Page 1

• F3B-style soarer makes an ideal first aileron model.

• Strong turbulated wing allows winch launching and low-speed sink.

• Rugged, lightweight balsa/life ply construction.

READ THROUGH THIS INSTRUCTION MANUAL FIRST. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modification. In no

case shall Dynaflite's liability exceed the original cost of the purchased kit. Further, Dynaflite reserves

the right to change or modify this warranty without notice. In that Dynaflite has no control over the

final assembly or material used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled product. By the act of using

the user-assembled product, the user accepts all resulting liability. If you are not prepared to accept

the liability associated with the use of this product, return this kit immediately in new and unused

condition to the place of purchase.

BCATP03 Printed in USA Entire Contents © Copyright 1996

WARRANTY

Page 2

Congratulations and thank you for purchasing the

Dynaflite Bobcat. Once you have learned the basics of

thermal flying, the Bobcat is an ideal "second"

sailplane. With its "flat" wing and ailerons, the Bobcat

is more maneuverable than beginner, two-channel,

rudder-only models so you will be able to chase those

elusive thermals more aggressively. The Bobcat's

relatively thin airfoil makes it penetrate the wind for

competition flying and slope soaring, yet the flat

bottom makes it somewhat of a floater as well. You

can build the Bobcat with a steerable rudder, but only

advanced fliers will be able to take full advantage of

the additional steering capability. The instructions tell

you how to build a steerable rudder or build a fixed,

immovable rudder. You can mount micro, mini or full

size servos in the fuselage, but the ailerons require

either a mini or a micro servo. Most experts will also

use mini or micro servos in the fuselage. The generous

cabin area allows the Bobcat to accept full size,

standard configuration battery packs and receivers.

Let's get started!

2

Page 3

Your Bobcat is not a toy, but a sophisticated working

model that functions like a full-size airplane. Because

of its performance, if you do not assemble and

operate the Bobcat correctly, you could possibly injure

yourself or spectators and damage property.

To make your R/C modeling experience totally

enjoyable, we recommend that you get assistance

with assembly and your first flights from an

experienced, knowledgeable modeler. You'll learn

faster and avoid risk to your model before you're

truly ready to solo. Your local hobby shop has

information about flying clubs in your area whose

membership includes qualified instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,300

chartered clubs across the country. We recommend

you join the AMA which will provide you with

insurance coverage at AMA club sites and events.

AMA Membership is required at chartered club

fields where qualified flight instructors are available.

Contact the AMA at the address or toll-free phone

number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie.lN 47302

(800) 435-9262

Fax (317) 741-0057

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the photos or plan. In those instances the text

should be taken as correct.

2. You must take time to build straight, true and strong.

3. You must install all R/C and other components so

that the model operates properly on the ground and

in the

air.

4. You must test the operation of the model before the

first and each successive flight to insure that all

equipment operates correctly. You must also make

certain that the model has remained structurally sound.

NOTE: We, as the kit manufacturer, can provide

you with a quality kit and great instructions, but

ultimately the quality and flyability of your finished

model depends on how you assemble it; therefore,

we cannot in any way guarantee the performance

of your completed model and no representations

are expressed or implied as to the performance or

safety of your completed model.

Please inventory and inspect all parts carefully

before starting to build! If any parts are missing,

broken or defective or if you have any questions

about building or flying this model, please call us at

(217) 398-8970 and we'll be glad to help. If you are

calling for replacement parts, please look up the

part numbers and have them ready when calling.

3

Page 4

REQUIRED SUPPLIES

AND TOOLS

REQUIRED ACCESSORIES

These are the items "not included" with your kit, that

you will need to purchase separately. Items in

parentheses (OSMG2691) are suggested part

numbers recognized by distributors and hobby

shops and are listed for your ordering convenience.

GPM is the Great Planes® brand, TOP is the Top

Flite® brand and HCA is the Hobbico® brand.

4 Channel Aircraft Radio System with 1 or 2

standard, mini or micro servos and 1 mini or

micro servo

2-Meter Hi-Start Launch System

Approximately 2 rolls Top Flite MonoKote®

covering

1 /4" Latex Foam Rubber Padding

(HCAQ1000)

1/16" Foam Wing Seating Tape

(GPMQ4422)

#64 Rubber Bands (1 /4 Ib box - HCAQ2020)

(3 sets) 36" Flexible Cable Pushrod for

Elevator and Ailerons (GPMQ3702)

36" Solid Wire Pushrod Set (optional) for

Steerable Rudder (GPMQ3716)

(1 pc.) 2-56 Nylon Clevis (optional) for

Steerable Rudder (GPMQ3800, pkg. of 2)

(3 pcs.) Standard Solder Clevises (for .074

wire/cable) (GPMQ3810, pkg. of 2)

(1 pc.) 1/16" Threaded Ball Link for Aileron

Servo (GPMQ3842)

(2 pcs.) 2-56 Screw-Lock Pushrod Connectors

(GPMQ3870, pkg. of 2)

These are the building tools and adhesives that you

will need to build your Bobcat.

We recommend Great Planes Pro™ CA and Epoxy

2 oz. Thin CA (GPMR6003)

2 oz. Medium CA+ (GPMR6009)

CA Applicator Tips (HCAR3780)

CA Accelerator (GPMR6035)

30-Minute Pro Epoxy (GPMR6047)

#1 Hobby Knife Handle (XACR4305)

#11 Blades (Qty 100. - HCAR0311) or (Qty.

