Page 1

TM

TM

•

Simple

Ent

ry Level

Construction

• Stable Flight Characteristics

• Excellent R/C Trainer

READ THROUGH THIS INSTRUCTION MANUAL FIRST. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

Instruction Manual

WARRANTY

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modification. In no

case shall Dynaflite's liability exceed the original cost of the purchased kit. Further, Dynaflite reserves

the right to change or modify this warranty without notice. In that Dynaflite has no control over the

final assembly or material used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled product. By the act of using

the user-assembled product, the user accepts all resulting liability. If you are not prepared to accept

the liability associated with the use of this product, return this kit immediately in new and unused

condition to the place of purchase.

WANDP03 Printed in USA

MADE IN

Page 2

I

ntroduction.......................................................2

Precautions........................................................3

Preparations.......................................................3

Required

Suggested Building Supplies........................3-4

Optional Building Supplies...........................4

Building

Glossary of Terms Used in

This

Manual

Die-Cut

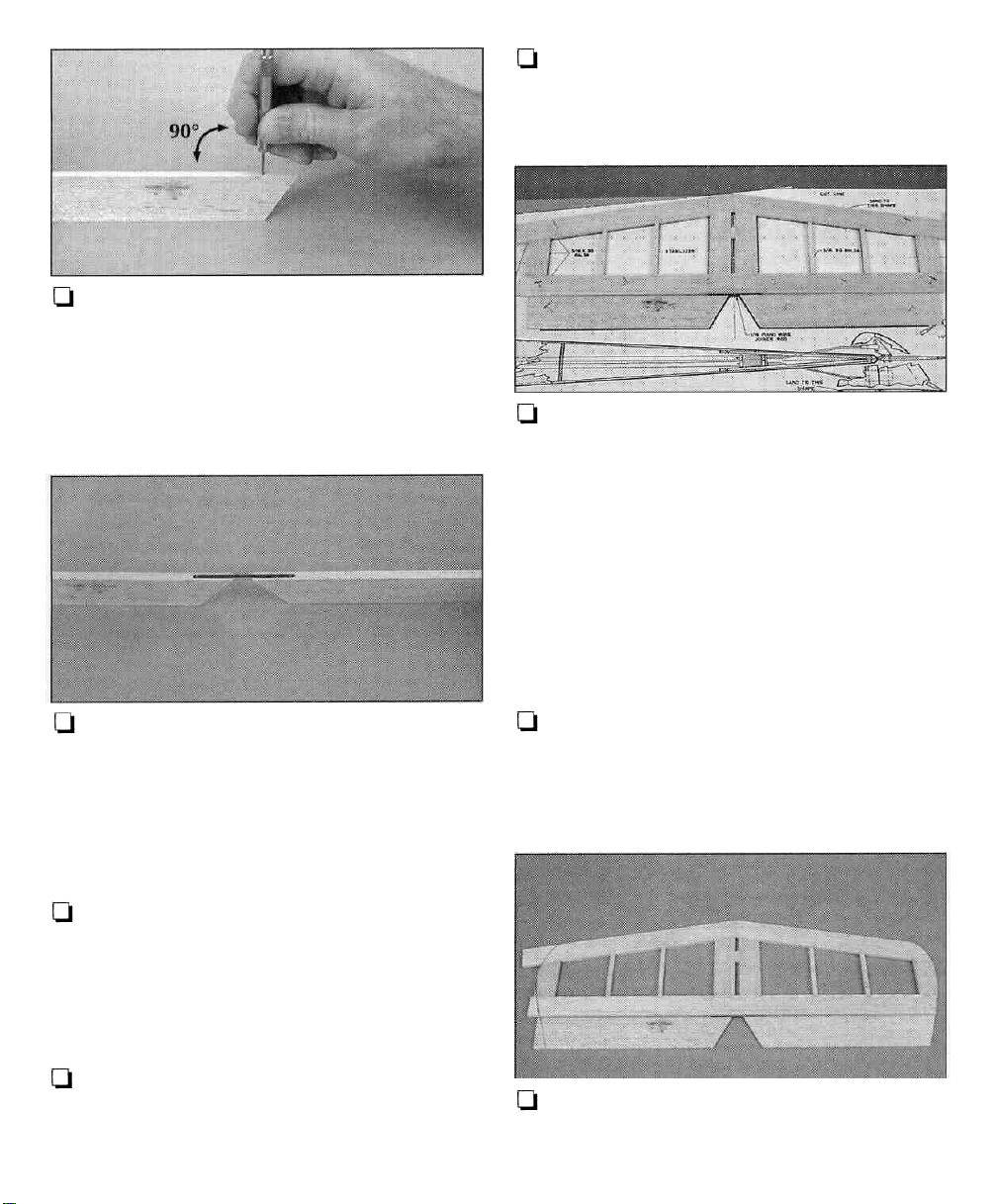

Build the Horizontal Stabilizer

and Elevator..................................................8-10

Install the Hinges

Finish

the

Build the Fuselage........................................11-15

Install the Hatch

Build the

Build the

Final

Wing

Align

the

Balance the

Finishing

Final Assembly............................................22-23

Assemble

Install the Radio

Set

the Control

Balance

Pre-Flight..........................................................27

Charge the

Ground

Range Check

Flying

First

Landing......................................................28

Items

..............................................3

Notes.................................................4-5

and

Plans.....................................

Patterns..................................................7

.........................................10-11

Fin

and

Rudder..................................11

...........................................15-16

Wing

Root

Panel............................16-18

Wing

Tip Panel

Assembly

Stabilizer

Model

.....................................................21-22

the

Pushrods

System

Throws

Your

Model.....................................26-27

Batteries

Check

Your

...............................................................28

Flight...................................................28

..............................18-20

........................................20

to

the

Wing

.........................21

Laterally..............................2

................................23-24

...............................24-25

......................................26

....................................27

Your

Model...........................27

Model.............................28

5-6

The 72" version of the Wanderer was developed by

Mark Smith as a first-time building and flying

project. Since its introduction in 1975, over 85,000

kits have been produced. Over the years the

Wanderer has been updated with many changes

recommended to us by first-time builders. The

Wanderer still has the same basic aerodynamics as

the original kit, but has been simplified to make

assembly quicker and easier.

At Dynaflite we take pride in offering kits that are

simple and straightforward to build and provide

value for your modeling dollar.

To make your R/C modeling experience totally

enjoyable, we recommend that you get assistance

with your first flights from an experienced,

1

knowledgeable modeler. You'll learn faster and

avoid risk to your model before you're truly ready to

solo. Your local hobby shop has information about

flying clubs in your area whose membership

includes qualified instructors.

You can also contact the national Academy

Model Aeronautics (AMA), which has more than

2/500 chartered clubs across the country. We

recommend you join the AMA, which will provide

you with insurance coverage at AMA club sites and

events. AMA Membership is required at chartered

club fields where qualified flight instructors are

available. Contact the AMA at the address or tollfree phone number below:

of

Congratulations on your choice of this kit for your

next project. If you are new to radio control

modeling, we would like to take a minute to give

you some background on the Wanderer.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie,IN 47302

(800) 435-9262

Fax (765) 741 -0057

Internet address : http://www.modelaircraft.org

2

Page 3

1. You must assemble the sailplane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the photos or plan. In those instances the text

should be taken as correct.

2. You must take time to build straight, true and strong.

3. You must install all R/C and other components so

that the model operates properly on the ground and

in the

air.

4. You must test the operation of the model before

the first and each successive flight to insure that all

equipment operates correctly. You must also make

certain that the model has remained structurally

sound, especially after a rough landing.

NOTE: We, as the kit manufacturer, provide you

with a quality kit and great instructions, but

ultimately the quality and flyability of your

finished model depends on how you assembled it;

therefore, we cannot in any way guarantee the

performance of your completed model and no

representations are expressed or implied as to the

performance or safety of your completed model.

REQUIRED ITEMS

These are the items not included with your kit; you

will need to purchase them separately. Items in

parentheses (GPMQ4243) are suggested part

numbers recognized by distributors and hobby

shops and are listed for your ordering convenience.

GPM is the Great Planes® brand, TOP is the Top

Flite®

brand,

is the Dynaflite™ brand.

HCA

is

the

Hobbico®

2 - 4 channel radio with two standard servos.

Top Flite MonoKote® (Approximately 2 rolls)

1/4" Latex Foam Rubber (HCAQ1050)

Switch and Charge Jack (GPMM1000)

2 Meter Up-Start (DYNP8305) or Standard

Hi-Start(DYNP8301)

brand

and DYN

SUGGESTED BUILDING

SUPPLIES

We recommend Great Planes Pro™ CA and Epoxy

glue.

