Page 1

• BUILDS QUICKLY

• REALISTIC FUN SCALE® MODEL

• HUGE, 89" WINGSPAN (IMAA Legal)

READ THROUGH THIS INSTRUCTION MANUAL FIRST. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

Instruction Manual

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Dynaflite's liability exceed the original cost of the purchased kit.

Further, Dynaflite reserves the right to change or modify this warranty without notice. In that

Dynaflite has no control over the final assembly or material used for final assembly, no liability

shall be assumed nor accepted for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled product, the user accepts all

resulting liability. If the buyer is not prepared to accept the liability associated with the use of

this product, return this kit immediately in new and unused condition to the place of purchase.

CHPGP03 Printed in USA V1.0 Entire Contents © Copyright 2000

WARRANTY

Page 2

Introduction................................................2

Precautions ................................................2

Preparations

..............................................3

Required Accessories..........................................3

Optional

Suggested

Building

Adhesives

Accessories

Supplies

Notes

..........................................4

............................................4

....................................................5

............................................................5

Common Abbreviations......................................6

Types

of

Wood

....................................................6

Inch/Metric Ruler..................................................6

Die-Cut Patterns............................................7 & 8

Build the Stabilizer & Elevators

................9

Build the Vertical Fin & Rudder................10

Build the

Build

Build the Wing

Join the Wing

Build the Ailerons

Fuselage

the

Bulkheads

....................................12

..........................................12

..........................................19

Panels

................................23

....................................26

Build the Flaps..........................................27

Mount

Finish the

the Wing

Fuselage

to

the Fuselage

..............28

..................................29

Final Assembly..........................................33

Finishing

Set the Control Throws

Balance

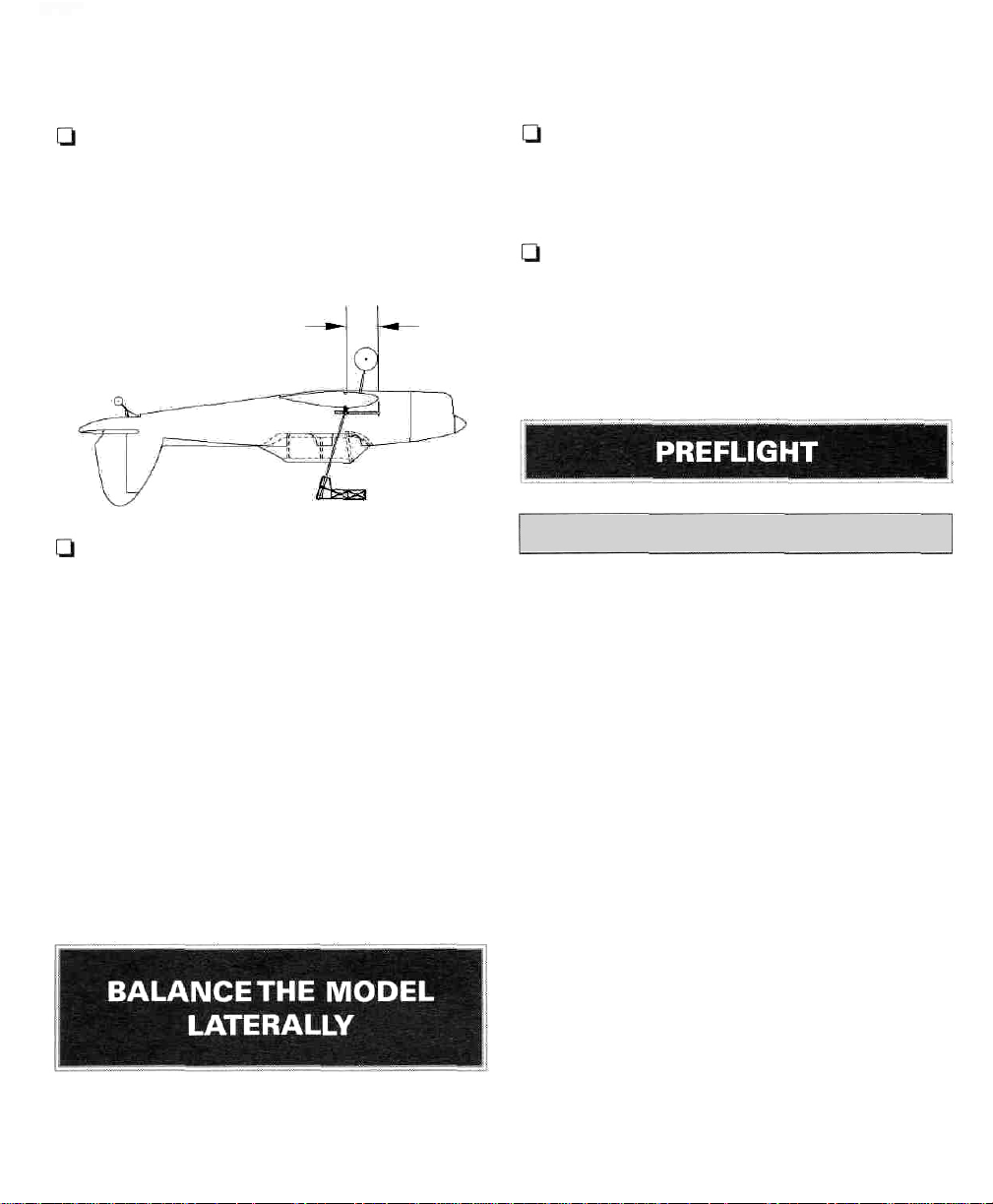

Balance the Model Laterally

..................................................35

............................36

Your

Model

..................................36

....................37

Preflight....................................................37

At

Home

............................................................37

At the Flying Site ..............................................38

Engine Safety Precautions

AMA

Safety Code (excerpt)

......................38

......................39

Flying ........................................................39

Find a Safe

Place

to

Fly

....................................39

Takeoff................................................................40

Flight ..................................................................40

Landing

..............................................................40

At Dynaflite we take pride in offering kits that

are simple and straightforward to build and

provide value for your modeling dollar.

Because of the size and cost of this model we

assume you have built several models and have

a general working knowledge of modeling and

its terms. If you HAVE NOT built and flown

several kits, do yourself a favor - back up and

get some experience before beginning this kit.

1.You must build the plane according to the

plan and instructions. Do not alter or modify

the model, as doing so may result in an unsafe

or unflyable model. In a few cases the plan

and instructions may differ slightly from

the photos. In those instances the plan

and written instructions are correct.

2. You must take time to build straight, true

and strong.

3. You must use a proper R/C radio that is in

first class condition, the correct size of engine

and correct components (fuel tank, wheels,

etc.) throughout your building process.

4. You must properly install all R/C and other

components so that the model operates

properly on the ground and in the air.

5. You must test the operation of the model

before every flight to insure that all equipment

is operating and you must make certain that the

model has remained structurally sound.

Congratulations on your choice of this kit for

your next project. The Chipmunk is a Fun Scale®

model of a true classic aircraft. It has the

presence that only a big model can carry off.

6. If you are not already an experienced R/C

pilot, you must fly the model only with the

help of a competent, experienced R/C pilot.

Remember: Take your time and follow

instructions to end up with a well-built

model that is straight and true.

2

Page 3

Your Chipmunk is not a toy, but a sophisticated

working model that functions very much like an

actual airplane. Because of its realistic

performance, if you do not assemble and

operate your Chipmunk correctly, you could

possibly injure yourself or spectators and

damage property.

If you are calling for replacement parts,

please look up the part numbers and the

kit identification number (stamped on the

end of the carton) and have them ready

when you call.

To make your R/C modeling experience

totally enjoyable, get assistance with

assembly and your first flights from an

experienced, knowledgeable modeler.

You'll learn faster and avoid risking your model

before you're truly ready to solo. Your local

hobby shop has information about flying clubs

in your area whose membership includes

qualified instructors.

Your Dynaflite Chipmunk is intended for

scale and general sport flying including mild

aerobatics such as chandelles, stall turns,

loops and rolls. Its structure is designed to

withstand such stresses. If you intend to use

your Chipmunk for more rigorous types of

flying such as aggressive aerobatics or

flying from rough fields, it is your

responsibility to reinforce areas of the

model that will be subjected to the resulting

unusually high stresses.

Note: We, as the kit manufacturer, provide

you with a quality kit and great instructions,

but ultimately the quality and flyability of

your finished model depends on how you

assembled it; therefore, we cannot in any

way guarantee the performance of your

completed model and no representations are

expressed or implied as to the performance or

Isafety of your completed model.

Please inspect all parts carefully before

you start to build! If any parts are missing,

broken or defective, or if you have any

questions about building or flying this

model, please call us at (217) 398-8970.

You can also reach us by e-mail at:

productsupport@dyna flite. com

You can also contact the Academy of Model

Aeronautics (AMA), which has more than 2,500

chartered clubs across the country. We

recommend you join the AMA which will insure

you at AMA club sites and events. AMA

Membership is required at chartered club fields

where qualified flight instructors are available.

Contact the AMA at the address or toll-free

phone number below.

Academy of Model

Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(800) 435-9262

Fax (765) 741-0057

Internet address:

http://www.modelaircraft.org

REQUIRED ACCESSORIES

These are the items "not included" with you kit,

that you will need to purchase separately. Items

in parentheses such as (GPMQ4107) are suggested

part numbers recognized by distributors and

hobby shops and are listed for your ordering

3

Page 4

convenience. GPM is the Great Planes® brand,

TOP is the Top Flite® brand and HCA is the

Hobbico® brand.

4-6 Channel Radio with One Standard Servo

(Three with Flaps) and Five HighTorque Servos.

(2) "Y" Connectors (Ailerons, Flaps)

(2) 12" Servo Extension Wires

Engine - 1.08 to 1.5 2-stroke, 1.2 to 1.6

4-stroke or 25cc Gasoline

Exhaust Header, In-cowl Muffler

Fuel Filler Valve (GPMQ4160 Glow,

GPMQ4161 Gas)

2-3/4" Spinner (GPMQ4527, Red)

Engine Mount and Mounting Hardware

16 oz. Fuel Tank (GPMQ4107) (or Gasoline

CompatibleTank)

Standard Fuel Tubing (GPMQ4131) (or

Gasoline CompatibleTubing)

(2) 4" Main Wheels (ROBQ1537)

(1) 1-1/2"Tail Wheel (GPMQ4243)

(4) 1/4" Wheel Collars (DUBQ1200)

(2) 1/8" Wheel Collars (GPMQ4304)

Top Flite MonoKote® Covering Film

(Approx. Four 6' Rolls)

Paint for Fuelproofing and Painting the

Engine Cowl and the Canopy

(Dor (2) 1/5 Scale Pilot(s)

1/4" Latex Foam Rubber (HCAQ1000)

(19) Heavy Duty Hinges (Twenty Seven

with flaps) (ROBQ2510)

All Pushrods and Control Hardware

- (4) Heavy Duty Control Horns (Six with

Flaps) (DUBQ1985)

- (5) 4-40 Threaded Metal Clevis (Seven with

Flaps) (GPMQ3794)

-(5) 4-40 Metal Solder Clevis (Seven with

Flaps) (GPMQ3814)

- (5) 4-40 Hex Nuts (Seven with Flaps)

(GPMQ3304)

- (2) 4-40 x 12" Wire Pushrod, Threaded One

End (Four with Flaps) (GPMQ3752)

- (3) 4-40 x 48" Pushrods (GPMQ3718)

- (1) Throttle Pushrod (GPMQ3700)

- Throttle Hardware

OPTIONAL ACCESSORIES

(2) Robart RoboStruts (Shock Absorbing)

(ROBQ1600)

SUGGESTED SUPPLIES

4 oz.Thin CA Adhesive - (GPMR6004)

4 oz. Medium CA Adhesive - (GPMR6010)

2 oz. Thick CA Adhesive - (GPMR6015)

CA Accelerator - (HCAR3750)

CAApplicatorTips - (HCAR3780)

6-Minute Epoxy - (GPMR6045)

30-Minute Epoxy - (GPMR6047)

4 oz. Aliphatic Resin Glue (GPMR6161)

Great Planes Plan Protector (GPMR6167)

4

Page 5

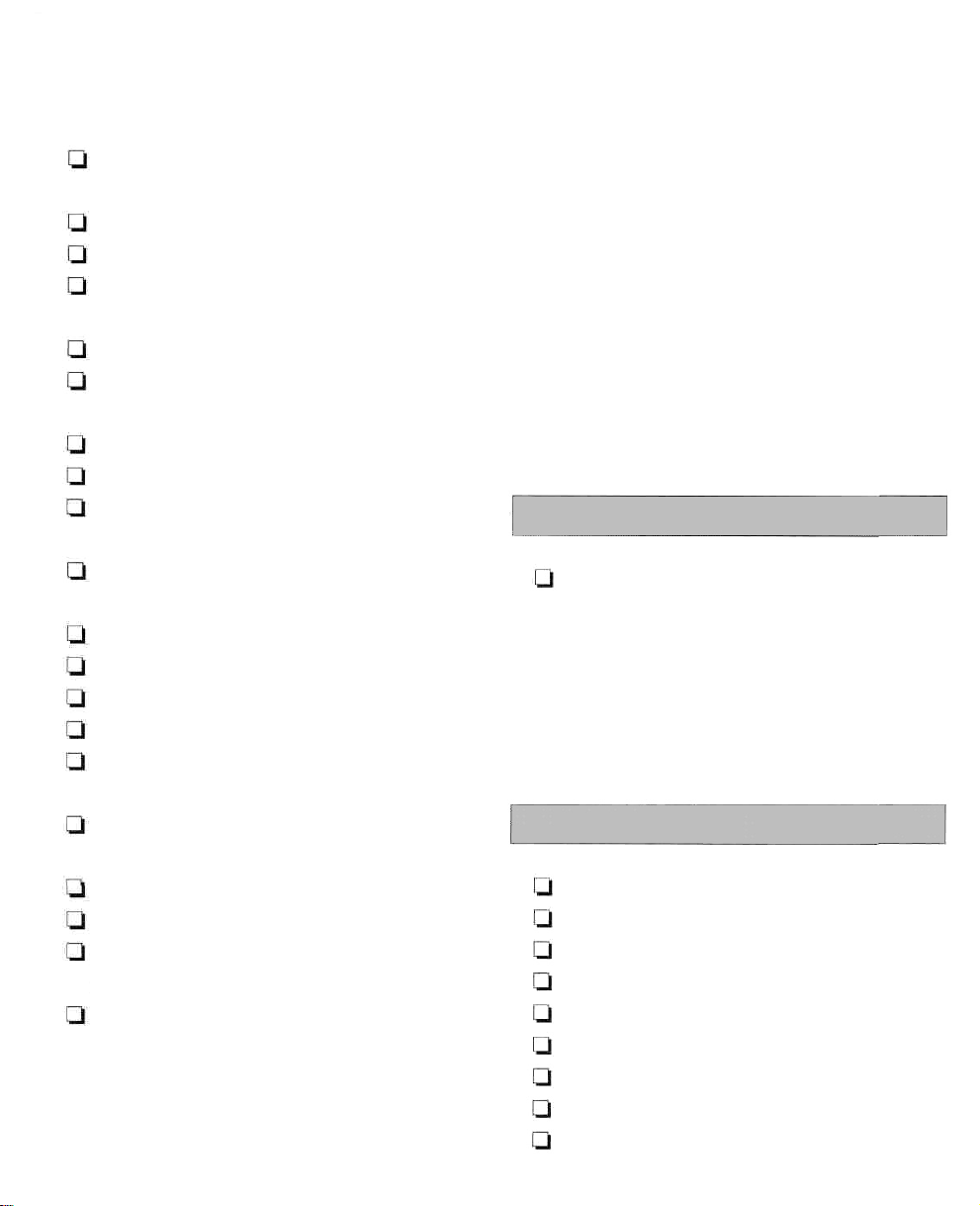

A flat, durable, easy-to-handle sanding tool is a

necessity for building model airplanes. Great

.Planes makes a complete range if Easy-Touch"

Bar Sanders and replaceable Easy-Touch

adhesive-backed sandpaper. On our workbench,

we have four 11" Easy-Touch Bar Sanders,

equipped with #50, #80, #150 and #220-grit

sandpaper. This setup is all that is required for

almost any sanding task. Custom sanding blocks

can be made from balsa for sanding hard-to-

reach spots. We also keep some #320-grit wetor-dry sandpaper for finish sanding before

covering.

the pieces as you cut them for later reference.

By doing this now, you won't have to splice

pieces together later.

ADHESIVES

This kit is built with three types of glue.

Cyanoacrylate: CA glues cure almost instantaneously

and are moderately strong. There are different

viscosities of CA's intended for different

conditions you will encounter when you build.

Thin CA is great for "tack-gluing," for glue joints

that fit well and for parts that are already joined

but need to be permanently bonded. Medium

CA is used for general construction where you

apply glue to one part, then join it to another

part. Thick CA is great for glue joints that don't

fit perfectly or parts that require a little time for

positioning before the glue cures. You will

encounter many other conditions that require

one or the other types of CA.

For future reference, here's a list of Easy-Touch

Bar Sanders and adhesive-backed sandpaper:

5-1/2" Bar Sander(GPMR6169)

11" Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

12' Roll of adhesive-backed sandpaper,

80-grit(GPMR6180)

150-grit(GPMR6183)

220-grit (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

BUILDING NOTES

IMPORTANT: During construction you will be

using a number of balsa sticks to frame various

assemblies. Ample material is included but you

should study the plans, then make an effort to

cut the longest pieces you will need first. Label

Always use CA in a well ventilated area. Open

some windows or place a fan in the room to

circulate the air. Do not lean directly over your

work when you use CA and look away while it

cures or "sets off." CA can cure immediately

upon contact with skin so if you accidentally

bond your fingers, do not use vigorous motion

to separate them. Use CA Debonder (GPMR6039)

or acetone (nail polish remover) or soak your

fingers in warm water for a few minutes.

Never point the tip of a CA bottle toward your

face and be especially careful when you unclog

a CAtip. Hobbico CAApplicatorTips (HCAR3780)

are highly recommended and will help keep the

bottle from clogging. Keep paper towels or

tissues close by to immediately absorb excess

CA dropped on your model or work area. Read

all the warning labels on your CA bottle. CA

Accelerator is a chemical that you can spray

over uncured CA to make it cure immediately. A

mist spray of accelerator will do the job. Do not

inhale the vapors! Some modelers "preprime"

5

Page 6

the parts to be glued with accelerator, join

them, then add the CA. This way the CA is

guaranteed to cure immediately. This

prepriming is especially handy when you use

thin CA because it will cure before all of the

glue soaks into the wood away from the joint.

We do not recommend you build your entire

model with this method and use accelerator

only when necessary. Often, overspray from

accelerator used hours or even days earlier on

nearby glue joints will cause the CA you use on

the next step to cure prematurely and

unexpectedly - so be careful!

Throughout the assembly of this model, THIN

CA should be used unless the step calls for

another type of adhesive.

minute epoxy is the strongest as it allows the

epoxy to soak into the wood thoroughly. While

itsets within 30 minutes, it is not fully cured for

two or more hours.

COMMON

Fuse = Fuselage

Ply = Plywood

" = Inches

ABBREVIATIONS

Stab = Horizontal Stabilizer

LE = Leading edge (front)

TE =Trailing edge (rear)

Aliphatic Resin: Resin glues require that parts

be pinned or clamped together while the glue

dries; typically 15 - 30 minutes. Resin glues are

very strong and work well with balsa and

plywoods.