5-XACR2911)

Hobbico Builders Triangle (HCAR0480) or

similar

Medium T-pins (HCAR5150)

Wax Paper

Electric Drill

Drill

Bits:

1/16",

(or 7/64"), 11/64" (or 5/32")

#1 Phillips Screwdriver

Top Flite Covering Iron (TOPR2100)

Hot Sock'" (for your covering iron, TOPR2175)

Single-edge Razor Blades (100, HCAR0312)

Denatured or IsopropyI Alcohol (for epoxy

clean-up)

HobbyLite" Balsa Filler (HCAR3401)

Bar Sander or Sanding Block and Sandpaper

3/32",

5/32",

3/16",

#36

(coarse, medium, fine grit - see next page)

4

Page 5

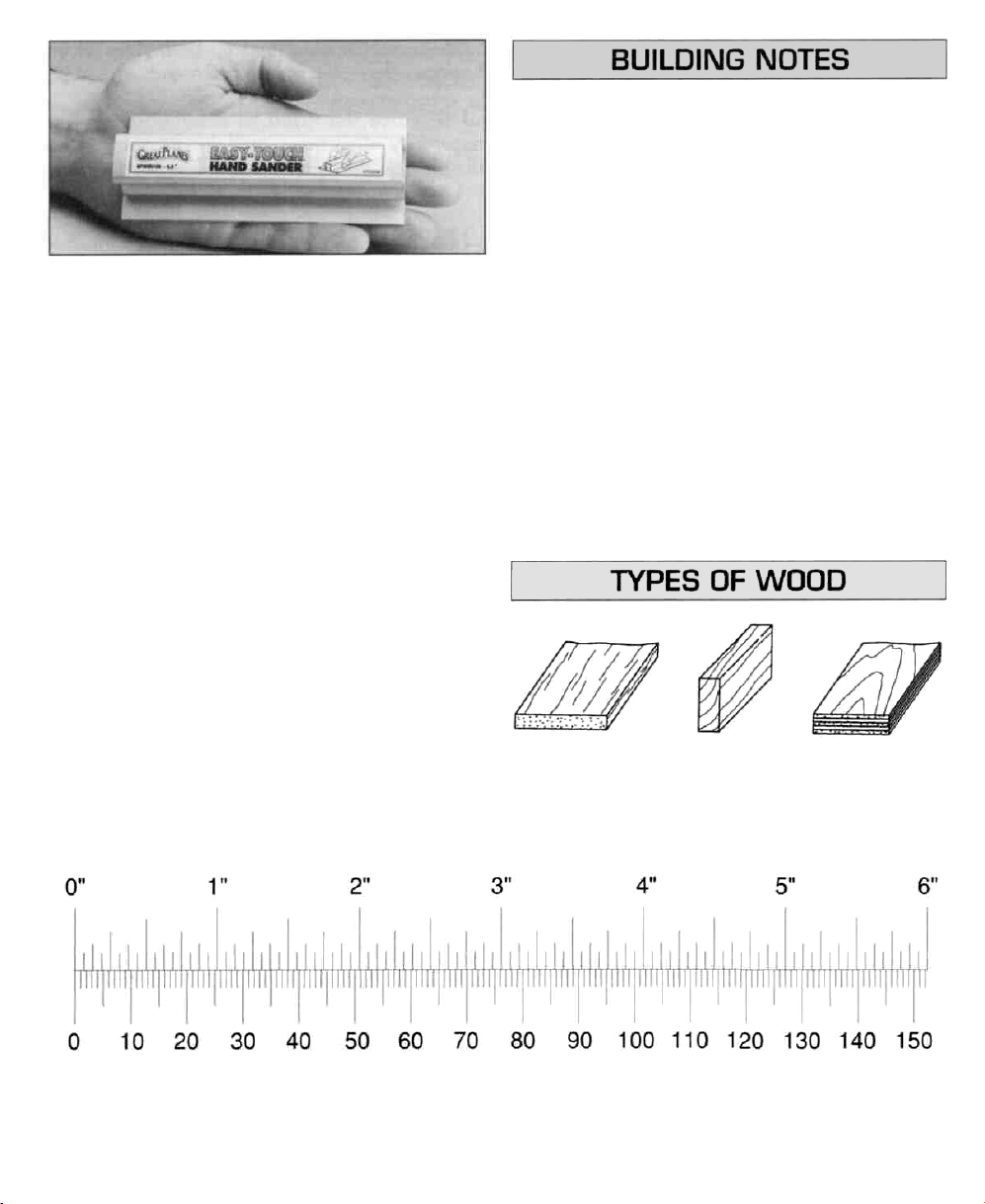

A flat, durable, easy-to-handle sanding tool is a

necessity for building model airplanes. Great Planes

makes a complete range of Easy-Touch" Bar Sanders

and replaceable Easy-Touch adhesive-backed

sandpaper.

• When you see the term "test

instructions, it means you should first position

the part on the assembly without using any

glue. Slightly modify or "custom fit" the part as

necessary for the best fit.

• Whenever just "epoxy" is specified, you may

use either 30-minute epoxy or 6-minute epoxy.

When 30-minute epoxy is specified, it is highly

recommended that you use only 30-minute

epoxy because you will need either the working

time and/or the additional strength.

fit"

in the

For future reference, here's a list of Easy-Touch

Sanders and adhesive-backed sandpaper:

5-1/2" Bar Sander (GPMR6169)

11 "Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

12" Roll of adhesive-backed sandpaper,

80-grit (GPMR6180)

150-grit (GPMR6183)

220-grit (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

Inch Scale

Bar

• Do not throw away any leftover material

after you have completed your Bobcat. Some

small pieces of leftover balsa or plywood are

used during construction.