Please inventory and inspect all parts carefully

before starting to build. If any parts are missing,

broken or defective, or if you have any questions

about building or flying this model, please call us

at (217) 398-8970 and we'll be glad to help. If

you are calling for replacement parts, please

look up the part numbers and have them ready

when calling.

2 oz. Pro CA (Thin, GPMR6003)

1 oz. Pro CA- (Thick, GPMR6014)

6-Minute Pro Epoxy (GPMR6045)

30-Minute Pro Epoxy (GPMR6047)

4 oz. Pro Wood Glue (GPMR6161)

Hand or electric drill

Sealing Iron (TOPR2100)

Hobby saw

3

Page 4

SUGGESTED BUILDING

SUPPLIES, CON'T.

Hobby Knife (HCARO 105)

#11 Blades

Pliers (Common and Needle Nose)

Screw driver (Phillips)

T-pins(HCAQ5150)

60" Retractable Tape Measure (HCAR0478)

Straightedge With Scale

Masking Tape (TOPR8018)

Sandpaper (coarse, medium, fine grit)

Easy-Touch™ Bar Sander (or similar)

Plan Protector (GPMR6167)

Lightweight Balsa Filler such as Hobbico®

HobbyLite™ (Hobbico HCAR3400)

IsopropyI Rubbing Alcohol (70%)

Ballpoint Pen

90° Building Square

Heavy Sewing Thread (any color)

#64 Rubber Bands

Drill bits: 1/16", 5/64", 3/32", and 3/16"

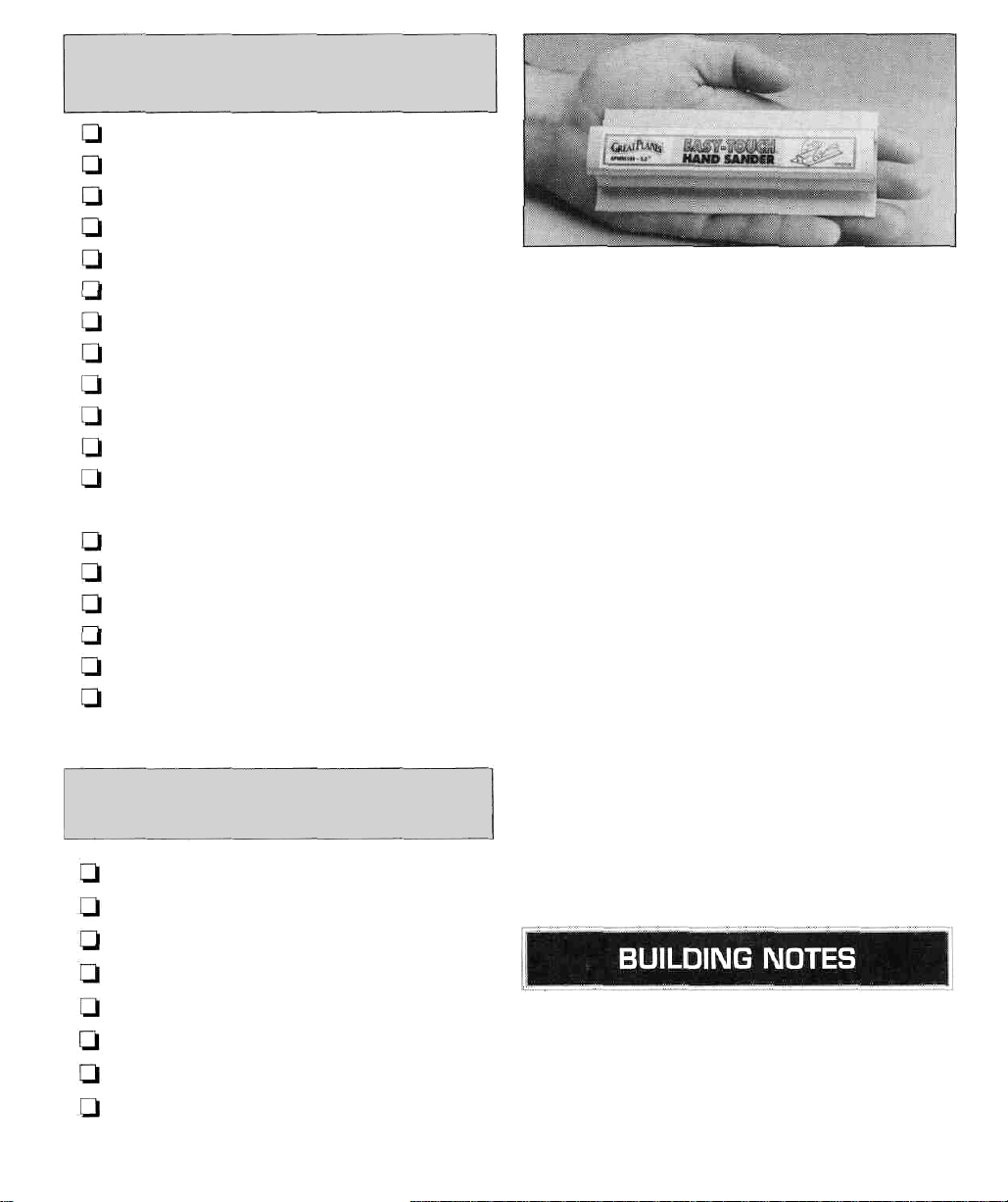

Great Planes Easy-Touch Bar Sanders are made

from lightweight extruded aluminum and can be

found at most hobby shops. They are available in

five sizes - 5-1/2" (GPMR6169) for those tight,

hard to reach spots; 11" (GPMR6170) for most

general purpose sanding; and 22" (GPMR6172),

33" (GPMR6174) and 44" (GPMR6176) for long

surfaces such as wing leading edges. Easy-Touch

Adhesive-Backed Sandpaper comes in 2" x 12"

rolls of 80-grit (GPMR6180), 150-grit (GPMR6183)

and 220-grit (GPMR6185) and an assortment of 5-

1/2" long strips (GPMR6189) for the short bar

sander. The adhesive-backed sandpaper is easy to

apply and remove from your sanding bar when it's

time for replacement.

Custom sanding blocks can be made from balsa or

hardwood blocks and dowels for sanding difficult to

reach spots.

OPTIONAL BUILDING

SUPPLIES

CA Applicator Tips (HCAR3780)

Epoxy Brushes (GPMR8060)

Epoxy Mixing Sticks (GPMR8055)

CA Debonder (GPMR6039)

Hot Sock™ (TOPR2175)

Single Edge Razor Blades (HCAR0312)

Heat Gun (TOPR2000)

Razor Plane (Master Airscrew®)

• When you see the term "test fit" in the

instructions, it means you should first position

the part on the assembly without using any

glue and then slightly modify or sand the part

as necessary for the best fit.

4

Page 5

• Whenever the instructions tell you to glue pieces

together, thin CA should be used. When a

specific type of glue is required, the instructions

will state the type of glue that is highly

recommended. When 30-minute epoxy is

specified, it is highly recommended that you

use only 30-minute (or slower) epoxy because

you will need either the working time and/or

the additional strength.

Airfoil: A curved structure designed to create lift by

the reaction to air moving over its surface.

C.G. (Center of Gravity): This is the point at which

the model balances forward and aft and side-to-side.

• Do not throw away any leftover material until

after you have completed your model. Some

small pieces of leftover balsa or plywood are

used during construction.

This kit is built using three types of glue.

Cyanoacrylate - CA glues cure almost instantly and

are moderately strong. There are three common

types used: thin, medium and thick. Thin CA cures

the fastest but will not span gaps between parts.

Medium and thick CA are used where parts do not

fit perfectly. CA glue does not bond well to most

plywoods and hardwoods. CA glues are also brittle.

When using CA glues we recommend keeping a

bottle of CA debonder on your building table in

case you need to undo a joint or "un-stick"

your fingers.

Aliphatic Resin - Resin glues require that parts be

pinned or clamped together while the glue dries typically 15 to 30 minutes. Resin glues are very

strong and work well with balsa and plywoods.

Clevis: A small clip which is threaded onto the wire

end of a pushrod and connects the pushrod to the

control horn of a control surface. The threads allow

fine adjustment of pushrod length.

Control Horn: The arm which is attached to a

control surface at the hingeline and is connected to

a pushrod.