Epoxy: Epoxy glues are the strongest but

require the most time to cure. Six-minute epoxy

cures the fastest; it sets within six minutes but

is not fully cured for one hour or more. Thirty-

Inch Scale

0"

1"

2"

3"

TYPES OF WOOD

Balsa Basswood Plywood

4"

5"

6"

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

Metric Scale

6

Page 7

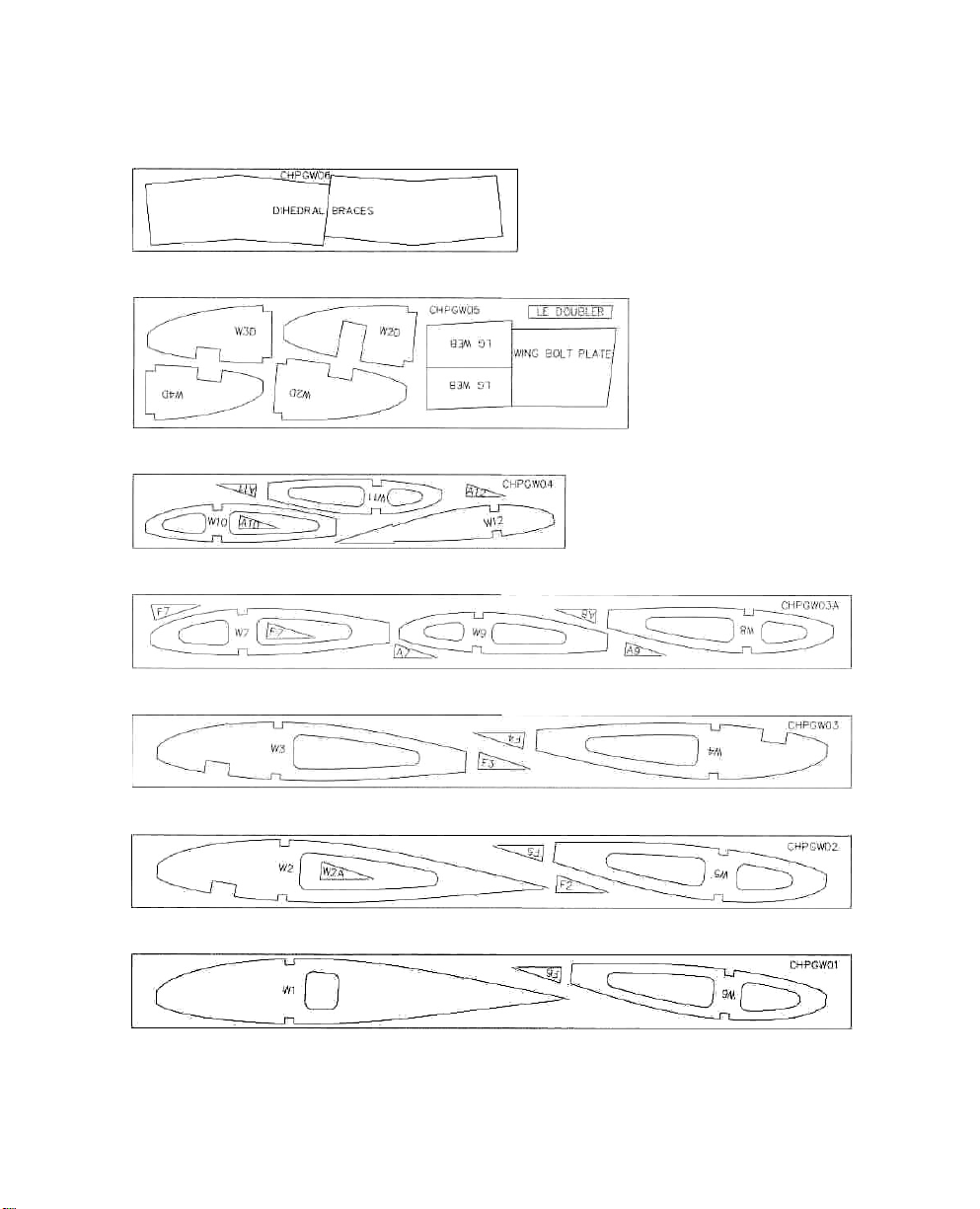

Die-Cut Pattern

CHPGIPW06

1/16" X 3-3/8" X 16" PLY

CHPGW05

CHPGW04 2 REQ.

CHPGW03A 2 REQ.

1 REQ.

1/8" X 5-3/8" X 20-5/8" PLY

3/32" X 3" X 18" BALSA

Note: If you will be building functional flaps for your

Chipmunk, glue in the lightening holes in ribs W4

and W5.

Note: This page shows the location of the die-cut

parts for the wing. Not all parts are marked on the die

sheets. Be sure to mark all parts with a ball point pen

prior to removing them from the die sheets.

2

REQ,

3/32" X 3" X 30" BALSA

CHPGW03 2 REQ.

3/32" X 3" X 30" BALSA

CHPGW02 2 REQ.

3/32" X 3" X 30" BALSA

CHPGW01 2 REQ.

3/32" X 3" X 30" BALSA

7

Page 8

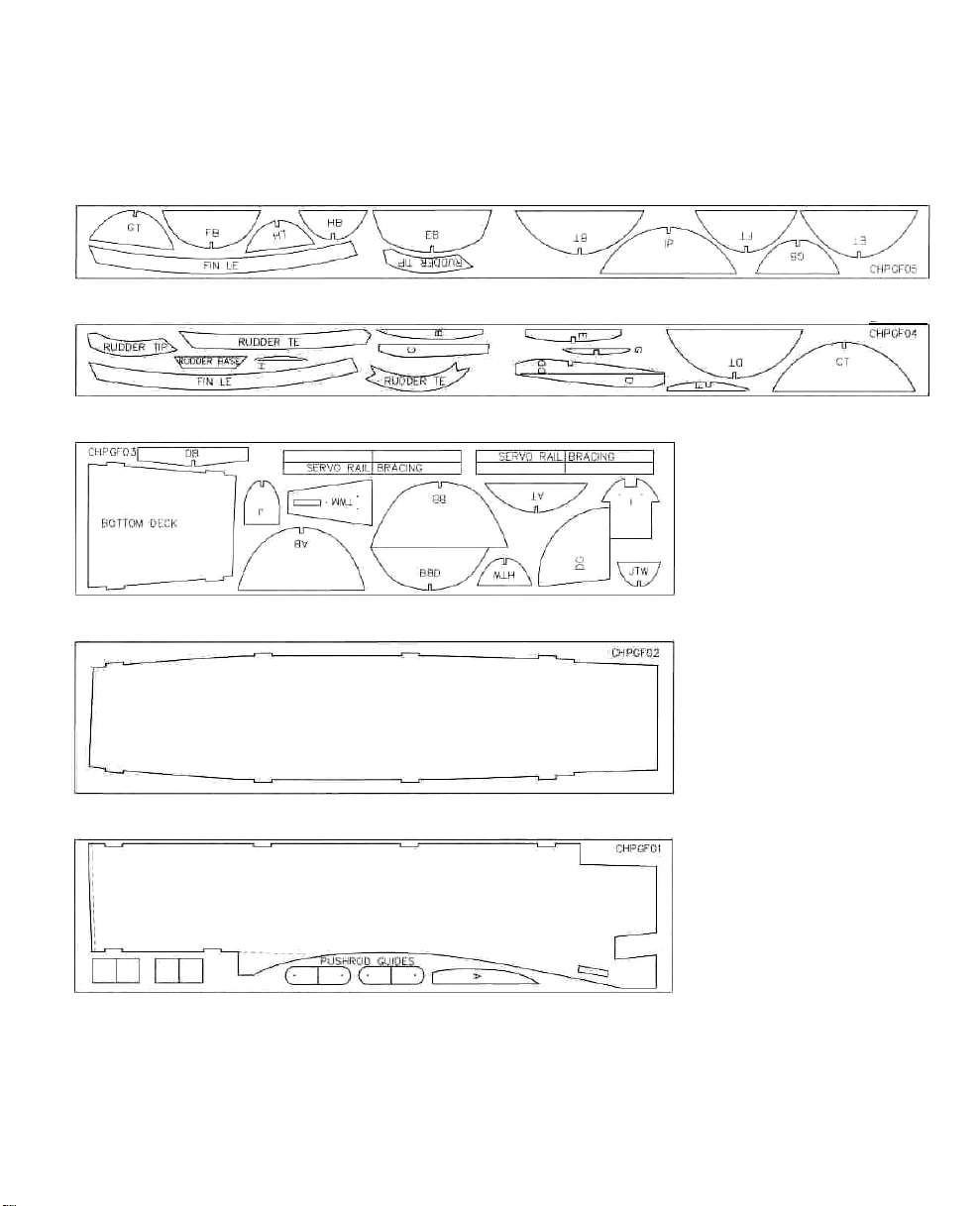

Die-Cut Pattern

CHPGF05 1 REQ.

1/8" X 3" X 36" BALSA

CHPGF04

1/8" X 3" X 36" BALSA

CHPGF03 1 REQ,

1/8" X 6-3/8" X 25-1/4" PLY

CHPGF02 1 REQ.

2

REQ.

TOP DECK

1/8" X 6-3/8" X 25-1/4" PLY

CHPGF01 2 REQ.

FUSELAGE SIDE

CONTROL

HORN

MOUNTS

1/8"

X

6-3/8" X 25-1/4"

PLY

Note: This page shows the location of the

die-cut parts for the fuselage. Not all parts are

marked on the die sheets. Be sure to mark all

parts with a ball point pen prior to removing

them from the die sheets.

8

Page 9

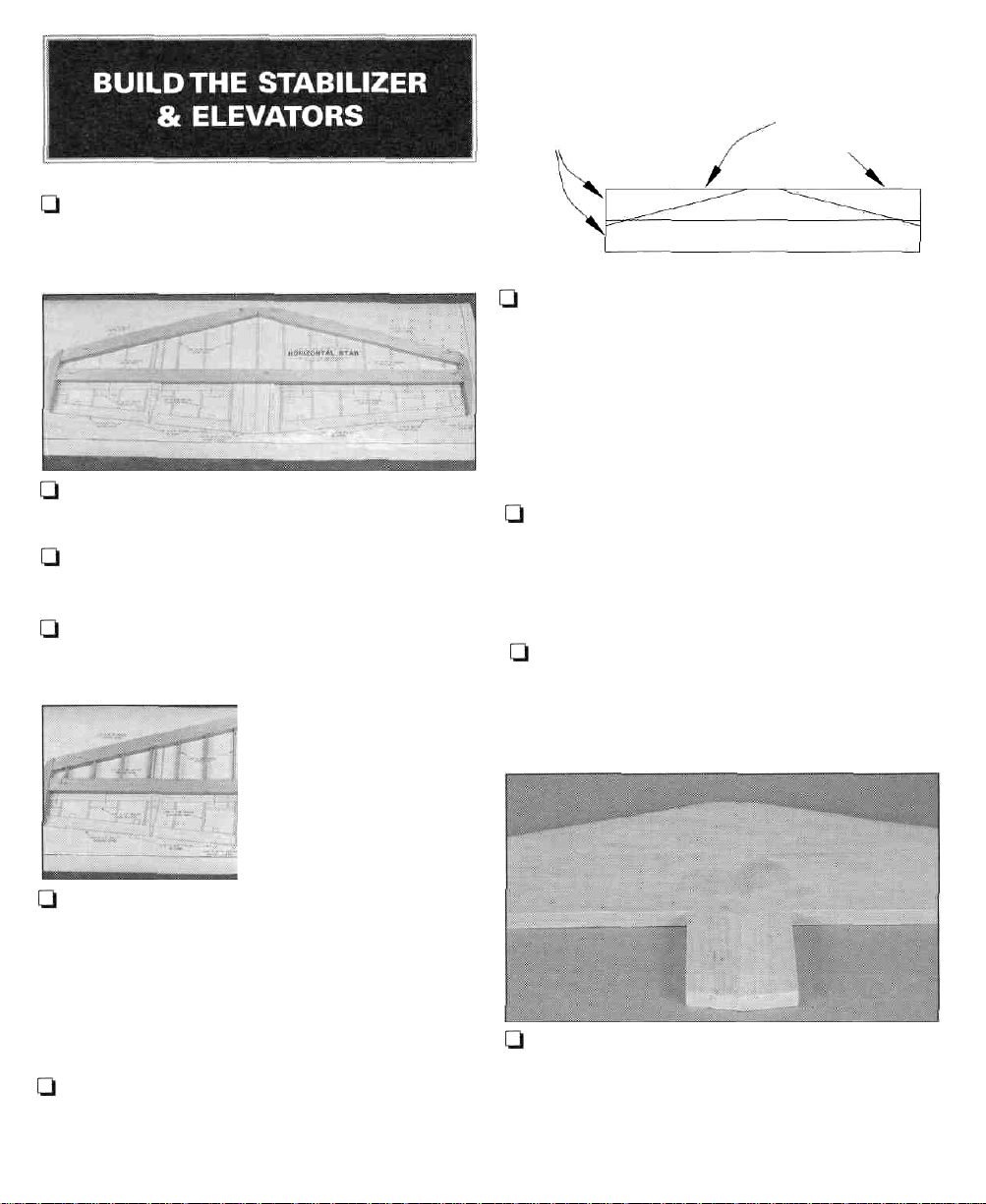

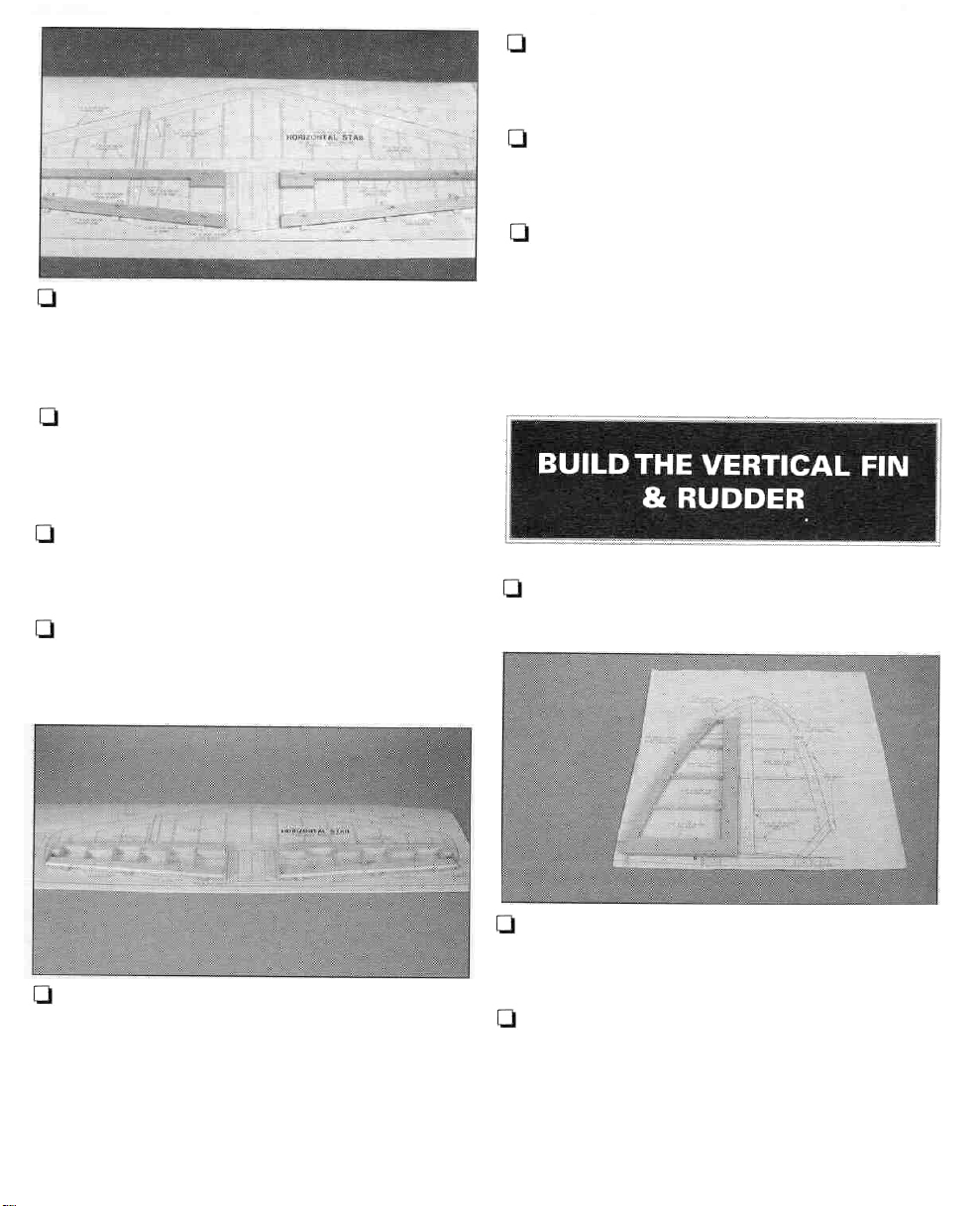

STAB SHEETING

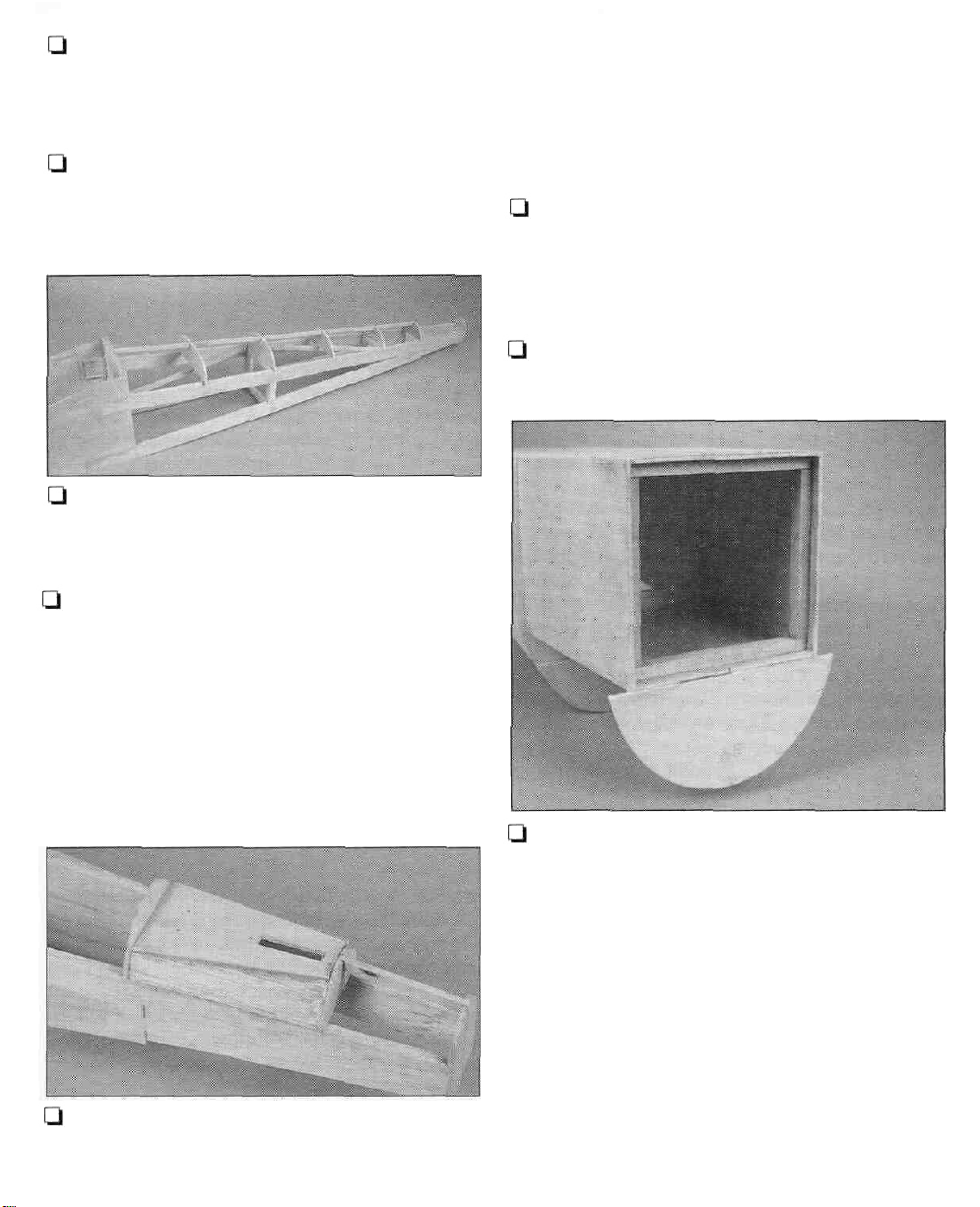

1. Cut the stabilizer drawing from the fuselage

plan and place it on your building board. Cover

the plan with Great Planes Plan Protector.

