. Cover the fi n

drawing with wax paper so the glue will not stick.

There are different viscosities of CA’s intended for

different conditions you will encounter when you

build. Thin CA is great for “tack-gluing,” for glue

joints that fi t well and for parts that are already

joined but need to be permanently bonded. Medium

CA is used for general construction where you apply

glue to one part, then join it to another part. Thick

CA is great for glue joints that don’t fi t perfectly

or parts that require a little time for positioning

before the glue cures. You will encounter many

Refer to this photo while you build the fi n.

❏ 1. Cut the fi n trailing edge from a 1/4" x 3/8"

x 36" balsa stick, then pin it over its location on

the plan. Many modelers fi nd that they can more

6

Page 7

accurately cut small balsa sticks (such as the ones

used in the tail surfaces) with a single-edge razor

blade rather than a hobby knife.

❏ 2. Cut the fi n leading edge from a 1/4" x 1/4" x 24"

balsa stick, then pin it over its location on the plan.

❏ 3. Cut the two base pieces and the tip of the

fi n from the same 1/4" x 1/4" balsa stick, then glue

them to the LE (leading edge) and TE (trailing edge)

with medium CA and pin them in position.

❏ 4. Cut the two fi n “ribs” from one of the 1/8" x

1/4" x 24" balsa sticks, then glue them in position

over their location on the plan.

❏ 5. Make the gusset for the corner of the fi n TE

and the base of the fi n from the 1/4" x 3/8" balsa

stick you used in step 1.

❏ 6. Remove the T-pins, then lift the fi n from your

building board. We will instruct you to build the

dorsal part of the fi n after you position the fi n on

the fuselage. Reinforce glue joints that don’t look

strong with medium CA.

Build the Rudder, Stabilizer

and Elevator

Use the following building sequence for the rudder,

stabilizer and elevator as a guide to cut the balsa

sticks and pin them to the plan, then glue them

together the same as you did for the fi n. Don’t

forget to cover the plan with wax paper.

Rudder Building Sequence

❏ 2. The TE, then the bottom from a 1/4" x 1/2"

x 12" balsa stick.

❏ 3. The “balance tab” part of the rudder and the

tip from the remainder of the 1/4" x 1/4" balsa stick

you used for the fi n and another 1/4" x 1/4" x 24"

balsa stick if needed.

❏ 4. The “ribs” from the remainder of the 1/8" x

1/4" stick you used for the fi n.

❏ 5. Remove the T-pins and lift the rudder from the

building board. Reinforce glue joints that don’t look

strong with medium CA.

Stabilizer Building Sequence

Refer to this photo while you build the stabilizer.

❏ 1. The TE, LEs, tips, then LE “brace” from two

1/4" x 3/8" x 36" balsa sticks. To make the brace for

the LE, fi rst cut the 1/4" x 3/8" piece to a length of

4-1/4", then mark a centerline. Use a straightedge

and a hobby knife with a #11 blade to cut the angle

on the brace that extends from the centerline to

both corners.

Refer to this photo while you build the rudder.

❏ 1. The LE from the remainder of the 1/4" x 3/8"

stick used in step 1 of the fi n.

❏ 2. 1/8" x 1/4" x 24" basswood stab spar.

❏ 3. The stab center (in front of and behind the

basswood spar) from the 1/4" x 1-1/2" x 3- 7/8"

balsa sheet.

❏ 4. The stab ribs from 1/8" x 1/4" x 24" balsa sticks.

❏ 5. Remove the T-pins and lift the stab from your

building board. Reinforce glue joints that don’t look

strong with medium CA.

7

Page 8

Elevator Building Sequence

Refer to this photo while you build the elevator.

❏ 1. The LEs as shown on the plan, cut from a 1/4"

x 3/8" x 36" balsa stick. Use a hobby knife to cut

the “notches” for the 3/16" elevator joiner dowel.

Pin the LEs to the plan.

❏ 2. The TEs and tip ends from the remaining

1/4" x 3/8" balsa sticks from previous steps. Do

not make the elevator root ends until instructed

to do so (the roots are the ends of the elevators

nearest the fuselage).

❏ 3. Test fi t the 3/16" x 3-3/4" elevator joiner

dowel in the notches in the LEs of the elevators,

then if necessary adjust the notches so the dowel

is parallel to the TE of the stab on the plan.

❏ 4. Glue the dowel in position with epoxy. Stick

T-pins into your building board in front of the dowel

to hold it against the elevators. Slightly raise the

dowel so it is centered in the LEs, then wipe away

excess epoxy before it cures.

❏ 5. After the epoxy fully cures cut, then glue the

elevator root ends to the assembly.

❏ 6. The elevator ribs from remaining 1/8" x 1/4"

balsa sticks, then the control horn base for the right

elevator from leftover 1/4" x 3/8" balsa.

A note about sanding

“built-up” tail surfaces

Be careful when you sand a balsa structure

made up of “sticks.” The part fl exes and moves

while you sand and it can be diffi cult to keep your

sanding block fl at so you do not snag any of the

small ribs or over-sand one area and thin it more

than another area. Due to the design and slow

fl ying speed of the Butterfl y, a perfectly smooth

fi nish is not necessary. For this model, the

purpose of sanding is just to remove any glue

bumps or uneven edges. Stop sanding when

you have reduced most of the high spots. Use a

large sanding block or a fl at bar sander and do

not apply much pressure while you sand. Enjoy

– it’s not a racing plane – it’s a fl oater.

❏ 7. Remove the elevator from the plan, then add

CA to glue joints that don’t look strong.

Finish The Tail Surfaces

❏ 1. See the note below, then use your bar sander

or a sanding block and 220-grit sandpaper to even

the edges and blend the ribs, LEs and TEs of all

the tail surfaces so they are fl at and smooth.

❏ 2. Use a ballpoint pen to mark the location of

the hinges on the control surfaces as shown in

the photo.

Note: The plan shows two hinges in each elevator

but use three as indicated in the photo.

8

Page 9

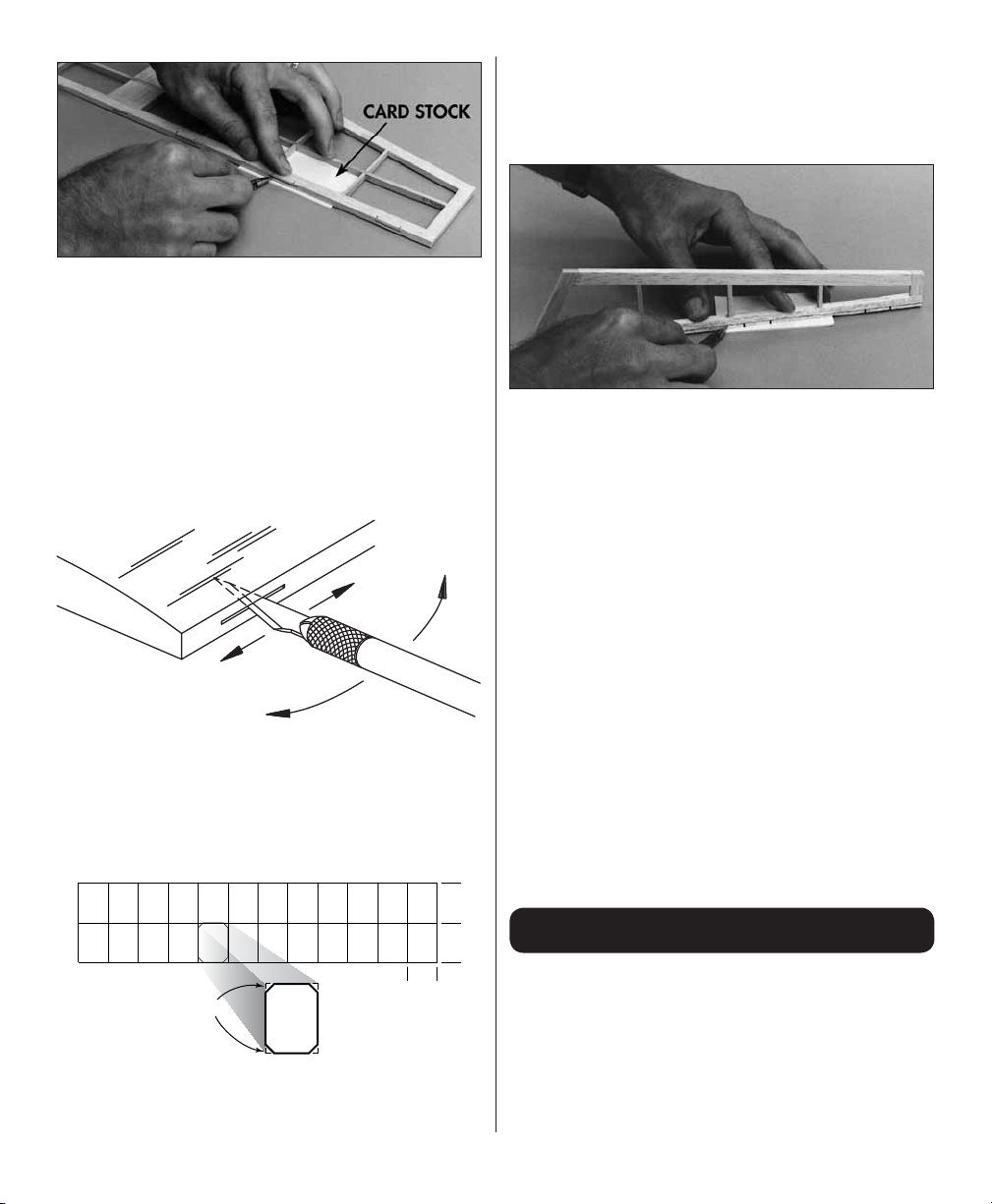

❏ 3. Lay the stabilizer on your building table. Use

thin card stock or business cards to raise the stab

so you can mark the hinge slots in the center of

the TE at the hinge locations. Mark the hinge slots

in the TE of the fi n the same way.

❏ 6. Test join (remember, this means no glue)

the elevator to the stab and the rudder to the fi n

with the hinges. Adjust the width of the hinge

slots if necessary.

❏ 4. Use the same procedure to mark the centerline

the entire length of the LE of the rudder and the

elevator.

Cut the Hinge Slot with a

Hobby Knife and a No. 11 Blade

❏ 5. Use a hobby knife with a #11 blade to make

the hinge slots. The fi rst cut should be a shallow

slit to establish the hinge slot location. After the fi rst

cut, make several more cuts going slightly deeper

each time. Move the knife from side to side and

widen the slot as you cut.

1"

1"

❏ 7. Separate the elevator from the stab and the

rudder from the fi n. Use the “pen-and-card stock”

technique to mark a guideline 3/32” to 1/8" from

the LE on both sides of the elevator and rudder.

The guidelines indicate where to round the LE for

control movement.

❏ 8. Use the guidelines and a sanding block or

razor plane to round the leading edges of the rudder

and elevator equally.

❏ 9. Mark a centerline on the trailing edge of the

rudder and elevator with a ballpoint pen. Use your

bar sander or sanding block and 150-grit sandpaper

to taper the rudder and elevator as shown on the

cross-section of the plan or simply round the trailing

edges the same as the leading edges.

Build the Wing

Snip the Corners

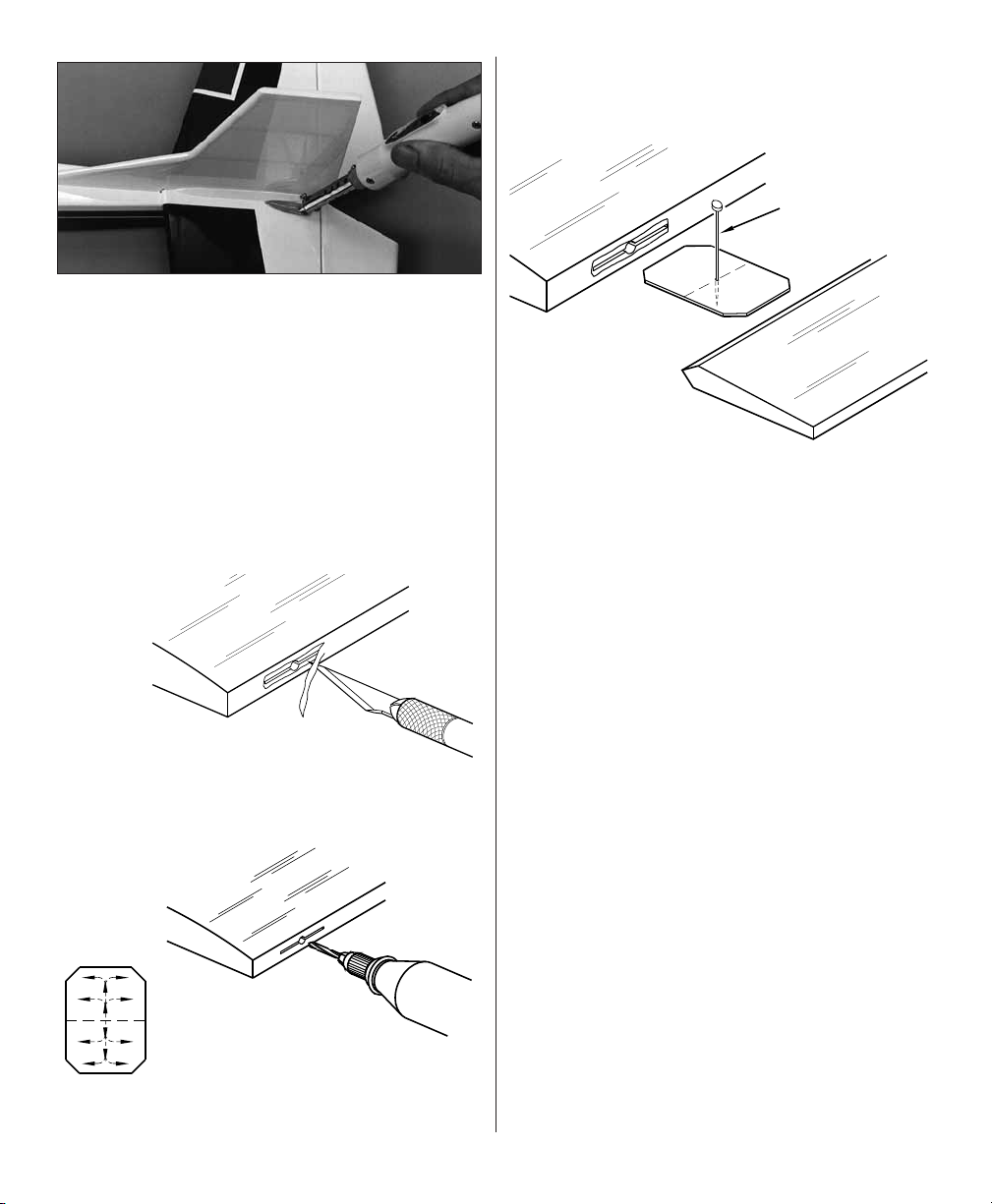

3/4"

Cut eight hinges from the hinge material supplied

as shown in the sketch. Snip the corners off so

they go into the slots easier.

