Page 1

PARTS LIST

❏ 1 Instruction sheet

❏ 1 Instrument panel

❏ 1 Instrument panel lens

❏ 1 Seat back

❏ 1 Seat bottom

❏ 1 Luggage tank top

❏ 1 Luggage tank bottom

❏ 2 Luggage tank joiner

❏ 1 Elastic seat belts

❏ 1 Fiberglass tape

❏ 1 Small parts bag: bomb release wire, bomb release

mechanism,

dowels, pins, 2- #2 x 3/8" screws, 4- #4 x 5/8" screws

TOOLS AND SUPPLIES

❏Thin CA (Great Planes

®

Pro™recommended)

❏ 6-Minute epoxy

❏ Canopy glue

❏ Hobby knife and #11 blades

❏ Plastic filler putty or Bondo

®

❏ 80, 220 and 400-grit wet/dry sandpaper

❏ Selection of small paint brushes

❏ Model enamel paint – (Testors enamel recommended)

❏ Needle nose pliers

❏ Wood stain

❏ Gloss varnish or polyurethane

❏ Clear silicone adhesive

❏ 1. Follow the embossed “cut lines” on each part with a shar p

hobby knife to score the plastic. Gently flex the plastic along the

score to break the scrap from around the edges. Sand each par t

with progressively finer grades of sandpaper to smooth the edges.

Finish the part off by wet sanding the entire exposed surface with

400-grit paper to give the plastic a “tooth”for better paint adhesion.

❏ 2. Use thin CA to glue the seat back to the top surface of the

seat bottom, flush with the rear edge.

❏3. Using sketch #1 as a template, bend the wire to create a “U”

shape as shown in the above image.The center section is 1/4"

wide.

❏ 4. Using sketch #2 as a template, bend the legs in opposite

directions

as shown in the above image.The center section has a

height of 1/4"

.

❏ 5. Cut out the marked hole on the luggage tank top. Roughen

the inside of the tank for about a 2" area around the holes with 80-

grit sandpaper.Glue the wire to the inside of the tank with thin CA.

Use 6-minute epoxy to glue the furnished strip of fiberglass cloth

over the clip to reinforce the joint.

]

SCALE COCKPIT KIT – ASSEMBLY INSTRUCTIONS

Congratulations for being one of those modelers who takes pride in

flying a truly finished model; inside and out! The little bit of extra effort

required to assemble and install this accessory kit will be rewarded by

your personal satisfaction and the applause of your buddies. We have

provided the basic ingredients – you provide the imagination to finish

the details to your liking.All it takes is a couple of evenings and you will

have an even better looking model. Have fun and try to be gracious

when accepting the compliments at the field!

Copyright © 2001

Printed in USA – FBCKP01 V1.1

™

88884444"""" FFFFuuuunnnn SS

SSccccaaaalllleeee FFFFllllyyyy

BB

BBaaaabbbbyyyy

Sketch #1

/4" [6.35mm

Sketch #2

1/4" [6.35mm]