Q 2. Cut the trailing edge from 1/2" x 15/16" x

36" balsa and pin it in place over the plan.

Ql 3. Cut both leading edges from 1/2" x 15/16"

x 36" balsa and pin them in place over the plan.

Q 4. Cut and fit the ribs from 1/8" x 1/2" x 30"

balsa. Cut the longer ribs first. When satisfied

with the fit, glue them into position.

1/16"X3"X30"

BALSA SHEETING

USE LEFTOVER

FOR FIN SHEETING

Q7. Sheet the stab with 1/16" x 3" x 30" balsa on

both the top and bottom. Do this with the stab

flat on your building board and use care not to

twist it as you glue the sheeting into place. Use

pieces of leftover 1/16" balsa sheeting to sheet

the stab tips.

Ql 8, Sand the trailing edge of the stab flat as

shown on the cross-section of the plan. Rough

sand the stab to the shape shown.

I—I 9. Mark the centerline on the rear edge of the

TE along its entire length.

l-l 5. Cut and shape the tips from 1/2" x 3/4" x

12" balsa using the plans as a guide. Glue and

pin them in place.

Note: It is important that the ribs fit the LE and

TE well. It is not important that each rib fit the

exact location shown on the plan.

Q 6. Remove the stab from the plan. Sand the

top and bottom surfaces flat and even. Use care

not to gouge any of the ribs.

LI 10. Cut the four stab filler blocks from 5/8" x

15/16" x 18" balsa and glue them to the center of

the stabTE as shown on the plan and photo.

Note that two of these blocks are cut to a width

of 3/4".

9

Page 10

Q 16. Notch the LE of both elevators where

shown on the plan and fit and glue the die-cut

1/8" ply horn bases into place.

Q 17. Remove the elevators from the plan and

rough sand them to the shape shown in the

cross-section. Use care not to gouge the ribs.

[.-111. Build both elevators at the same time. Cut

the leading edges from 5/8" x 1/2" x 30" balsa

and pin them to the plan.The leftover 5/8" x 1/2"

balsa will be used later for hinge blocks.

Ql 12. Cut some shims from 3/16" x 3/8" x 24"

balsa and place them in position over the plan

at theTE.The remainder of this stick will be used

for the fin ribs so be sure to save at least 14".

l-t 13. Cut the trailing edges from 1/4" x 3/4" x

30" balsa. Pin them into position on top of the

shims.

Q 14. Cut and fit the eight elevator hinge blocks

from 5/8" x 1/2" x 30" balsa. Glue them into

position where shown on the plan.

Q 18. Mark

leading edges along their entire length. Using

the cross-section on the plan as a reference,

sand

shown. Make sure the angle of the "V" is

enough to allow for the full up and down

movement of the elevators.

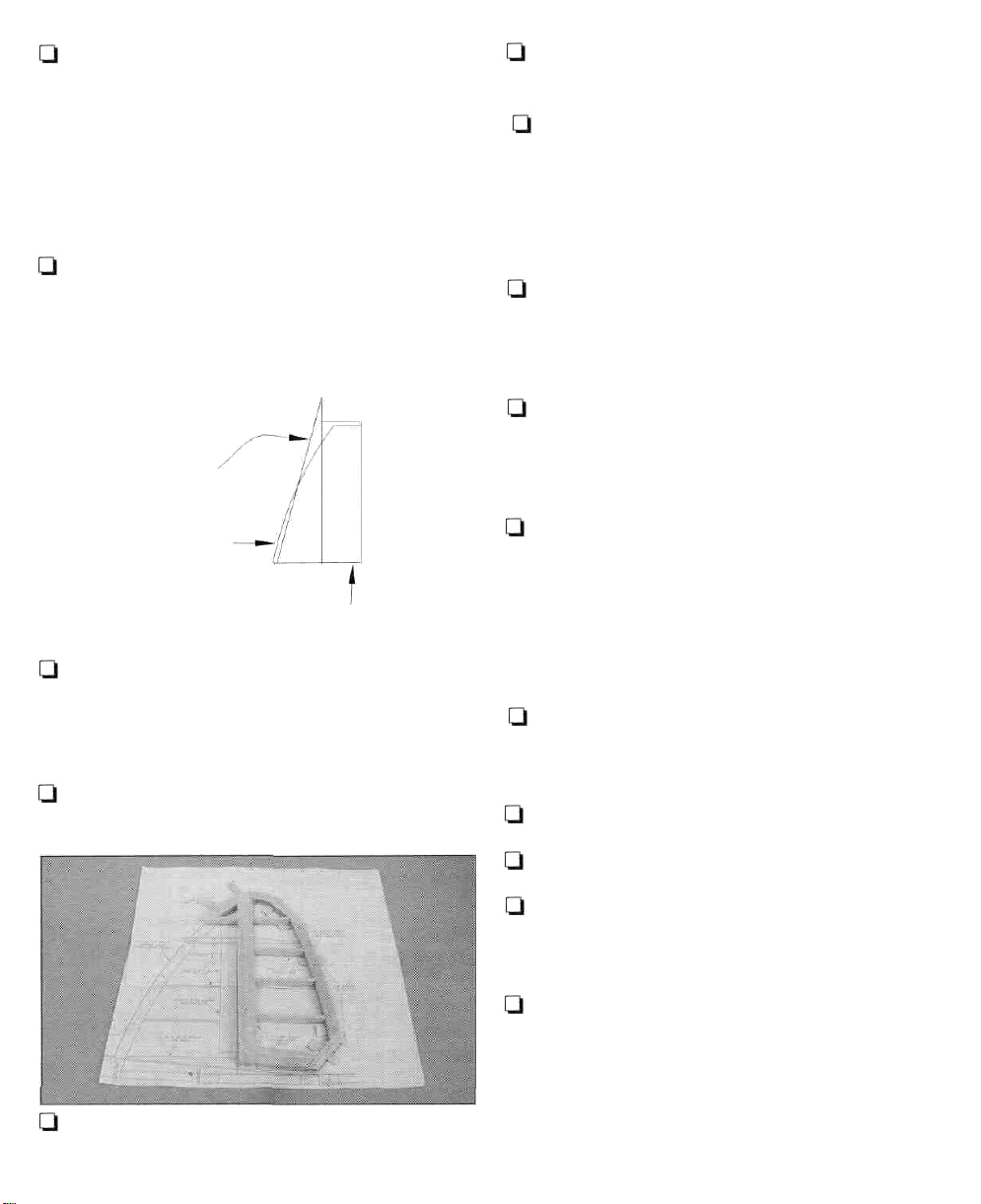

Q 1. Cover the fin/rudder drawing with Plan

Protector.

the leading edges to the "V" shape

the

centerline

of the

elevator

Ql 15. Cut and fit the ribs from 1/8" x 5/8" x 36"

balsa. Cut the longer ribs first. When satisfied

with the fit, glue them into position. Note that

the root and tip ribs extend full length. Note: It

is important that the ribs fit the LE andTE well.

It is

not

important that each rib fit the exact

location shown on the plan.

Q 2. Glue the three die-cut 1/8" balsa fin leading

edge pieces together to form a LE lamination.

Pin this in place over the plan.

[-I 3. Cut the fin post (trailing edge) from 3/8" x

15/16" x 18" balsa and pin it in position.

Q 4. Cut the fin base from the remaining 3/8" x

15/16" balsa and pin it into position. Glue all

three pieces together.

10

Page 11

5. Cut and fit the ribs from the remainder of

the 3/16" x 3/8" x 24" balsa. Cut the longer ribs

first. When satisfied with the fit, glue them into

position.

Note: It is important that the ribs fit the LE and

TE well. It is

not

important that each rib fit the

exact location shown on the plan.

Q 6. Remove the fin from the plan. Sand the top

and bottom surfaces flat and even. Use care not

to gouge any of the ribs.

FIN SHEETING

LEFTOVER

STAB SHEETING

Q 10. Cut the rudder base from the rest of the

1/2" x 15/16" balsa. Glue and pin it into place.

I—I 11. The rudder tip leading edge is built up

from three laminations of die-cut 1/8" balsa

pieces, for a total thickness of 3/8". Glue the

three pieces together and pin them in place on

the plan, using some leftover 1/16" balsa shims

where shown.

Q 12.The rudder trailing edge is built from two

laminations of die-cut 1/8" balsa pieces, for a

total thickness of 1/4". Build two of these

assemblies using the plan as a reference.

Q 13. Cut some shims from leftover 1/8" balsa

and place them in position over the plan at the

TE where shown. Pin and glue the TE into

position.

SCRAP

SHEETING

1/16" X 3" X 10-1/2"

BALSA SHEETING

LJ 7. Sheet the fin with 1/16" x 3" x 30" balsa on

both sides. Do this with the fin flat on your

building board and use care not to twist it as

you glue the sheeting into place.

Q 8. Rough sand the fin to the shape shown in

the cross-section.

Q 9. Cut the rudder leading edge from 1/2" x

15/16" x 18" balsa and pin it to the plan.

Q 14. Cut and fit the ribs from 3/16" x 1/2" x 18"

balsa. Cut the longer ribs first. When satisfied

with the fit, glue them into position.

Note: It is important that the ribs fit the LE and

TE well. It is

not

important that each rib fit the

exact location shown on the plan.

Q 15. Remove the rudder from the plan and

rough sand it to the shape shown in the cross-

section.

Q 16. Tack glue the rudder to the fin.

Q 17. Sand the assembly to its final shape.

Q 18. Separate the rudder from the fin. Sand

the trailing edge of the fin flat as shown on the

cross-section on the plan.

Q 19. Mark the centerline of the fin trailing edge

and rudder leading edge along their entire

length. Using the cross-section on the plan as a

reference, sand the rudder leading edge to

the "V" shape shown. Make sure the angle of

the "V" is enough to allow for the full left and

right movement of the rudder.

11

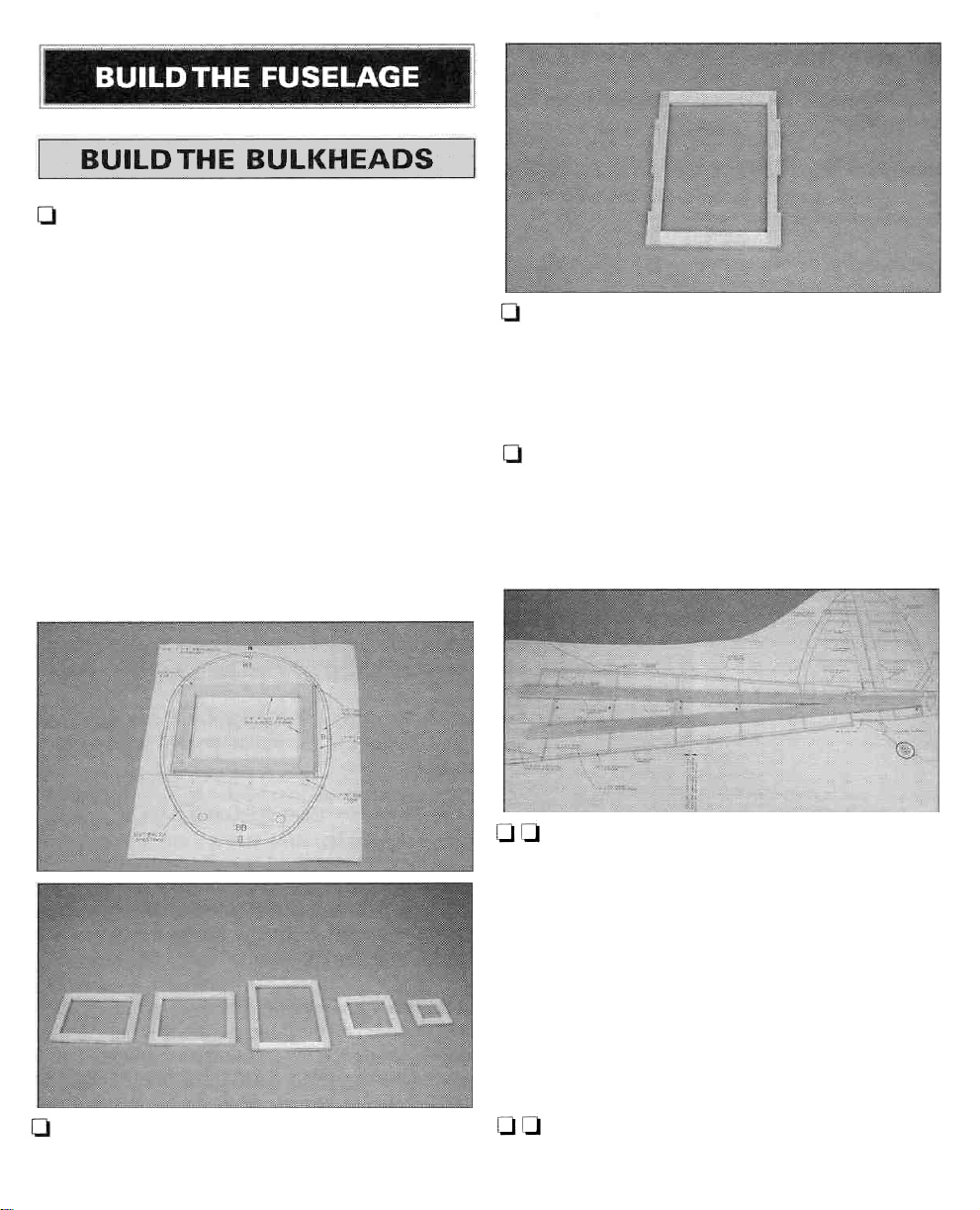

Page 12

Q 1.The fuselage plan is in two pieces. Cut the

plan as indicated and tape the two parts

together. Cut the fuselage top view from the

plan. Cut the drawings for bulkheads B, C, D, F

and H from the plan. Place the bulkhead

drawings on your workbench and cover them

with Plan Protector.

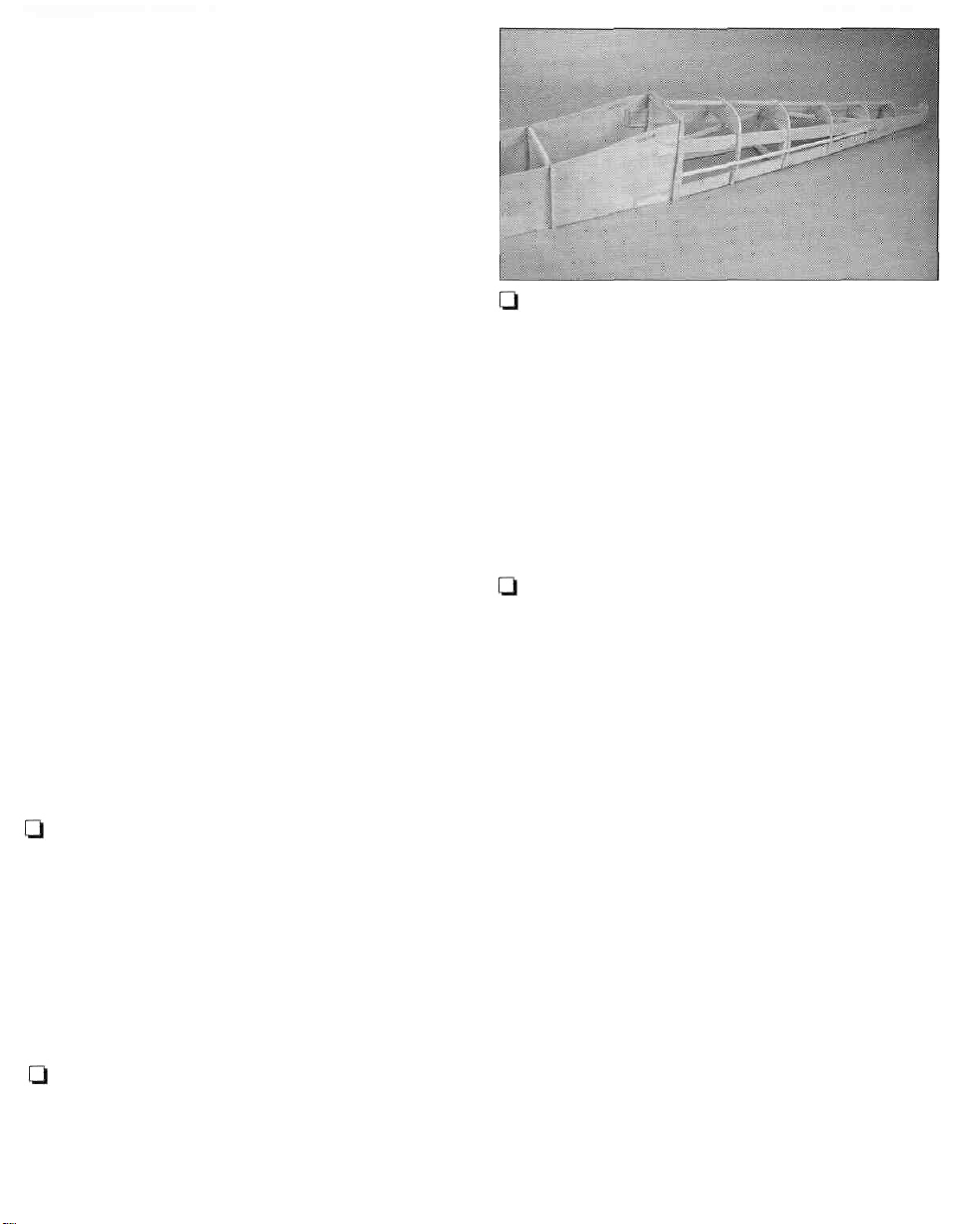

[-I 3. Inner bulkhead D has notches cut in the

sides for the longerons and longeron doublers.

These notches may be cut now or later when

the inner bulkhead is fitted to the fuselage side.

Q 4. Place the fuselage side plan on your

workbench and cover it with Plan Protector

from bulkhead D aft. Begin construction by

building the right rear side structure.

Q 2. Build inner bulkheads B, C, D, F and H over

the drawings using 1/4" x 1/2" x 24" balsa sticks.

l-t Q 5. Using two 1/4" x 15/16" x 36" balsa sticks,

cut and fit the rear side longerons. Pin and glue

the parts into position.

Note: The top longeron ends at the leading

edge of the stab. A separate 1/4" x 15/16" x 5-9/16"

stab mount is glued to the rear of the top

longeron, 1/8" below the top edge. The bottom

longeron has an angled cut and notch that fit

the top longeron and stab mount.

Q l-l 6. Cut the upright at bulkhead F from 1/4"

x 1/2" x 24" balsa and glue it into position.