Build the Inner Wing Panels

Build the right wing half fi rst so your progress

matches the photos in the manual. Lay the right

wing plan over your building board, then cover the

plan with wax paper.

9

Page 10

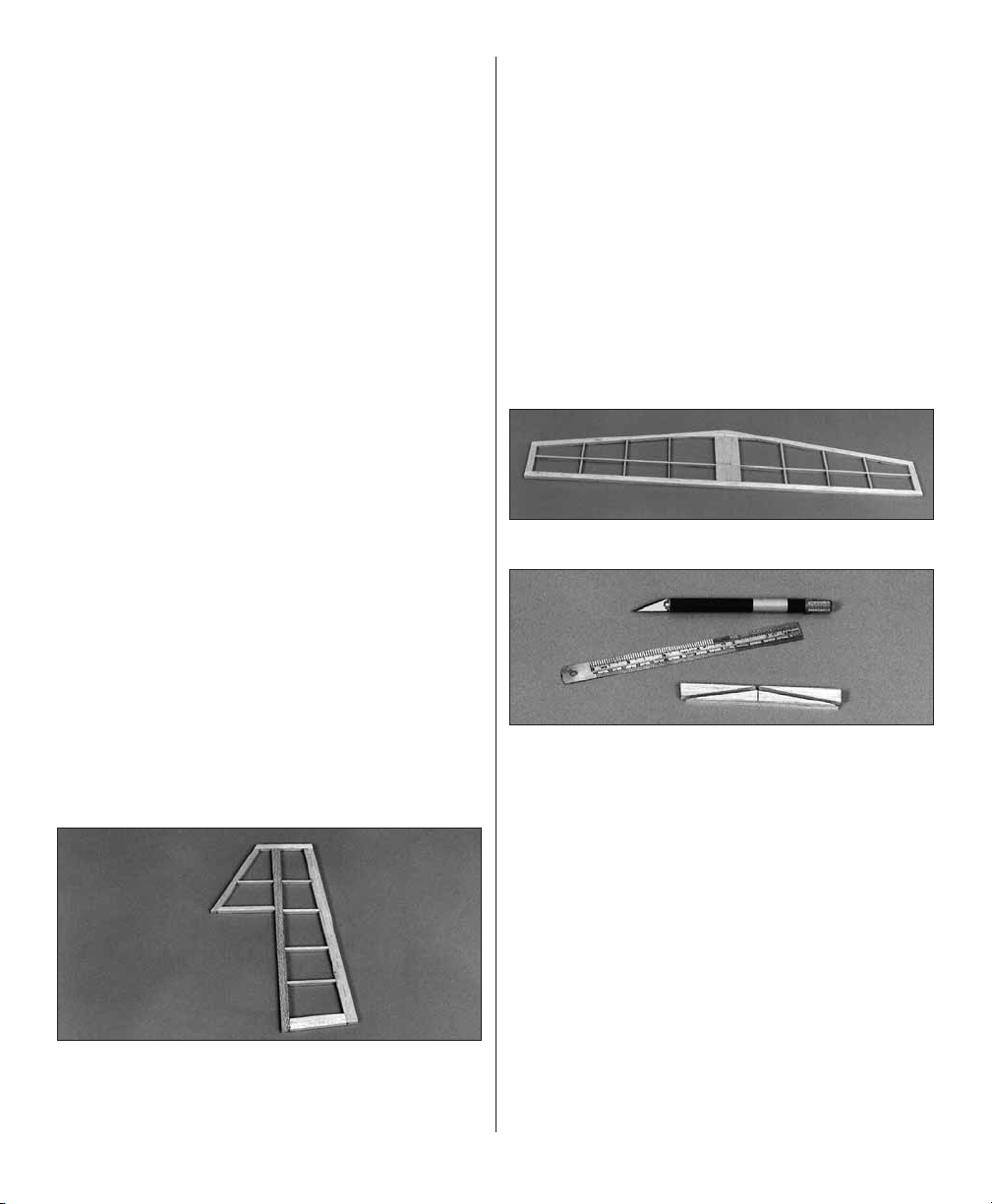

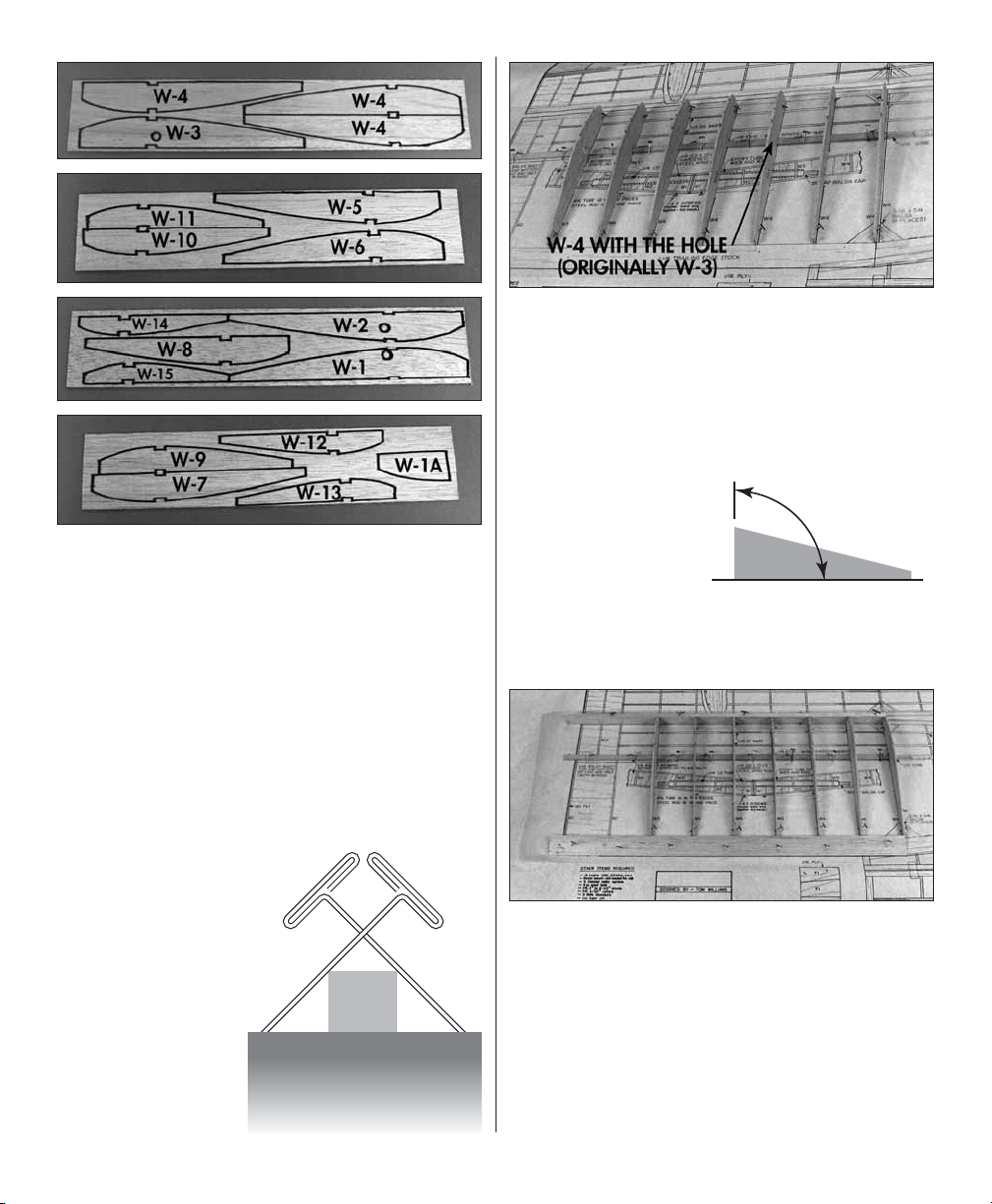

❏ 1. Before you remove the balsa ribs from their

die sheets, use the photos to identify the ribs and

mark them with a ballpoint pen as shown. If you

plan to cover the wing with transparent MonoKote

fi lm, mark the ribs neatly all in the same location

or mark them in an inconspicuous location so the

marks will not be seen through the covering.

❏ 2. Remove all the ribs from their die sheets, then

use a bar sander and 220-grit sandpaper to remove

any slivers or die-cutting irregularities. Save the

leftover 1/16" plywood from the W-1s to be used

later during fi nal landing gear installation.

❏ ❏ 3. Pin a 1/8" x

3/8" x 24" basswood

T-Pin

bottom inner spar

over its location

on the plan so the

tip “ends” at the

centerline between

the laminated W-4s

Spar

as shown on the plan.

Do not insert T-pins

Work Surface

through the spar

but install them in a

criss-cross pattern.

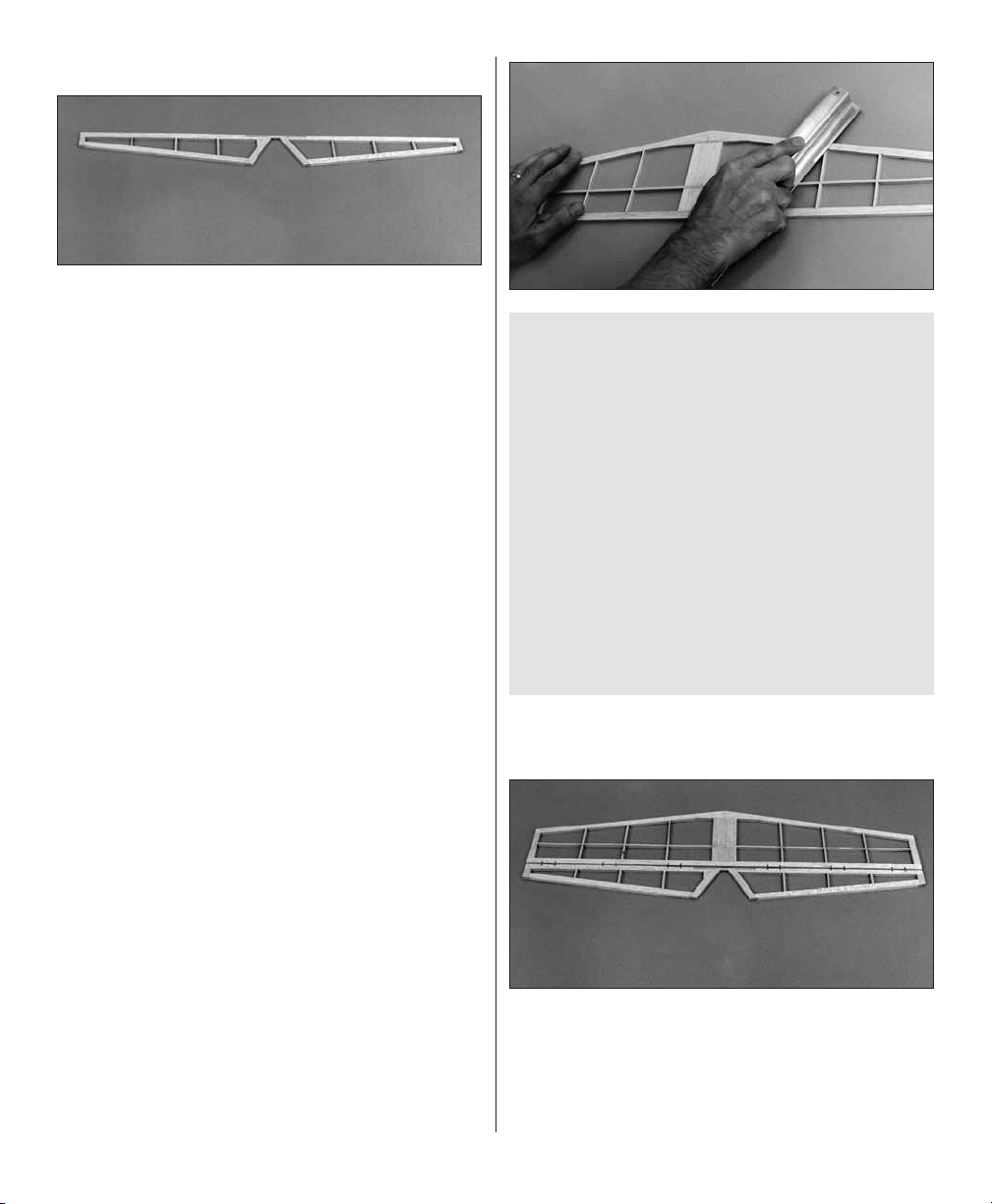

❏ ❏ 4. Position rib W-3 on the bottom spar and pin

it to the building board over its location on the plan.