Die-Cut Parts: Precut parts stamped out of a sheet of

wood. The parts require a minimum of preparation.

Dihedral: The V-shaped bend in the wing. Typically

more dihedral causes more aerodynamic stability in

an airplane, and allows the rudder to control both

the roll and yaw axis.

Doubler: Part of the structure that is laminated to

another part to increase its strength.

Elevator: The hinged control surface located at the

trailing edge of the horizontal stabilizer, which

provides control of the model about the pitch axis

and causes the model to climb or dive. The correct

direction of control is to pull the transmitter elevator

control stick back, towards the bottom of the

transmitter, to move the elevator upward, which

causes the airplane to climb. Pushing the control

stick forward will cause the model to dive.

Epoxy - Six-minute epoxy cures the fastest; it sets

within six minutes but is not fully cured for one hour

or more. Thirty-minute epoxy is the strongest as it

allows the epoxy to soak into the wood thoroughly.

While it sets within 30-minutes, it is not fully cured

for two or more hours.

Foam Rubber: A soft foam material used to wrap

the receiver and receiver battery for protection.

Gusset: A brace used to reinforce the joint between

2 parts.

5

Page 6

High-Start: A device used to launch a model glider

like a slingshot. This device consists of a stake, an

elastic tube/ monofilament line (or string), a

parachute or streamer and a ring for attaching the

high-start to the glider.

Laminate: The process of gluing a multiple number

of sheets face-to-face to increase strength.

Horizontal Stabilizer: The non-moving horizontal

tail surface at the back of the fuselage which

provides aerodynamic pitch stability.

Pitch Axis: The sailplane axis controlled by the

elevator. Pitch is illustrated by holding the sailplane

at each wing tip. Raising or lowering the nose is the

pitch movement.

Sailplane: An airplane which flies without an

engine. Sailplanes are designed to ride on warm,

rising air currents, called thermals. Sailplanes are

launched by several methods: a giant sling shot

called a high-start; a winch which pulls the sailplane

up like a kite; or with the assistance of a small

engine or electric motor.

Servo: The electronic/mechanical device which

moves the control surfaces of the sailplane

according to the commands from the receiver. The

radio device which does the physical work inside

the sailplane.

Servo arm: The removable arm or wheel which

bolts to the output shaft of a servo and connects to

the push rod.

Tow Hook: A device used to connect the tow line to

the sailplane during launch.

(Transmitter: The hand-held radio controller. This is

the unit that sends out the commands that you input.

Pushrod: A rigid piece of steel, plastic or wood used

to transfer movement from a servo to a control surface.

Receiver (RX): The radio unit in the sailplane which

receives the transmitter signal and relays the control

to the servos. This is somewhat similar to the radio

you may have in your family automobile, except the

radio in the glider perceives commands from the

transmitter and the radio in your car perceives

music from the radio station.

Rudder: Hinged control surface located at the

trailing edge of the vertical stabilizer, which

provides control of the sailplane about the yaw axis

and causes the sailplane to yaw left or right. Left

rudder movement causes the sailplane to yaw left

and right rudder movement causes it to yaw right.

Vertical stabilizer: The non-moving surface that is

perpendicular to the horizontal stabilizer, often

referred to as the fin, providing lateral stability. The

rudder attaches to this surface.

Wing: The main lifting surface of an airplane.

Yaw Axis: The glider axis controlled by the rudder.

Yaw is illustrated by hanging the glider level by a

wire located at the center of gravity. Left or right

movement of the nose is the yaw movement. Many

gliders are not equipped with ailerons and the roll

and yaw axis are controlled by the rudder. This is

due to the larger amount of dihedral in the wing and

is why most sailplanes have a large amount of dihedral.

6

Page 7

Die-Cut Layout

INNER

PANEL

GUSSETS

OUTER

PANEL

GUSSETS

NOTES ON REMOVAL OF DIE CUT PARTS FROM THE SHEET

1. Sand both sides of all die cut sheets enough to remove loose wood Fibers.

2. Bend each sheet slightly, along the direction of the grain, to identify the

side that is not cut completely through.

3. Sand this side until most of the parts can be easily removed from the sheet.

4. If a part is difficult to remove, use a sharp hobby knife to cut any

slivers of wood that are holding it in place.

7

Page 8

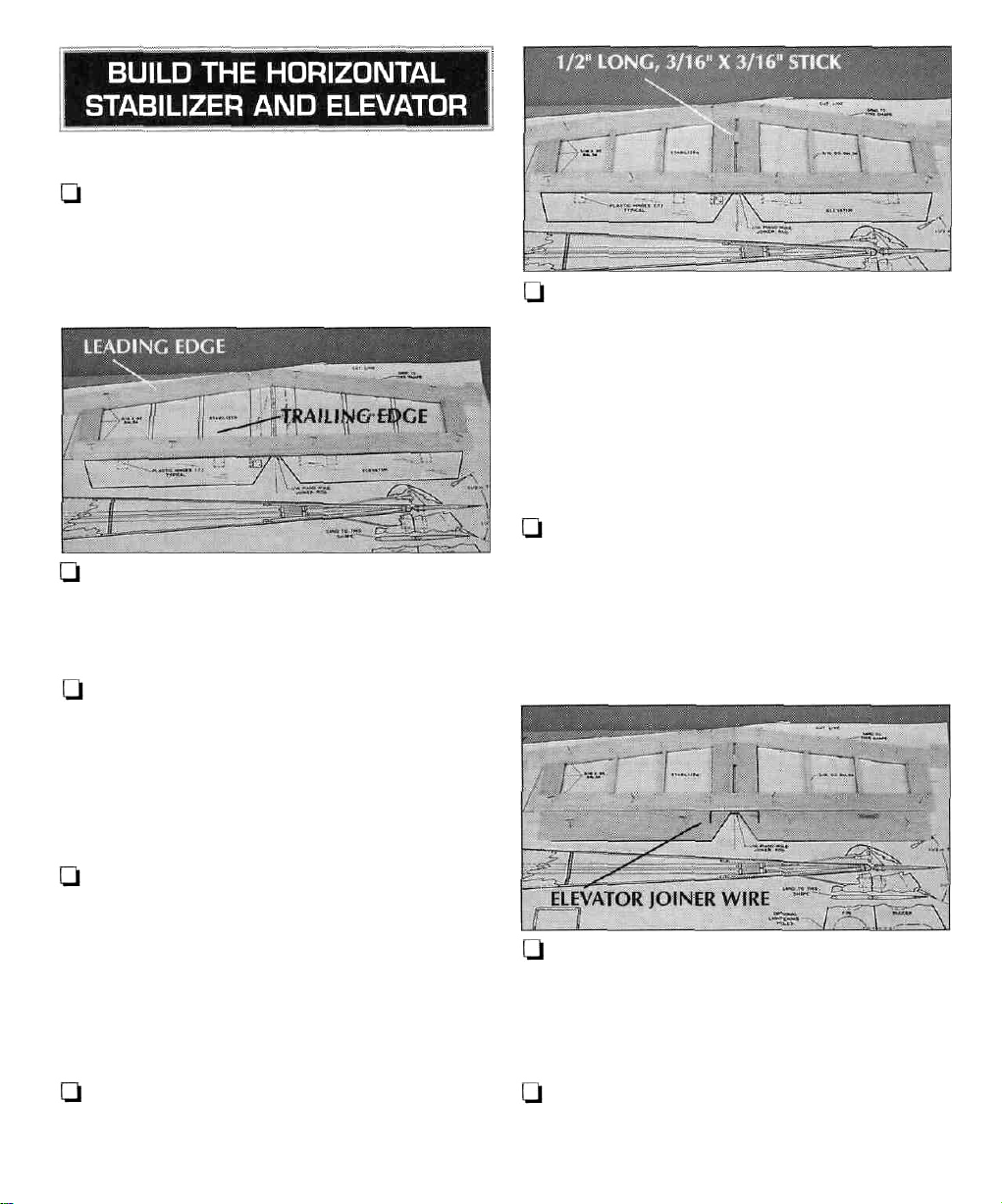

1. Unroll the plan sheet. Roll the plans inside out

to make them lie flat. Wax paper or Great Planes

Plan Protector placed over the plan will prevent

glue from sticking to the plan.

U 2. Cut an 18" long piece from the 3/16" x 15/16"

x 30" balsa stick. Pin the 18" long piece over the

horizontal stabilizer trailing edge.