12

Page 13

CUT ALONG

EMBOSSED LINE

RIGHT FUSE SIDE

[-] 7. Locate one of the die-cut 1/8" ply forward

fuselage sides. Cut off the front end of this side

along the embossed line.This will establish two

degrees of right thrust. Note: Only the right

forward fuselage side has this cut made.

I-J10. Place the right fuselage side over the plan

and mark the locations of bulkheads B, C, D, E,

F, G, H, HTW and I on the side. Place the left side

over the right and transfer the marks to the left

side. Next, mark each inner bulkhead at the

center of the top edge. These marks and lines

will be used to align the fuselage in the

following steps.

l-l Q 8. Fit this ply fuselage front to the fuse rear.

Cut doublers for the two joints from 1/8" x 1/4"

x 30" balsa. When satisfied with the fit, glue the

ply front and doublers to the fuse rear with

6-minute epoxy.

Q 9.The left fuselage side is built over the right

side. Remove the right side from your building

board and turn it over. Use the leftover 1/8" x

1/4" stick to shim the forward ply side. Cover the

side with Plan Protector. Follow steps 5, 6 and 8

to build the left side, aligning the parts over the

right side. Do not cut the front end of the

left forward ply side.

Q 11. Glue inner bulkheads B, C and D to the

right fuselage side using 6-minute epoxy. Be

sure the bulkheads are at a 90° angle to the

side. Epoxy will produce the strongest joint but

you can use thin CA with accelerator if you are

in a hurry. Inspect each joint for gaps and re-glue

if necessary. Note:

The

top edge of each bulkhead

is 1/8" below the top edge of the ply side.

13

Page 14

Q 12. Glue the die-cut 1/8" ply fuselage top and

bottom decks to the right fuselage side. The

parts interlock. Do not glue the bulkheads to the

decks. IMPORTANT: Be absolutely certain that

the shorter side of the top and bottom decks are

glued to the right ply side. This establishes the

proper amount of right thrust. The front of each

deck should extend exactly to the front of the

ply fuselage side.

t_] 15. Lightly sand the sides of bulkheads F and

H to match the slope of the sides. Install them in

their proper locations in the fuselage sides and

hold them in position with pins. Do NOT glue

until later.

Q 16. Place the fuselage upside-down over the

top fuselage plan. Align the top deck with the

plan and pin it into place. Use some blocks to

hold the tail of the fuselage in place over the

plan. Align the center mark on each bulkhead

with the centerline on the plan. Sight down

from above the fuselage to double check the

alignment. When you are satisfied that

everything is aligned properly, glue bulkheads

F, H, and J to the fuselage sides.

Q 13. Glue the left fuselage side to inner bulkheads

B, C and D using 6-minute epoxy. Align the

bulkheads with the marks you made earlier.

Before the epoxy cures, sight across the top of

both sides to double check the alignment.

Q 14. Pull the tail together and tack glue die-cut

1/8" ply bulkhead J to the rear of the longerons.

Q 17. Use the 1/4" x 1/4" x30" balsa stick to glue

a cross-brace between bulkhead D and F, and

between F and H.This bracing will make the tail

more rigid.

l-l 18. Glue the die-cut 1/8" ply bottom bulkhead

formers AB and BB for bulkheads A and B into

position. Glue doubler BBD to the FRONT of BB.

Note: Make sure that AB follows the angle

established for the firewall. Use side formers A

and B to help in centering AB and BB.

14

Page 15

Q 19. Cut a stringer from 1/8" x 1/4" x 31"

basswood to length and glue into place to the

bottom of formers AB and BB.The remainder of

this stringer will be used on the top formers.

Ql 20. Bend the forward part of the wing saddle

on the 1/8" ply fuselage side along the

embossed cut line so that it conforms to BB.

Glue it into position.

Q 21. Glue the die-cut 1/8" balsa bottom

bulkhead formers EB, FB, GB, HB and HTW into

position.

l-l 22. Tack glue the die-cut 1/8" ply bulkhead

former DB to the FRONT of bulkhead D. Glue

another 1/8" x 1/4" x 31" basswood stringer to

the bottom of formers DB, EB, FB, GB, HB

and HTW.

fuselage side view as a guide. These mount

blocks are glued to the bottom longeron at an

angle to conform to the curve on bottom

formers HTW and JTW. Sand the blocks as

needed for this angle and glue them to the

bottom longeron.

Q 24. Glue the die-cut 1/8" ply tailwheel mount

into position on these blocks. Glue the die-cut

1/8" ply former JTW to the rear of this

assembly. Glue a piece of 1/8" x 1/4" basswood

stringer between JTW and J.

Q 25. Remove the fuselage assembly from the

building board.

Note: The exact position of DB will be

determined when the wing is fitted to the

fuselage. For now, just tack glueit so that the

stringer is straight.

Q 23. Cut and fit the tailwheel mount blocks

from leftover 1/4" x 15/16" balsa using the

I-] 26. Time to mount your engine. Before you

glue the firewall into position, you should add

some reinforcing sticks to the inside of the

fuselage as shown in the above photo. Use the

1/4" x 3/8" x 36" basswood stick for this purpose

(DO NOT use the longer basswood wing

spars). Glue them into position with 30-minute

epoxy. While you are waiting for the epoxy to

cure you can mount your engine to the engine

mount you have chosen. Position the mount on

the plan at the firewall then locate the engine on

the mount to fit the front of the cowl properly.

Check the position on the model to be sure

blind nuts and bolts will clear the structure. If

15

Page 16

you

will

be

using

the Great

Planes

Isolation

Mount™ you will need to reposition the

Mounting Grommets as shown on the plan.

Note: Depending on the type of engine you are

installing, you may need to add spacers

between the engine mount and firewall. Layers

of

aircraft grade 1/4" plywood (not included)

work well for this. The firewall location is

designed so that a typical gasoline engine can

be

mounted on a Great Planes Isolation Mount

(GPMA2000, not included).

Gasoline Engine Note: Gasoline engines

mounted on an isolation mount, such as the

Great Planes Large Engine Isolation Mount™,

may need to be mounted on the centerline of

the model. This is needed to obtain clearance

between the mounting bolts of the isolation

mount and the engine on the relatively narrow

firewall. Shim the engine as needed to obtain 0°

of right thrust (about 1/8").

Q 29. Glue the die-cut 1/8" ply and balsa side

bulkhead formers A, B, C, D, E, F, G and H into

position on both sides of the fuselage. The flat

end of A and B goes towards the bottom of the

fuselage. The flat end of the rest of the formers

goes towards the top of the fuselage (E and F

can be glued on either way). The angled end of

C goes towards the bottom. Glue side former

DD to the rear of D. Note that DD is slightly

wider than D and should protrude from D by

about 1/32".

Ql 30. Cut two 3/16" x 3/16" x 24" balsa stringers

to length and glue them into place on side

formers DD, E, F, G and H.

Most engines will fit inside the cowl if the engine

is mounted inverted. Be sure to allow for adequate

cooling.

Q 27. Drill the 1/4" x 4-1/8" x 4-1/4" ply firewall

as needed for your engine mount and install

any required blind nuts. Glue the firewall to the

fuselage with 30-minute epoxy. For added security

you can pin the firewall to the fuselage if

desired. Drill small holes through the sides of

the fuselage into the firewall and epoxy in small

dowels or toothpicks.

Ul

28.

Once the epoxy has cured, install any

spacers needed for your engine mount. Be sure

to install any blind nuts required to bolt your

engine mount to the spacers.

Now is a good time to install the servos and

route the servo pushrods before any more

formers and sheeting are glued into place.

There are eight die-cut 1/8" ply pushrod guides

provided for this purpose. You may also need

some leftover 1/4" x 3/4" balsa sticks as well.The

plan shows the servos mounted just forward of

theTE of the wing.This is a good location if you

will be using a lighter engine such as a 1.20

4-stroke engine. Our prototype model, with an

O.S. FS-120 Surpass 4-stroke engine, balanced

without any lead required with the servos

positioned as shown on the plan. If you will be

using a heavier gasoline engine you may want

to mount the servos in the tail of the model.This

can be done easily by notching the longerons

for the servos, allowing them to protrude from

the fuselage side. If you do this, use some

leftover 1/4" x 3/8" basswood to reinforce the

longerons.

16

Page 17

Note: If you will be entering your Chipmunk in

IMAA events you need to review their

requirements for servo and control linkage

sizes. They require high-torque servos on

control surfaces and 4-40 size control linkages,

with metal clevises.

Q 31. Install the servos and route the pushrods

for the servo installation you will be using.

Note:

You

will need to temporarily mount the

tailwheel assembly. The lower side longeron

will need to be carved out in the area where the

pushrod clevis will connect to the rudder torque

rod horn.

Q 33, Glue the die-cut 1/8" ply and balsa top

bulkhead formers AT, BT, IP, (2) CT and (2) DT

into position.

Note: Make sure that AT follows the angle

established for the firewall.

Q 34. Cut a 1/8" x 1/4" x 31" basswood stringer

to length and glue into place to top formers AT,

BT and IP. Do the same for the two CT top

formers. Use the remainder of the 1/8" x 1/4" x

31" stringer used on the bottom formers.

Q 32. Glue the 1/4" x 1-1/4" x 5-1/4" ply wing

hold down block into the slots in the fuselage

sides with 30-minute epoxy. Cut and glue some

1/4" x 3/8" reinforcing sticks into place using a

leftover basswood stick.

Q 35. Glue the die-cut 1/8" piy and balsa top

bulkhead formers ET, FT, GT, HT and I into

position.

Q 36. Cut a 1/8" x 1/4" x 31" basswood stringer

to length and glue into place to top formers DT

(both), ET, FT, GT and HT.

17

Page 18

1-1 37. Glue two sheets of 1/8" x 3" x 24" balsa

together to form a sheet 6" wide. Sand the outer

side of this sheet flat and smooth. Cut, fit and

glue this sheet into position to the left fuselage

side between side formers A and D with the

smooth side out. Align the top edge of the sheet

even with the top of the top deck. Note: This

sheet should extend only to former D and

should not cover DD. Wet the sheeting as

needed to allow it to bend better.

D 38. Make and glue a second balsa sheet to

the right fuselage side.

Q 40. Use some more leftover 1/8" balsa

sheeting to cut, fit and glue filler strips between

the side sheeting and the ply fuselage sides at

the wing saddle area. Angle the strips slightly to

conform to the 6° dihedral angle of the wing.

Note:

There

is a small section of sheeting that

needs to be added at bulkhead D. This will be

added later when the fuselage bottom is

sheeted.

Q 41. Use 1/8" x 3" x 30" balsa to sheet the top

of the fuselage between AT and IP Also sheet

the area between the front and rear CT's.

Q 39. Using some leftover 1/8" balsa sheeting

cut, fit and glue filler strips between the

sheeting you just added and the fuselage top

deck. You only need to do this in the area of the

front and rear cockpits, between top formers IP

and CT and between CT and DT.

LI 42. Use leftover 1/8" x 3" balsa sheeting to

sheet the bottom of the fuselage between AB

and

BB.

Before the rear of the fuselage is sheeted the wing

must be fitted to the fuselage. So, it's time to:

18

Page 19

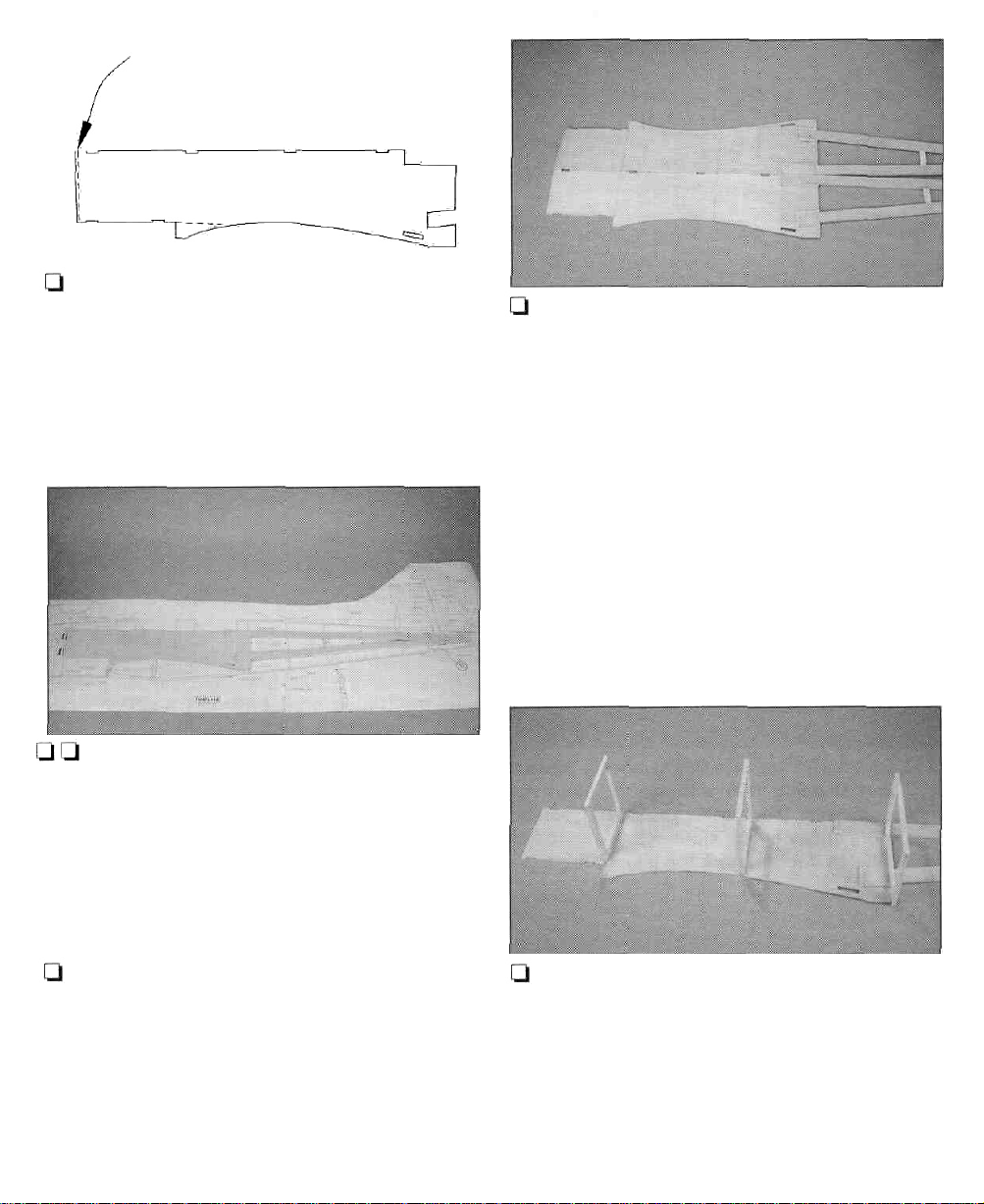

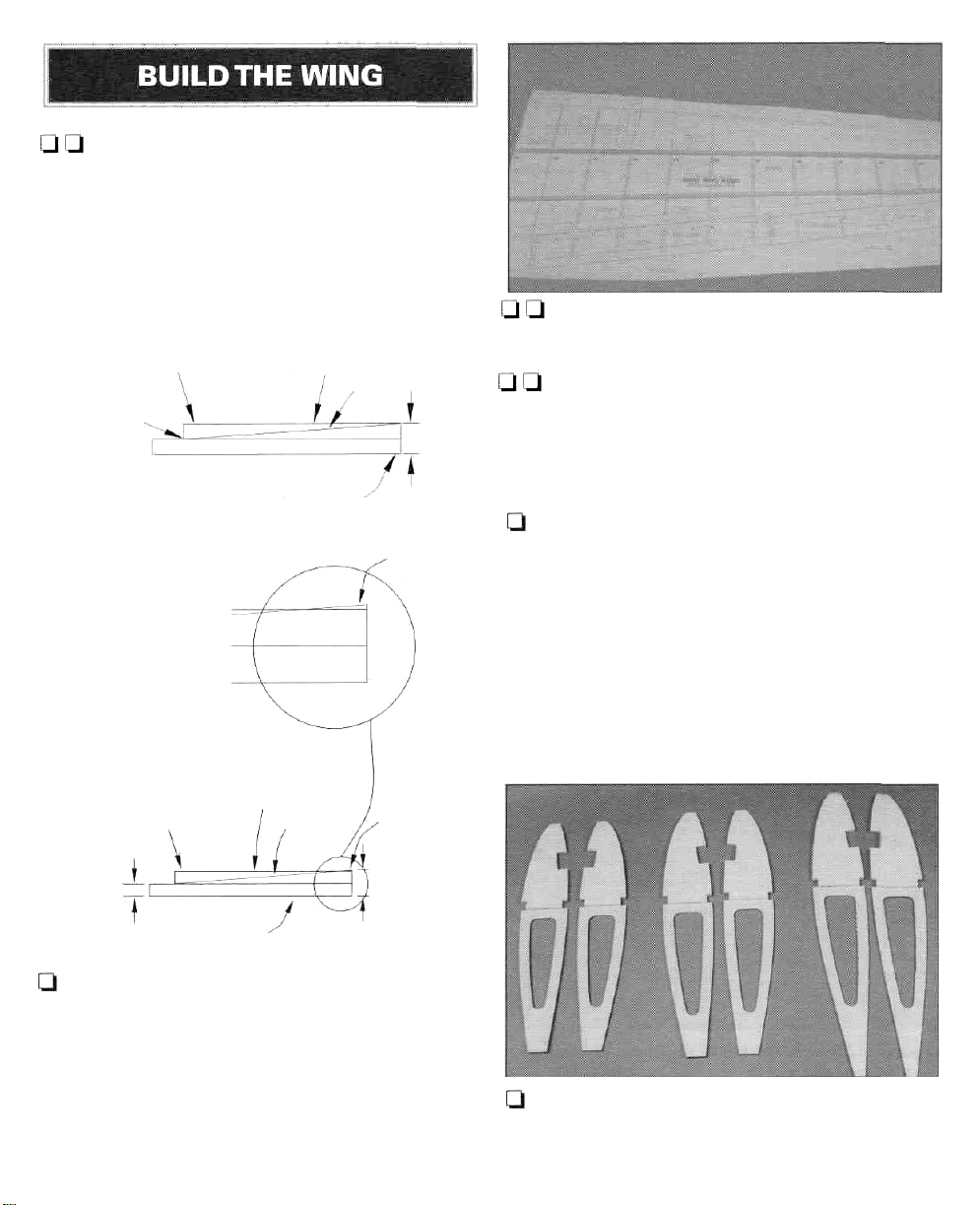

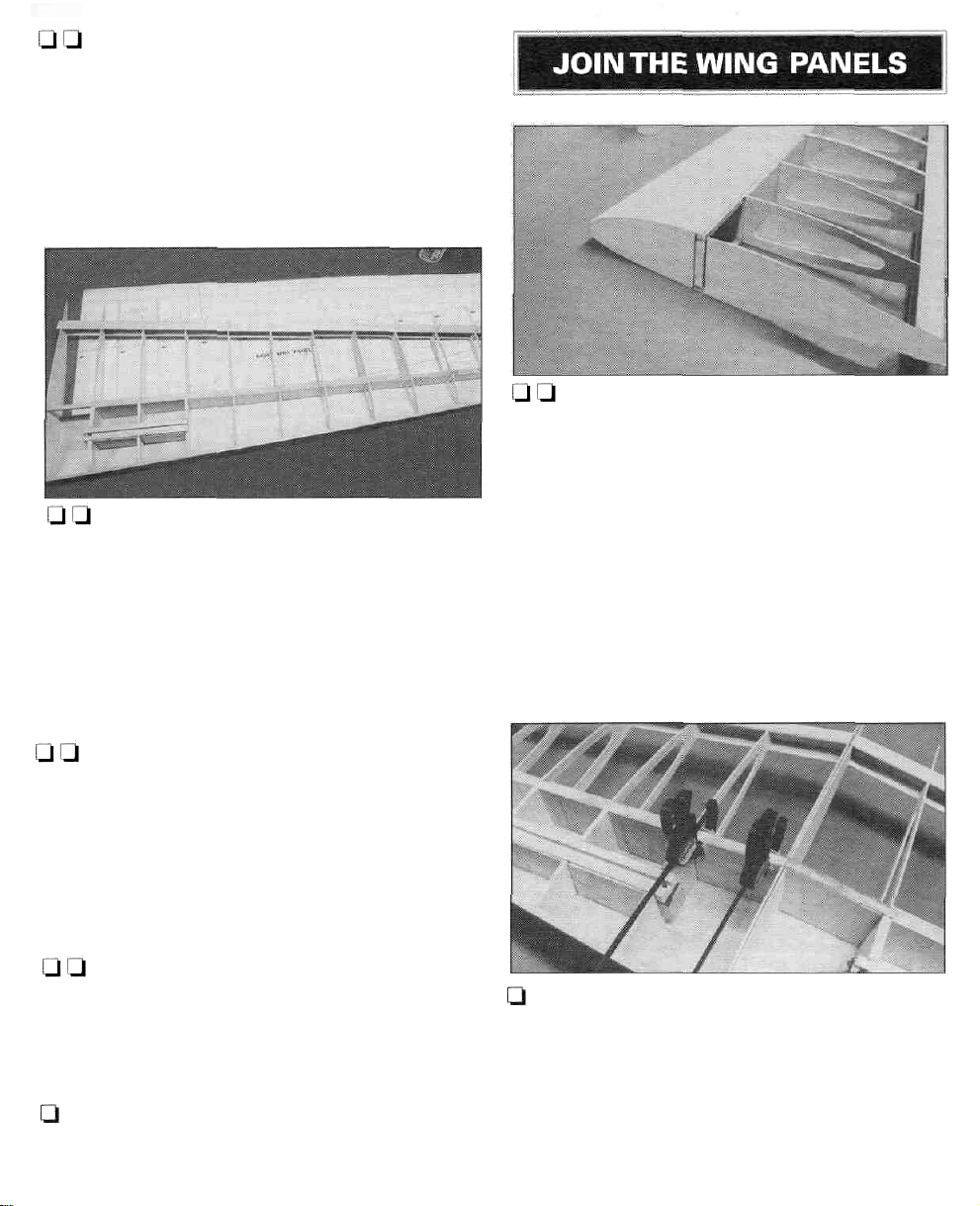

Q Q 1. Lay the right wing plan on your building

board and cover it with Plan Protector.