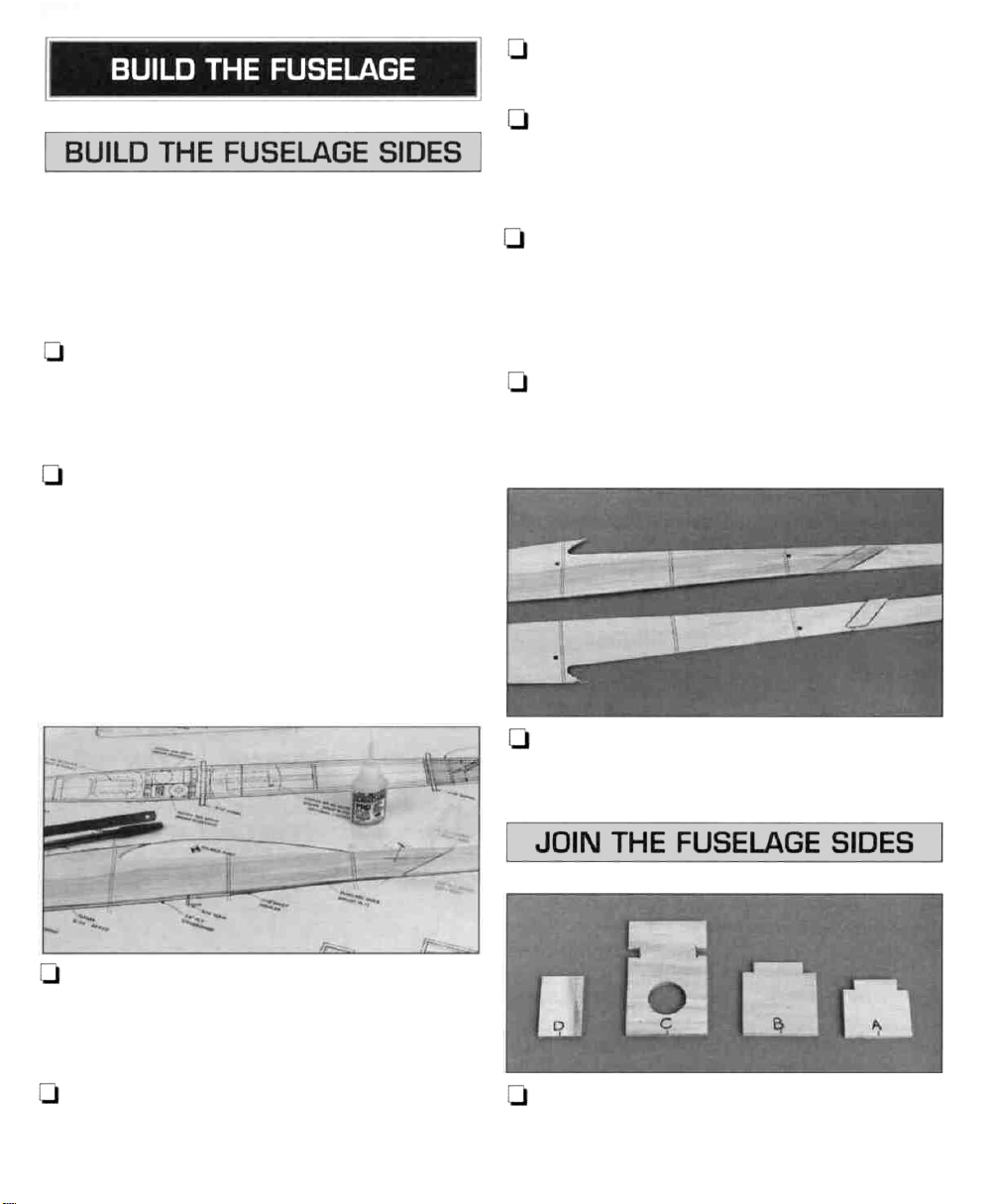

Balsa Basswood Plywood

until

Metric Scale

5

Page 6

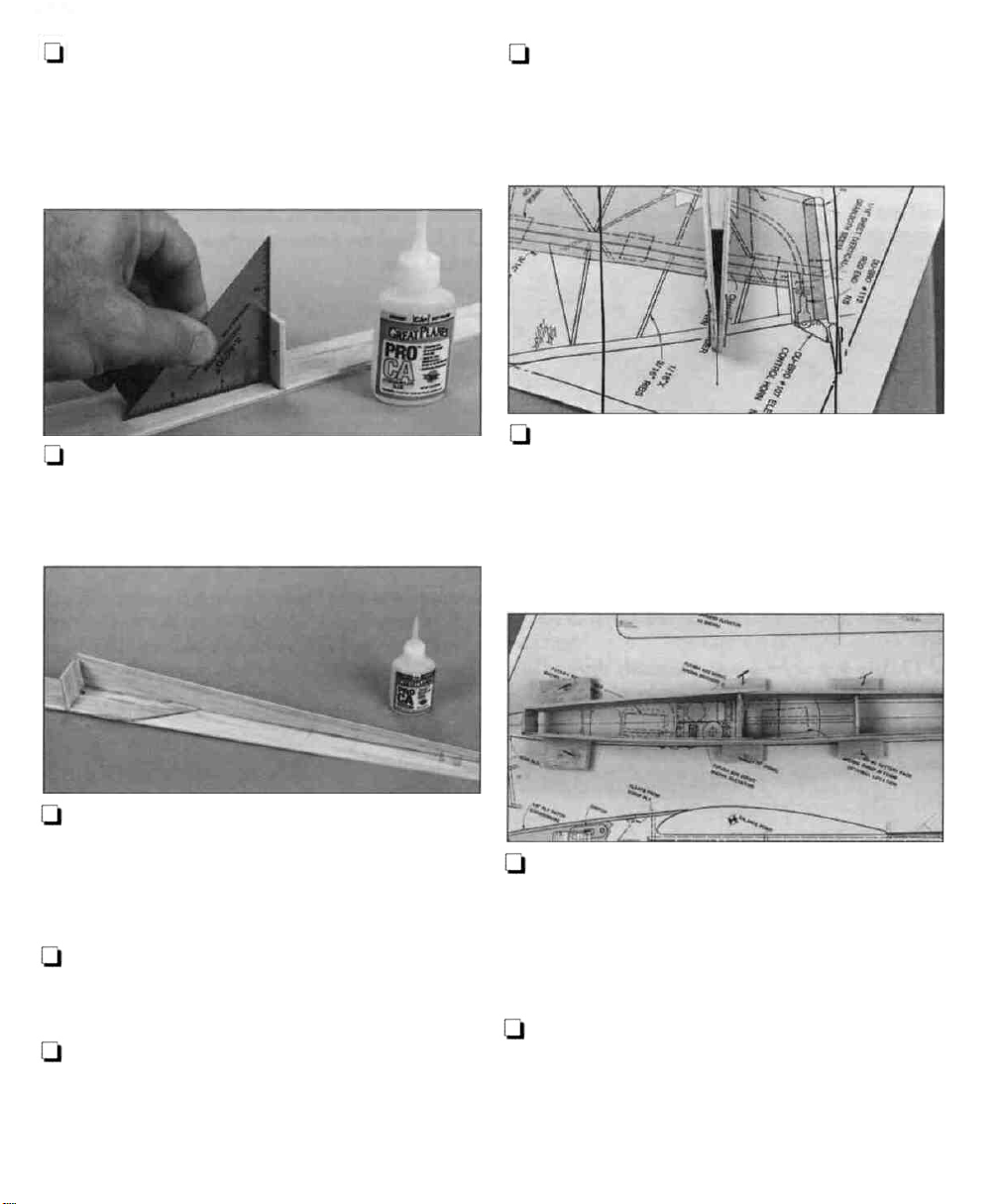

All the parts in the following steps are die-cut 1/8"

plywood unless otherwise noted. After you remove

die-cut parts from their die sheets, remove slivers

and die-cutting irregularities with a bar sander and

80-grit sandpaper.