Q 3. Cut a 10" long piece from the remaining

3/16" x 15/16" x 12"

over the left leading edge of the horizontal

stabilizer. Carefully mark and cut the end of the

leading edge to match the centerline of the

stabilizer. Pin the left leading edge piece in position.

balsa

stick.

Place

the

stick

LJ 6. From the remaining 3/16" x 15/16" balsa

stick, cut and fit stabilizer center sections between

the leading edges and trailing edge. Position the fin

between the two center sections for the proper

spacing. DO NOT glue the fin in position. Glue the

center sections to the leading and trailing edge.

Q 7. From a 3/16" x 3/16" x 24" balsa stick, cut/

fit and glue stabilizer ribs between the leading edge

and trailing edge. Also, cut a 1 /2" long piece and

glue it in position between the stabilizer center sections.

Ul 4. Cut another 10" long piece from the second

3/16" x 15/16" x 30"

over the right leading edge of the horizontal

stabilizer and cut the end of the right leading edge

to butt tightly against the center of the left leading

edge. Pin the right leading edge piece in position

and glue it to the left leading edge.

Q 5. From the remaining 3/16" x 15/16" x 20"

balsa stick, cut, fit and glue stabilizer tips between

the leading and trailing edges.

balsa

stick.

Place

the

stick

I—l 8. Pin the two shaped balsa elevators in position

over the plans, making sure the beveled ends are

toward the center.

Q 9. Center the pre-bent 1/16" elevator joiner

wire on the elevators and mark the location of the

"arms" on the leading edge of the elevators.

8

Page 9

Q 10. Drill 1/16" holes, 9/16" deep, in the

leading edge of the elevators at the marked

locations. Make sure the two holes are perpendicular

to the leading edge. Be careful that the drill bit does

not break through the sides of the elevators.

Q 14. For a more secure fit, file or grind four or

five notches in each arm of the elevator joiner wire.

Thoroughly clean the joiner wire with isopropyi alcohol.

Q 15. Pack 30-minute epoxy into both elevator

joiner wire holes and in the groove on the leading

edge of the elevators. Install the joiner wire in both

elevators. Wipe off any excess epoxy with a paper

towel dampened with isopropyi alcohol. Before the

epoxy cures, place a piece of wax paper over the

joiner wire and pin the elevators flat to the building

board with the leading edge against the trailing

edge of the stabilizer.

Q 11. Cut a small groove from the hole to the

inboard end of the elevators. Gradually deepen the

groove until the joiner wire fits flush with the leading

edge of the elevators. With the elevator joiner wire

installed, the wire must be flush with the leading

edge of the elevators.

Q 12. With the joiner wire installed in the

elevators, place the assembly on a flat surface.

MAKE SURE both elevators lie flat. If they do not,

remove the joiner wire and twist it slightly. It is very

important that both elevators lie flat.

U 13. Remove the joiner wire. Mark a centerline

on the leading edge of both elevators and carefully

sand the leading edges to a "V shape as shown on

the fuselage plan.

Q 16. Remove the elevator and stabilizer from the

building board after the epoxy has cured.

1-J 17. Draw the outline for the tips on the stabilizer

and elevator using the plan as a pattern. Cut and

sand the stabilizer and elevator tips to shape.

9

Page 10

Q 18. Sand the top and bottom of the stabilizer

smooth. Sand a radius on the leading edge and tips

of the stabilizer and the tips of the elevator using the

stabilizer view as a guide.

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

1"

1"

1/2"

l-l 1. Cut the 2" x 9" hinge strip into 6 individual

(1/2" x 1") hinges and bevel the corners as shown.

Q 2. Place the stabilizer and the elevator on the

plan and mark the location of the hinges. Also,

mark the centerline on the trailing edge of the

stabilizer.

Q 4. Drill a 3/32" hole, 1/2" deep, in the center

of the hinge slot. Drilling the hole will twist some of

the wood fibers into the slot, making it difficult to

insert the hinge. Re-insert the knife blade into the

slot and work it back and forth a few times to clean

out the slot.

Q 5. Test fit the hinges into the slots and

temporarily attach the elevator to verify the fit and

operation. DO NOT glue the hinges at this time.

They will be glued in after the sailplane is covered.

CUT HINGE SLOT

WITH HOBBY KNIFE

AND #11 BLADE

Q

3. Cut the

hinge

slots

using a #11

blade.

Test

fit

the hinges into the slots. If the hinges do not slide in

easily, work the knife blade back and forth in the

slots a few times to provide more clearance.

RIGHT

WRONG

Q 6. Place a nylon control horn on the bottom of

the left elevator as shown on the plan. With the four

clevis holes aligned with the hinge line, drill a

3/32" hole through both holes in the horn base.

10

Page 11

NOTE: The control horn in the photo was painted for

clarity (The control horns in the kit are made of while

plastic).

Ul 5. Sand a radius on the leading edge of the fin

as shown on the cross section view.

Q 7. Insert two 2-56 x 1/2" machine screws

through the horn base and elevator. Place the nut

plate on top of the elevator and thread the machine

screw into the nut plate.

Ul 8. Remove the nut plate and control horn.

Reinforce the elevator by applying a couple of drops

of thin CA on the elevator where the control horn

is mounted.

Q 1. Draw a centerline completely around the edge

of the shaped balsa rudder. This will help keep the

rudder symmetrical while sanding.

Q 2. Carefully sand the shaped balsa fin and

rudder to the shape shown on the fuselage cross

section. NOTE: The weight of the fin and rudder can

be reduced by cutting lightening holes in them as

shown on the plan. This may reduce the weight

required in the nose to balance the sailplane.

Q 6. Mark and install the hinges following the

same procedure used on the stabilizer and elevator.

DO NOT glue the hinges in at this time.

Q 7. Install the control horn on the rudder following

the same procedure used with the elevator.

[.-I 1. Place wax paper or Great Planes Plan

Protector over the fuselage plan to prevent glue

from sticking to the plan.

Q 2. Put the two die-cut 3/32" balsa fuselage

sides together and check that they are the same size

and shape. If not/ lightly sand them. Compare the

fuselage sides to the fuselage plan.

Q 3. Cut a notch in the leading edge of the rudder

to clear the elevator joiner wire as shown on the plan.

Q 4. Sand a "V" on the leading edge of the rudder.

Use the cross section view as a guide.

[-1 3. Lay the fuselage sides top edge to top edge as

shown. Mark one fuselage side left and the other right.

Q 4. Lightly sand the edges of the die-cut 1/8"

plywood fuselage doublers.

11

Page 12

Qi 5. Use thick CA to glue the fuselage doublers

onto the fuselage sides, aligning the top and front

edges. Make sure to glue the doublers to the sides

with the right and left written on them.

U 6. On the left fuselage side place two marks at

the locations shown.

U 8. Pin the right fuselage side to the fuselage

plan. Use a straightedge to draw vertical lines on

the fuselage doubler and fuselage side at stations

"B" through "E". Also mark the 1/8" x 1/4" balsa

bottom cross brace, as shown on the plan.

Q 9. Remove the right fuselage side from your

building board and continue the lines around the

edges of the fuselage side.

Q 10. Hold the fuselage sides together (balsa-tobalsa) aligning the edges. Transfer the marks to the

edges of the left fuselage side. Draw vertical lines on

the fuselage doubler and balsa side, connecting the

marks. Also mark the location of the 1/8" x 1/4"

balsa bottom cross brace.

Ql 11. Cut 5-1/2" long pieces from each of the two

1/8"x1/4"x

10" balsa

sticks.

Q 7. Clamp the fuselage sides together so that the

balsa sides are against each other and the edges

align. Set the assembly on a piece of leftover

plywood with the two marks you made facing up. At

each mark, drill a 3/16" hole through the fuselage

sides. Make sure the holes are drilled perpendicular

to the fuselage sides.

Q 12. From the remaining 1/8" x 1/4" balsa

sticks, cut and glue two side braces at station "E".

NOTE: The front edges of the braces are glued

along the station line.

12

Page 13

U 13. From the remaining 3/16" square balsa

stick used on the stabilizer, cut two 1" long tail

posts. Glue a tail post to the aft end of both fuselage

sides. Glue the 5-1/2" balsa stick, cut in step 11, to

each fuselage side, flush with the stabilizer seat.

Q 14. From the 3/16" x 3/16" x 24" balsa stick,

cut two 9-3/4" long wing saddle doublers. Glue the

wing saddle doublers to the plywood fuselage doublers,

flush with the top edge of the fuselage doublers.