Note: It will be easier if you prepare all four

leading edge wing skins at the same time.

BOTTOM WING SKIN

USE LEFTOVER

FOR OTHER SKIN

3/32"

X 3" X

BALSA SHEETING

42"

CUT

CUT FROM

CORNER

TO CORNER

SAVE LEFTOVER FOR

FUSE SHEETING

3"

WIDE

3/32"

BALSA SHEETING

TOP WING SKIN

3/32" X 3" X 42"

BALSA SHEETING

3/32" X 3" X 48"

BALSA SHEETING

X 3" X 48"

CUT LINE

LINE

6-3/8"

WIDE

SCRAP

BALSA

SCRAP

BALSA

6" WIDE

Q 2. Prepare the four leading edge wing skins

according to the sketches above. The skins for

the top of the wing are 3/8" wider than those for

the bottom. Glue the skins together using your

favorite method (we use masking tape to form

a hinge and then join them with aliphatic resin

glue). Sand the best side smooth with 150-grit

sandpaper.

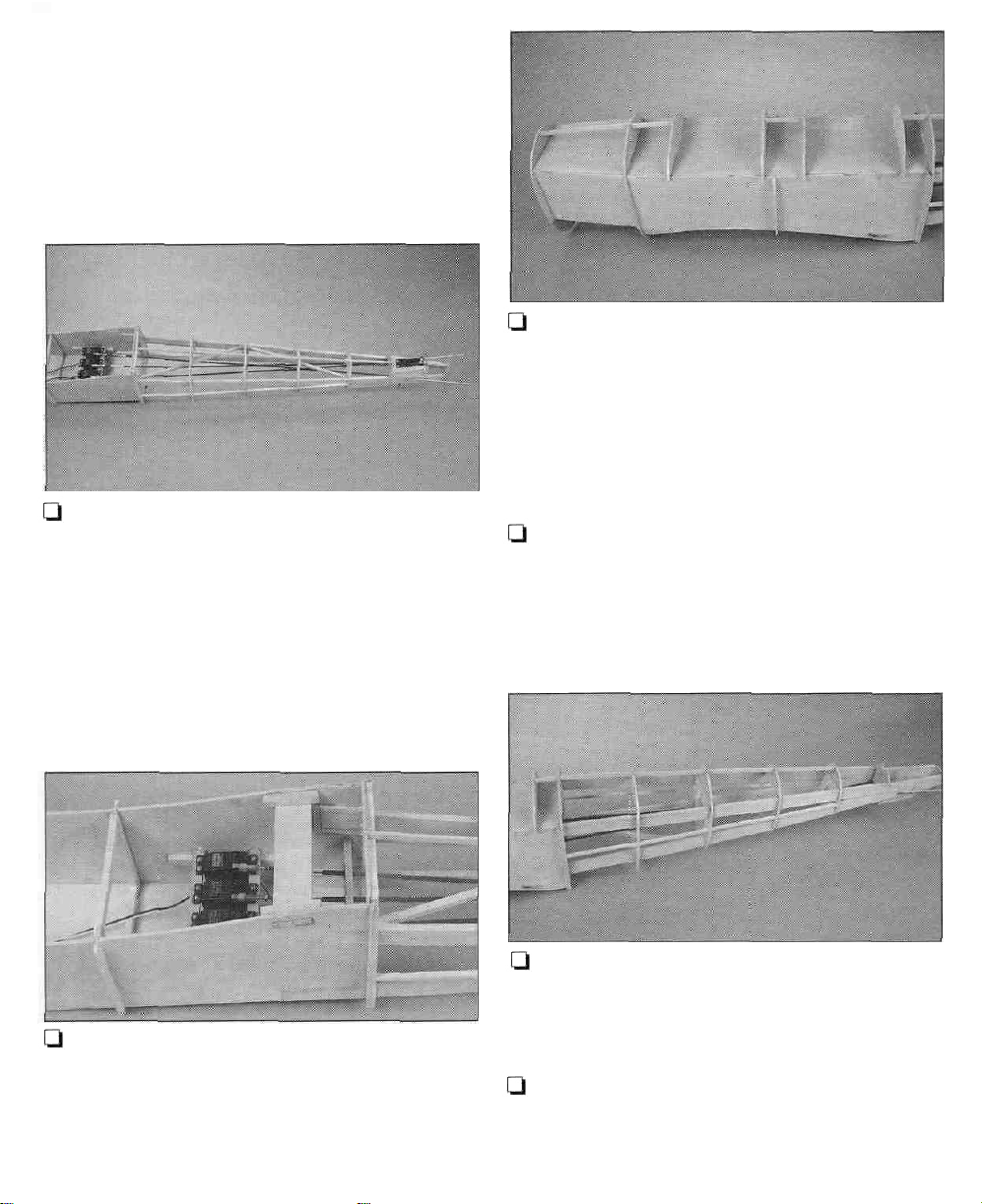

U U 3. Pin the 1/4" x 3/8" x 44" basswood lower

spar over the plan.

l-l t-l 4. Pin a 1/4" x3/8" x 44" basswood stick on

the dashed lines called "shim stick." This will

hold the rear of the ribs at the proper angle until

there are enough pieces to hold the wing rigid.

(Save the shim stick for later use.)

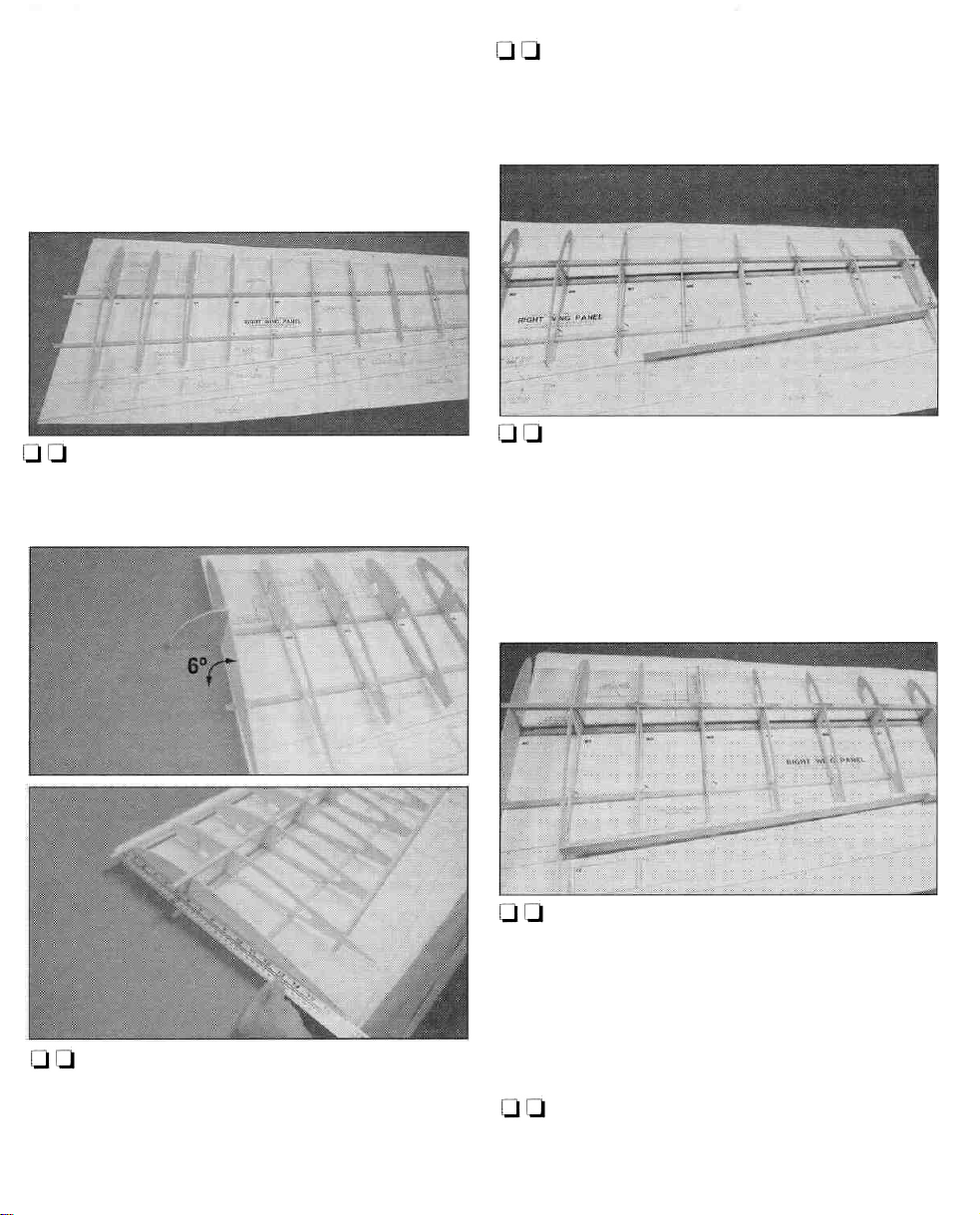

Q 5. Punch the ribs from their die-cut sheets,

sanding the backs of the sheets lightly if they do

not come out easily. Number each rib as you do

so; don't forget to number the aileron and flap

ribs as well. Check the fit of the spar to the spar

notches in each rib.

Note: If you will be building functional flaps for

your Chipmunk, glue in the rear lightening

holes in ribs W4 and W5.

Q 6. Glue the die-cut 1/8" ply landing gear

doublersto ribsW2,W3 andW4 using 30-minute

epoxy. Glue them to the sides shown on the

19

Page 20

plan. There are two doublers for W2. The one

with the long cutout is glued to the side facing

the wing root. This cutout will lock in the

landing gear stub (torque) block. Check the fit of

the landing gear block and stub block in their

cutouts. Make sure you make a set for the right

and left wing panels.

I-] Q 7. Glue ribsW2 -W12 into place on the lower

spar with a drop of CA, making sure they are

vertical. Pin the rear of each rib to the shim stick.

Q Q 9. Glue the 1/4" x 3/8" x 44" basswood top

spar to the ribs.

Q Q 10. Cut a 1/4" x 3/4" x 24" balsa stick to the

correct length and glue it to the rear of W8-W12.

The tip end is glued to the side of W12. Glue the

top flush with the top edges of the ribs.The stick

extends midway between W7 andW8.

Q Q 8. Use the dihedral gauge to obtain the

proper angle (six degrees) ofW1. GlueWl into

place on the lower spar. Pin the rear ofW1 to

the shim stick. Use a long straightedge to insure

thatWI is straight.

Q Q 11. Cut a 1/4" x 7/8" x 30" balsa stick to the

correct length and glue it to the rear ofW2 -W8.

The root end is glued to the side ofW2. The tip

end glues to the side ofW8 and the front of the

outerTE.

Q Q 12. Use the remainder of the 1/4" x 7/8"

balsa stick to cut and fit aTE piece between W1

andW2.

20

Page 21

13. Glue the 1/4" x 1/2" x 48" balsa leading

edge stick to the front of the ribs. Align the top

of the LE even with the tops of the ribs. Use a

long metal straightedge to get the LE as straight

as possible. IMPORTANT: Use a straightedge

along the sides of W1 and W12 to insure that

they are straight and flat.

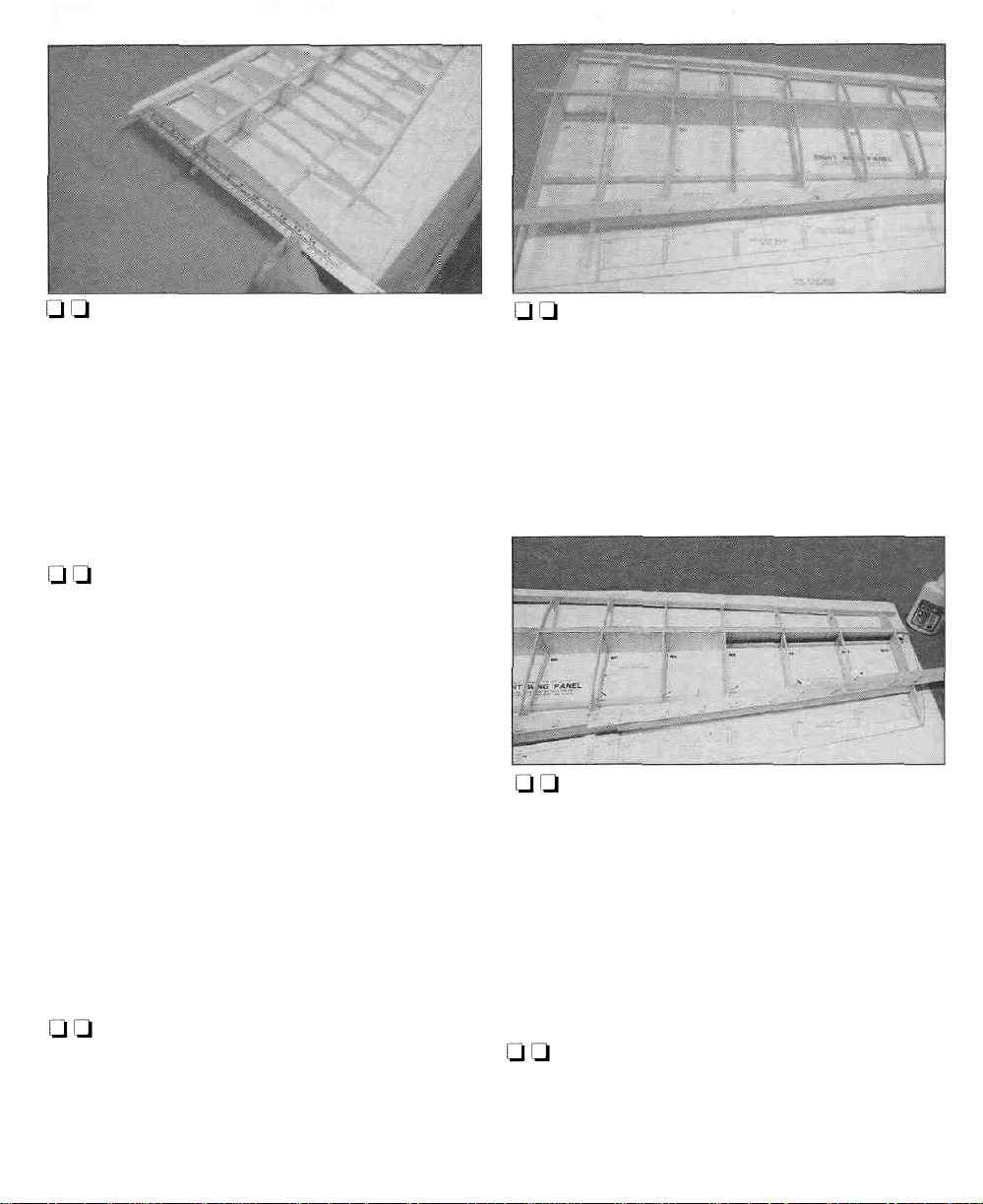

Q Q 14. Use a 3/32" x 4" x 36" balsa sheet to

prepare the spar webs. Note: The sheeting

provided is ample to prepare all of the webs,

but there is no extra material so work carefully.

There is webbing from W2 to W12 glued to the

front of the spars and from W2 to W9 glued to

the rear of the spars. Start with the ribs that are

spaced the widest first. Trim and sand the sheet

to fit between the two ribs. Sand the bottom

edge of the sheet to fit the angle of the lower

spar, then mark and cut the sheet to the proper

height. Continue cutting, trimming, sanding, and

gluing the sheet for all of the webbing. Be sure

to remove any pins that will be hidden by the

webbing before gluing it into position.

Q Q 16. Glue a 3/32" x 15/16" x 24" balsa TE

sheet to the inner TE and ribs using aliphatic

resin. Note that the sheeting extends from W1

toW7 and is trimmed at an angle. Use your long

straightedge to keepWI straight.

Q Q 17. Glue a 3/32" x 15/16" x 24" balsa TE

sheet to the outer TE and ribs using aliphatic

resin. Note that the sheeting extends from W7

to W12 and is trimmed at an angle. Study the

plan to see how the sheeting is trimmed to fit

the flap tip.

Q Q 15. Prepare the TE that you installed in

steps 10 and 11 for sheeting. Carve and sand the

TE to blend with the top of ribs W1-W12. If you

are not a careful sander you may want to put

some masking tape on the tops of the ribs so

that you won't alter their shape.

[-1L118. Prepare the 1/4" x 1/2" balsa LE that you

installed in step 13 for sheeting. Carve and sand

the LE to blend with the tops of the ribs. Use

masking tape on the ribs so that you don't alter

their shape.