Page 2

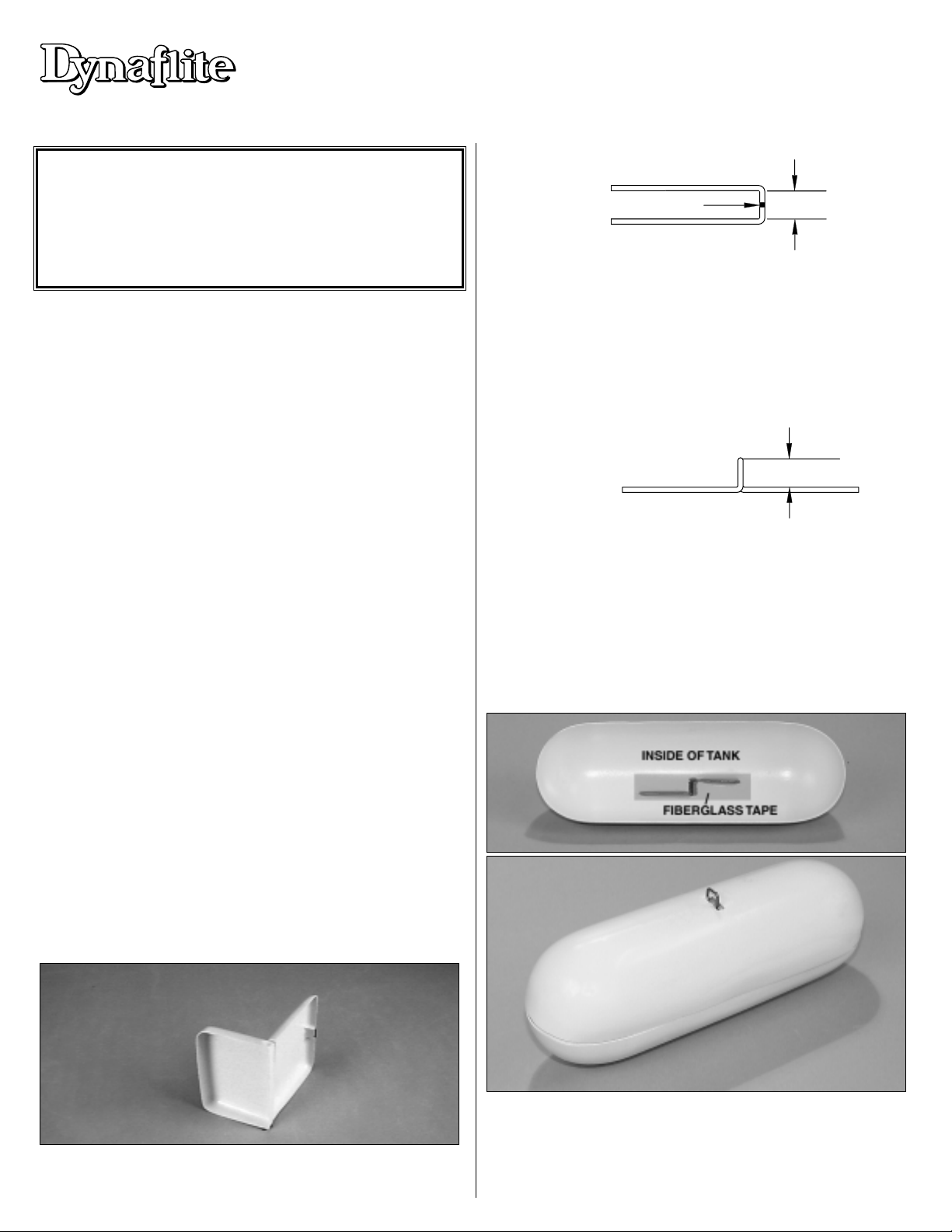

❏ 6. Tr im the 3/8" x 10" strips of plastic to fit around the inside of

the bottom half of the luggage tank. Center the strips on the inside

edge of the tank bottom to form a flange and glue them in position

with thin CA.