LJ 17. Place a leftover piece of 3/16" balsa over

the fuselage top view in front of the tail post. With

the fuselage sides inverted, align the sides with the

fuselage top view. With the tail posts aligned and

the sides of the fuselage perpendicular to the

building table, glue the tail posts together.

Q 18. Pin the fuselage sides to the building board

at former F-5. With F-5 still perpendicular to the

building board, glue it to the fuselage sides.

U 15. Using the fuselage top view as a guide,

lightly sand the tail posts to the angle shown to

allow the aft end of the fuselage sides to meet

properly.

Q 16. Pin the die-cut 1/8" plywood former F-5 in

position over the fuselage top view, perpendicular to

the building board. Make sure the longest side of

F-5 is against the building board.

I—I 19. Glue the die-cut 1/8" plywood formers F-4

and F-3 in position. Make sure the formers are

perpendicular to the building board and the

fuselage sides are aligned over the plan.

Q 20. Place the die-cut 1/8" plywood former F-1

in position. Use masking tape or clamps to hold the

fuselage sides against F-1. Check the alignment of

the fuselage sides over the plan before gluing F-1 to

the fuselage sides.

13

Page 14

Q

21.

Test

fit

the

two

1/4" x 1/2" x 2-1/4"

basswood tow hook blocks in the notches of the

plywood fuselage doubler. When you're satisfied

with the fit/ glue the blocks to the fuselage sides and

doubters with aliphatic resin or 6-minute epoxy.

After the epoxy cures/ drill a 3/32" hole in the

center of both blocks.

Q 22. Lightly sand the bottom of the fuselage so

that the plywood fuselage doublers and formers are

flush with the balsa fuselage sides.

[-] 24. From the 1/8" x 1/4" x 10" balsa stick, cut

and glue the bottom cross brace between the

fuselage sides, flush with the bottom edge. Glue the

1/4" x 3/8" x 1" balsa end cap to the tail post,

flush with the fuselage sides.

Q 25. Use thick CA to glue the 3/32" x 3" x 30"

balsa aft fuselage bottom to the edge of the 3/16"

bottom fuselage sheet, the tow hook blocks and the

fuselage sides.

Ul 26. After the glue has cured, remove the

fuselage from your building board. Starting at the

tow hook blocks, trim the aft fuselage bottom to

within 1/16" of the fuselage sides. Do not attempt

to trim the fuselage bottom from the tail post

forward. The wood may split or your knife may cut

into the fuselage sides. Save the leftover aft fuselage

bottom sheeting.

U 23. Sheet the bottom front of the fuselage with

the three 3/16" x 2-1/2" x 3" balsa bottom

forward sheets. Start at the middle of the front tow

hook block and work toward former F-1. The balsa

sheets are installed with the grain running across the

fuselage. Wetting the top of the sheets with a 50-50

mix of water and isopropyi alcohol will make the

sheets easier to mold to the fuselage contour. Use a

leftover piece of 3/16" balsa from the stabilizer to

fill the gap between the third sheet and former F-1.

Sand the sheets flush with the balsa fuselage sides.

U 27. Sand the fuselage bottom flush with the

fuselage sides.

Q 28. From the leftover 1/8" x 1/4" balsa stick,

cut and glue a top cross brace in front of the

stabilizer base, flush with the top edge of the

fuselage sides.

14

Page 15

a

21.

Test

fit the

basswood tow hook blocks in the notches of the

plywood fuselage doubler. When you're satisfied

with the fit, glue the blocks to the fuselage sides and

doublers with aliphatic resin or 6-minute epoxy.

After the epoxy cures, drill a3/32" hole in the

center of both blocks.

Q 22. Lightly sand the bottom of the fuselage so

that the plywood fuselage doublers and formers are

flush with the balsa fuselage sides.

two

1/4" x 1/2" x 2-1/4"

Q 24. From the 1/8" x 1/4" x 10" balsa stick, cut

and glue the bottom cross brace between the

fuselage sides, flush with the bottom edge. Glue the

1/4" x 3/8" x 1" balsa end cap to the tail post,

flush with the fuselage sides.

Q 25. Use thick CA to glue the 3/32" x 3" x 30"

balsa aft fuselage bottom to the edge of the 3/16"

bottom fuselage sheet, the tow hook blocks and the

fuselage sides.

Q 26. After the glue has cured, remove the

fuselage from your building board. Starting at the

tow hook blocks, trim the aft fuselage bottom to

within 1/16" of the fuselage sides. Do not attempt

to trim the fuselage bottom from the tail post

forward. The wood may split or your knife may cut

into the fuselage sides. Save the leftover aft fuselage

bottom sheeting.

Q 23. Sheet the bottom front of the fuselage with

the three 3/16" x 2-1/2" x 3" balsa bottom

forward sheets. Start at the middle of the front tow

hook block and work toward former F-1. The balsa

sheets are installed with the grain running across the

fuselage. Wetting the top of the sheets with a 50-50

mix of water and isopropyi alcohol will make the

sheets easier to mold to the fuselage contour. Use a

leftover piece of 3/16" balsa from the stabilizer to

fill the gap between the third sheet and former F-1.

Sand the sheets flush with the balsa fuselage sides.

—1 27. Sand the fuselage bottom flush with the

fuselage sides.

Q 28. From the leftover 1/8" x 1/4" balsa stick,

cut and glue a top cross brace in front of the

stabilizer base, flush with the top edge of the

fuselage sides.

14

Page 16

Q 29. Glue the 3/32" x 3" x 15" balsa aft

fuselage top from former F-4 to the front of the

stabilizer base. Trim and sand the aft fuselage top

flush with the fuselage sides.

Q 1. Trim the aft edge of the 5/8" x 2-1/2" x

5-3/4" balsa hatch block to match the radius on

the fuselage sides.

Q 4. Drill a 1/16" hole through the center of the

1/4" x 1/2" x 1-1/2" basswood hatch hold-

down block.

Q 5. Glue the hatch hold-down block to the front of

former F-3 and the underside of the sheet glued on

in step 3. After the glue has cured, insert a T-pin,

from the bottom, through the hole in the hatch holddown block and 3/32" sheet. Mark the hole

location on the sheet.

Q 6. Cut a 7/8" long hatch tab from the 1/16" x

3/8" x 1 -3/4" plywood strip. Round the corners on

the hatch tab and drill a 3/32" hole at one end at

the location shown on the plan. The remaining piece

will be used later as the hatch tongue.

Q 2. With the 1/2" x 1-7/16" x 2" balsa filler

block snug against the front of the hatch block, glue

the filler block to the fuselage. Do not glue the filler

block to the hatch block. After the glue has cured,

remove the hatch block.

U 3. From a leftover piece of 3/32" balsa sheet,

cut a 3/4" x 2-1/2" rectangle with the grain

running along the long dimension. Glue this sheet to

the top of the fuselage, with the front edge flush with

the aft edge of the hatch cut-out.

Q 7. Use a #2 x 1 /2" sheet metal screw to attach

the hatch tab to the fuselage at the mark made in

step 5. The hatch tab should be snug but still

able to rotate.

Q 8. Sand the filler block flush with the front of

former F-1.

t—1 9. If you are building the sailplane version, glue

the 2" x 2" x 2" balsa nose block to former F-1 and

the filler block. If you are building the .049 powered

version, cut out and glue the optional 1/16"

plywood firewall (not included) to former F-1 and

the filler block. The template is shown on the plan.

15

Page 17

Q 10. Make two 3/16" balsa hatch keys from

leftover 3/16" square sticks. Wedge the hatch keys

between the fuselage sides at the locations shown

on the plan. Do not glue the hatch keys to the

fuselage sides.

Q 11. With the hatch keys flush or slightly higher

than the fuselage sides, put a bead of thick CA

along the top of the hatch keys. Place the hatch in

position and hold it in place until the glue cures. Do

not glue the hatch keys to the fuselage sides.

Ql 12. Remove the hatch and glue the hatch tongue,

cut in step 6, centered on the front of the hatch.

[-1 13. After the glue has cured, test fit the hatch on

the fuselage and lock it in place with the hatch tab.

d 16. Sand the bottom of the fuselage, blending

the 3/16" bottom forward sheeting into the 3/32"

bottom aft sheeting. Use the cross sections shown on

the plan as a guide to sand a radius on the corners.

Be careful not to sand the corners too thin and

weaken the structure. Sand a radius on the 1/4"

end

cap.

LJ LJ 1. Lay the right wing plan on your building

board and cover it with Plan Protector or wax paper.

Q Q 2. Before removing the die-cut 3/32" balsa

ribs from the die sheets, label each rib using the die

patterns on page 7.