21

Page 22

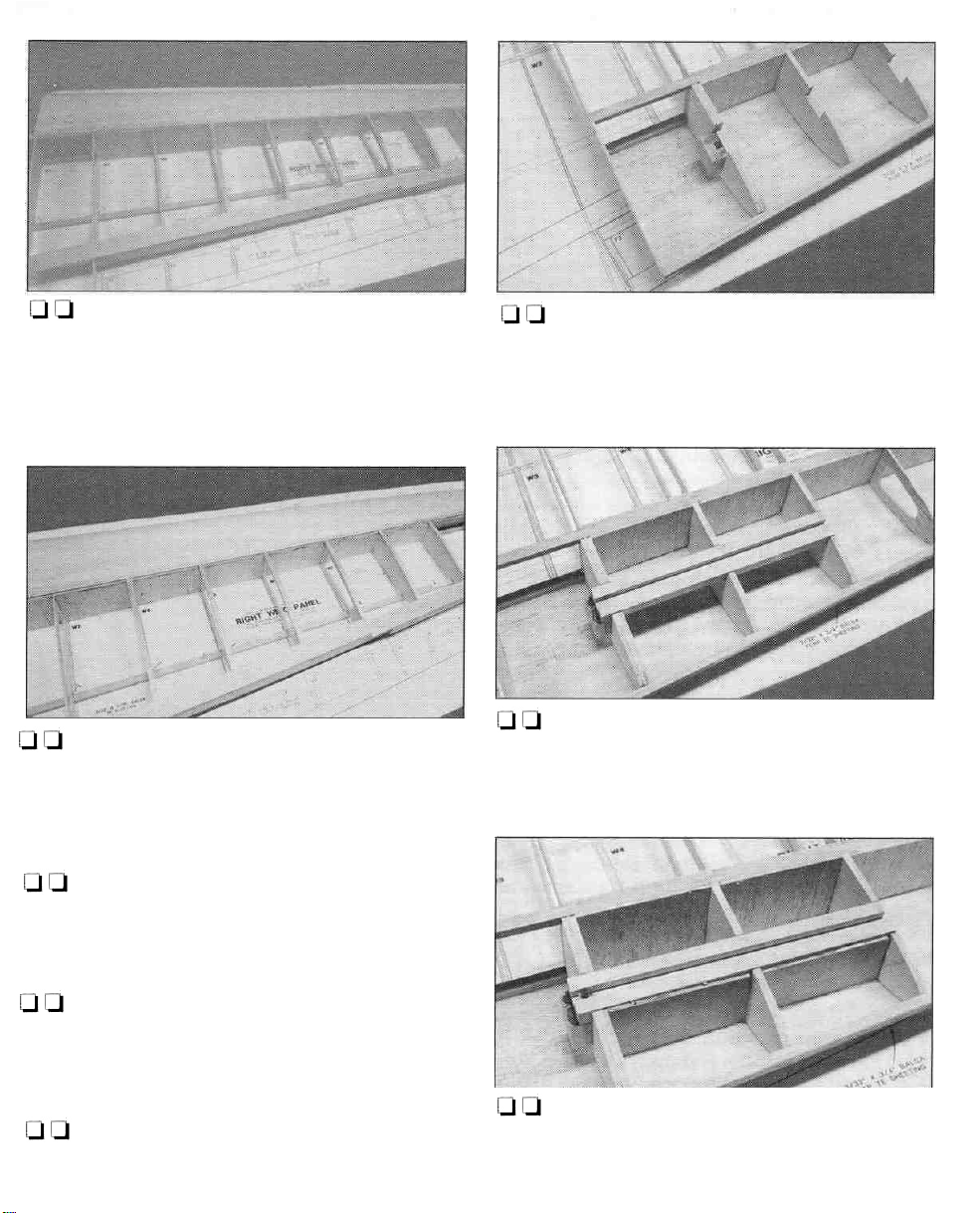

1—1 19. Glue the leading edge skin that you

prepared in step 2 to the top spar, ribs and LE

using aliphatic resin. The sheeting extends to

the center of the spar.

I-] Q 20. Using 3/32" x 1/4" x 30" balsa, cut, trim

and glue cap strips on the tops of ribsW4 -W12.

Cut the longer pieces first.

Ul Q 21. After the glue has fully dried, remove

the wing from the building board.

Ql [-1 24. Glue the landing gear's 5/8" x 1" x 1"

maple stub block to W2 using 30-minute epoxy.

The block fits into the long cutout in the 1/8" ply

doubler. The groove faces W2.

Q Q 25. Check the fit of the 1/2" x 1" x 8-1/2"

maple landing gear rail in ribsW2,W3 andW4.

When satisfied with the fit, glue it in place with

30-minute epoxy.

Q Q 22. Carve and sand theTE and LE to blend

with the bottom of the ribs as you did in steps

15

and

18.

Q Q 23. Trim the LE and TE sheeting and the

spars even with ribsW1 and W12.

Ql Ql 26. Fit and glue the die-cut 1/8" ply webs

to the front of the landing gear rail using

30-minute epoxy.

22

Page 23

U U 27. Using a 1/4" bit, drill a hole through the

landing gear rail into the stub block. Radius the

top of the hole to fit the bend in the 1/4" landing

gear wire. (See the photo at step 26.)

Q Q 28. Glue a 3/32" x 15/16" x 24" balsa TE

sheet to the bottom of the inner TE and ribs

using aliphatic glue. Note that the sheeting

extends from W1 to W7 and is trimmed at an

angle. Use your straightedge to keep W1

straight.

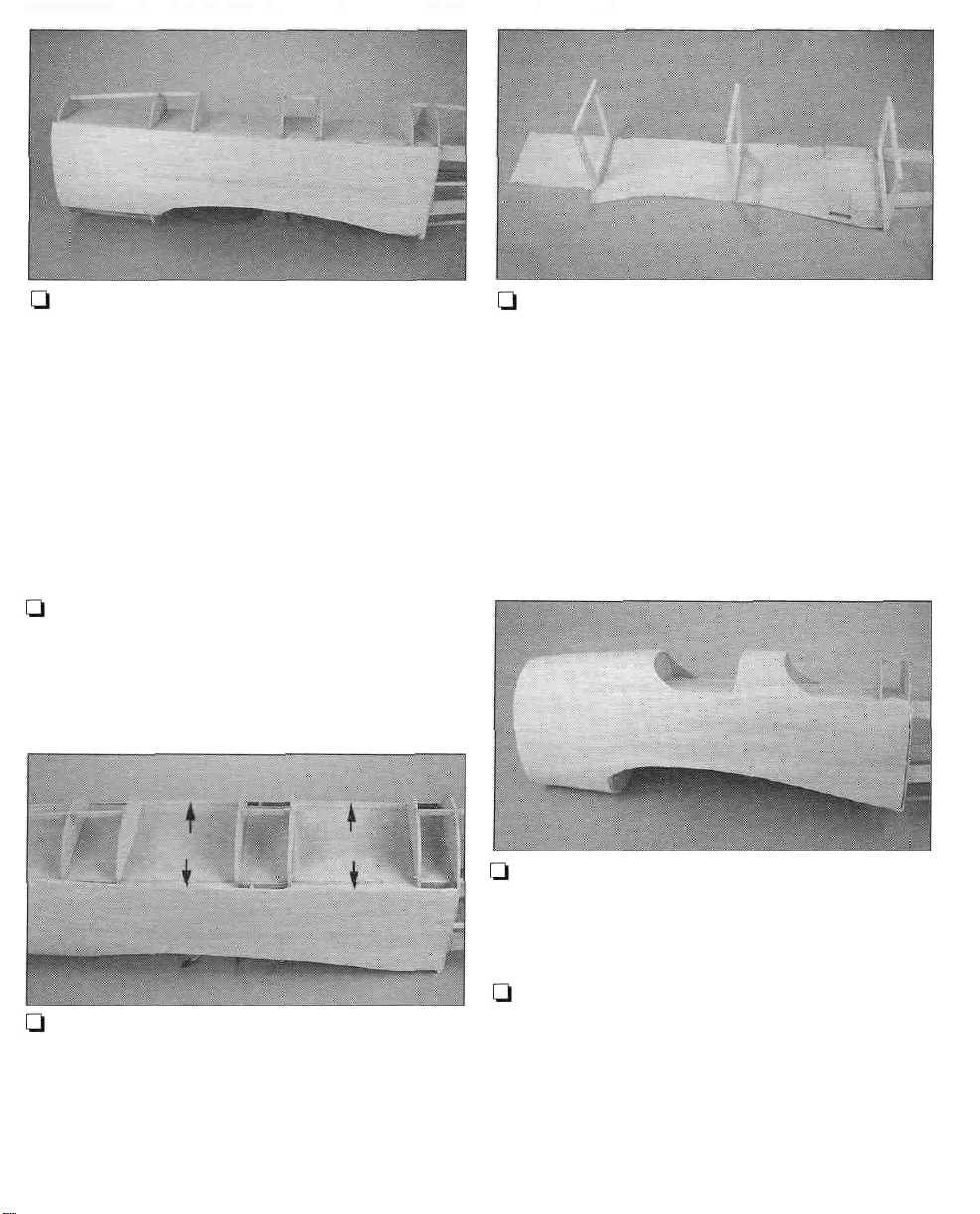

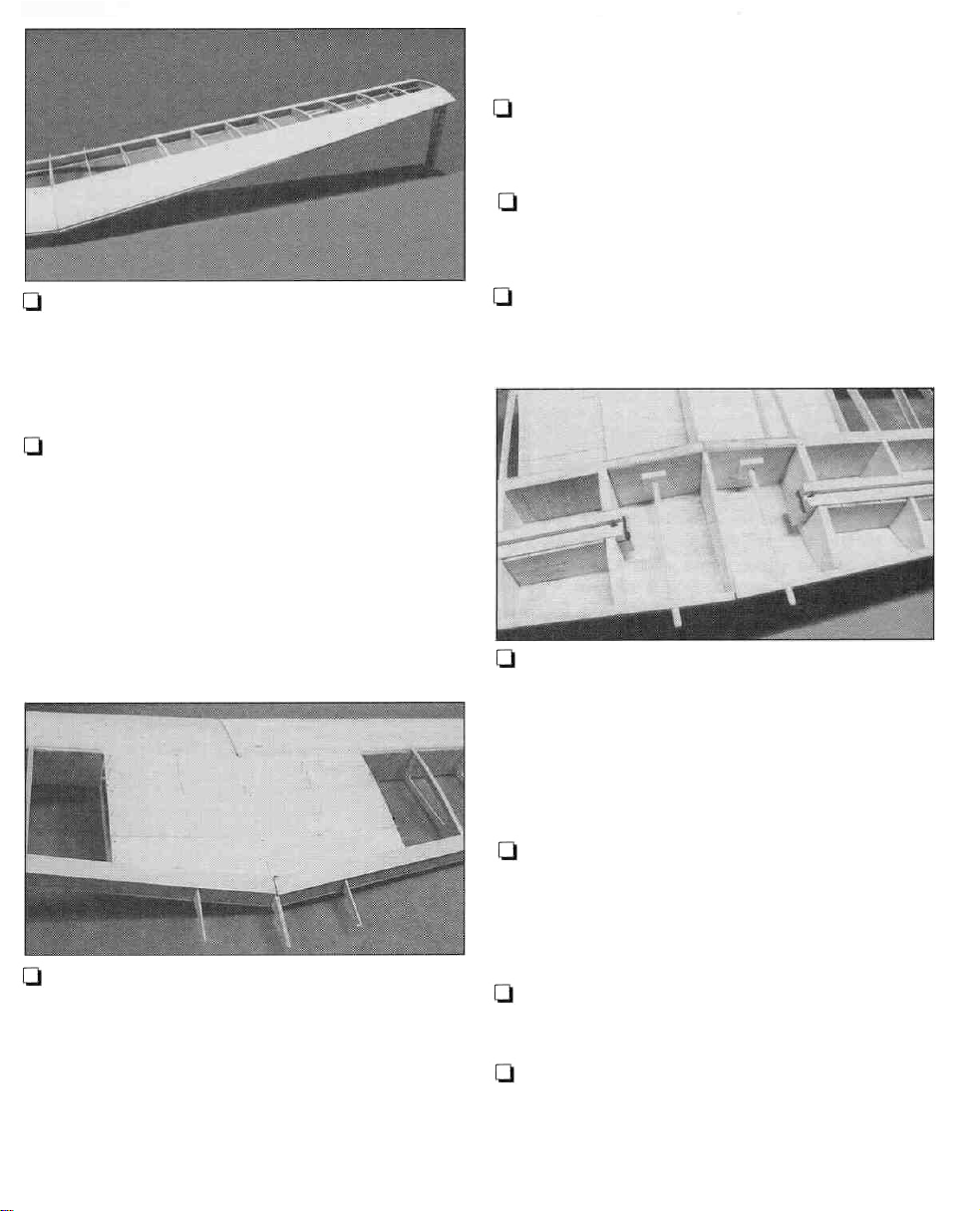

U U 1. Prepare the wing panels for joining by

cutting a 1/16" wide slot in front of and behind

the spars in W1 as shown in the photo.

Q Q 29. Glue a 3/32" x 15/16" x 24" balsaTE sheet

to the bottom of the outer TE and ribs using

aliphatic glue. Note that the sheeting extends

from W7 to W12 and is trimmed at an angle.

Q Q 30.Trim theTE sheeting even with ribsW1

andW12.

Q 31. Return to step one and assemble the left

wing panel.

Q 2.Test fit the die-cut 1/16" ply dihedral braces

to the wing panels. The shorter ply brace goes

on the forward side of the spars. When satisfied

with the fit, glue the braces to left wing panel

with 30-minute epoxy. Remove the right panel

and clean off any epoxy that seeped out from

the joint.

23

Page 24

but it is a bit harder to install this way. Do not

sheet the bottom center section at this time.

Q 6. Glue the die-cut 1/8" ply LE doublers to the

rear of the LE between W1 andW2 on both wing

panels.

[-1 7. Drill two 5/16" holes through the wing LE

and doubler where shown on the plan and in

the photo.

LI 3. After the epoxy has cured, slide the right

panel back into position. Position the right

panel flat on your building board and prop the

left tip off the building board. Don't you wish

your surface was longer!!

Q 4. Measure the distance under the left wing

tip at the bottom of rib W12. If it is 8-3/4" you

have exactly six degrees of dihedral in each

panel. Don't be concerned if it is a little off as

the dihedral angle is not at all critical. If it is off

by more than 1/2" you might want to find out

why, but you don't really need to fix it. When

you are satisfied, glue the dihedral braces to the

right wing panel with 30-minute epoxy. Use

epoxy on theW1 ribs as well.

Q 5. Using 3/32" x 3" x 36" balsa, sheet the top

center of the wing from W3 to W3.The strength

of the center section is important so we

recommend that you use aliphatic resin glue.

Note in the photo that we used one continuous

piece across the entire center section rather

than two pieces from W1 to W3 on each side.

This greatly increases the strength of the joint,

Q 8. Cut two 1/4" x 7/8" x 7/8" balsa blocks from

leftover sticks and drill a 5/16" hole in the center

of both blocks.

Q 9. Slide the 5/16" x 6" wing dowels through

the holes in the LE and put a block on the end of

each dowel. Align the blocks on the 1/16" ply

dihedral braces so that the dowels are parallel

to the wing centerline. Glue the BLOCKS

ONLY to the dihedral braces with 6-minute

epoxy. Remove the dowels before the epoxy sets.

I-] 10. Fit the wing to the fuselage. Center the

wing and mark the location of the dowels on

bulkhead B. This is done by putting a pencil

through the hole in the LE and marking the

bulkhead.

Q 11. Remove the wing and drill 5/16" holes into

bulkhead B.

Q 12. Put the dowels into the wing and fit the

wing back onto the fuselage. Make any

adjustments needed to get the dowels to fit

properly into the holes in bulkhead B. When

24

Page 25

satisfied with the fit, glue the dowels into the

wing with 6-minute epoxy. Use caution not to

get any epoxy on the fuselage.

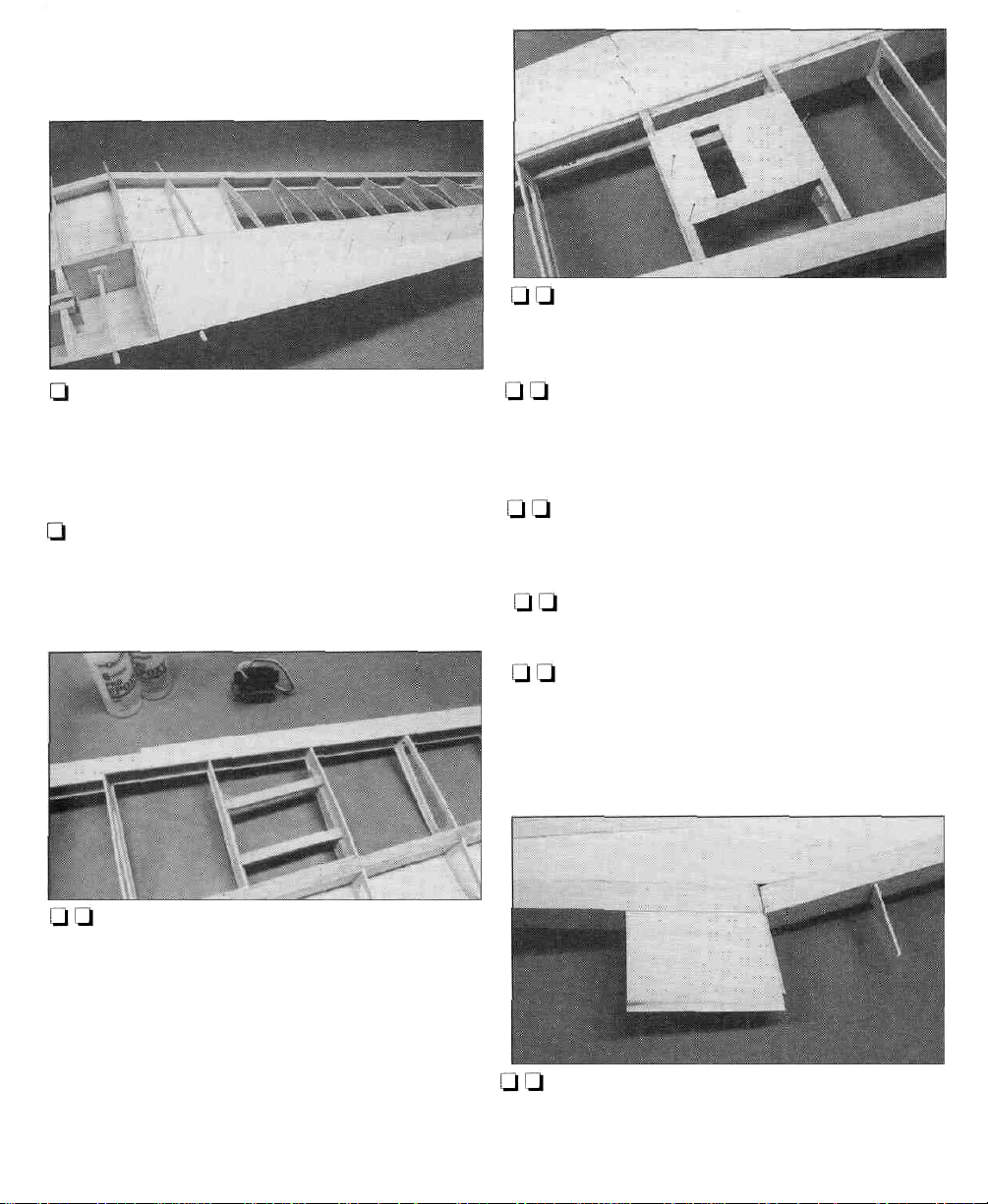

Q Q 16. Sheet the area around the servo using

leftover 3/32" x 3" balsa.This gives the covering

a place to adhere to.

Q 13. Using the leading edge wing skins you

prepared earlier, sheet the bottom LE of both

wing panels. We find it easiest to use aliphatic

resin on the ribs and medium CA on the spar.