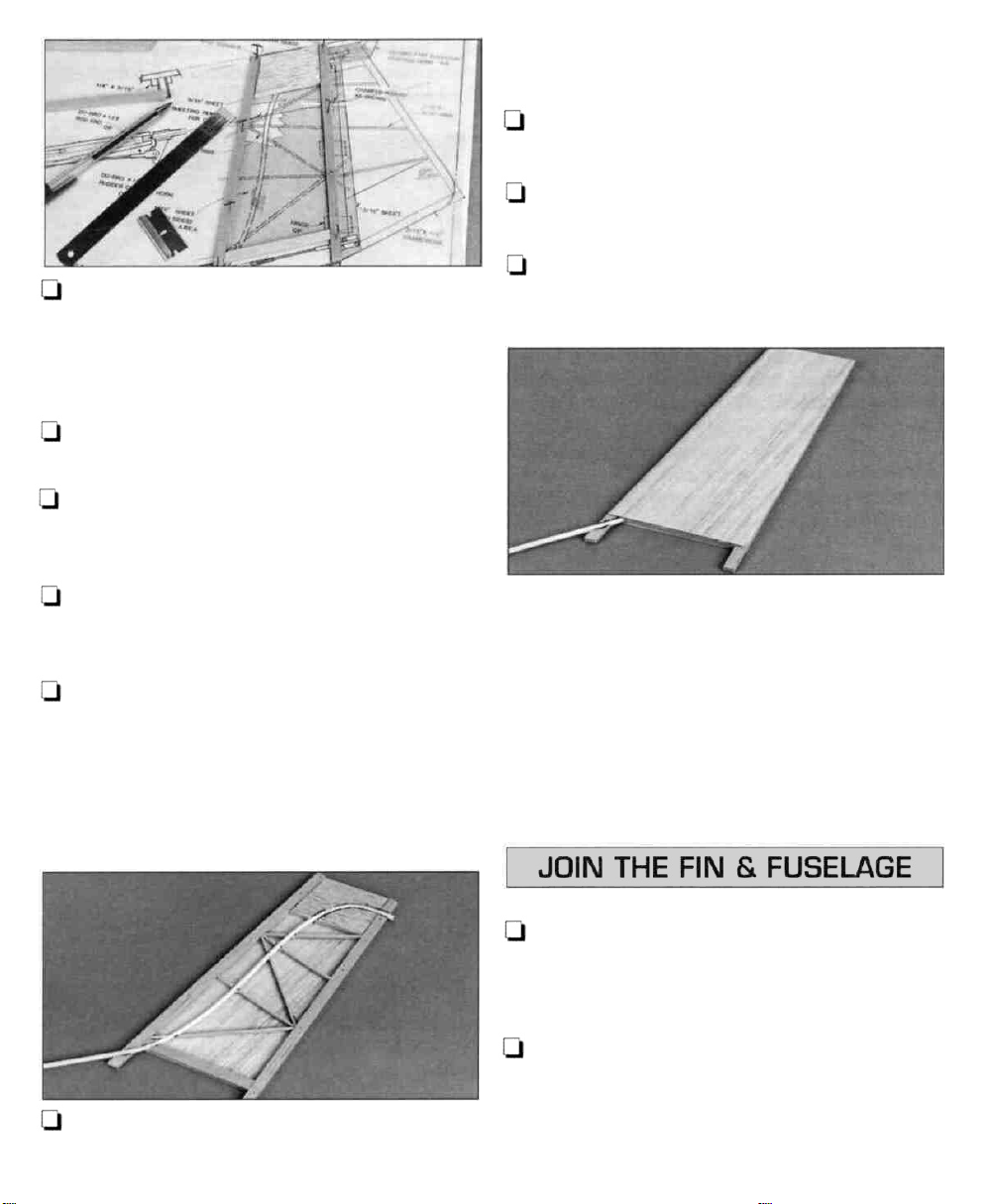

1. Unroll the fuselage plan. Reroll it the opposite

way so it will lie flat. Align the side view of the

fuselage plan over a flat building board into which

you can stick T-pins.

Q 2. Lay a piece of wax paper on the fuselage plan

over the joint between the forward and aft fuselage

sides

so

glue

will

not stick

forward right fuselage side over its location on the

plan. Test fit the aft right fuselage side to it. Use

your bar sander to adjust the forward edge of the aft

fuselage side so it accurately aligns with its location

over the plan. Glue it to the forward fuselage side

with medium CA.

to

the

plan.

Pin

the

Q 5. Sand the glue joint on both sides of the

fuselage sides so it is smooth and even.

U 6. Place the fuselage sides together and

accurately align them. Drill 3/16" holes in the

dimples on the left fuselage side for the wing

hold-down dowels.

U 7. Transfer the lines you marked on the inside of

the right fuselage side to the left fuselage side by

marking them on the top and bottom of the left

fuselage side. Draw the lines with a straightedge

and your ballpoint pen.

Q 8. Use medium CA to glue the left and right

fuselage side joiners to the inside of the left and

right fuselage sides, respectively, so their top edges

are 1/16" below the top edges of the fuselage sides.

U 3. Before you remove the right fuselage side from

the plan, use a straightedge and a ballpoint pen to

accurately mark the location of the three formers

onto the fuselage side.

U 4. Remove the right fuselage side from the plan.

Glue the forward left fuselage side to the aft left

fuselage side the same way.

LJ 9. Sand the bottom edges of the joiners so they

are even with the bottoms of the fuselage sides.