Q Q 3. Stack the W-1 through W-3 ribs together.

Insert the 1/2" x 3/8" x 24" basswood main spar in

the slot of the ribs. Lightly sand the leading and

trailing edges flush.

Q Q

4.

Test

fit

the

wing

spars in

trim the slots as necessary. Important: The slots in

the bottom of the W-1 ribs are 1/16" shallower than

the spars. This is to allow the 1/16" sheeting to fit

between the spars, flush with the top of the spars.

all

the ribs

and

U 14. Carve and sand the hatch, filler block, nose

block and 3/16" bottom sheeting to shape as

shown in the G-G cross section on the plan.

LJ 15. Cut the two pushrod exit slots at the aft end

of the fuselage. Make sure the lower slot (rudder) is

on the right side of the fuselage. The upper slot

(elevator) is on the left side of the fuselage.

U U 5. Pin the shaped 5/16" x 15/16" x

balsa trailing edge to the building board. Make

the front of the trailing edge and the tip end

aligned with the wing plan. The root end

16

24"

sure

are

will

Page 18

overhang the wing plan slightly. Also/ the 90° edge

on the trailing edge goes against the building

board. See the cross section on the left wing plan.

U U 6. Using a W-3 rib as a spacer/ pin the

shaped 5/16" x 3/8" x 24" balsa leading edge

over the plan. Note that the angled edge of the

leading edge faces up and the tip end is aligned

with rib W-4.

1-1/2"

1/8"

Q Q 7. Cut a bevel as shown on one end of the

1/4" x 1/2" x 24" basswood main spar.

Q Q 9. Pin the 1/4" x 3/8" x 10" basswood root

spar in position.

Q Q 10. Place the W-2 inboard and W-3 outboard

ribs in position to check the alignment of the main

and root spars.

Q 11. Cut two center sheets 4-1/8" long from

each of the five 1/16" x 3" x 9" balsa sheets. Set

five

of

these

sheets

aside. They

will

be

used

on the

left wing panel.

,^WJiy».

U LJ 12. Trim one of the center sheets to fit between

the leading edge and the main spar. Make sure the

spar/ leading edge and center sheet are against the

building board before gluing. Trim and glue the

second center sheet between the main spar and root

spar and the third center sheet between the root spar

and trailing edge. Save the leftover balsa sheet for

use in step 16 when sheeting the top center section.

LJ U 8. Pin the main spar over the plan with the

beveled edge down and at the tip end. Align the tip

end with the plan using a T-pin at the tip end to

prevent the main spar from moving.

U U 13. Cut the root rib dihedral template from the

plan and glue it to a piece of cardboard.

QQ14. Use the root rib gauge to set the

the W-1 root rib. Align the bottom edge of

angle of

the

rib with the centerline on the plan.

17

W-1

Page 19

Qi Q 15. Glue the two remaining W-1 ribs/ the

three W-2 ribs and the five W-3 ribs in place/

perpendicular to the building board.

Q Q 16. Glue one of the previously cut 4-1/8"

long center sheets on top of the three W-1 ribs,

butted against the leading edge. Glue the second

center sheet on top of the three W-1 ribs, butted

against the first sheet. Use a piece of leftover center

sheeting from step 12 to finish sheeting the center

section.

inboard end of the leading edge so that it butts

against the root panel leading edge. Place the W-11

rib in position and pin the leading edge in place,

but do not glue it to the root panel.

1"

1/8"

Ql t—1 3. Cut a bevel as shown on one end of the

1 /4" x 3/8" x 16" basswood tip spar.

Ql Q 4. Place the tip spar over the plan, bevel side

down. Place a pin at the inboard and outboard

ends of the spar to hold it in place. Use a clothes pin

or clamp to hold the tip spar against the main spar.

Q Q 1. Place the shaped 5/16" x 15/16" x 15"

balsa trailing edge over the wing tip plan. Trim the

inboard end of the trailing edge so that it butts

against the root panel trailing edge. Pin the trailing

edge in place but do not glue it to the root panel.

Q Q 2. Place the shaped 5/16" x 3/8" x 15"

balsa leading edge over the wing tip plan. Trim the

Q Q 5. Cut the polyhedral rib gauge template from

the plan and glue it to a piece of cardboard.

d Q 6. Use the polyhedral rib gauge to set the

angle of the W-4 root rib. Align the bottom edge of

the W-4 rib with the centerline on the plan. Glue the

rib to the tip spar and the leading and trailing edge.

Avoid gluing the rib to the main spar and the

leading and trailing edge of the root wing panel.

18

Page 20

Q Q 7. Fit the remaining W-5 through W-11 ribs

in place, perpendicular to the building board. You

may need to bevel the ends of the ribs to match the

angle of the leading and trailing edge. When you

are satisfied with the fit, glue the ribs to the tip spar

and leading and trailing edge.

U U 12. Use a razor saw and a sanding block to

trim the spars and leading and trailing edges flush

with the W-1 and W-11 ribs. Be careful to not

remove any of the rib, changing its angle.

Q Q 13. Glue the shaped 5/8" x 15/16" x 5-5/8"

balsa wing tip to rib W-11. Note the wing tip cross

section on the plan for the proper orientation.

I—I Q 14. Trim and sand the wing tip to shape. An

easy procedure to obtain the proper shape is to

cover the leading and trailing edge and ribs W-9

and W-10 with masking tape. Sand the wing tip to

the shape of rib W-11 using a sanding bar, but be

careful not to sand through the masking tape or

ribW-11.

Q Q 8. Remove the tip panel assembly from your

building board. Leave the root wing panel assembly

in place.

U U 9. Place the tip panel against the root panel

and raise the tip panel 3-3/4" at rib W-11. Notice

that the leading and trailing edges of both panels

do not fit correctly. Carefully sand the leading and

trailing edges of the wing tip panel flush with the

face of rib W-4.

LI Q 10. After checking that both panels fit

together correctly, use aliphatic resin or 30-minute

epoxy to glue the spars, leading and trailing edges

together. Make

rib W-11. Use clamps to hold the spars together

until the epoxy cures.

Q Q 11. After the epoxy cures, remove the wing

half from the building board.

sure

the

tip panel

is

raised

3-3/4"

at

Q Q 15. Locate the 1/8" plywood leading edge

template and clean-up the die-cutting around the

radius, if needed.

Q Q 16. Use the leading edge template and the

wing cross section at W-1 (shown on the fuselage

side view) as a guide while sanding the wing root

panel leading edge. The correct shape of the

leading edge is very important to the flight

characteristics of the Wanderer.

Q Q 17. Note that the tip panel ribs get smaller as

they go from W-4 to W-1 1. Carefully taper the

leading edge to match the front of the wing tip ribs.

Q Q 18. Using the leading edge template as a

general guide, sand a radius on the tip panel

leading edge.

19

Page 21

Ql Q 19. Use a sanding bar to carefully sand the

top and bottom of the wing ribs, spars, center

sheeting and leading and trailing edges flush. Do

not alter the shape of the ribs while sanding.

Q Q 20. Trim the four die-cut 3/32" x 1/2" x

1 /2" balsa gussets to fit on both sides of rib W-4 at

the leading and trailing edge. When satisfied with

the fit/ glue them in place.

Q 21. Go back to step 5 of Build The Wing Root

Pane/and build the left wing.

Q 1. Now that both wing halves are assembled,

give them a final sanding with #400-grit sandpaper.

Use a shop vacuum or compressed air to remove the

sanding dust from the wing panels.

U 2. Pin or weigh down the root panel of the left

wing. With the right wing panel elevated 3-1/4" at

rib W-4, test fit the right wing panel against the left

wing panel. If needed, lightly sand the root ribs of

the wing panels to fit.

Q 4. Handle wing with care. The center section has

little strength at this point.

U 5. Draw a line on the top and bottom of the wing

1" on each side of the center joint.

1—1 6. Read this step completely before starting. In a

well ventilated area, prop the wing up off of the

building surface. Mix approximately 5 oz. of

30-minute epoxy following the manufacturer's

instructions. Brush a thin coat of epoxy on the center

joint between the previously drawn lines. Starting at

the trailing edge, lay the 2" fiberglass cloth on the

epoxy. Use your brush to work the cloth into the

epoxy, making sure the epoxy penetrates into the

cloth. Work your way along the top of the wing,

wrapping the cloth around the leading edge and

working back toward the trailing edge on the

bottom of the wing. If the epoxy has not come

through the cloth, apply more epoxy to the area. Do

not allow the epoxy to run or puddle, as this just

adds weight, not strength. Allow the epoxy to fully

cure before moving the wing.