Thin CA can then be used on the LE.

Q 14. Using 3/32" x 3" x 36" balsa, sheet the bottom

center of the wing from W3 to W3. Using one

continuous piece across the entire center-section

will increase the strength of the joint.

Q Q 15. Working on the left wing panel, build

the aileron servo mount between ribs W8 and

W9. Cut two servo mount rails from the 1/4" x

3/8" x 44" basswood shim stick used earlier. Cut

two 3-3/4" long bracing strips from die-cut 1/8"

ply servo rail brace strip. Fit and glue these

pieces into place, spacing the rails to fit the

servo you will be using. Position the rails so the

top of the servo will protrude below the wing

the desired amount.

Oil-] 17. If you are installing flaps on your Chipmunk,

build the flap servo mount between ribsW4 and

W5 as you did above for the aileron servo. Sheet

the area around the servo.

Q l-l 18. Using 3/32" x 1/4" x 30" balsa strips cut,

fit and glue cap strips on the bottom of ribs

W4-W7andW10-W12.

Q t-1 19. Cap strip ribs W8 and W9 where there

is no sheeting.

Q Q 20. Locate a 1-1/2" x 1-5/8" x 9-1/2" balsa

block. Shape the block to the outline of the wing

tip using the plan as a guide. Glue the block

onto tip rib W12. Rough carve and sand the

wing tip block to shape.

l-l l-l 21. Use some leftover 3/32" x 3" sheeting to

cut aTE sheet to go between ribs W1, W2 and

W2A (W2A is added in the next step). Use the

25

Page 26

plan as a guide to cut the sheeting to the proper

size. Glue this piece to the tops of the ribs.

1-1 Q 22. GlueW2A into position. Sand theTE of

the sheeting on the bottom to match the

contour of W1,W2 andW2A.

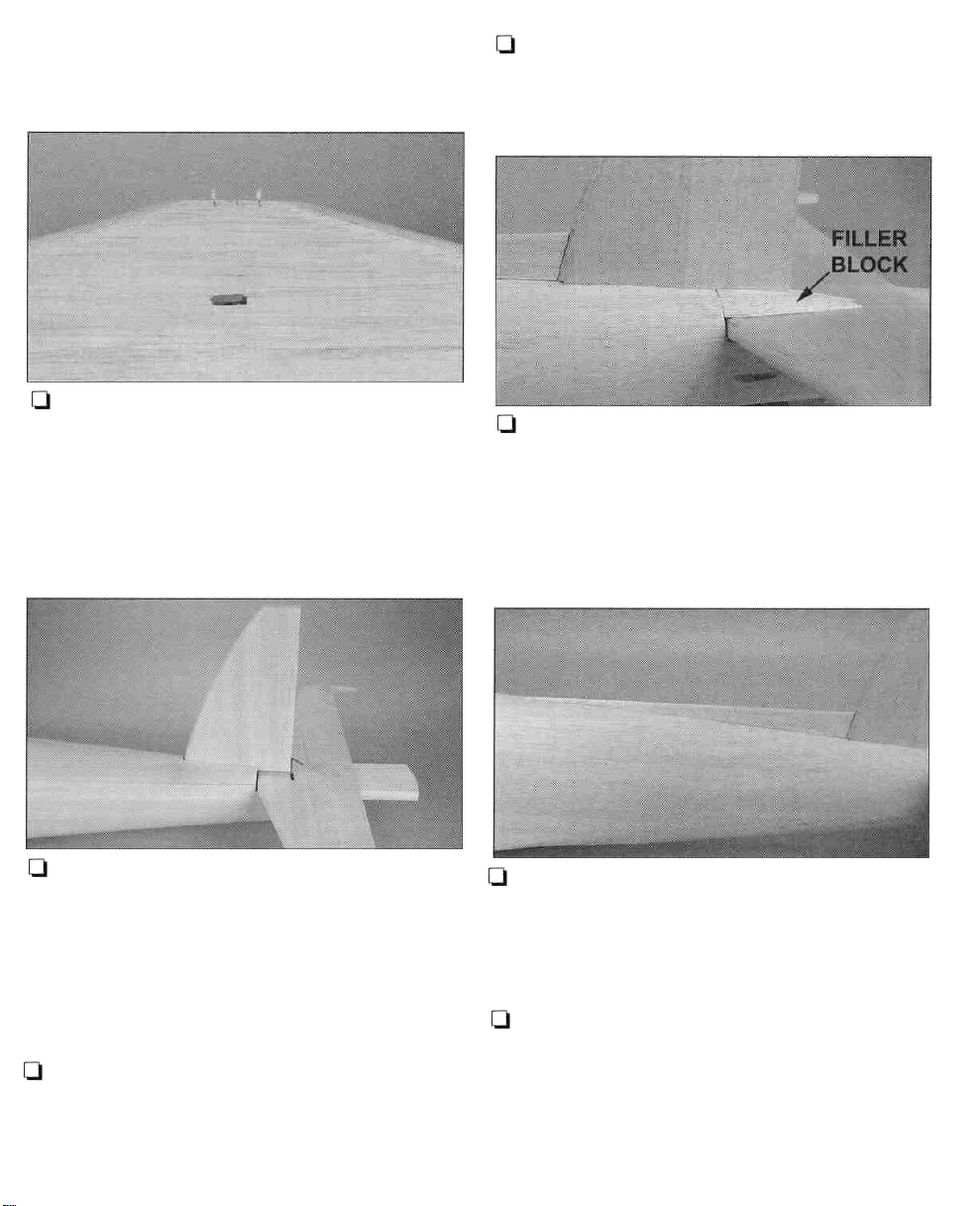

a Q 23. Cut the 5/8" x 2" x 8-1/2" balsa filler

block to fit between W1 and W2. Glue it into

position. Sand the block to match the contour of

the bottoms ofW1 and W2. (W2A is not shown

in the photo.)

Ui Q 24. Cut anotherTE sheet to shape and glue

it to W1, W2, W2A and the block.

Q Q 3. Cut the LE from 1/4" x 3/4" x 24" balsa.

Sand the bottom of the LE to match the angle of

the aileron ribs at their LE. Glue and pin it to

the

3/32" x 1/2" LE sheet.

I-] l-l 4. Glue ribs A7 -A12 into place.

Q Q 5. From a 1/4" x 1/2" x 36" balsa stick, cut

and glue two horn reinforcement blocks where

the aileron horn will mount.

Q Q 6. Cut and glue hinge blocks into position

from the 1/4" x 1/2" balsa.

Q Q 7. Remove the aileron from the plan. Carve

and sand the top of the LE to match the contour

of the ribs. Taper theTE as well. Be careful as it

is easy to sand into the ribs.

Q25. Return to step 15 for the other wing panel.

Q 26. Rough sand the entire wing.

Ul t-1 1. Cover the right wing panel with Plan

Protector. Cut the bottom LE sheet from 3/32" x

1/2" x 24" balsa and pin it to the plan.

Q Q 2. Cut the bottomTE sheet from 3/32" x 3/4"

x 24" balsa and pin it to the plan.

Q Q 8. Glue the top 3/32" x 1/2" LE sheet into

position.

Q Q 9. Glue the top 3/32" x 3/4" TE sheet into

position. Cut, fit and glue cap strips to the top

and bottom of the aileron ribs using 3/32" x 1/4"

x 30" balsa.

Q Q 10. Fit the die-cut 1/8" ply horn base where

shown on the plan and glue it in place.

i-l Q 11. Sand the Aileron to fit the wing. Mark

the centerline of the aileron leading edge along

its entire length. Using the cross-section on the

plan as a reference, sand the leading edge to

the "V" shape shown. Make sure the "V" is

large enough to allow for the full up and down

movement of the aileron.

26

Page 27

[-I Q 12. Cut four additional hinge blocks from

the 1/4" x 1/2" balsa. Glue these into position in

theTE of the wing opposite the position of the

blocks in the aileron.

Q 13. Return to step one and build the left

aileron.

Note: You must build the flaps even if you will

not be installing working flaps. If you will not be

installing working flaps, simply glue the flaps to

theTE of the wing

Q [-I 7. Remove the flap from the plan. Carve

and sand the top of the LE to match the contour

of the ribs. Taper theTE as well. Be careful as it

is easy to sand into the ribs.

Q Q 8. Glue the top 3/32" x 1/2" LE sheet

into position.

Q Q 9. Glue the top 3/32" x 3/4" TE sheet

into place. Cut, fit and glue cap strips to the top

and bottom of the flap ribs using 3/32" x 1/4"

x 30" balsa.

Q Q 1. Cover the right wing panel with Plan

Protector. Cut the bottom LE sheet from 3/32" x

1/2" x 24" balsa and pin it to the plan.

Q Q 2. Cut the bottom TE sheet from 3/32" x 3/4"

x 24" balsa and pin it to the plan.

Q Q 3. Cut the LE from 1/4" x 7/8" x 24" balsa.

Sand the bottom of the LE to match the angle of

the flap ribs at their LE. Glue and pin it to the

3/32" x 1/2" LE sheet.

Q Q 4. Glue ribs F2 - F7 into place. Note that

there are two F7 ribs.

Ql Q 5. From a 1/4" x 1/2" x 36" balsa stick, cut

and glue two horn reinforcement blocks where

the flap horn will mount.

Q Ql 6. Cut and glue hinge blocks into position

from 1/4" x 1/2" balsa.

Q l_l10. Fit the die-cut 1/8" ply horn base where

shown on the plan and glue it in place.

HINGE

GOES HERE

SAND ANGLE

LJ U 11. Sand the flap to fit the wing. The flaps

are hinged along the bottom of the flap, not

along the centerline as the ailerons were. Sand

an angle along the bottom 1/4" of the flap LE.

Make sure the angle is large enough to allow

for the full down movement of the flap.

27

Page 28

Q Q 12. Cut four additional hinge blocks from

the 1/4" x 1/2" balsa. Glue these into position in

theTE of the wing opposite the position of the

blocks in the flap.

Q 13. Return to step one (1) and build the left flap.

WING

FLAP

FLAP

[-.I 2. Mark the location of the wing bolt plate on

the outside of the fuselage. Mount the wing on

the fuselage and align it squarely to the

fuselage. This is easily done using a piece of

string as a guide. Put a pin in the tail of the

fuselage on the centerline.Tie a loop in one end

of the string and place it over the pin. Move the

other end of the string to one wing tip and put

some masking tape around the string. Draw an

arrow on the tape where it reaches the wing tip.

Now swing the string over to the other wing tip.

If the tip aligns with the arrow the wing is

properly aligned. If not, adjust the wing's

position and try again. Continue to adjust the

wing until both wing tips are aligned with the

arrow on the tape. Secure the wing exactly in

this position.

TRIM ALONG LINE

FROM FLAP CORNERS

Q 1. Mount and align the wing with the fuselage

(see step 2). The center TE sheeting that was

added earlier will need to be trimmed where it

extends past bulkhead DB. Lightly mark the

outline of the fuselage on the top of the wing.

Now mark the location of the front of former DB

on the wing. Remove the wing from the

fuselage. Draw a line on the top of the wing

connecting the aft most corners of the flaps.

Compare this line to the marks you made for

the front edge of former DB. If the line

connecting the corners of the flaps is even with

the marks for former DB, then you are all set.

Trim the wing along this line. If the line does not

line up as above you will need to adjust where

you trim the wing.

Q 3. Drill two pilot holes for the 1/4-20 wing

bolts using a 13/64" bit. Drill the holes through

the wing and into the ply wing bolt plate so that

the holes will be centered fore/aft in the wing

bolt plate.

l-l 4. Remove the wing from the fuselage. Tap

the holes in the ply plate with a 1/4-20 tap. Apply

a couple of drops of thin CA to the threads to

harden them. After the CA has cured, run the

tap through the threads to clean them up.

28

Page 29

Q 5. Fit the two die-cut 1/8" ply wing bolt plates

for the wing bolt holes onto the bottom of the

wing. Glue these into position over the holes with

6-minute epoxy.

l—l 6. Enlarge the wing bolt holes in only the

wing with a 17/64" bit, drilling through the 1/8"

ply plates as well.

I—I 7. Fiberglass both sides of the center of the

wing with 3" tape (included). Put a small patch

around the wing dowels as well.

Q 8. After the fiberglass has dried, put some

Plan Protector on the center of the wing at the

leading and trailing edges where they will touch

the fuselage. Bolt the wing to the fuselage with

the 1/4-20 nylon bolts.

[-I 12. Glue doubler DB to the front of bulkhead

D. Align DB 3/32" above (towards the top of the

fuselage) the TE of the wing to allow for the

3/32" balsa sheeting that will be added to the

bottom of the fuselage.

Q 13. Remove the wing from the fuselage.

Make any adjustments needed to the trailing

edge of the wing where it fits to DB.

Q 9. Use leftover 1/8" ply to make a bulkhead

for where the leading edge of the wing meets

the fuselage. First fit it to the bottom surface of

the wing, then use a pencil to draw the outline

where it meets the fuselage. Now trim this

bulkhead to shape allowing for the 3/32"

sheeting that will be used to fair the wing with

the fuselage.

Note: The above photo shows how the wing

should look after you finish step 11.

Q 10. Position the bulkhead back on the wing.

When satisfied with the fit, glue it to the

WING ONLY.

Q 11. Cut and fit 3/32" balsa from leftover wing

sheeting to smoothly fair the wing with the fuselage.

Glue the sheeting to the former and wing.

CAUTION: Read and study steps 1-5 before

doing anything!

Q 1. Use the 3/8" x 3/8" x 30" balsa stick to cut,

fit and glue filler strips between formers DB and

EB, EB and FB and between former FB and the

lower longeron on both sides of the fuselage as

shown in the photo. These strips are used as a

place to glue the side sheeting to and also form

a filler block for sanding to shape where the

bottom sheeting meets the side sheeting.

Page 30

SIDE SHEETING 1.1/4"

5"

Q 2. Add a stringer to the fuselage from former

DT to HT. Use the supplied 3/16" x 3/16" x 24"

balsa sticks. Cut notches in top formers DT, ET,

FT, GT and HT, and add a stringer to each side as

shown in the photo above. This will provide a

gluing surface where the top sheeting meets

the side sheeting.

Before sheeting the rear of the fuselage you

should decide what technique you would like to

use. Some modelers prefer to add sheeting in

strips, going from stringer to stringer, one strip

at a time. This requires considerable sanding

once the sheeting has been glued into place.

2-1/2"

13-1/2"

31"

36""

3"

Q 4. If you will be making skins to do the

sheeting, cut and fit the individual pieces from

3/32" x 3" x 36" balsa sheets. Glue them together

and sand them flat and smooth. Make two

skins, one for each side.

Our favorite technique is to fit the individual

sheets and then glue them together flat on your

building board to form a "skin." You can then

sand the skin flat and smooth before it is glued

into position.This requires a bit of finesse when

gluing the skin into place. Use a mix of water

and rubbing alcohol to allow the skin to bend

and conform to the curves more easily. This

technique will give a more consistent shape

and smoother finish.

t-1 3. If you will be sheeting the fuselage one

sheet at a time, sheet the fuselage sides using

the 3/32" x 3"x 36" balsa sheets. Then skip to

step 6.

Q 5. Glue the skin to the fuselage side. Wet the

balsa sheeting with water and alcohol to allow

it to conform to the shape of the sides and

bottom. See the note at step 7.

Q 6. Using some leftover 1/8" sheeting, glue the

small piece of side sheeting into place at

bulkhead D.

30

Page 31

1-1 7. Sand the side sheeting fiat across the 3/8"

x 3/8" filler strips from DB to EB. Sheet the

bottom of the fuselage using 3/32" x 3" x 30"

balsa sheets.

clevis (GPMQ3814) at the rudder end and a 4-40

metal threaded clevis (GPMQ3794) at the servo

end with a 4-40 hex nut.

CJ 11. Fit the horizontal stab to the fuselage. To

do this you will need to cut a slot in the stab for

the rudder torque rod. Cut this slot spanwise as

shown in the photo above. Fit the stab into

position centered on the fuselage centerline.

Pin it into position temporarily.

Note: Notice how the sheeting at the tailwheel

has been cut out to fit the tailwheel bracket.

Q 8. Sheet the top of the fuselage using 3/32" x

3" x 30" balsa sheets.The sheeting extends from

the front most former DT to former I.

D 9. Mount the tailwheel bracket with the wire

tailwheel assembly to the ply tailwheel mount

with #4 x 3/8" sheet metal screws.

Q 10. From the top of the fuselage, install and

connect the rudder pushrod between the

rudder horn and servo. Make sure you install a

clevis retainer and have the linkage properly

adjusted as there is no access to this area after

you finish this section. (Refer to the plans for

the proper installation of the rudder linkage.)

Note: Our prototype model used a 4-40 solid

wire pushrod (GPMQ3718), a 4-40 metal solder

Q 12. Fit the vertical fin to the fuselage.You will

need to cut a slot in the fuselage from former I

forward to former H. Notch former H for the fin

to fit into it.

Q 13. When you are satisfied with the fit of the

stab and fin, remove them from the fuselage.

Glue some leftover 1/4" x 1/2" balsa to the

inside of the top longerons where the stab will

be glued to the fuselage to provide some

additional gluing area.

Q 14. Bolt the wing to the fuselage and set the

assembled wing and fuse on your table. My, my

big isn't it! Maybe you can use the dining

31

Page 32

room table for the next steps. Just make sure to

cover the table so you don't scratch it or get

glue on it, lest - well, you get the idea.

Q 15. Next, you will mount the stab to the

fuselage, but before doing so you need to look

more closely at it. As this is a large model, you

should not depend on glue alone to hold the

stab in place. The plan shows 1/8" dowels that

are keyed into former I. You could also use

some leftover 1/4" x 3/8" basswood glued to the

top of the stab and to former I.

Q 18. When the epoxy has cured remove the

wing. Bring the model back to your workbench

with thanks for the use of the table.

Ol 19. Using the 5/8" x 15/16" x 12" balsa block,

carve and fit a filler block to each side of the fin.

This filler block extends from former I aft and

blends with the bottom of the rudder. Glue it

into position, and then, fill in and blend any areas

that need it with leftover wood and hobby filler.

Q 16. Fit the stab into position and adjust the

stab mount as needed to make the stab parallel

with the wing. Be careful not to change the

incidence angle of the stab. Put a pin in the

nose of the fuselage on the centerline. Use your

string to align the stab just as you did for the

wing. When satisfied with the alignment, glue

the stab in position with 30-minute epoxy.

Q 17. Glue the fin into the fuselage and the top

of the stab with 30-minute epoxy. Be sure the

fin is vertical to the stab and aligned with the

fuselage centerline.

Q 20. Use the 3/16" x 1-1/2" x 18" balsa sheeting

to make a dorsal fin as shown on the plan. Glue

it into position and use filler as needed to blend

it with the fin.

Q 21. Using the 1-5/8" x 2" x 4-3/4" balsa block,

roughly carve and sand the tailcone to shape.

Then, glue it into position.

Now for the final details.