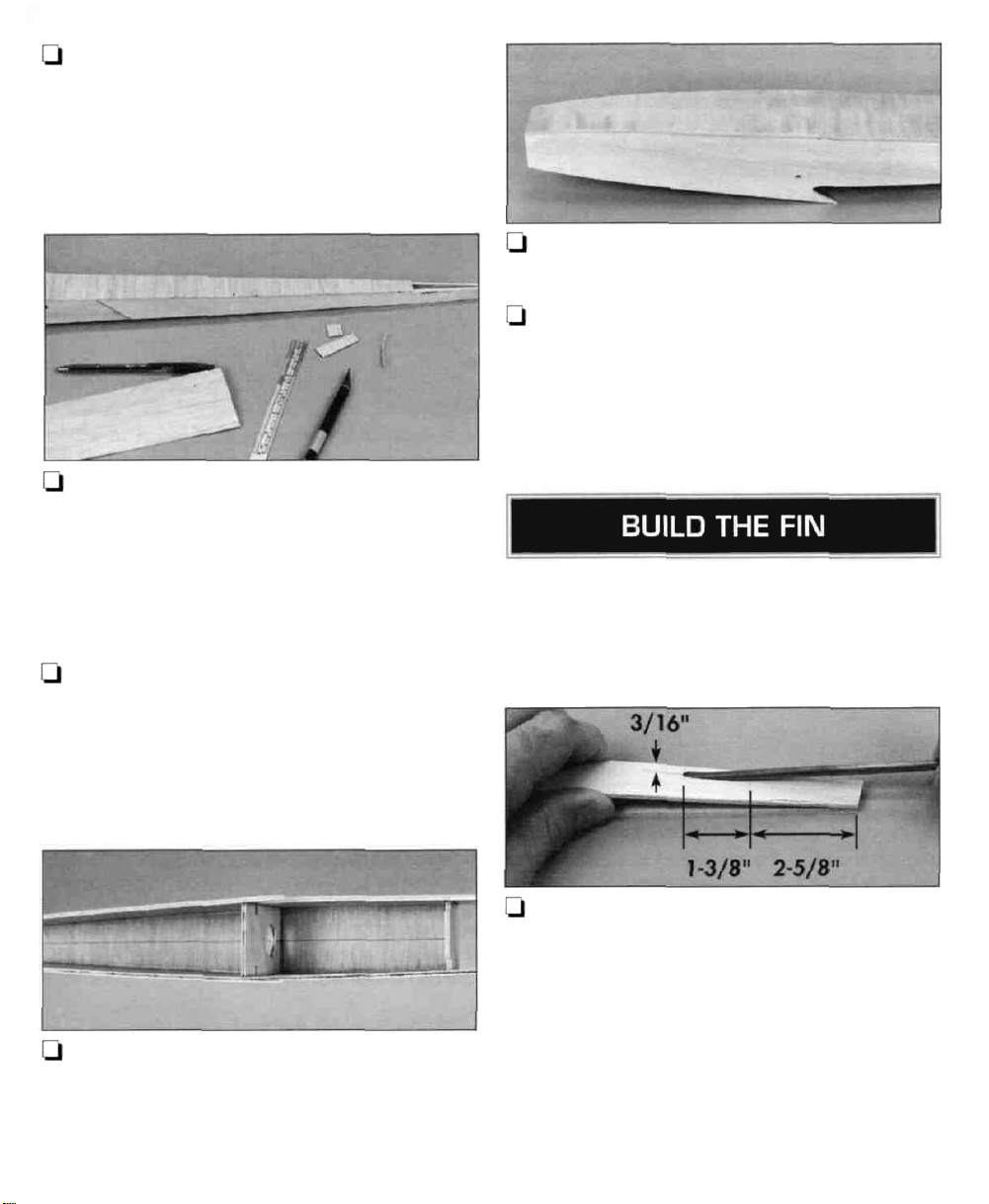

CJ 1. Accurately mark the center of the bottom of the

bulkheads. Label them as shown on the plan and in

the photo.

6

Page 7

D

2.

Optional: Drill a 3/16" hole near the bottom

of bulkheads A and B for an antenna guide tube (not

included). The hole in bulkhead B must be slightly off

center so the guide tube will not interfere with the

tow hook block.

LJ 3. Use medium CA to glue bulkhead A to the

right fuselage side so it is even with the fuse bottom.

Use a small 90 degree triangle to hold the bulkhead

perpendicular to the fuse side while you glue.

Q 7. Use a straightedge and a ballpoint pen

extend the centerline on the top view of the fuselage

plan an additional 9" from the rear of the fuselage

on the plan. Cover the top view of the plan with wax

paper from bulkhead A to bulkhead D.

LJ 8. Position the fuselage on the top view and

accurately align the aft end of the fuselage over the

centerline, then hold it in position with a large T-pin

on both sides. Align the centerline on bulkhead A

with the centerline on the plan. Hold the fuse in

position with a balsa block and T-pins on both sides

of the fuse.

to

Q 4. Remove the die-cut 1/16" balsa

the die sheet and sand off slivers and die-cutting

irregularities. Cut the aft end of the crutch so it

matches the length shown on the plan.

Q 5. Use thin CA to glue the crutch to the right

fuselage side so it is perpendicular and the front of the

crutch overlaps bulkhead A as shown on the plan.

LJ 6. Join the left fuselage side to the right fuselage

side. Accurately align bulkhead A with the lines you

marked on the left fuse side and align the crutch with

the left fuse side. Use medium CA to glue bulkhead

A to the left fuse side.

crutch

from

Q 9. Fit, but do not glue, the rest of the bulkheads

between the fuse sides. Use the "balsa block and

T-pin" technique to hold the fuselage in position so

the centerlines of the formers align with the

centerline on the plan. Hold the fuse sides to

bulkhead D with masking tape.

U 10. Double-check that the formers align with both

the plan and the lines you marked on the inside of

the fuse sides. Also make sure that the bottoms of the

formers align with the bottoms of the fuse sides. Glue

the formers to the fuse sides with thin CA, followed

with medium CA.