Q 3. When satisfied with the fit, use aliphatic resin

or 30-minute epoxy to glue the wing panels

together. Support the right wing panel at rib W-4

and pin the root ribs together. Allow the epoxy to

fully cure before removing the wing from the building

board.

U 7. After the epoxy cures, sand off any surplus

epoxy and rough edges. Trim the cloth that is

overhanging at the trailing edge flush with the

trailing edge of the wing.

20

Page 22

1—1 1. Temporarily install the two 3-3/4" wing hold

down dowels in the fuselage. Set the wing on the

fuselage and secure it by hooking a couple of

rubber bands (not included) over the forward

dowel/ stretching the rubber bands over the wing

and hooking them over the aft dowel. Set the

stabilizer in the stabilizer saddle. Check the

alignment of the stabilizer with the wing from the

front and rear of the model. If the stabilizer tips are

not equidistant above the wing/ carefully sand the

high side of the stabilizer saddle until the stabilizer

and wing are aligned. Use a tape measure to set the

stabilizer tips equal distances from the nose.

Q 2. Use T-pins to hold the stabilizer in position on

the fuselage while marking the bottom of the

stabilizer where it meets the fuselage. Do not glue it

in position at this time.

Make sure that all the surfaces to be covered have

been sanded to remove any irregularities. The

Dynaflite Wanderer can be covered with Top Flite®

MonoKote® or EconoKote® film, using the suggested

covering sequence that follows.

Suggested Covering Sequence

Fuselage and Tail:

1. Fuselage bottom

2. Fuselage right side

3. Fuselage left side

4. Fuselage top

5. Fin TE, followed by the fin sides

6. Stabilizer TE/ followed by the bottom and top

(only cover the bottom of the stabilizer up to the

marks where the fuselage meets the stabilizer)

7. Elevator LE and root ends

8. Elevator bottoms/ followed by the top

9. Rudder LE, right side followed by the left side

10. Hatch

Wing: Tack the covering to the wing tips and

leading and trailing edges. Do not shrink the

covering until after the wing is completely covered.

Do not confuse this procedure with "checking the

C.G." That will be discussed later in the manual.

Now that the model is nearly completed/ you should

balance it laterally (side-to-side). An airplane that is

laterally balanced will track better. Here's how:

U 1. Temporarily attach the stabilizer/ elevators, fin,

rudder and wing. Lift the model by the nose and the

bottom of the fuse near the rudder. This will require

an assistant. Do this several times.

Q 2. The wing that consistently drops indicates the

heavy side. Balance the model by adding weight to

the other wing tip.

1. Tips of wing

2. Trailing edges of wing

3. Bottom of both wing halves

4. Top of both wing root halves (extend the

covering 1/4" past rib W-4 and tack it to the

outboard face of the rib)

5. Top of both wing tip halves

After the wing is completely covered/ shrink the

covering on the bottom of the wing, keeping the

wing as straight as possible. Next, place the wing

root panel against a flat building surface and shrink

the covering on it.

Once the root panels are done, place a tip panel on

a flat surface. Place a 1 /4" thick shim under the aft

21

Page 23

end of the wing tip. While holding the wing leading

edge and trailing edge at rib W-4 firmly against the

flat surface, shrink the covering. This will put a slight

twist in the wing called "washout." This washout will

help prevent tip stalls when flying.

After all the covering on the wing is shrunk, iron the

covering to each wing rib.

the fit, glue the fin to the stabilizer with 30-minute

epoxy or aliphatic resin. Make sure the fin is 90° to

the stabilizer. Masking tape and T-pins can be used

to hold it in place while the epoxy cures.

5. Cut and shape the 3/32" x 1/4" x 10-3/4"

basswood nose and tail skid. Bevel the forward

face of the nose skid before gluing it on. Place the

skids in position and mark the outline of the skids on

the fuselage. Carefully remove the covering from

inside the outline. Glue the skids on the fuselage

with thick CA. The skids may be varnished or

painted after installation.

LJ 1. Center and glue the two 3-3/4" wing hold

down dowels in the fuselage.

U 2. Set the wing on the fuselage and secure it to

the fuselage by hooking a couple of rubber bands

(not included) over the forward dowel, stretching the

rubber bands over the wing and hooking them over

the aft dowel. Again, set the stabilizer in the

stabilizer saddle. Check the alignment of the

stabilizer with the wing from the front and rear of

the model. Use a tape measure to set the stabilizer

tips equal distance from the nose.

U 3. Use 30-minute epoxy to glue the stabilizer in

position on the fuselage, rechecking the alignment

before the epoxy cures.

d 6. Starting with the elevators and stab/ cut the

covering from the hinge slots.

The most common mistake made by modelers when

installing a CA type of hinge is not applying a

sufficient amount of glue to fully secure the hinge

over its entire surface area; or, the hinge slots are

very tight, restricting the flow of CA to the back of

the hinges. This results in hinges that are only "tack

glued" approximately 1/8" to 1/4" into the hinge

slots. The following technique has been developed to

help ensure thorough and secure gluing.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

Q 4. Remove the covering from the bottom 3/16"

of the fin. Be very careful not to cut into the fin. Test

fit the fin in the slot at the aft end of the stabilizer.

The trailing edge of the fin should be flush with the

trailing edge of the stabilizer. When satisfied with

1 7. It is best to leave a very slight hinge gap,

rather than closing it up tight, to help prevent the

CA from wicking along the hinge line. Make sure

the control surfaces will deflect to the recommended

throws without binding. If you have cut your hinge

slots too deep, the hinges may slide in too far,

22

Page 24

leaving only a small portion of the hinge in the

control surface. To avoid this, you may insert a small

pin through the center of each hinge before

installing. This pin will keep the hinge centered while

you install the control surfaces.

Q 8. Install the hinges in the elevator and attach the

elevator to the stabilizer.

Ql 9. Apply 6 drops of thin CA adhesive to both

sides of each hinge. Allow a few seconds between

drops for the CA to wick into the slot.

Q 10. Follow the same procedure to install the

rudder on the fin.

Q 11. Reinstall the control horns.

LJ 3. Lay one of the threaded rods over the rudder

pushrod on the fuselage top view. The pin in the

clevis should be aligned with the hinge line of the

rudder and fin. Using a pliers/ make two bends in

the threaded rod at the locations shown on the plan.

Q 12. Use a T-pin inserted through the tow hook

block from the inside of the fuselage to locate the

tow hook pilot holes. Thread a 4-40 nut onto the

tow hook. Then, thread the tow hook into the tow

hook block from the bottom of the fuselage to the

depth shown on the plan.

Q

1.

Locate

pushrods. Mark one of the rods "elevator" and the

other "rudder".

Q 2. Thread a nylon clevis 20 turns onto both of

the 2-56 x 12" threaded rods.

the two

1/4"

x1/4"x

22-1/2"

balsa

LJ 4. Cut the rod 6-1/4" from the non-threaded

end. Save the piece of non-threaded rod. On the

threaded rod make a 90° bend 1 /4" from the end

of the rod, opposite the clevis.

Q 5. Use the same procedure to make the elevator

pushrod.

Q 6. Lay both pieces of balsa pushrod material

over the plan at their proper position. Mark the

pushrods at the hole location for the metal rods

(approximately 1-1/8" from the end). Drill a 3/32"

hole through the balsa pushrods at both marks (see

step 9).

LJ 7. Cut a groove in each pushrod from the hole to

the end of the pushrod. The groove needs to

wide enough for the metal rod to fit in.

LJ 8. Taper the end of both balsa pushrods

shown on the plan.

23

be

as

Page 25

Q 3. Place a spacer made from leftover 3/32"

balsa sheet between the rudder and elevator servos.

Mount the servos on the servo rails using the screws

provided with the radio system. Remove the spacer

after the servos are mounted. Wrap the receiver and

receiver battery in foam rubber and place them in

front of the servos.

LJ 9. Install the metal rods in each balsa pushrod.

Wrap the ends of the pushrods with heavy-duty

button thread and apply epoxy to hold the thread in

position and add strength. Set the pushrods aside to

allow the epoxy to cure.