Position the six W-4s of the inner wing panel on

the spar and pin them to the building board as well.

Note: Substitute the third W-4 rib in from the tip

with a W-3.

❏ ❏ 5. Position a

3/8" x 1-1/4" x 21"

90º

tapered balsa inner

TE over its location

on the plan so the

tip aligns with the

Bottom

centerline at the

laminated W-4s on the plan. Securely pin the TE to

the building board so it tightly contacts the wing ribs.

❏ ❏ 6. Position a 3/8" x 3/4" x 21" balsa inner LE

over its location on the plan so the tip aligns with

the centerline at the laminated W-4s on the plan.

Securely pin the LE to the building board so it tightly

contacts the wing ribs.

10

Page 11

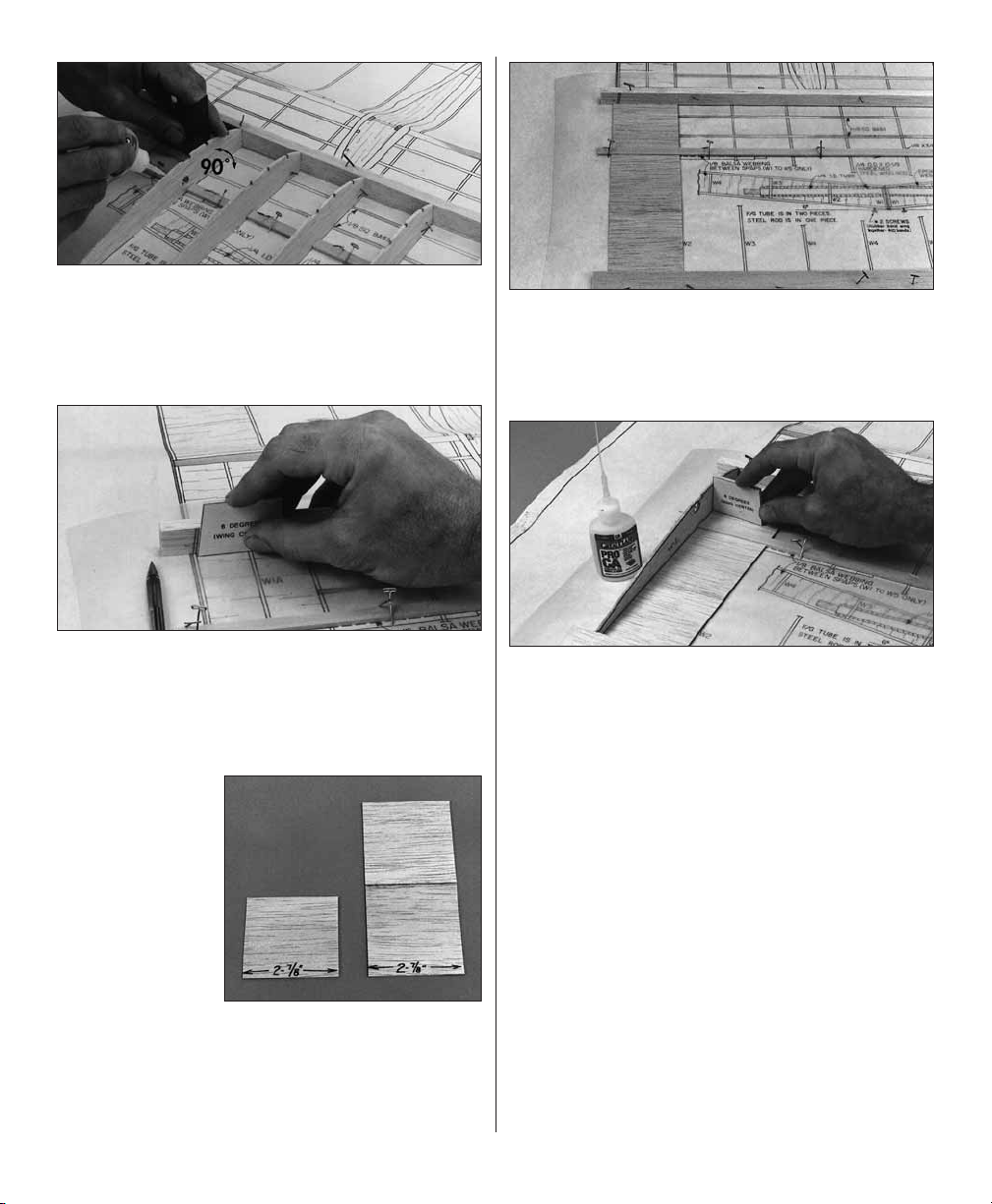

❏ ❏ 7. Remove the T-pins in rib W-3. Use a 90-

degree triangle to hold W-3 perpendicular to the

building board, then glue it to the spar, LE and TE

with medium or thin CA. Glue the W-4s to the spar,

LE and TE the same way.

❏ ❏ 10. Use medium or thin CA to glue the sheets

in position so the outer edges align with the outer

edge of rib W-2. The sheeting will be sanded fl ush

with the balsa W-1 after the wing is removed from

the plan.

❏ ❏ 8. Use the die-cut 1/8" plywood wing center

gauge to accurately mark where the balsa W-1

contacts the LE so you know where to position W-1

after the bottom sheeting is glued in place. Mark

the TE the same way.

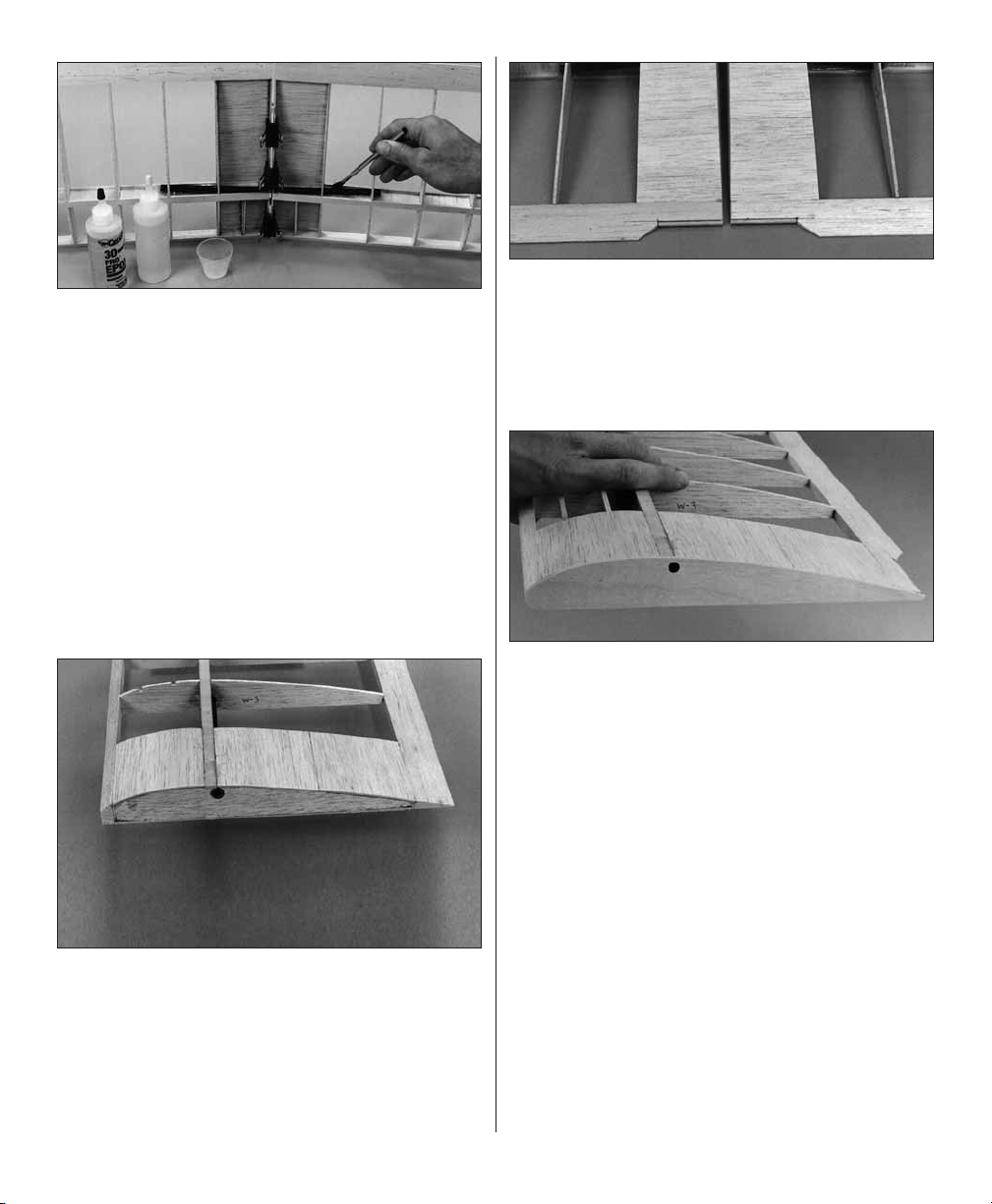

❏ ❏ 9. Cut three

2-7/8" wide strips

from the 1/16" x 3"

x 36" balsa sheet.

Glue two of the

strips together

to make the aft

bottom sheeting

behind the bottom

spar. The other

strip is to be used

for the forwar d bottom sheeting ahead of the spar.

Use a straightedge and a sharp #11 blade to trim

the sheets so they fi t between the LE and bottom

spar and the TE and bottom spar, but leave the

sheets 2-7/8" wide.

❏ ❏ 11. Align W-1 with the marks on the LE and

TE, then glue it in position using the wing center

gauge to set the correct angle.

❏ ❏ 12. Glue W-2 in position with thin or medium

CA. While gluing, hold W-2 perpendicular to your

building board as you did with the W-4s.

❏ ❏ 13. Trim, test fi t, then glue the 1/8" balsa

vertical grain shear webs between only the W-4

ribs (that’s fi ve shear webs). Note that the shear

webs between the W-4s are centered on the bottom

spar. You will have to temporarily remove the T-pins

that interfere with the shear webs, then replace the

T-pins through the shear web after you glue each

web into position. See the following photo.

❏ ❏ 14. Trim and test fi t, but do not glue the

remaining shear webs. Use the wing center gauge

to cut the angle for the shear web that fi ts between

W-1 and W-2.

11

Page 12

❏ ❏ 15. Slide the composite wing joiner tube

into the holes of W-1, W-2 and W-3. The holes in

the ribs are slightly oversize so you can accurately

position the tube when you permanently glue it

into the wing. Position the joiner tube so it rests

against the forward edge of the holes in the ribs,

then position the shear webs so they contact the

tube yet remain vertical. Glue the shear webs to

the wing (not the joiner tube) in this position.

❏ ❏ 16. Remove the joiner tube, then test fi t the

1/8" x 3/8" x 21" basswood inner upper spar in

the notches of the ribs. Make sure none of the

crossed T-pins interfere with the top spar and you

will be able to remove them after you permanently

glue the spar into position. If necessary, trim the

shear webs that do not allow the spar to rest fully

into the notches of the ribs. Use medium or thick

CA to glue the upper spar to the assembly so the

end is even with the outer rib W-4.

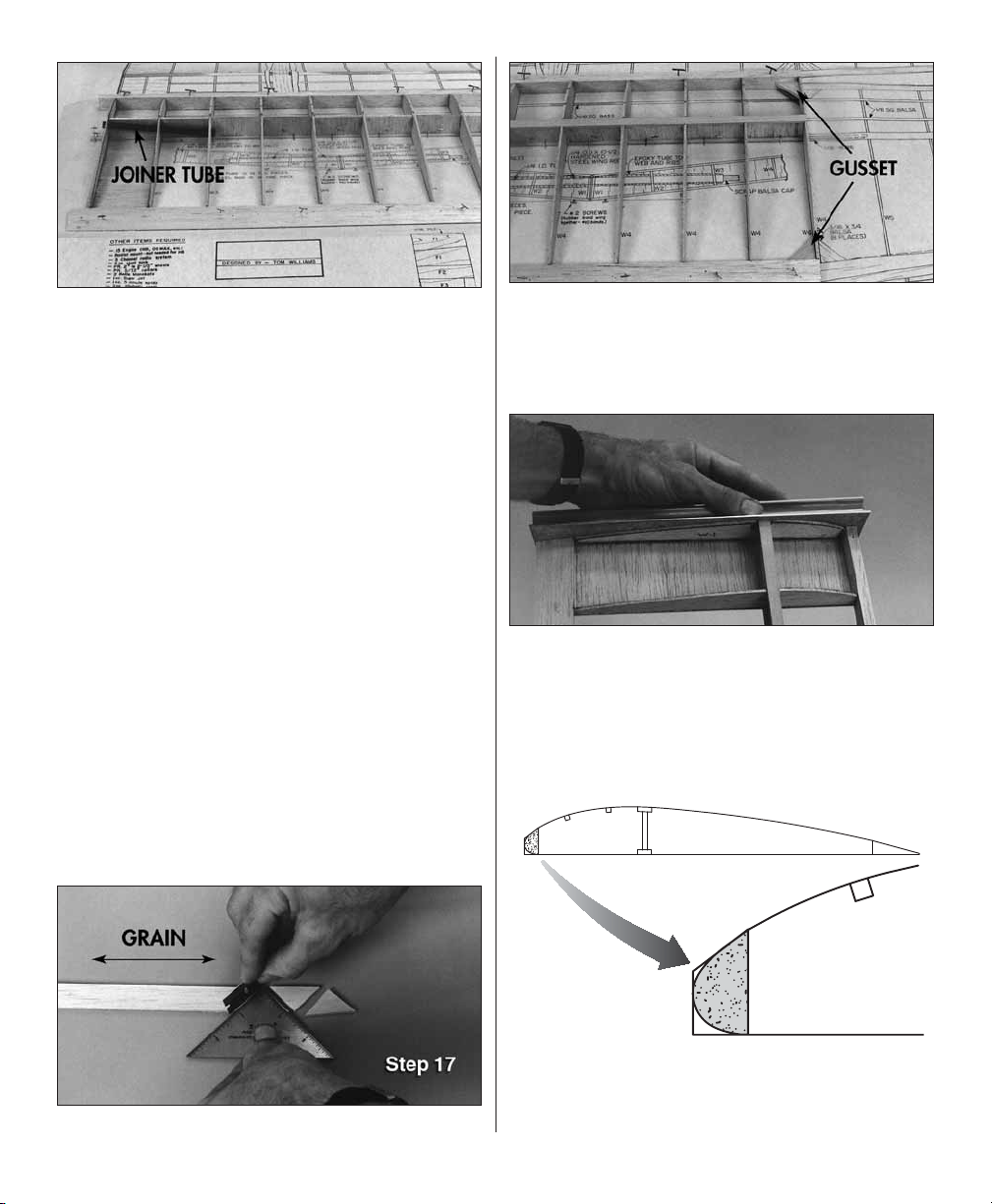

❏ ❏ 17. Make two gussets from the 3/16" x 3/4" x

12" balsa sheet, then glue them in position. If you

have one, use a small building triangle to accurately

cut the gussets. Note the grain direction as shown

in the photo.