7

Page 8

U 11. Remove the fuselage from your building

board. Sand the bottom so the formers and fuselage

sides are even. Sand the top of the fuselage sides

and the crutch so they are even.

Q 12. Glue the cross-grain sheeting cut from a

1/16" x 3" x 24" balsa sheet to the aft fuselage top.

The cross grain sheeting should extend from

bulkhead A aft to the end of the crutch.

U 13. Use a straightedge to accurately draw a line

with a ballpoint pen down the center of the 1/8" x

2" x 23-7/8" cross-grain plywood sheet. Cut the

sheet to a length of 12-3/4".

LJ 15. Sand the bottom ply sheet so it is even with

the fuse sides.

LI 16. Glue the 1/4" x 3/8" x 4-1/4" basswood

tow hook anchor to the inside of the forward fuse

bottom, between bulkheads A and B with medium

CA. Note that the 1 /4" side of the anchor is the side

that contacts the fuse bottom.

Note: Perform step 1 only if your are an experienced

pilot who will be able to take advantage of

a steerable rudder. Ailerons alone will allow

intermediate fliers to turn the Bobcat properly.

Q 14. Use medium CA to glue the 12-3/4"

cross-grain plywood sheet to the bottom of the

fuselage so the aft edge aligns with the middle of

bulkhead B and the centerline on the bottom sheet

aligns with the center marks on the bulkheads.

LJ 1. Make the slot for the rudder pushrod guide

tube in the rear of the left fuselage side at the

location shown in the photo and on the plan. Use a

3/16" brass tube sharpened at one end, a 3/16"

drill or a hobby knife.

Do not use CA Accelerator while you build the fin.

Residual accelerator may cure the CA you use to

glue on the fin sheeting before you have a chance

to position it.

8

Page 9

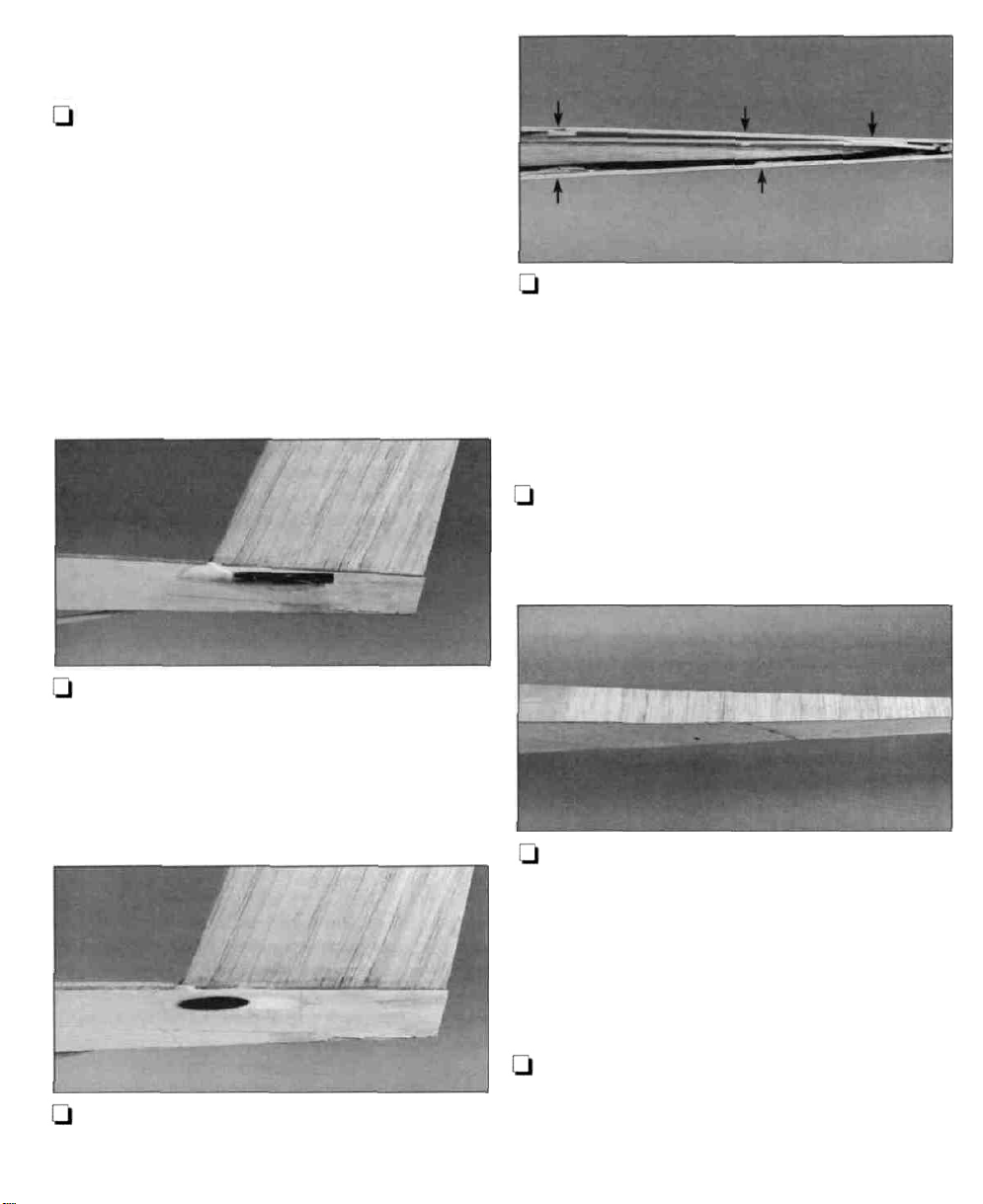

Q 2. Place a sheet of wax paper over the rudder

and fin plan. Build the fin frame from the 3/16" x

1/4" x 24" balsa stick and the 3/16" x 1-3/8" x

24" balsa sheet. Build accurately because the fin

establishes the incidence of the stab.

Q 3. Cut the fin ribs from the 1 /16" x 3/16" x 24"

balsa stick. Glue them in position.

U 4. Remove the fin from your building board and

peel off the wax paper. Carefully sand both sides of

the fin flat.

tip

of the fin

to make sure the grooves are deep enough.