Q 1. Place a couple of pieces of leftover 1/16"

balsa sheeting in the bottom of the radio

compartment to raise the servos. Install the rubber

grommets and eyelets on the rudder and elevator

servos. Set the servos in the radio compartment. Test

fit the aft 1/4" x 1/2" x 2" basswood servo rail in

position. The rail should be snug against the

fuselage sides, but not so tight that it causes the

fuselage sides to bow outward. Once you're

satisfied with the fit, use 6-minute epoxy or aliphatic

resin to glue the aft servo rail in place.

Q 2. After the epoxy cures/ test fit the forward

1/4" x 1/2" x 2" basswood servo rail in position

and glue it in place.

CUT

STRAIN RELIEF

INSIDE FUSELAGE

CUT

RUBBER

BAND

Q 4. Drill a small hole in the side of the fuselage

next to the receiver. Route the receiver antenna out

the hole and attach it to the vertical stabilizer with a

rubber band and T-pin.

Q 5. Install the receiver switch in the side of the

fuselage and connect it to the receiver and receiver

battery.

U 6. Drill a 3/32" hole 1-1/8" from the end of

both balsa pushrods. The holes should be on the

same sides as the holes used for the threaded rod.

Cut a groove from each hole to the end of the

pushrod. The groove needs to be wide enough for

the leftover metal rod to fit in.

24

T-PIN

Page 26

Q 7. Make a 90° bend 1 /4" from the end of both

leftover metal rods. Insert the metal rods in the

grooves of the balsa pushrods and use thread and

epoxy to secure them using the same procedure

as before.

Q 8. Remove the clevises from the pushrods and

insert them in the fuselage. Make sure the correct

pushrod exits the correct slot at the aft end of the

fuselage.

Q 9. Reinstall the clevises to the pushrods and

connect them to the control horns.

Q 10. Install a servo wheel on each servo. Switch

on the transmitter and receiver and center the trims

on your transmitter. Switch the radio system off.

Q 12. Remove the clevises from the pushrods and

the pushrods from the fuselage. Bend the pushrods

down at a 90° angle. Make a second 90° bend

approximately 3/16" from the first bend and trim the

excess rod 1 /8" from the second bend.

LJ 11. With the rudder and elevator in the neutral

position, mark the elevator pushrod where it crosses

the servo wheel at the 3 o'clock position. Mark the

rudder pushrod where it crosses the rudder servo

wheel at the 9 o'clock position.

Q 13. Remove the servo wheels from the servos.

Use a 5/64" drill to enlarge the hole in the servo

wheel for the pushrod. Insert the pushrods in the

servo wheels and reinstall the servo wheels on

the servos.

Ul 14. Install the hatch and switch the radio system

on. Move the controls on the transmitter to check for

any binding of the pushrods.

25

Page 27

We recommend the following control surface throws:

4-CHANNEL RADIO SET-UP

(STANDARD MODE 2)

ELEVATOR MOVES UP

RUDDER MOVES RIGHT

2-CHANNEL RADIO SET-UP

ELEVATOR MOVES UP

Elevator: 3/8" [9.5mm] up

Rudder: 1-1/2" [38mm] left

Note: The balance and control throws for the

Wanderer have been extensively tested. This chart

indicates the settings at which the Wanderer flies

best. Please set up your model to the specifications

listed above. If, after you become comfortable with

your Wanderer, you would like to adjust the throws

to suit your tastes, that's fine. Too much throw can

force the sailplane into a stall, so remember, "more

is not always better."

NOTE: This section is VERY important and must NOT

be omitted! A model that is not properly balanced

will be unstable and possibly unflyable.

3/8"[9.5mm] down

1-1/2"[38mm] right

RUDDER MOVES RIGHT

The throws are measured at the widest part of the

elevator and rudder. Adjust the position of the

pushrods at the servo wheels to control the amount

of throw. You may also use the ATV's if your

transmitter has them but the mechanical linkages

should still be set so the ATV's are near 100% for

the best servo resolution (smoothest, most

proportional movement).

2-11/16"

[68 mm]

Q 1. The balance point (C.G.) is located 2-11/16"

[68 mm] back from the leading edge of the wing,

next to the fuse sides as shown in the sketch and on

the fuselage plan. Accurately mark the balance

point on the bottom of the wing on both sides of the

fuselage. Use thin strips of tape or a felt-tip pen to

make the marks.

26

Page 28

Hint: Reference the full-size fuse plan to help you

locate the proper balance point. This is the balance

point at which your model should balance for your

first flights. After initial trim flights and when you

become more acquainted with your Wanderer, you

may wish to experiment by shifting the balance up

to 3/16"

its flying characteristics. Moving the balance

forward may improve the smoothness and stability,

but the model may become more difficult to slow for

landing. Moving the balance aft makes the model

more agile with a lighter, snappier "feel." In any

case, please start at the location we recommend. Do

not at any time balance your model outside the

recommended C.G. range.

[5

mm] forward or backward to change

3. Set the model on the balancer at the balance

point. If the tail drops, the model is "tail heavy" and

you must add weight to the nose to balance the

model. If the nose drops, it is "nose heavy" and you

must add weight to the tail to balance the model.

NOTE: Weight may be added by using Great Planes

(GPMQ4485) "stick-on" lead weights. Later, if the

balance is O.K., you can glue the weights inside the

fuselage permanently.

If possible, first attempt to balance the model by

changing the position of the receiver battery. If you

are unable to obtain good balance by doing so,

then it will be necessary to add weight to the nose

or tail to achieve the proper balance point.

At this time check all connections, including servo

horn screws, clevises and servo cords.

Q 2. Attach the wing to the fuselage with six #64

rubber bands, two on each side running straight

across the wing and two crossing the wing to form

an "X". With the wing attached to the fuselage and

all parts of the model installed (ready to fly), hold

the model right side up with the stabilizer level. The

Great Planes CG Machine™ Balancer works great

for balancing the model.

CHARGE THE BATTERIES

Follow the battery charging procedures in your

radio instruction manual. You should always charge

your transmitter and receiver batteries the night

before you go flying and at other times as

recommended by the radio manufacturer.

GROUND CHECK YOUR

MODEL

Inspect your radio installation and confirm that all

the control surfaces respond correctly to the

transmitter inputs. Make sure all screws remain tight

and the hinges are secure.

27

Page 29

RANGE CHECK YOUR MODEL

LANDING

Whenever you go to the flying field, check the

operational range of the radio before the first flight

of the day. First, make sure no one else is on your

frequency (channel). With your transmitter on and

the antenna collapsed you should be able to walk at

least 100 feet away from the model and still have

control. While you work the controls, have a helper

stand by your model and tell you what the control

surfaces are doing. If the control surfaces are not

always responding correctly, do not fly! Find and

correct the problem first. Look for loose servo

connections or corrosion, a defective on/off switch,

low battery voltage or a defective receiver battery, a

damaged receiver antenna, or a receiver crystal that

may have been damaged from a previous crash.

When it's time to land, fly a normal rectangular

landing pattern with your final approach directly

into the wind. For your first few landings/ plan to

land slightly faster than stall speed.

Have a ball! But always remember to think about

your next move and plan each maneuver before you

do it. Impulsively "jamming the sticks" without any

thought is what gets most fliers in trouble, not lack of

flying skill. Happy Landings!

DYNAFLITE™ HI-STARTS

DYFP8301 (Standard) .

DYFP8302 (Heavy-Duty)

We recommend that if you have never previously

flown an R/C airplane, you find an experienced

sailplane pilot. An experienced pilot will be able to

help you get the Wanderer trimmed properly and to

help you with your first few flights. If you cannot

locate an experienced pilot, we recommend that you

gently hand launch the Wanderer a few times to get

the sailplane trimmed out for a smooth glide. Get

the feel of the controls. Try to avoid using the rudder.

At this low of an altitude the wing tips may catch the

ground and damage the Wanderer. After you are

comfortable with the controls, you can then move up

to a

hi-start launch.

We recommend that you take it easy with your

Wanderer for the first several flights, gradually

"getting acquainted" with this great model.

• Compact power for high-altitude launches.

• Complete systems for 2-meter and unlimited class

sailplanes.

A Dynaflite Hi-Start and 800' of clear launch

all you need to send your sailplane rocketing up to 500'

in the air! Easy to lay out and retrieve, Hi-Starts include

everything required for sailplane launches: 100' of UVstabilized surgical tubing, injection-molded reel,

parachute, steel stake and tow ring, and nylon tow line.

Standard Hi-Start with 1/8" diameter tubing offers

strong, steady power for 2-meter sailplanes. Heavy-Duty

Hi-Start with 3/16" diameter tubing provides the launch

power needed for sailplanes spanning 100" or more.

area are

Loading...

Loading...