❏ ❏ 18. Remove the T-pins and lift the wing panel

from your building board. Trim the ends of the spars,

LE and TE, then use your bar sander and 150-grit

sandpaper to make the spars, LE, TE and bottom

sheeting fi t perfectly fl ush with W-1.

❏ ❏ 19. Glue W-1A into position with medium CA.

❏ ❏ 20. See the Tip that follows, then use a razor

plane, a hobby knife with a carving blade or a #11

blade to roughly carve the leading edge according

to the sketch.

12

Page 13

Note: Leave the leading edge at least 1/16" high

"

in front of ribs W-1, 2 and 3 to accommodate the

top sheeting. You will fi nal sand the LE after you

join the inner panels to the outer panels and glue

the top sheeting in position.

TIP: How To Use A Razor Plane

We highly recommend a razor plane to shape

the LEs because it is the safest, fastest and

most accurate method to remove large quantities

of balsa.

A. Adjust your razor plane so it removes about

1/64" or less balsa at a time.

B. Position the LE of the wing panel at the edge

of your work bench so it is supported and the

bench does not interfere with the razor plane.

Area to Trim Off

3/4

❏ ❏ 1. Trim the end of a 3/8" x 1-1/4" x 30" tapered

balsa outer trailing edge so it matches the angle at

W-4 shown on the plan. Mark the tip end of the TE

3/4" away from the aft edge. Use a straightedge and

a ballpoint pen to mark a line on the TE connecting

the mark you made at the tip with the forward edge

of the other end (the root) of the TE.

❏ ❏ 2. Use the line you marked (or a straightedge)

as a guide to trim the TE with a sharp #11 hobby

knife as shown on the wing plan.

❏ ❏ 3. Cover the outer panel of the right wing plan

with wax paper, then use the “crossed T-pin” method

to pin the 1/8" x 3/8" x 30" basswood bottom outer

main spar in position so the root end aligns with

the plan at W-4.

❏ ❏ 4. Position the odd numbered ribs and

W-4 on the bottom spar, then pin them to your

building board.

C. Hold the razor plane at an angle to the grain

direction as shown in the photo.

D. Work slowly and inspect your work frequently.

Before you know it you will shave the LE down

quite far.

❏ 21. Arrange the plan so the left inner wing panel

is over your building board, then cover it with wax

paper. Return to step 3 and build the left inner wing

panel the same way as the right. Don’t forget to

switch to the left wing panel plan so you do

not build two right panels.

Build the Outer Wing Panels

Start with the right outer wing panel so your

progress matches the photos in the manual.

❏ ❏ 5. Pin the outer TE and the 3/8" x 3/4" x 30"

balsa outer LE to the building board so they tightly

contact the ribs and the ends align where indicated

on the plan at W-4.

13

Page 14

❏ ❏ 6. Remove the T-pins from rib W-4. Use the

wing tip panel gauge to set W-4 at the correct

angle and glue it to the TE, bottom spar and LE.

❏ ❏ 7. One rib at a time, remove the T-pins and use

a building triangle to hold the rib vertical, then use

medium or thin CA to glue the ribs you installed to

the bottom spar, LE and TE.

❏ ❏ 8. Install, then glue the remaining ribs to the

assembly using a building triangle to make sure

they are vertical.

❏ ❏ 9. Cut, then install the gussets at W-4 from

the 3/16" x 3/4" balsa stick. Due to the taper of

the LE and TE these gussets are not exactly a

90-degree angle.

❏ ❏ 10. Add the 1/8" balsa cross-grain shear web

between W-4 and W-5. Use the die-cut 1/8 plywood

wing tip panel gauge to cut the end of the web

that contacts W-4.

❏ ❏ 11. Test fi t, then use medium or thick CA to

glue the 1/8" x 3/8" x 30" basswood top outer spar

to the ribs and shear web. Don’t forget to make

sure the crossed T-pins are not in the way and you

can remove them after you permanently glue the

spar into position.

❏ ❏ 13. Remove the T-pins, then lift the panel

from the plan. Use a razor saw to cut the ends of

the spars, LE and TE so they extend past W-15 by

approximately 1/32" to 1/16". Use your bar sander

to sand the ends fl ush with W-15 and W-4.

❏ ❏ 14. Use a razor plane, a hobby carving blade

or a #11 blade to roughly carve the leading edge

the same way as you carved the inner wing panels.

❏ ❏ 12. Test fi t, then use medium CA to glue both

1/8" x 1/8" x 30" balsa outer turbulator spars in

the notches of the ribs so the ends extend past

W-4 by approximately 1/16" (you can sand them

fl ush later).

❏ ❏ 15. Glue the 3/4" x 6-1/4" triangle balsa wing

tip to W-15. The aft edge of the wing tip should

align with the aft edge of the TE. It may appear

that the triangle wing tip is too short because it

does not align with the LE, but as indicated on the

plan you will shape the LE to align with the wing tip.

14

Page 15

❏ ❏ 16. Roughly carve the wing tip with a razor

plane or a hobby knife. Final shape the tip and blend

it to W-15 with a bar sander and 150-grit sandpaper.

❏ ❏ 17. Carefully remove any glue blobs and blend

all the ribs to the spars, TE and LE with a bar sander

and 220-grit sandpaper.

❏ 3. Without any glue, temporarily join both inner

wing panels with the joiner tubes and the joiner

rod. Hold the wing halves together and inspect

the fi t between the W-1 ribs of the joining panels.

If necessary, separate the panels and use your bar

sander to adjust to the ends of the spars, LEs or

TEs so the W-1s fi t together well.

❏ 18. Arrange the plan so the left outer wing panel

is on your building board, then cover it with wax

paper. Return to step 1 and build the left wing panel

the same way you built the right. Don’t forget to

switch to the left wing panel plan so you do

not build two right panels.

Join the Inner Panels

Do not permanently join the inner wing panels, but

permanently install the joiner tubes so you can

temporarily join the panels for a days fl ying session.

Take the panels apart when it is time to go home.

❏ 1. Thoroughly roughen the outside of the wing

joiner tubes with 150-grit sandpaper so the glue will

stick. Use a metal fi le or a powered hand tool with

a cut-off wheel to remove the burrs and chamfer

the ends of the 1/4" x 10-1/2" steel wing joiner rod.

Remove any dirt or manufacturing oil from the rod

with a cloth dampened with alcohol or other solvent.

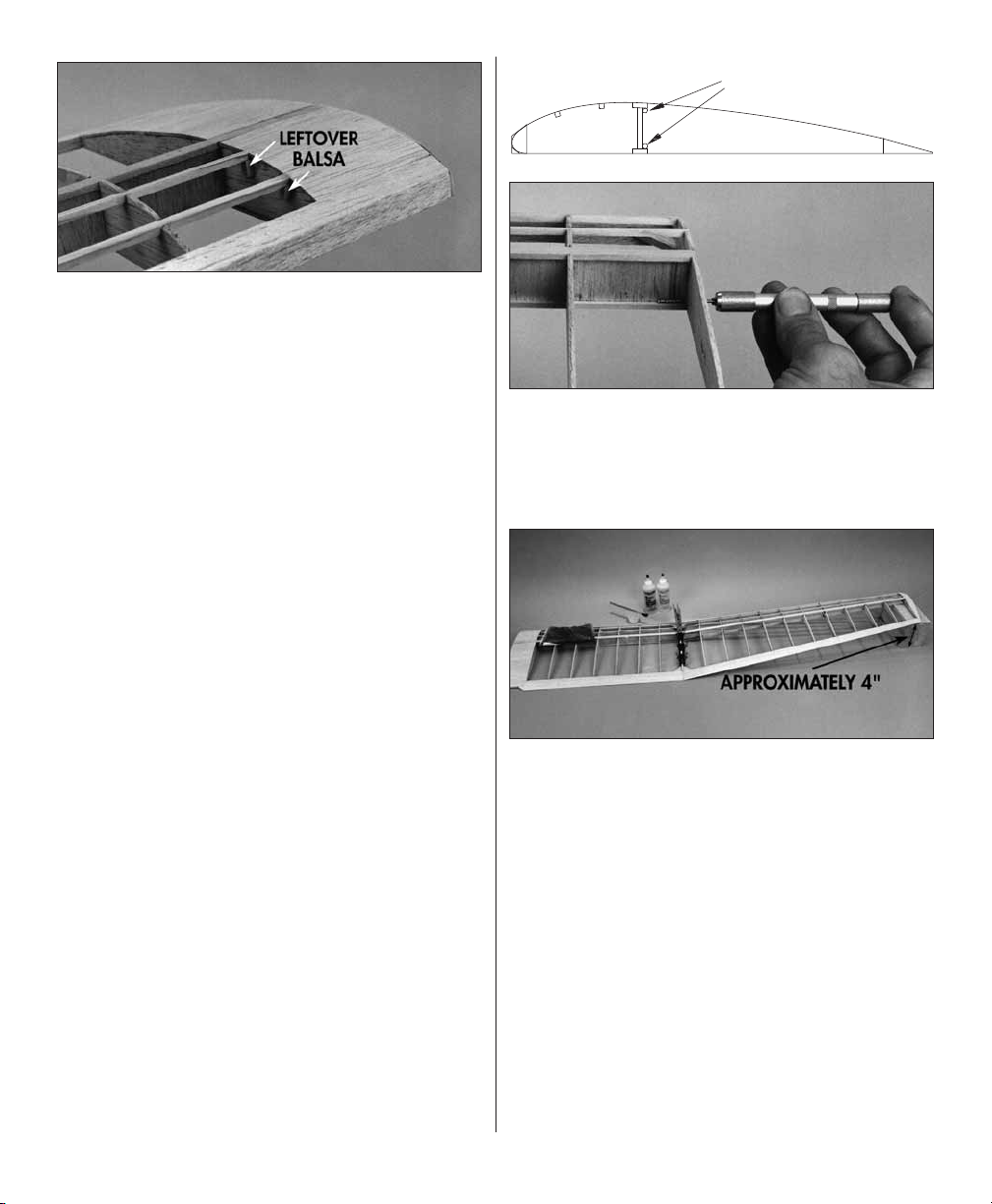

❏ 2. Plug one end of both wing joiner tubes with a

piece of 3/32" or 1/8" leftover balsa, then carefully

glue the plug in position with a few drops of thin

CA. Do not allow CA to fl ow into the tube because

it may interfere with the joiner rod.

❏ 4. With the joiner tubes and the joiner rod

in position, temporarily clamp the wing halves

together, then place a weight on one of the wing

panels to hold it down. Measure the height of the

outer W-4 from the building table. It should be

approximately 4-1/2".

❏ 5. Remove your clamps, then position 1/8"

leftover balsa “spacers” between the W-1s and

clamp them together. The spacers will allow both

joiner tubes to protrude 1/16" from the inner panels.

❏ 6. Use a stack of books, blocks of balsa or similar

to support the raised wing panel at W-4. Align the

joiner tubes so the ends meet in the center of

the wing and clamp the tubes to the shear webs.

“Spot-glue” the ends of the joiner tubes in each

wing panel with medium CA or epoxy.

15

Page 16

❏ 7. Carefully lift the wing from your building board

so you do not break the spot-glued joints, then place

it on the leading edges. Mix a batch of 30-minute

epoxy, then thoroughly glue the joiner tubes to the

shear webs, spars and ribs. Do not disturb the

wing until the epoxy cures.

❏ 8. Remove the clamps and separate the wing

panels. Make the top center section sheeting for

both wing panels from the remainder of the 1/16"

x 3" balsa sheet. Test fi t the sheets and confi rm

that the front and rear edges are fl ush with the TE,

upper spar and LE. If needed, trim the tops of the

ribs. Bevel the front edge of the front sheet so it

matches the LE, then glue the sheets in position.