U 8. Glue the tube in place with medium CA. Sheet

the left side of the fin the same way as the right.

Q 9. Sand the tip of the fin so it accurately matches

the plan. Round the leading edge.

U 10. If you will be building a functioning rudder,

mark the location of the hinges on the fin and cut the

hinge slots.

and

in

the cross braces.

Test

fit

the

tube

Q 5. Use a ballpoint pen to mark the left side of the

fin where the elevator pushrod tube (not included,

GPMQ3702) intersects the braces, base and tip.

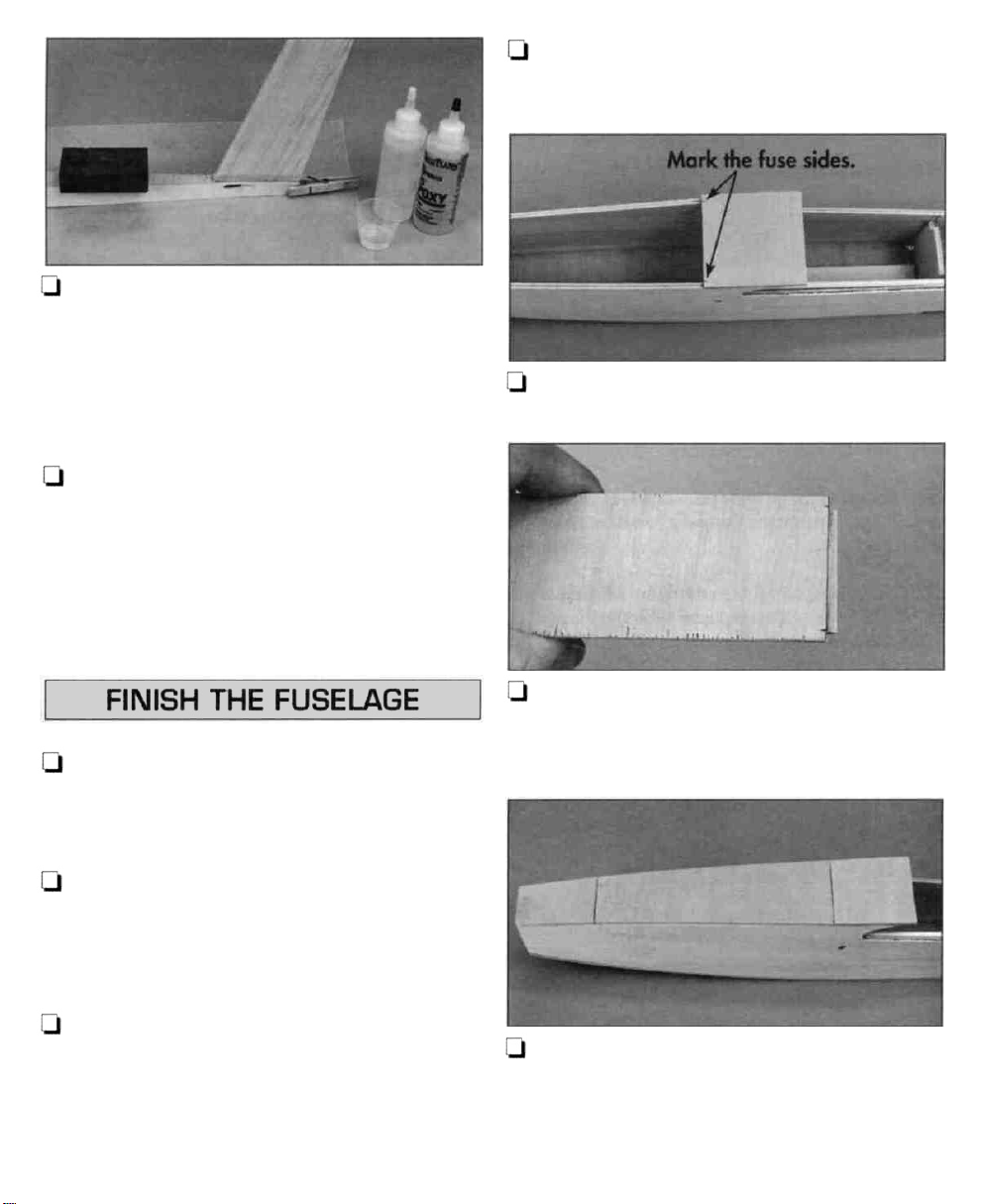

Q 6. Sheet the right side of the fin with a 1/16" x

3" x 24" balsa sheet. The bottom of the sheet should

align with the bottom of the horizontal 3/16" x 1/4"

"base" portion of the fin. The grain of the sheet

should run parallel to the LE. Use a small piece of

leftover 1/16" balsa sheet for the corner of the fin

the bottom of the

Q 7. Use a MultiPro™ or a hobby knife to cut

grooves for the elevator pushrod guide tube in the

TE.

A nice little piece of workmanship you have there,

isn't it?

at

Q 1. Test fit the fin and the guide tube in the

fuselage. If necessary, trim the aft edge of the 1/16"

balsa crutch and cross-grain sheeting so the TE of

the fin aligns with the end of the fuselage.

U 2. Place a piece of wax paper under the back of

the fuse to protect your workbench. Place weights on

top of the fuselage to keep it from moving around

while you work. Wrap masking tape 1/8" above the

bottom of the fin to keep excess epoxy off the fin.