32

Page 33

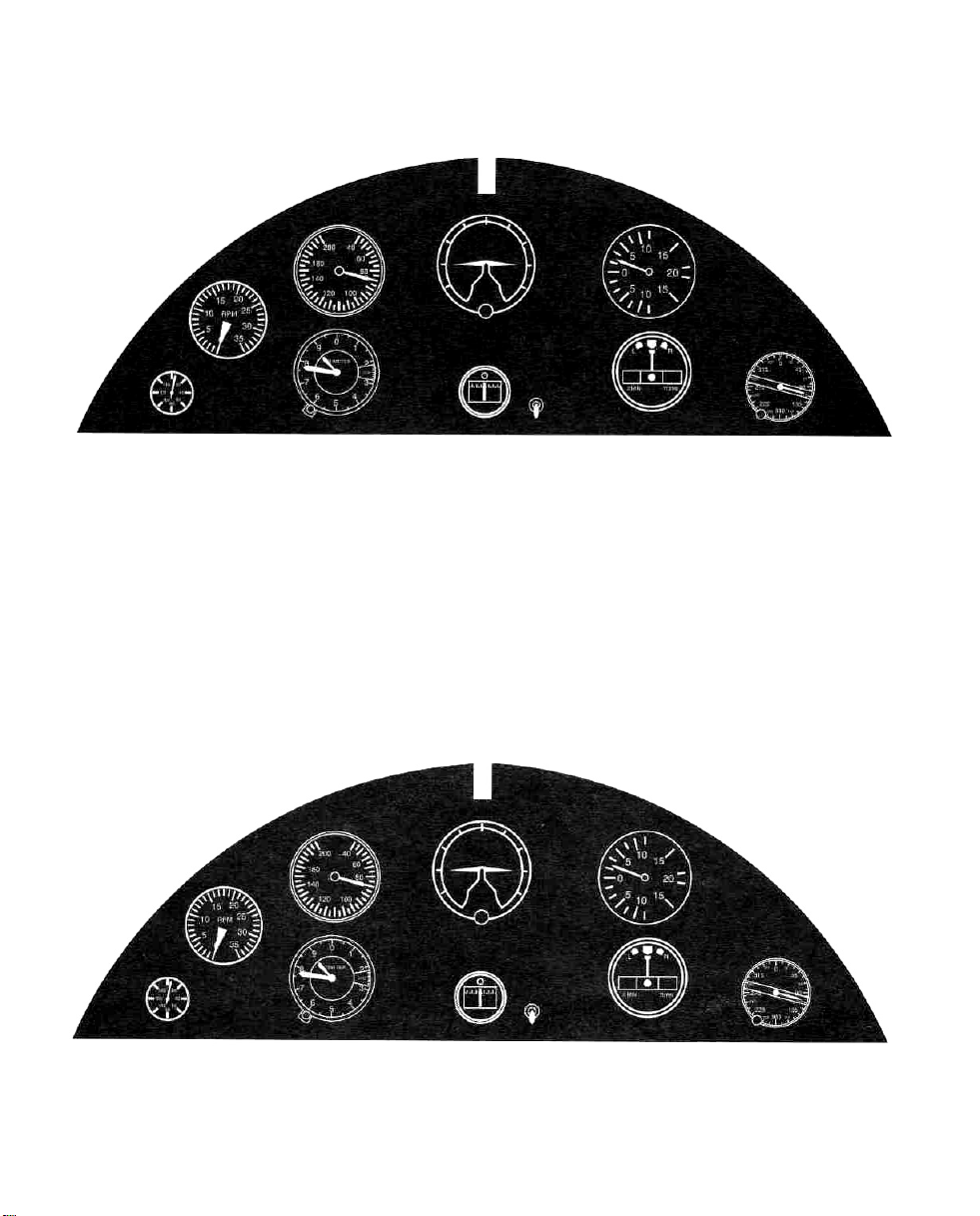

Q 1. Finish the cockpits. The cockpit area was

designed to be structure free so you can add as

much detail as desired.The simplest is to glue a

couple of Williams Brothers pilots to the top

deck. The kit includes two instrument panel

decals which can be positioned on the front

instrument panel and rear former CT, or you can

fashion separate instrument panels. Details in

the cockpit area will really dress up the

appearance of your model.

Q 2. Install your engine and mount on the

firewall.You should shim your mount as needed

to obtain three degrees of down thrust and two

degrees of right thrust.

Q 3. Fit the cowl. The plastic cowl comes in

halves and needs to be glued together. Before

gluing them, trim them to the proper width.The

kit includes a strip of plastic that is used to

reinforce the joint on the inside. Thin CA works

well for this. When you have glued the cowl

together, cut a small hole where the prop shaft

needs to exit the front. Slip the cowl onto the

fuselage and enlarge the hole as needed to

clear the engine thrust washer. As you continue

to fit the cowl to the fuselage and engine, you

may need to remove and reinstall the engine

several times. We have found that using a piece

of cardboard taped to the side of the fuselage is

the easiest way to locate the cutout for the

engine. Tape the cardboard to the fuselage and

cut an opening in it to fit your engine. Remove

the engine, install the cowl and transfer the

cutout to the cowl. If you go slowly and remove

a little material each time from the cowl, you

will be rewarded with a good looking cowl.

Q 4. When you are satisfied with the fit of the

cowl, remove it and glue the four 1/2" x 1/2"

x 3/4" hardwood blocks into place on the firewall.

Sand them to blend to the curve of the cowl.

Ql 5.To drill the mounting holes in the cowl use

the cardboard technique again. Tape some

cardboard to the fuselage side and mark the

center of the mounting blocks. Slip the cowl

into position and mark the location of the holes,

Drill the holes and mount the cowl with #6 x

1/2" sheet metal screws and washers.

Note: The following describes installing the

hinges for the elevators, ailerons, rudder and

flaps (if installed). It is highly recommended

that you obtain a Great Planes Slot Machine™

(GPMR4010) as it will greatly simplify the

process and make for a better installation.

Q 6. Hinge the control surfaces.The kit includes

a hinge strip from which you can cut CA hinges,

or you can use other hinges of your choice.The

following general guidelines will discuss

hinging. We will discuss hinging the elevator

but the same process is used to hinge the

rudder, ailerons and flaps.

A. If you have not already done so, mark the

centerline of theTE of the stab.

B.The LE of the elevators has already been

sanded to a "V," so this will be used as the

centerline.

C. Using the plan as a reference, mark the

locations of the hinges to be installed.

33

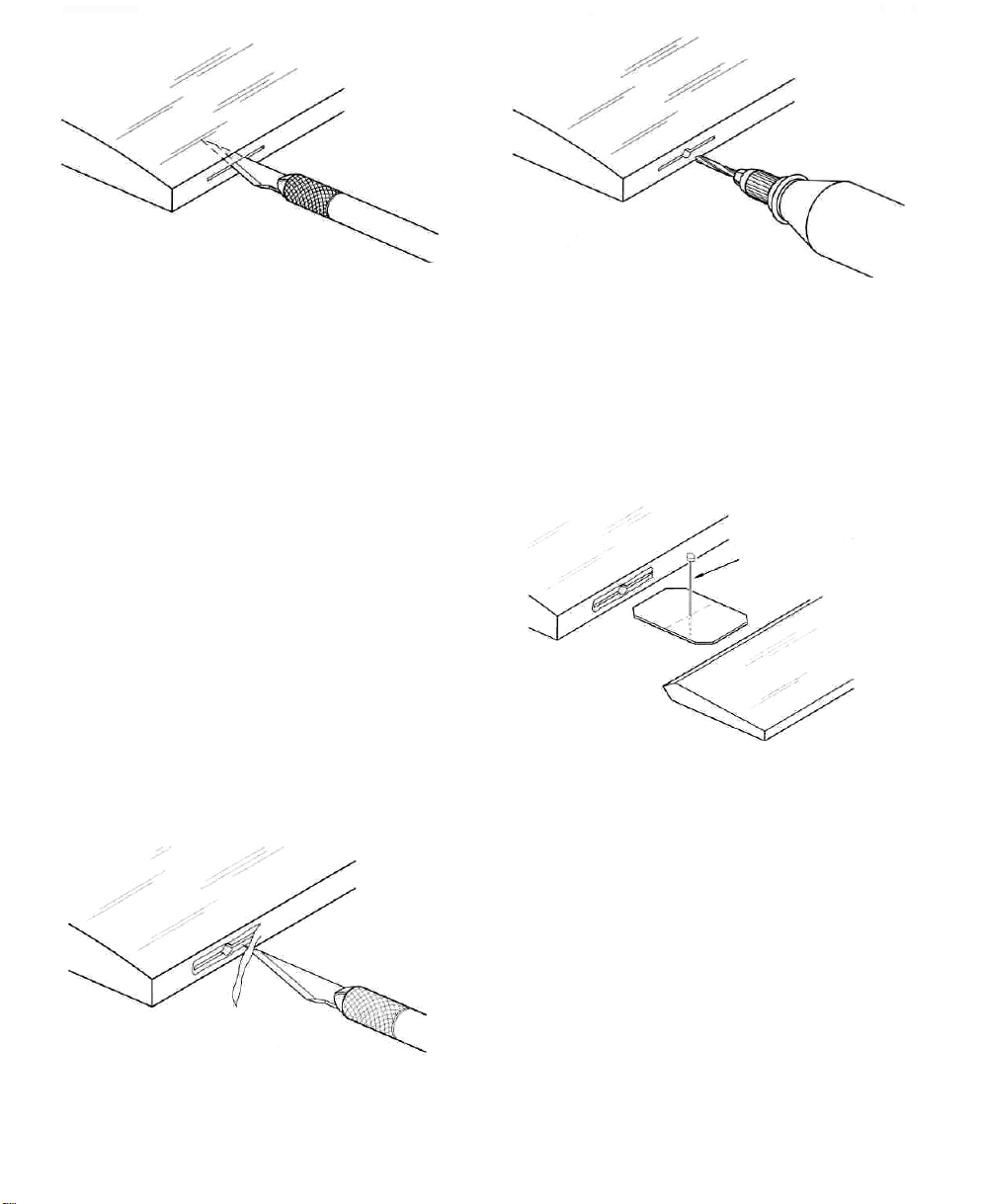

Page 34

CUT HINGE SLOT

WITH HOBBY KNIFE

AND #11 BLADE

D. Use a hobby knife with a #11 blade to

make the hinge slots.The first cut should

be a shallow slit to establish the hinge

slot location. After the first cut make

several more cuts, going slightly deeper

each time. Move the knife from side to

side and widen the slot as you cut.

E. Test join the elevators to the stab with the

hinges in place. DO NOT glue until later.

R Perform the same process for the rudder

ailerons and flaps.

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

B. Drill a 3/32" hole in the center of all the

hinge slots to allow the CA to fully

penetrate. This is best done with a highspeed tool such as a powered hand tool.

If you use a drill, remove slivers of balsa

wood from the hinge slots with a hobby

knife after you drill the holes.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

AFTER you have completely covered and

finished you model, perform the following:

CUT THE COVERING

AWAY FROM THE SLOT

A. Use your hobby knife and a sharp #11

blade to remove a small strip of covering

from the hinge slots to expose them.

C. Join the elevator to the stab with the

hinges. If the hinges will not stay

centered, insert a pin through the center

of the hinge, then join the surfaces and

remove the pins.

D. Confirm that the ends of the elevator

align with the ends of the stab, that the

hinges are centered and there is

approximately a 1/32" gap between the

TE of the stab and the LE of the elevator.

A small gap is desirable so you do not

inadvertently glue the elevator to the stab

with residual CA.

E. Carefully apply 6 drops of thin CA to each

side of all the hinges. Keep a tissue handy

34

Page 35

to wipe away excess CA. If you spill a few

drops of CA on the MonoKote® film you

can use CA Debonder (GPMR6039) to remove

it. Or wait until the CA fully cures, then

carefully lift it off with a hobby knife blade.

Do not use accelerator on any of the

hinges. Do not glue the hinges with

anything other than thin CA and do not

attempt to glue one half of the hinge at a

time with medium or thick CA. They will

not be secure and the control surfaces

could separate while the model is flying.

F. Let the CA fully cure, then flex the elevator

several times to check the movement.

G. Use the same procedure to hinge the

rudder, ailerons and flaps.

D 1.You may cover and finish your model now

if you desire. We prefer to install the radio

before finishing so we don't add any hanger

rash to our finished model. You may also want

to remove the engine.

Our radio installation consisted of the following:

A. One high torque servo for each aileron.

B. One standard size servo for each flap.

C. One high torque servo for each elevator,

with a separate pushrod for each.

D. One high torque servo for the rudder.

E. One standard size servo for the throttle.

F. We used a 1200 mAh battery pack to

allow for the additional servo drain.

While this is a large aircraft, it does not fly very

fast. We have found that the above installation

has worked very well.

Q 2. If you have not done so already, fuelproof

the engine and tank areas. Final sand the model.

Ul 3. Cover the model. We used Top Flite Super

MonoKote on the prototype model. For the

primary white color (TOPQ0204) we used two

six foot rolls for the wing and one six foot roll

for the fuselage. We used one can of Top Flite

LustreKote® Missile Red (TOPR7201) paint

sprayed directly on the white MonoKote. For

the black anti-glare area in front of the canopy

we used some flat black (TOPQ0508) we had

leftover from an earlier project.

Q 4. After you have finished covering, finish the

hinge installation as covered previously.

Q 5. Finish the cockpit area and install your pilots.

Q 6. Fit the canopy to the fuselage. The canopy

is supplied in two parts; a short front

windscreen area and a larger aft section. On the

full-size aircraft this large aft section would slide

aft for the pilots to enter. To install your canopy,

cut and fit the sections to the fuselage.Trim and

fit the area where the front and aft sections fit

together. Carefully cut the covering where they

will be glued to the fuselage so that the canopy

can be adhered to the wood. Use tape or paint

to detail the frame lines. We used RC-56 glue to

glue the completed canopy to the fuselage.

Q 7. Install your fuel system. We used a 16

tank (GPMQ4107) and a refueling valve

(GPMQ4160). If you are installing a gasoline

engine be sure to use a gasoline compatible

tank, refueling valve and fuel line. We mounted

our tank to the bottom deck on a layer of 1/4"

foam (HCAAIOOO).The tank is held in position

with some leftover 1/4" x 3/8" basswood sticks.

Q 8. Paint the cowl. We usedTop Flite LustreKote

white (TOPR7204), missile red (TOPR7201) and

flat black (TOPR7209).

35

oz.

Page 36

Q 9. Mount the landing gear and 4" wheels

(ROBQ1537).

Note: Optional landing gear struts are available

from Robart that fit this model. These struts not

only add a nice touch to the model but help

absorb landing stresses as well. Complete

instructions from Robart are included.

Ul 10. Mount the control horns to the ailerons,

flaps, elevators and rudder.

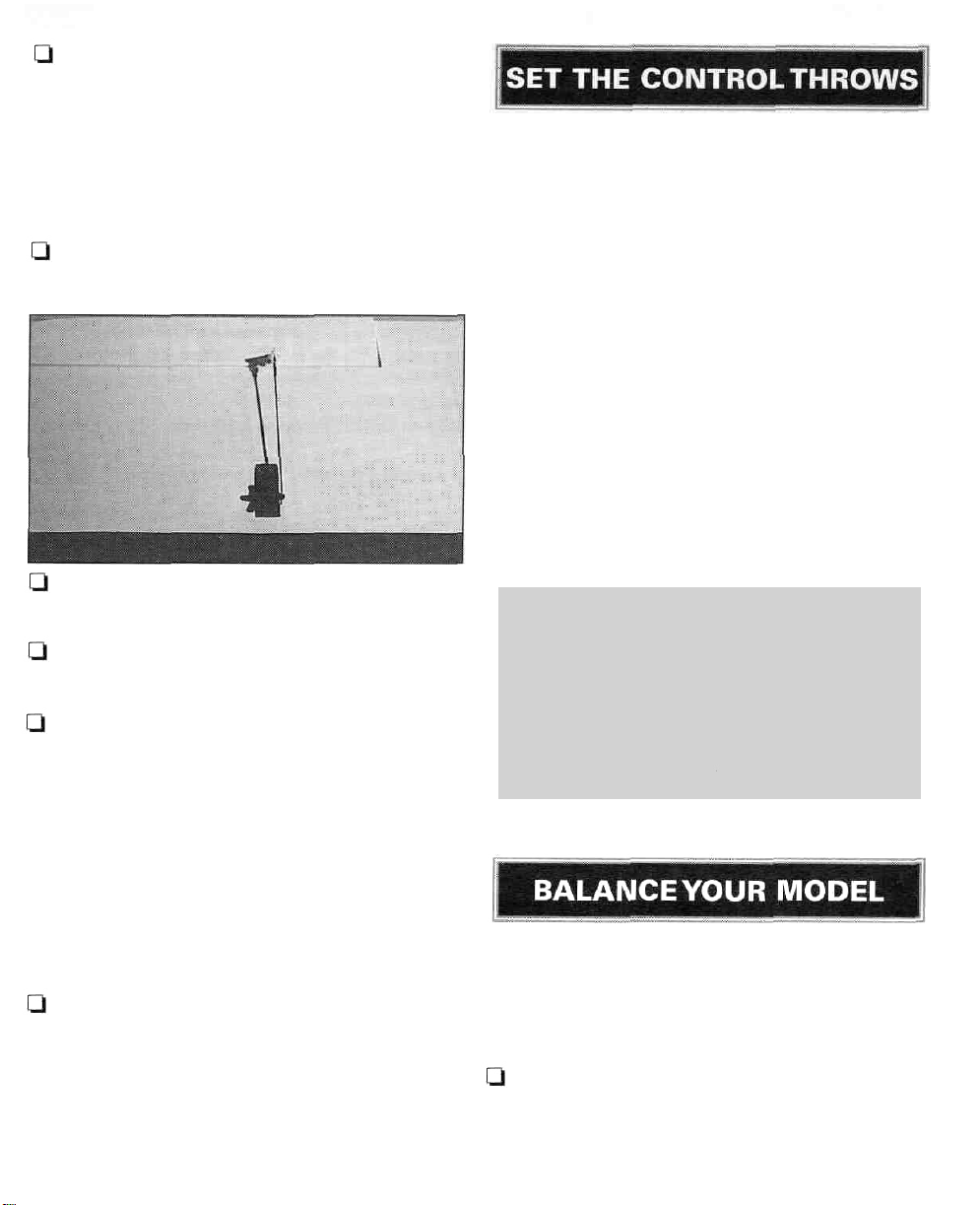

Measure the throws at the widest part of the

trailing edge of the rudder, elevator, flaps and

ailerons. After a few flights you may change the

throws to suit your flying style.

We recommend the following control surface

We recommend the following control surface

throws:

throws:

Q 11. Finish the installation of the control

linkages.

Q 12. Install the throttle servo and connect the

linkage to the engine.

Q 13. Final hookups and checks:

A. Take the servo arms off your servos, turn

on your radio and center all of the trims.

Reinstall all the servo arms and secure

them with screws.

B. Make sure that all clevises have a silicone

retainer installed.

Elevator

High Rate

1/2"

Up

Low Rate

3/8"

Up

1/2" Down 3/8" Down

Rudder

Ailerons

Left

2-1/8"

2-1/8"

Right

11/16" Up

1-3/4" Left

1-3/4" Right

1/2"

Up

9/16" Down 7/16" Down

Flaps

1-1/8" Down

Note: We used a Great Planes Accu-Throw™

Deflection Gauge (GPMR2405) to check the control

throws.

Throttle: Set the throttle so that at "high stick" the

carburetor barrel is fully open and at "low stick,"

with full to half throttle trim, the carburetor barrel

is nearly closed. At this position the engine should

run reliably at a low RPM (idle).To shut the engine

off, decrease the throttle trim tab.

C. Make sure that the control surfaces move

in the proper direction.

l-J 14. Identify your model. No matter if you fly

at an AMA sanctioned R/C club site or if you fly

somewhere on your own, you should always

have your name, address, telephone number

and AMA number on or inside your model. It is

required at all AMA R/C club flying sites and

AMA sanctioned flying events.

This section is IMPORTANT and MUST NOT

be omitted. A model that is not properly

balanced

will

be unstable and

possibly

unflyable.

l-l 1. Check the balance point with all components

installed in the model and the fuel tank empty.