❏ 9. Use a hobby knife and your bar sander with

150-grit sandpaper to trim the edge of the sheet

so it is even with W-1. Do not trim the ends of the

joiner tubes so they are fl ush with W-1.

❏ 10. Cut both of the TEs as shown on the plan.

Cut the 1/8" x 4" hardwood dowel into two pieces,

then test fi t and glue the dowels to the TEs of both

wing panels with medium CA. Use your bar sander

to true the end of the dowels so they are fl ush with

the ends of the wing.

❏ 11. Test fi t the die-cut 1/16" plywood W-1 root

ribs on the ends of the wing panels and the joiner

tubes. Then, glue them in position with medium

or thick CA. If you’ve just removed the W-1’s from

their die sheet, remember to save the leftover 1/16"

plywood to be used later during fi nal landing gear

installation.

❏ ❏ 12. Test fi t the 1/8" x 1/8" x 18" basswood

turbulator spars in the notches of the right wing

panel. The ends of the spars contact the center

sheeting and the tops of the spars are even with

the sheeting as shown in the following photo. If

necessary, adjust the notches so the spars fi t

fl ush with the tops of the ribs, then glue the spars

in position with thin or medium CA.

16

Page 17

❏ ❏ 13. Glue a piece of 1/8" leftover balsa to rib

W-2 to support the turbulator spars. Trim the ends

of the spars so they are even with the end of the

panel at rib W-4.

1/16" Holes

❏ 14. Glue the turbulator spars in the left wing

panel the same way.

❏ 15. Use a bar sander and 220-grit sandpaper on

both inner wing panels to carefully remove any glue

blobs and blend all the ribs to the spars, TE and LE.

Join the Outer & Inner Wing Panels

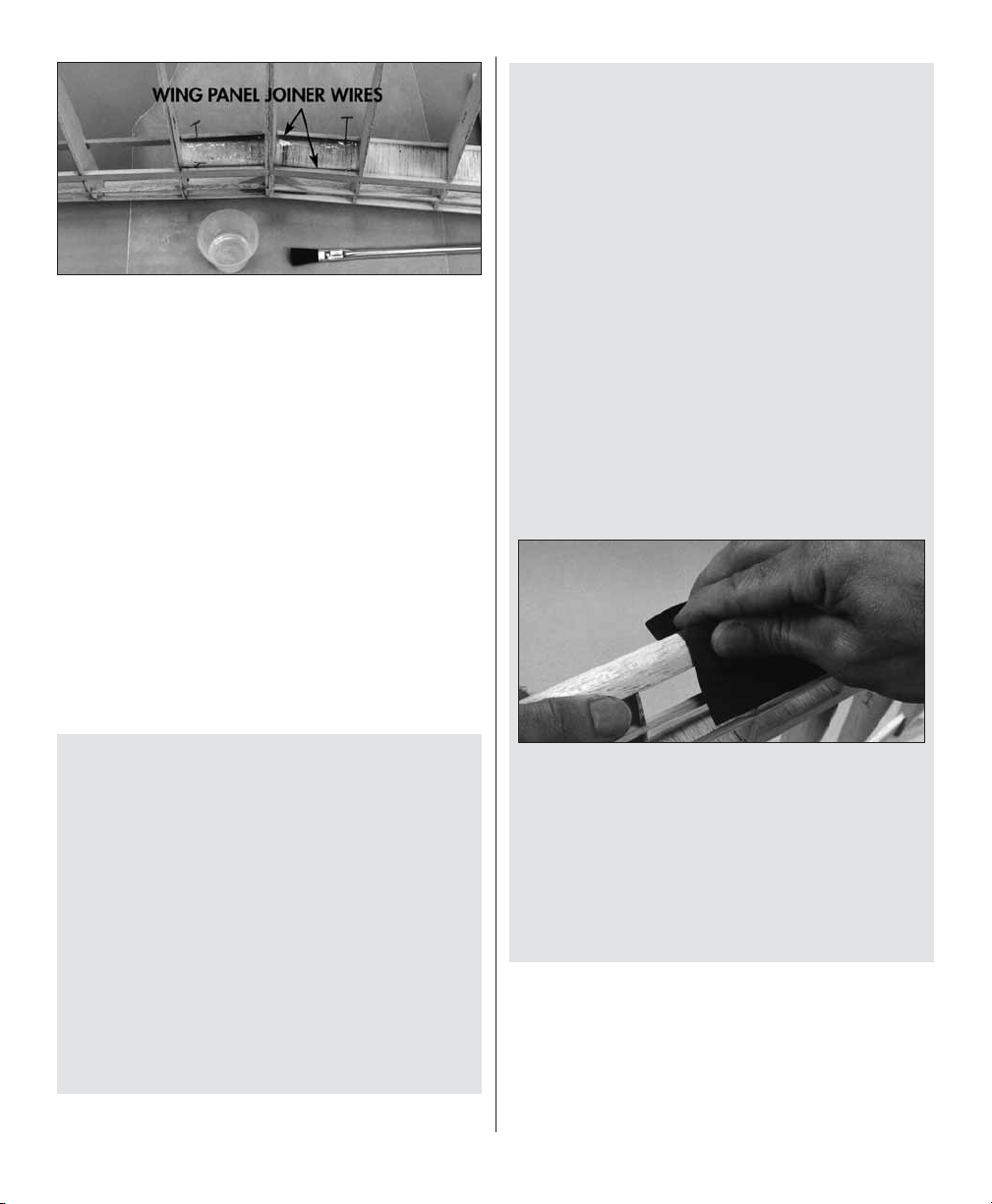

❏ 1. Remove the burrs and chamfer the ends of

the four 1/16" x 5" wing panel joiner wires with

a metal fi le or a powered hand tool and a cut-off

wheel. Remove any oil from the wires left from the

manufacturing process with a cloth dampened with

alcohol or other solvent. Thoroughly roughen the

wires with 150-girt sandpaper so the glue will stick.

❏ ❏ 2. Test fi t the right inner wing panel to the

right outer wing panel. If necessary, use your bar

sander to adjust the ends of the spars, LEs or TEs

for a good fi t.

❏ ❏ 4. Use a hobby knife or a 1/16" drill to make

two holes in both W-4 ribs to accept the wire wing

panel joiners. Bend, then test fi t the joiner wires.

Adjust the bends so the wires accurately match

the “bend” in the wing and fully contact the spars.

❏ ❏ 5. Apply a thin fi lm of epoxy to the W-4 ribs,

then join the two panels with the joiner wires.

Support the tip the same way you did when you

joined the inner panels. Place a sheet of wax paper

under the wing to protect your building board from

excess epoxy, then clamp the W-4 ribs together.

Wipe away excess epoxy before it cures. Do not

apply epoxy to the joiner wires until instructed

to do so.

❏ ❏ 3. With the mating W-4 ribs contacting each

other and the inner wing panel laying fl at on your

building table, rib W-15 of the outer panel should be

approximately 4" off the table. If necessary, adjust

the ends of the spars at the W-4s to achieve the

approximate 4" measurement.

17

Page 18

❏ ❏ 6. After the epoxy has fully cured, carefully

prop the wing up on its leading edge, then apply

30-minute epoxy to the wing joiner wires to securely

glue them to the shear webs and spars. Use T-pins if

necessary to hold the joiner wires against the spars.

Do not disturb the wing until the epoxy cures.

❏ 7. Return to step 2 and join the panels of the

other wing half the same way.

Finish the Wing

❏ 1. Drill a 1/16" hole in the bottom spar of both

wing halves where shown on the plan for the #2 x

3/8" screws to secure the wing halves with rubber

bands. We will instruct you to install the screws

after you cover the wings.

Here are some tips that can make shaping your

LEs a little easier and faster:

A. While you shape the LEs, frequently reference

the cross-section on the plan and the drawings

of the LE gauges on the plan. If you are a

perfectionist, cut the gauges from the plan, then

use rubber cement or spray adhesive to glue

them to leftover 1/8" plywood or thin cardboard

(such as a cereal box). Cut the gauges from the

wood or cardboard you glued them to, then test

fi t the gauges to the appropriate sections of the

wing to arrive at the correct shape.

B. We highly recommend a razor plane to shape

the LEs until they are nearly the shape shown on

the plan – leave enough material to fi nal shape

by sanding.

C. Shape the LEs of the inner panels fi rst since

they have a constant shape from W-1 to W-4.

❏ 2. See the Tip that follows, then shape the LEs

of both wing panels.

Tip: How To Final Shape The LEs

The Butterfly is a motor glider not a high

performance aerobatic model – it’s named the

“Butterfl y” after all! It is not critical that you shape

the leading edges with the greatest precision. You

probably would not notice any difference in the

fl ight performance of a Butterfl y with a leading

edge accurately fi nished by an expert builder and

a Butterfl y with a leading edge roughly carved to

shape with a hobby knife. This isn’t to say that

you should not always strive for building accuracy

and a good fi nish, but don’t worry if your LEs

don’t look perfect. Building a straight fuselage

and fl at, warp-free wings are where you should

concentrate most your building efforts.

D. After you roughly shape the LE’s by carving

(or using the razor plane), fi nal shape the LE’s

with a bar sander and 220-grit sandpaper. Wrap

a piece of 220-grit sandpaper around the LE and

fi nal sand by hand.

E. Once you shape the inner LE’s, use the gauges

to fi nal shape the outer LE’s and blend the two

together where they meet.

❏ 3. Inspect all glue joints of both wing panels. Add

CA to all glue joints that don’t look strong.

❏ 4. Final sand the wings with your bar sander

and 320-grit sandpaper and blend all the ribs with

TE, LE and spars.

18

Page 19

Build the Fuselage

Prepare the Fuse Sides

All the parts used during fuselage construction are

die-cut 1/8" plywood unless otherwise specifi ed.

❏ 1. Carefully remove the forward and aft fusela ge

sides from their die sheets, then remove slivers or

die-cutting irregularities with a bar sander.

❏ 2. Lay the forward fuselage sides on your work

bench opposite each other in a “mirror image.”

Mark the inside of the fuselage sides as the “right

inside” and the “left inside” with a ballpoint pen.

covered with wax paper to make sure the pieces

align. Use a bar sander and 150-grit sandpaper to

sand the two sides so they are fl at and even.

❏ 5. Glue a servo rail support to the inside of both

fuselage sides at the location shown in the photo.

❏ 3. Remove the portion of only the right fuselage

side indicated by the perforated line with a hobby

knife and a straightedge.

❏ 4. Glue the aft fuselage sides to the forward

fuselage sides with medium CA. Work over the plan

❏ 6. Place one of the fuselage sides on a piece of

scrap wood, then drill a 3/16" hole at both punch

marks for the wing dowels. Press down on the

fuselage side to keep the drill from splitting the

wood as it goes through. Repeat for the other

fuselage side.

❏ 7. While you have your drill and bits out, drill an

11/64" hole at the forward landing gear wire punch

mark in the right fuse side and the aft punch mark

in the left fuselage side. If you do not have an 11/64"

drill, you may use a 5/32" drill but you will have to

enlarge the hole slightly with a hobby knife.

❏ 8. Use thin CA to glue the 1/4" x 36" balsa triangle

fuselage reinforcement stringers to the top and

bottom of the inside of both fuselage sides. Be

certain you glue the stringers to the inside

of the fuselage sides. The front of the stringers

should be 1/8" aft of the front edge of the fuselage

sides (for F-5). Make the “splice” in the stringers

as shown on the plan at the rear of the fuselage.

19

Page 20

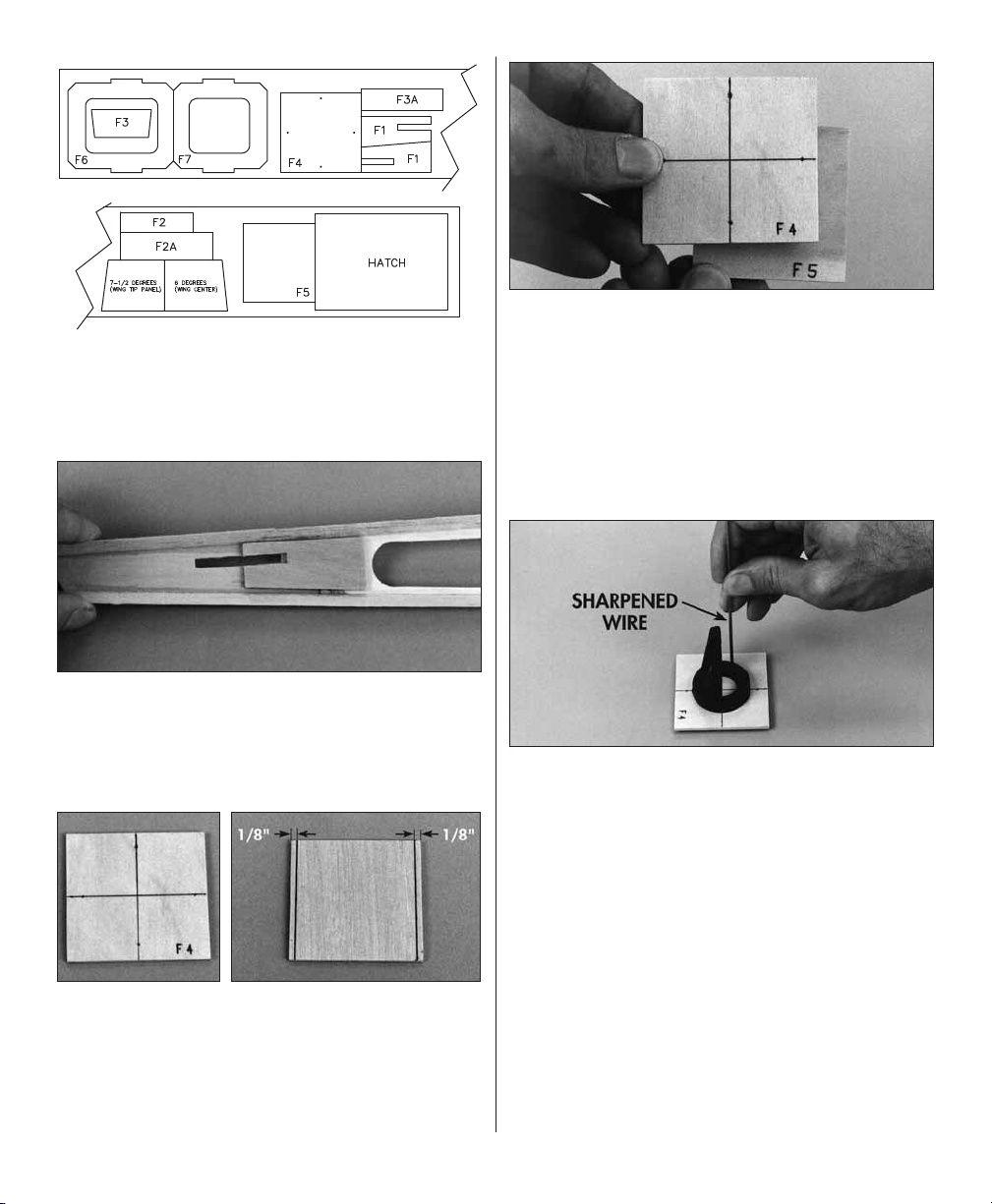

❏ 9. Use the above die drawing of the fuselage parts

to mark each part with a ballpoint pen exactly as

they are shown. This will insure proper orientation

of the formers during construction.