❏ 7. Glue the top of the tank to the bottom by “wicking” thin CA

around the joint between the two halves.Fill any gaps around the

seam with plastic filler putty or Bondo.Sand the seam smooth with

progressively finer grades of sandpaper ending by wet sanding

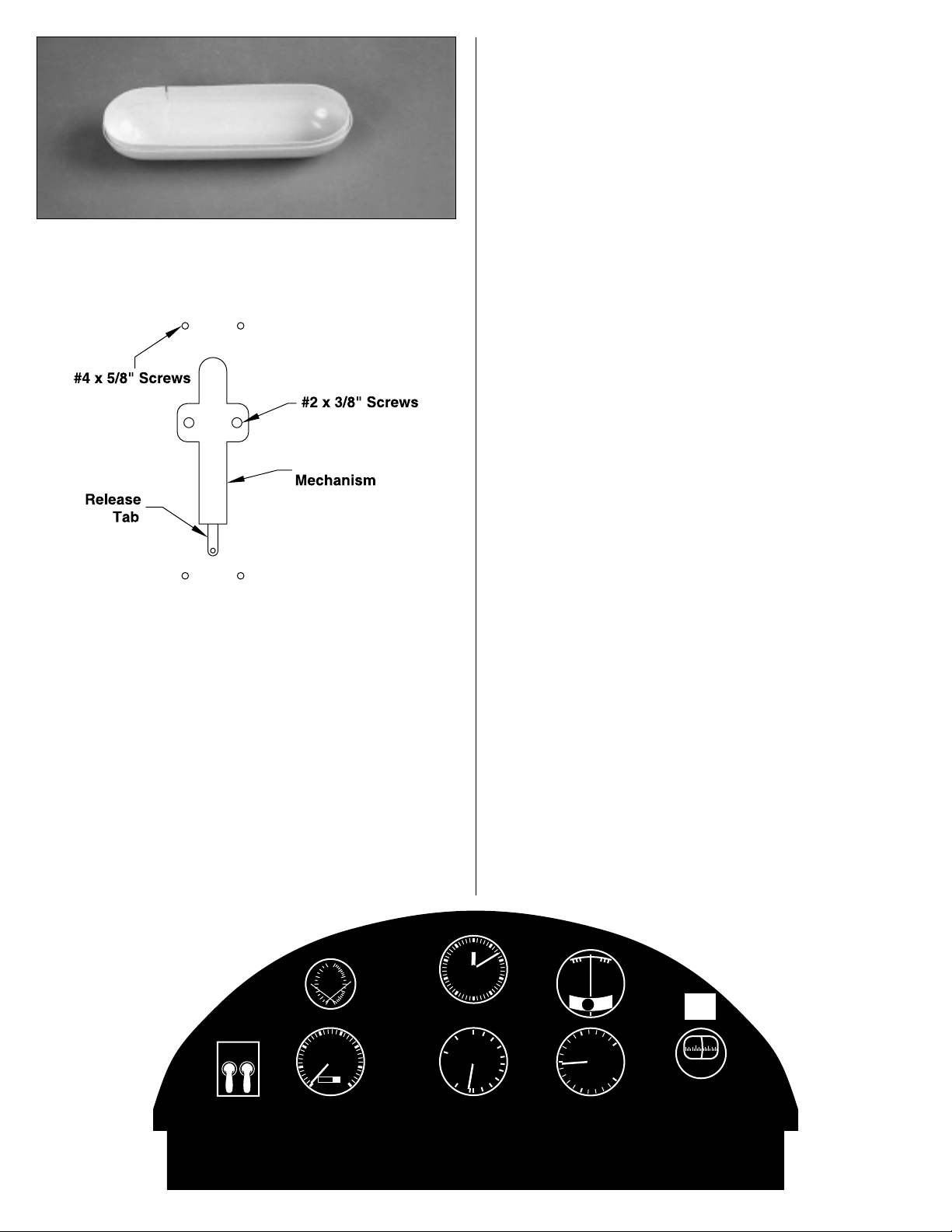

with 400-grit. Screw the tank mount to the centerline of the wing

with two #2 x 3/8" screws, approximately centered over the spar

(use the template above to properly install the luggage tank).

Use

the #4 x 5/8" screws to hold the luggage tank in position.

❏ 8. Paint the seat and luggage tank to your liking. If you will fly

with the luggage tank attached, be sure to use fuelproof paint to

protect the finish from exhaust oil. Cut the elastic seat belts to fit

your pilot figure. Glue them to the seat back notch and the seat

bottom with CA.

❏ 9. Apply a 1/4" bead of clear Silicone adhesive to the inside

edges of the seat bottom.Install the seat in the cockpit and hold or

weight it in position. The Silicone will flow down onto the floor

inside the seat and secure it in place. Carefully apply a few drops

of thin CA to the seat back edges, allowing the CA to “wic k”around

the joint between the seat and the aft cockpit bulkhead. Hold it in

position until the CA cures.

❏10. Before you add the instruments and clear Butyrate, sand the

laser-cut instrument panel smooth with 400-grit sandpaper. Apply

a wood stain to bring out the color of the grain. Finish the

instrument panel with Varnish or Polyurethane for a high gloss.

❏ 11. Trace the outline of the instrument panel onto the clear

plastic sheet with a sharp hobby knife, to score the plastic.Flex the

plastic to break away the e xcess material.Sand the edges smooth.

Glue the clear plastic to the back of the instrument panel with

“canopy glue” or epoxy. Note: The plastic will stick better if the

contact surface is lightly sanded, Be careful NOT to scratch the

exposed “lens” areas.

❏ 12. Cut the paper instruments to fit the back of the instrument

panel (IP). Glue them to the clear plastic with Canopy glue.

❏ 13. Cut and glue a piece of scrap balsa to the back of the

instrument panel assembly. Use pliers to push the control knobs

(pins) through the front of the panel. Apply a spot of CA on the

back of the IP to secure them in position.Add other surface details

as desired. Attach the instrument panel to the model with Silicone

adhesive.

❏ 14. Paint the dowel “control-stick” with aluminum enamel. After

the paint has dried, wrap one end with a few layers of electricians

tape to form a hand grip. Mark the location of the control-stick on

the cockpit floor then drill a 1/16" diameter hole through the

marked spot. Carefully drill a 1/16" diameter hole about 3/8" deep

into the bottom of the control-stick. Install a #2 x 3/8" sheet metal

screw from beneath the cockpit floor so that it just protrudes into

the cockpit area. Apply a dab of epoxy to the bottom of the control

stick.Twist the control stick onto the protruding screw and secure

it with a screwdriver.

If you have questions or comments write or call:

DYNAFLITE

P.O.Box 788

Urbana, IL 61803

(217) 398-8970

Luggage T ank

Template

Release

0

9 l

240

60

200

40

160

20

120

l5

20

l0

25

RPM

30

5

21

9649

0

35

28

73

ALT

6

4

5

60

80

40

100

120

KNOTS

20

140

0

l

CLIMB

DESCENT

l

IIVMINX IIVMINX

IIVMINXIIVMINX

IIVMINX IIVMINX

IIVMINX IIVMINX

IIVMINX IIVMINX

2

2

36

Loading...

Loading...