❏ 10. Use medium CA to glue the notched aft

fuse side joiners (F-1) to both fuselage sides so

the front edge of the notches in the joiners are 1/4"

ahead of the front edge of the notches in the fuse

sides as shown in the photo.

❏ 12. Glue F-5 to F-4 with epoxy so the edges of

F-5 align with the lines on the back of F-4 and the

top edges of F-4 and F-5 are even. From now on

this assembly will be referred to as the “fi rewall.”

Make certain that the “F-4” and “F-5” designations

you marked are in the same orientation. If the parts

are slightly warped, clamp them to a fl at table or

board with wax paper between the board and the

parts. Wipe away excess epoxy before it cures.

❏ 13. Center the engine mount (not included) on

the fi rewall so the “rails” align with the horizontal

line. Use a piece of wire sharpened at one end to

mark the location of the engine mount holes on the

fi rewall. Remove the mount and drill 1/8" holes at

the marks to fasten mount with 4-40 x 1/2" machine

screws and 4-40 blind nuts (not included). We used

a Hayes 061 KM-15 engine mount (HAYG1061)

on our prototype.

❏ 11. Use a ballpoint pen and a straightedge to

draw a line connecting the punch marks on the

front of F-4 to indicate the position of your engine

mount. Draw two vertical lines (with the grain of

the wood) on the back of F-4 1/8" from each side

to indicate the position of F-5.

20

Page 21

❏ 14. Insert 4-40 blind nuts into the holes from the

back of the fi rewall, then lightly tap them all the way

in with a hammer. Apply medium CA around the

edges of the blind nuts to permanently secure them.

❏ 15. Drill a 3/16" hole through the punch mark

in the right side of F-6 for the throttle pushrod

guide tube.

Join the Fuselage Sides

down over the top view of the fuselage plan. Make

sure the fuselage sides fully contact your fl at

building table and the formers and sides align

with the plan. Adjust the notches in the left fuse

side if necessary, then use medium CA to glue the

left side to the formers.

❏ 4. Beginning at former F-6, pin the fuselage in

position over the top view of the plan by inserting

T-pins through the triangle fuselage reinforcement

stringers into your building board. Accurately align

the fuselage with the plan as you proceed toward

the rear. Insert all the T-pins so they are all at

the same angle, slanting forward for example, so

you will be able to remove the fuselage from your

building board after you glue the sheeting in position.

Do not insert any T-pins in front of F-6.

❏ 5. Place a piece of wax paper under the front

of the fuselage at the fi rewall. Glue the fi rewall to

the fuse sides with 30-minute epoxy. Immediately

proceed to the next step.

❏ 1. Fit F-6 into the forward notch of the right

fuselage side. Use a small square or a 90-degree

triangle to hold F-6 perpendicular and use

medium CA to securely glue it in position. The

“F-6” designation must face forward.

❏ 2. Glue F-7 to the right fuse side the same way

as F-6.

❏ 3. Test fi t the left fuselage side to the assembly.

Position the temporarily joined fuse sides upside-

❏ 6. Before the epoxy cures, pin the front of the

fuselage to the plan the same way you did the rear

of the fuselage. The fi rewall should align with the

dashed line which represents the position of the

fi rewall on the plan when the fuselage is upside-

down. Use masking tape to hold the fuse sides

together until the epoxy cures.

❏ 7. Use medium or thick CA to glue a piece of

triangle stock to both corners where the fi rewall

meets the fuselage sides.

21

Page 22

Sheet the Fuse Bottom

❏ 1. Mark the location of the landing gear rails on

the bottom edges of the fuse sides and the triangle

fuse side stringers as shown in the photo. Remove

the portion of triangle stringers on both fuselage

sides between the lines you marked.

❏ 6. Remove as many T-pins as possible, then

carefully lift the fuselage off your building board

and remove the remaining T-pins.

❏ 7. Sand the ply and balsa fuselage bottom even

with the fuse sides.

❏ 8. Use a metal fi le or a powered hand tool with

a cut-off wheel to remove any burrs and chamfer

the ends of both 5/32" landing gear wires.

❏ 9. Fit one of the landing gear wires through the

hole in the right fuselage side and hold it in position

as shown on the plan. Position the landing gear

wire as accurately as you can so it has the same

amount of forward “rake” as shown on the plan.

Place the

right fuselage side next to the wire as shown on

the plan. Use thin CA to glue the aft landing gear

bearing to the fuselage side.

aft landing gear bearing

inside the

❏ 2. Position the landing gear rails between the

fuselage sides and align them with the landing gear

holes as shown on the plan. Glue the landing gear

rails in position with medium CA.

❏ 3. Sand the bottom of the fuselage with your

bar sander and 150-grit sandpaper so the formers,

triangle side stringers and the landing gear rails

are even.

❏ 4. Bevel the one end of the 1/16" x 3" x 12"

plywood forwar d fuselage bottom so it matches

the right thrust angle of the fi rewall, then glue it to

the bottom of the fuselage with medium or thick CA.

❏ 5. Cut the cross-grain bottom fuselage sheeting

from the 1/16" x 2" x 36" balsa sheet, then glue the

individual planks in position with medium CA. Use

your builders triangle to keep the fuselage sides

perpendicular as you proceed.

❏ 10. Position the f orwar d landing gear bearing

on the right fuselage side next to the landing gear

wire and glue it in position with thin CA.

❏ 11. Insert the other landing gear wire in the

fuselage and position it so it matches the angle

of the left wire. Glue the forward and aft landing

gear bearings to the left fuselage side the same

way you did for the right side.

❏ 12. Remove the landing gear wires. You will

permanently install the landing gear after you cover

the model.

Finish the Fuselage

❏ 1. Use the remaining balsa triangle stock to

reinforce formers F-6 and F-7 where shown on

the plan.

22

Page 23

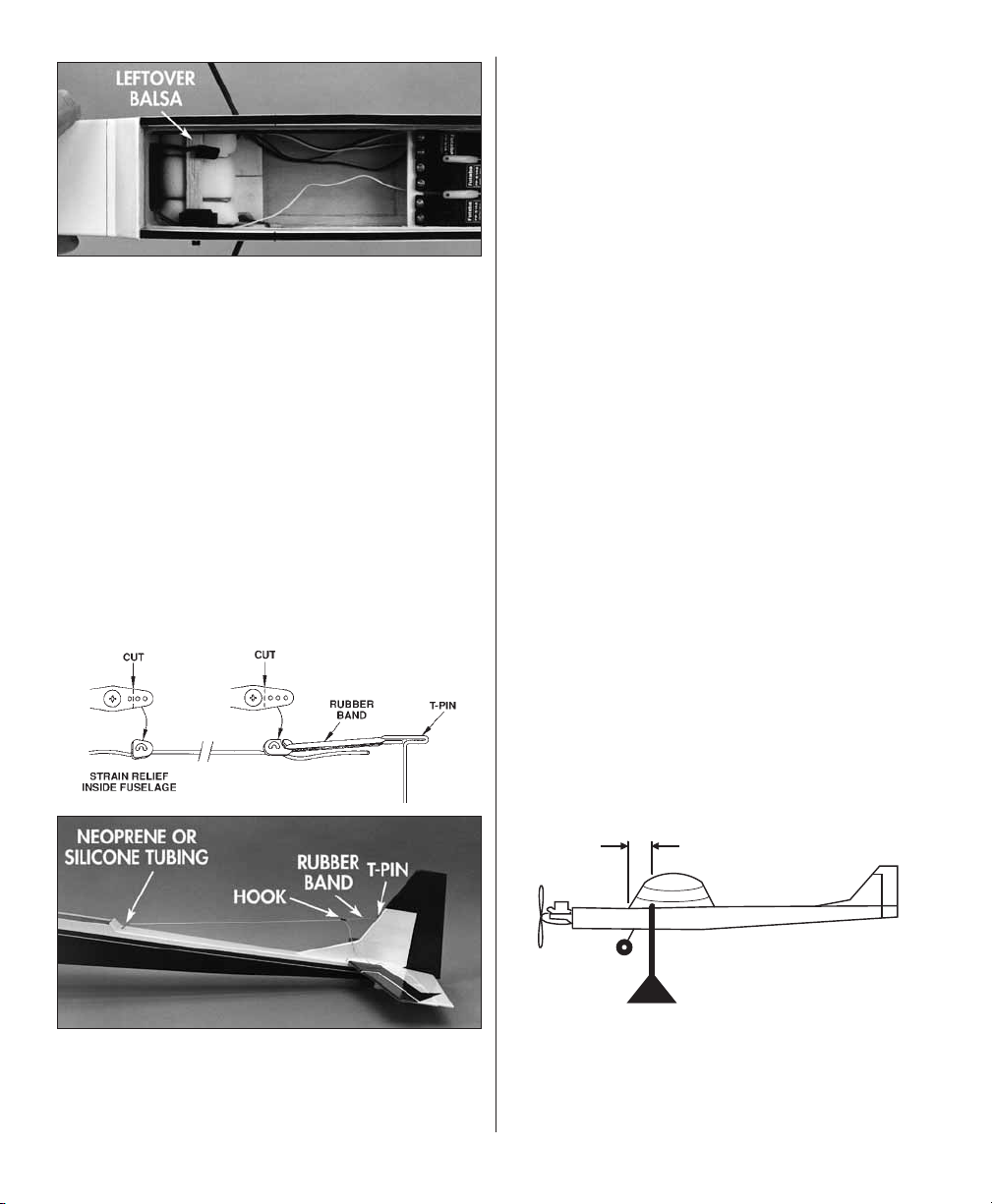

❏ 2. Cut two 36" outer pushrod guide tubes to a

length of 24". Use 150-grit sandpaper to carefully

(so you do not snap them in two) roughen the

outside of the tubes so glue will stick to them. Save

the remaining 12" from one of the tubes for the

throttle pushrod guide tube.

❏ 3. Use a small, round wood fi le or a hobby knife

to bevel the aft edge of the slot in both fuselage

sides for the pushrod guide tubes.

Forward

❏ 5. Position the guide tubes so approximately 1/2"

protrudes from the slots at the rear of the fuselage.

Use medium CA to glue only the aft support in

position but do not glue the tubes to the support

and do not glue the front support in position until

instructed to do so.

❏ 6. Glue the pushrod guide tubes in the slots in the

rear of the fuselage with thin CA, then fi ll the slots

with HobbyLite fi ller or glue the tubes in the slots

with epoxy and microballoons. If you’ve never heard

of microballoons, it’s a powder made of microscopic

glass “balloons” that you mix with epoxy to use as

a fi ller or adhesive. The microballoons and epoxy

mixture is harder to sand than regular fi ller so it

is used only where structural strength is required.

Aft

❏ 4. Make a forwar d and aft pushr od guide tube

support as shown in the sketch from leftover 1/4"

x 3/8" balsa. Position the aft support as shown in

the photo and position the forward support in front

of F-7. Insert the pushrod guide tubes.

❏ 7. Sand the fi ller and pushrod tubes with your

bar sander and 150-grit sandpaper so they are

fl ush with the fuselage sides.

❏ 8. Glue the pushrod tubes to only the aft support.

❏ 9. Use your bar sander to sand the tops of the

fuse sides so the formers, the triangle side stringers

and the fuse sides are all even.

❏ 10. Position the stab on the fuselage so the

trailing edge is 1" aft of the end of the fuse (as

shown on the plan). Use a ballpoint pen to mark

the location of the stab leading edge on the top of

the fuse sides and triangle stringers.

23

Page 24

❏ 11. Cut the cross-grain aft top fuselage

sheeting from the 1/16" x 2" x 24" balsa sheet

and the remainder of the 1/16" balsa sheet you

used for the bottom of the fuse. Position and glue

(with medium CA) the individual planks between

F-7 and the marks you just made.

❏ 12. Trim, then sand the sides of the top sheeting

so it is even with the fuse sides. Sand the top

sheeting so it is fl at, even and smooth.

❏ 13. Make the cabin sides from the 1/4" x 1/2"

balsa sticks, then glue them to the top of the fuse

sides in the location shown on the plan.

❏ 14. Mount the engine mount to the fi rewall

with 4-40 x 1/2" machine screws and blind nuts

(not included).

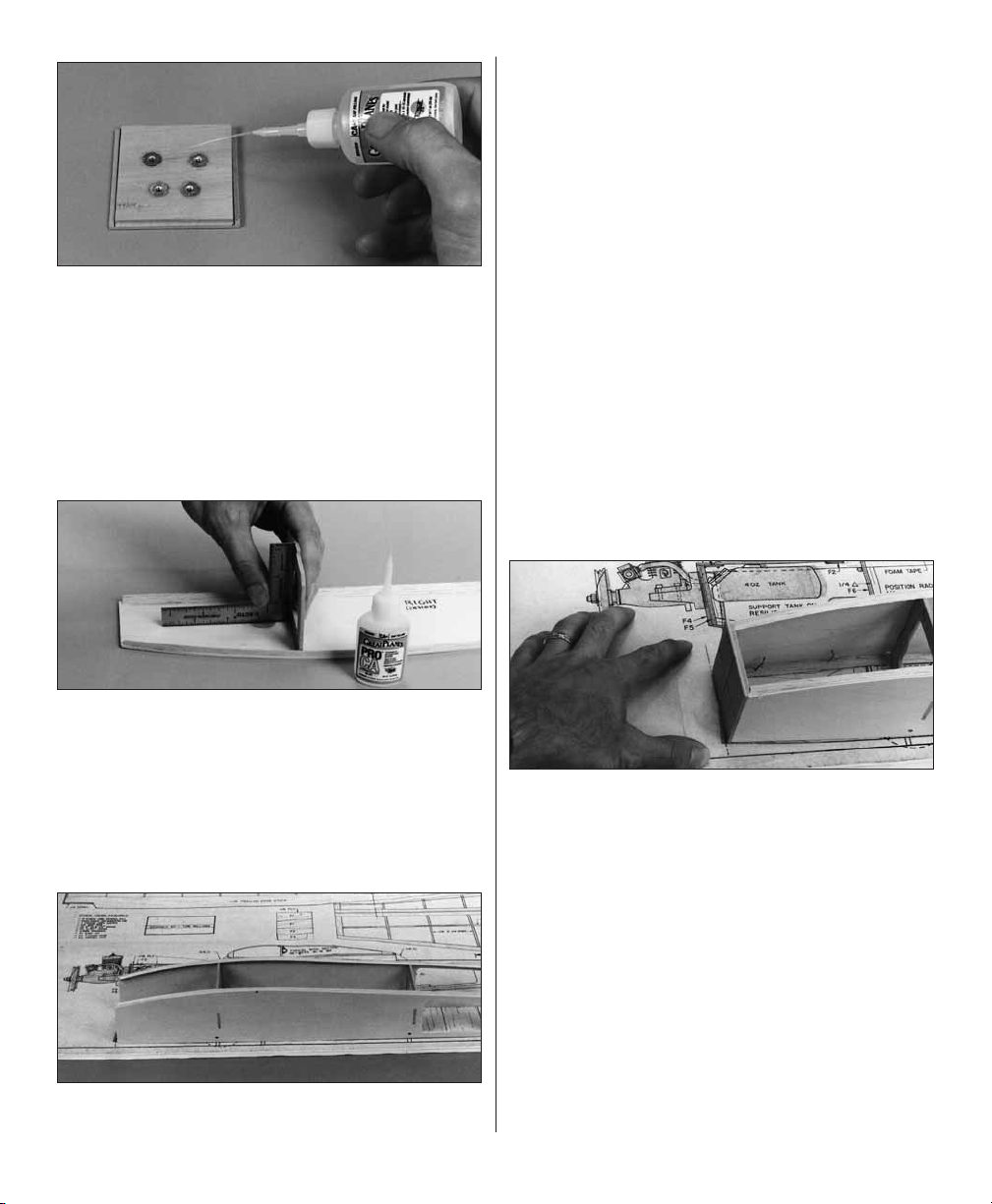

❏ 16. See the information about fuel tanks that

follows, then test fi t a 4 oz. fuel tank in the fuselage.

You may support the tank with layers of foam (“R/C

foam” used to protect receivers and batteries and

cushion fuel tanks) or build fuel tank supports

from leftover 1/8" plywood. Place one layer of 1/4"

foam between the tank and the tank fl oor.

A Crash Course In Fuel Tanks

A. In order f or an engine to draw fuel from the

tank, three things are important:

1. The pick-up line inside the tank must be cut

to a length so it is as long as possible, yet does

not allow the “clunk” (the weight at the end of the

line) to contact the rear of the tank. If the clunk is

able to touch the rear of the tank, it may become

stuck in a position that is above the fuel level,

thus preventing fuel fl ow to the engine.

❏ 15. Position your engine on the engine mount and

mark the location of the engine mounting holes. Drill

3/32" holes in the mount, then secure the engine

to the mount with #4 x 1/2" screws (not included).

2. Position the fuel tank so its centerline is

as close as possible to the same level as the

carburetor. This way, fuel fl ow will be nearly

consistent no matter if the tank is full or almost

empty.

3. Avoid kinks and sharp bends in the fuel line.

Position the tank inside the tank compartment

and drill the fuel line passage holes in the fi rewall

to allow the lines to exit without sharp bends. If

necessary, loop the fuel tubing inside the tank

compartment before it enters the fi rewall.

24

Page 25

B. Generally, all sport models require only two

fuel lines: one that goes to the top of the tank

for pressure or a vent and another for fuel pickup. Some models use a third line for a fuel fi ller

valve but this is not required on your Butterfl y. To

fi ll the tank, simply disconnect the pick-up line

from the carburetor and fi ll through it. When the

tank is full fuel will fl ow through the vent line that

is connected to your muffl er (disconnect the line

from the muffl er while fueling).

C. The line that comes from the top of the tank

and is connected to the muffl er is the vent or

“pressure” line. Exhaust pressure from the

muffl er pressurizes the fuel tank for reliable

fuel fl ow. Should the pressure line ever become

disconnected, You will notice that the engine will

run lean due to the decrease in pressure which

causes less fuel fl ow (by the way, “lean” means

not enough fuel and “rich” means too much fuel).

D. Frequently inspect your fuel lines for small

holes and replace them annually. Undetected

holes in fuel lines cause air or fuel leaks and

can cause a variety of engine running or starting

problems.

❏ 19. Temporarily install the 12" pushrod tube

(you saved from the remainder of the elevator and

rudder guide tubes) in the fuselage through the

fi rewall, past the fuel tank and through the hole

you previously drilled in F-6.

❏ 20. Remove the fuel tank, engine and fuel lines.

Glue the forward fuselage tops F-3A and F-2A

in position with medium CA. Glue the forward

hatch tab F-3 to the bottom of F-3A. (See photo

at step 23.)

❏ 21. Cut or sand a bevel to one end of the hatch

so it fi ts between F-3A and F-2A.

❏ 22. Glue the aft hatch tab to the hatch with

medium CA, then position the hatch and drill two

1/16" holes through the hatch and the forward

hatch tab.

❏ 17. Position the fuel tank in the fuselage, then

drill 1/4" holes (or 15/64" for precision) in the fi rewall

for the fuel lines. Plan carefully where you drill the

holes so the engine mount will not interfere with

the fuel lines. Temporarily connect the fuel lines

to make sure the holes are in the proper location.

❏ 18. Drill a 3/16" hole in the fi rewall for the throttle

pushrod guide tube.

❏ 23. Remove the hatch, then enlarge the holes

in the hatch only with a 3/32" drill. Fasten the

hatch to the fuselage with two #2 x 3/8" screws,

then sand the sides of the hatch so they are even

with the fuselage.

25

Page 26

❏ 24. Make the front and rear “windows” from the

3/4" x 6-1/4" balsa triangle stock. Glue the windows

in the position shown on the plan, then sand the

sides of the windows so they are even with the

fuse and cabin sides.

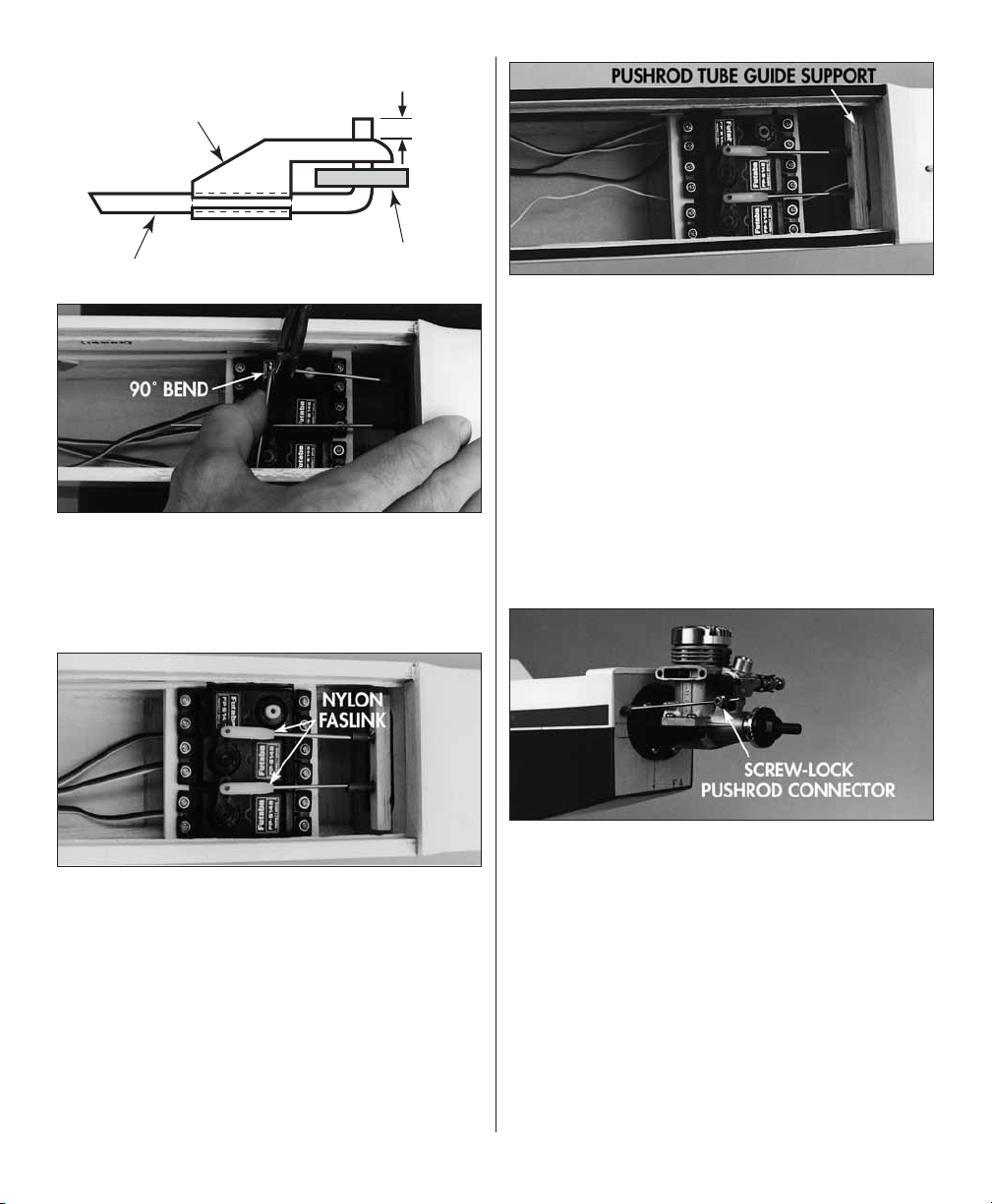

photo (not on the plan). The one-arm servo horns

shown in the photo are cut from six-arm servo

horns. The throttle servo arm has been shortened

by “cutting off the outer hole.” Drill 1/16" holes in

the servo rails, then mount the servos to the rails

with the screws included with your servos.

❏ 5. Optional: Drill or cut a hole in the back of

the fuselage and install a pushrod guide tube (not

included) to serve as an antenna guide. The front

of the tube should extend approximately 1" in front

of the servos. Glue the tube to the formers and the

aft 1/16" sheeting, then sand the end of the tube

so it is fl ush with the 1/16" sheeting.

❏ 25. Use leftover 1/16" balsa sheet to cover the

back of the fuselage.

Install the Servos

❏ 1. Cut two 2-1/2" sticks from the remaining 1/4"

x 3/8" balsa stick. Glue the sticks (centered) to the

ply servo rails.

❏ 2. Test fi t the servo rails and your servos on the

servo rail supports in the fuselage.

❏ 3. Position the rails so they support the servos

but allow enough space so you can remove the

servos when necessary. Glue the rails to the fuse

sides and the rail supports with medium CA.

Align the Stab and Fin

Align the Stab

❏ 1. Temporarily fasten the stabilizer to the fuselage

with T-pins. Use clothespins or clamps to hold a

long straightedge on the wing saddle portion of

the fuselage (the tops of the cabin sides). Stand

behind the airplane and view the stab and the

straightedge. If necessary, remove the stab and

use your bar sander and 150-grit sandpaper to

sand the top edges of the fuse sides so the stab

will lie fl at and parallel with the straightedge.

❏ 4. Install servo arms onto your servos, then

position the servos on the rails as shown in the

❏ 2. Accurately mark the center the top of the stab,

then use a square or a 90-degree triangle to mark

a centerline that extends from the leading edge to

the trailing edge.

26

Page 27

❏ 3. Accurately mark the center of the fuselage

top where the LE of the stab contacts the top

sheeting. Position the stab on the fuselage and

align the centerline you marked on the stab with

the mark on the fuse top. Pin only the LE of the

stab to the fuse.

❏ 4. Insert a T-pin

into the center

of the top of the

fuselage just behind

the firewall (use

the vertical line

you marked on the

center of the fi rewall as a reference).

❏ 5. Fold a piece of masking tape around a 36"

long piece of string, then mark an arrow on the

tape with a felt-tip pen. Tie the other end of the

string around the T-pin you inserted in the front of

the fuselage in the previous step. Slide the tape

along the string and adjust the stab until the arrow

aligns with both stab tips as shown in the bottom

photo. Pin the rear of the stab to the fuselage.

stab. This line indicates where you should apply

the covering “up to” and apply glue when it is time

to glue the stab to the fuse.

Align the Fin

❏ 1. Accurately mark the center of the fuselage

top near the rear “window.”

❏ 2. Use a straightedge to lightly draw a line

connecting the centerlines of the fuse top.

❏ 3. Position the fi n on the centerline of the stab,

then pin it in position. Placed wax paper on the aft

fuse top in front of the stab where the dorsal fi n

will be located.

❏ 6. Carefully turn the fuselage over and mark the

outline of the fuselage sides on the bottom of the

❏ 4. Make the two pieces of the dorsal fi n from

remaining 1/4" x 1/4" balsa, then glue them only

to the fi n with medium CA.

27

Page 28

❏ 5. Remove the wax paper, then lightly mark the

outline of the fi n on the fuse top and the stab with

a ballpoint pen.

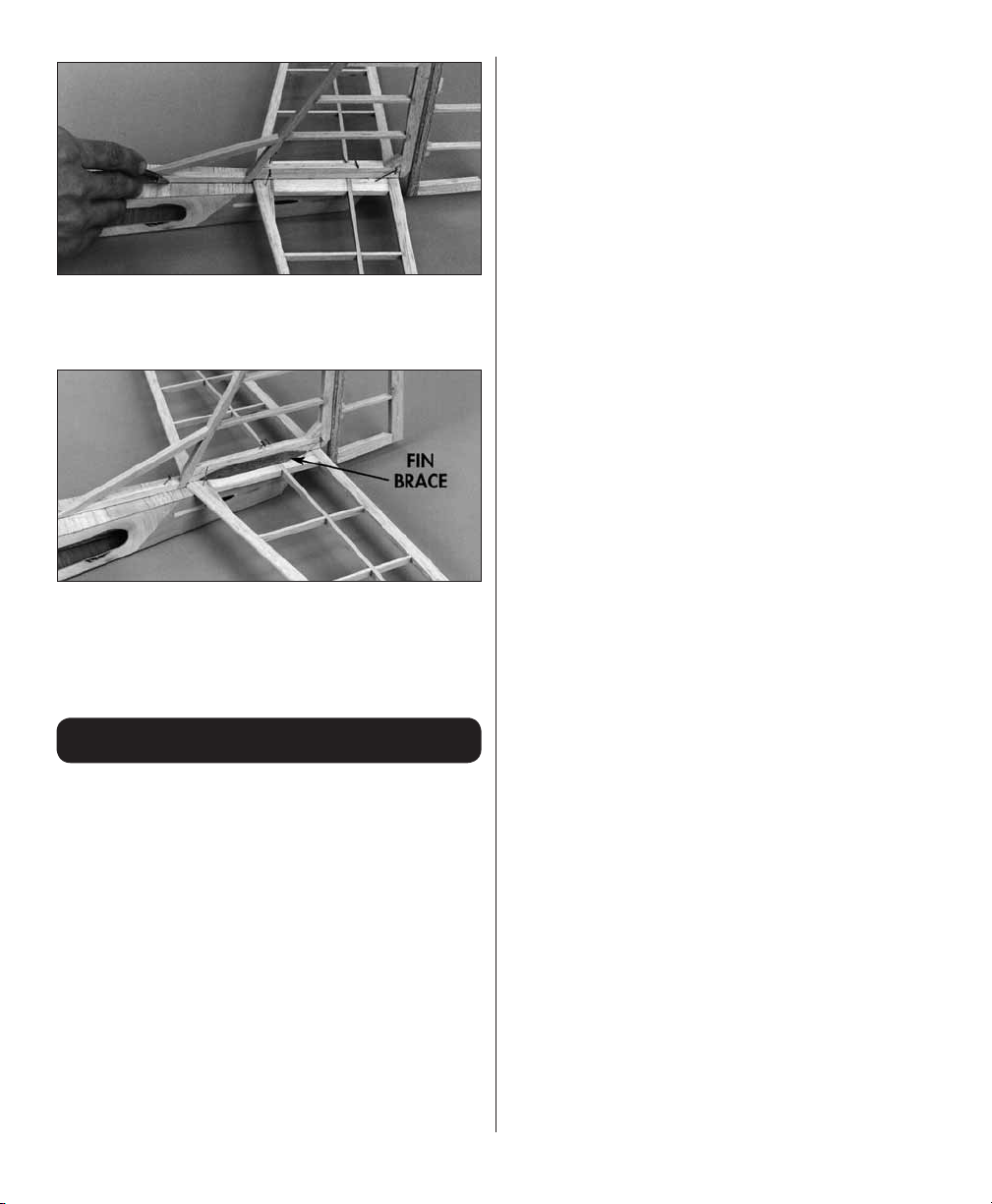

❏ 6. Make the fi n braces from the remaining 1/4"

balsa triangle stock. Make the braces 4" to 4-1/2"

long and bevel the ends. Position the braces on

the stab and trace their outlines on the fi n and stab

with a ballpoint pen.

Covering

Prepare for Covering

❏ 1. Inspect the entire model for glue joints that

don’t look strong and reinforce them with medium

or thin CA.

❏ 2. Remove the fi n (with the dorsal fi n) and stab

from the fuse. Final-sand the tail surfaces with

320-grit sandpaper being careful not to break any

of the tail ribs or “thin” the balsa too much in any

one area.

❏ 3. Slightly round the top and bottom corners of

the fuselage and the triangle stock “windows” with

your bar sander and 220-grit sandpaper. Sand the

fuselage so it is smooth and even. Fill all dents,

scratches and imperfect glue joints that may show

through the covering with HobbyLite fi ller.

❏ 4. Use medium CA to glue the die-cut 1/8"

plywood tail skid and balsa triangle reinforcements

to the bottom of the fuselage or glue the skid in

position after you cover the fuselage.

❏ 5. Test fi t the wing in the fuselage and adjust the

front and rear “windows” if necessary so the wing

will fi t between them.

Covering Sequence

Read the Covering Tips fi rst, then cover your

Butterfl y in this order:

Tail Surfaces:

1. Stab bottom right, then left

2. Stab top right, then left

3. Elevator ends

4. Elevator bottoms, then tops

5. Fin ends

6. Fin right, then left

7. Rudder right, then left

8. Triangular fi n reinforcements

Fuselage:

1. Bottom

2. One side, then the other

3. Top

4. “Windows”

5. Fuel tank hatch

6. Firewall

Wings:

1. Root (center) ends

2. Tips

3. Bottom inner panel

4. Bottom outer panel

5. Top inner panel

6. Top outer panel

Covering Tips

If this is the fi rst time you have covered a

model refrain from attempting a complicated

trim scheme. Add stripes, graphics and various

designs to your Butterfl y cut from different colors

of MonoKote fi lm, then iron them directly over the

28

Page 29

base color. Try just a single color base (usually a

lighter color such as white or yellow) with perhaps

a single stripe, your AMA number or some stick-on

graphics. A simple trim scheme will get you in the air

faster and look much better (not to mention give you

fewer headaches) than a model that was diffi cult

to cover because of a complicated trim scheme.

We will use the stabilizer as an example because

all of the techniques shown apply to the rest of

the Butterfl y too.

❏ 1. Here is a “rule of thumb” to keep in mind before

you begin: Wherever possible, apply the covering

so all seams face downward or rearward. This can

be done if you cover the bottom (of the wing, fuse,

stab, etc.) fi rst.

Start ironing at

Lines marked at

edges of fuse

the line and

work outward

Never cut the covering after you ir on it to the

wood except near the tips. Modelers who do

this may weaken the structure which could cause

it to fail during fl ight.

❏ 3. Use a straightedge to accurately trim the

covering near the LE and TE, but leave a little

“handle” around the corner and the tip so you can

pull the wrinkles out of the covering and stretch it

around the tip and corner as you heat it.

Stabilizer

Film

Cover only

to the lines

❏ 2. Cut the covering for one half of the bottom of

the stab so it is approximately 1" oversize. Use a

straightedge to cut the end that aligns with the lines

you drew indicating the fuselage. Use a Top Flite

MonoKote Iron with a Hot Sock to securely bond

the covering to the perimeter (LE, TE, tip, middle)

of the stab but do not fully shrink the covering at

this time.

Covering

❏ 4. Seal the front and rear of the covering to the

LE and TE, then heat the covering as you pull and

stretch it around the tip. It takes a little practice to

get all the wrinkles out so don’t be discouraged if

it doesn’t look perfect on your fi rst attempt (or the

second or third time). You can reheat and stretch the

covering many times. It helps to place the stab on

your workbench so the tip is over the edge. Place

a weight on top of the stab to hold it down. This

will allow you to pull the covering with one hand

and hold the iron in your other hand.

29

Page 30

❏ 5. Cut the excess covering from the tip with a

single-edge razor blade or a sharp hobby knife.

❏ 6. Cover the other side of the bottom of the stab

the same way.

the fi n reinforcement onto the covering, then take

the covering off the stab and cut out that portion

of the covering. This will allow you to glue the fi n

reinforcements directly to the bare wood and avoid

cutting the covering directly on the wood after

you iron it down. You can clean residual ink from the

covering with a cloth dampened with rubbing alcohol.

❏ 8. Iron the piece of covering you just “custom

cut” to the top of the stab, then cover the other

side the same way.

❏ 7. Temporarily position the top stab covering

and the triangle fi n reinforcement on the top of

the stab. Use a felt-tip pen to trace the outline of

❏ 9. Completely shrink the covering on the top

and bottom and thoroughly bond all the edges to

the frame.

❏ 10. Cover the triangle fi n reinforcements, then

trim the excess so it “overhangs” by approximately

3/32". This way all you have to do is glue them to

the fi n and stab and seal the edges with the iron.

30

Page 31

Join the Tail Surfaces

Join the Stab, Fin and Fuse

❏ 1. Apply a fi lm of 30-minute epoxy to the stab

and fuselage where they contact each other,

then position the stab on the fuselage. Use the

techniques described earlier (in Align The Stab)

to confi rm that the stab is aligned with the fuselage,

then use T-pins, weights or clamps to hold the stab

to the fuse until the epoxy fully cures. Use a cloth

dampened with alcohol to wipe away excess epoxy

before it cures.

❏ 2. Glue the fi n to the stab and fuse. Use a

90-degree triangle or a square to hold the fi n

perpendicular, then hold it in position with T-pins or

masking tape until the glue fully cures. If you require

a little working time to align the fi n use 30-minute

epoxy. Otherwise you may use 6-minute epoxy.

❏ 11. Use the methods described previously to

cover the rest of the model in the correct covering

sequence.

❏ 3. Test fi t the fi n reinforcements to the fi n and

stab. Take the reinforcements off the model, then

apply a bead of thick or medium CA to both “sides”

of one of the reinforcements. Immediately place the

fi n reinforcement on the fi n and stab and securely

hold it in position until the CA cures. Glue the other

reinforcement in position the same way.

31

Page 32

❏ 4. Use a MonoKote Iron or a Trim Seal Tool to

seal the perimeter of the reinforcements onto the

fi n and stab.

❏ 5. If necessary, cut 1/4" strips of MonoKote fi lm

and use your Trim Seal Tool to iron the strips in the

“corners” where the bottom of the stab meets the

fuse and the dorsal fi n meets the top of the fuse.

Hinge the Control Surfaces

IMPORTANT: Make sure you join the elevator

to the stab before you join the rudder to the fi n.

Cut the covering away from the slot

❏ 1. Use your hobby knife and a sharp #11 blade

to remove a small strip of covering from the hinge

slots to expose them.

The CA wicks along

the “tunnels” to the

entire hinge surface.

❏ 2. Drill a 3/32" hole in the center of all the hinge

slots to allow the CA to fully penetrate. This is best

done with a high-speed tool such as a powered

hand tool. If you use a drill, remove slivers of balsa

wood from the hinge slots with a hobby knife after

you drill the holes.

Temporary pin

to keep hinge

centered

❏ 3. Join the elevator to the stab with the hinges.

The horn plate of the stab (where the control

horn is fastened) should be on the right side. If the

hinges will not stay centered, insert a pin through

the center of the hinge, then join the surfaces and

remove the pins.

❏ 4. Confi rm that the ends of the elevator align with

the ends of the stab, that the hinges are centered

and there is approximately a 1/32" gap between the

TE of the stab and the LE of the elevator. A small

gap is desirable so you do not inadvertently glue

the elevator to the stab with residual CA.

❏ 5. Carefully apply 6 drops of thin CA to each

side of all the hinges. Keep a tissue handy to wipe

away excess CA. If you spill a few drops of CA

on the MonoKote fi lm you can use CA Debonder

(GPMR6039) to remove it. Or, wait until the CA

fully cures, then carefully lift it off with a hobby

knife blade.

Do not use accelerator on any of the hinges. Do

not glue the hinges with anything other than

thin CA and do not attempt to glue one half of

the hinge at a time with medium or thick CA.

They will not be secure and the controls could

separate while the model is fl ying.

❏ 6. Let the CA fully cure, then fl ex the elevator