9

Page 10

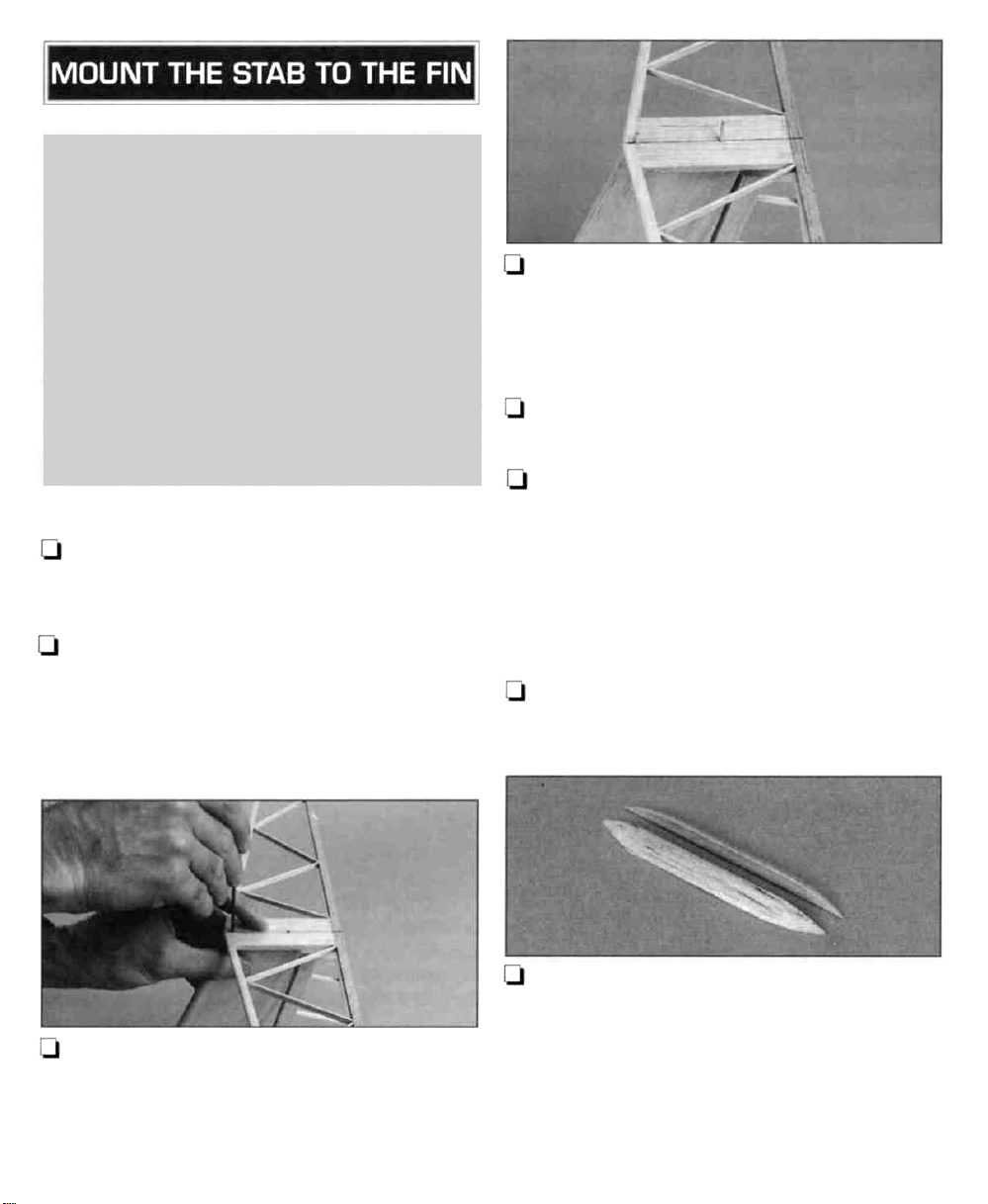

d 3. Apply 30-minute epoxy to the base of the fin,

the top of the fuse sides and all other mating surfaces.

Insert the fin into the fuse. Clamp the fuse sides to the

fin TE with a clothespin. Push a T-pin through the top

sheeting into the LE to hold the front of the fin down.

Immediately proceed to the next step.

Q 4. Make a fillet of epoxy joining the base of the

fin and the fuse. Use a 90 degree triangle to make

sure the fin is perpendicular. Remove the masking

tape before the epoxy cures and do not disturb the

model until the epoxy is fully cured.

Q 4. Glue the front hatch tongue to the bottom

the hatch so half of it protrudes past the front

edge

of the hatch.

U 5. Use a ballpoint pen to mark the inside edges

of the fuse sides on the aft 2" plywood strip.

of

Q 1. Cut two 2" pieces and one 5-3/4" piece from

the remaining cross-grain 1/8" x 2" plywood strip.

Use medium CA to glue one of the 2" strips to the

front of the fuselage as shown on the plan.

Q 2. Use the 5-3/4" plywood strip (which will

become the top of the hatch) as a spacer to glue the

other 2" plywood strip to the aft portion of the

fuselage cabin. Leave a small gap at both ends of the

hatch to provide clearance for the covering material.

U 3. Use the remaining 1/8" x 2" plywood strip to

make two 3/8" wide hatch tongues. The aft hatch

tongue should be the same width as the inside of the

fuse sides at the back of the hatch. The front hatch

tongue should be the same width as the fuse sides at

the front of the hatch.

LI 6. Position the hatch on the fuselage and transfer

the marks to the hatch so you know where to glue the

aft hatch tongue. Glue the aft hatch tongue so 1 /8" of

the tongue extends past the aft edge of the hatch.

Q 7. Fit the hatch to the fuselage by first inserting

the front hatch tongue under the front fuse top. Next,

bend the hatch so you can slip the aft tongue under

the aft cabin top. Sand all the plywood pieces so

they are even with the fuse sides.

10

Page 11

Skip to

step

11 if you

will

not be

building

the

functional rudder.

Q 8. Cut a 36" outer pushrod guide tube to a length

of 29". Use coarse sandpaper to roughen the

outside so glue will stick. Slide the tube through the

exit slot in the rear of the fuselage until the front of

the tube extends past bulkhead C the same amount

as the elevator guide tube (this should be about

Make sure the rudder guide tube does not interfere

with the fin LE or the elevator guide tube. If it does,

adjust the position of the exit slot until there is

no interference.

2").

LJ 11. Glue the elevator guide tube and the rudder

guide tube (if you have one) to the inside of the

fuselage sides in a few locations with epoxy.

Because of the angle at which the guide tubes enter

the fuselage at the rear, they should naturally contact

the inside of the fuselage sides in a few spots. This is

where you should glue them.

U 12. Sheet the bottom of the fuselage in a cross-grain

fashion with the remainder of the 1/16" x 3" x 24"

balsa sheet you used for the top of the fuselage.

Q 9. Glue the guide tube to the fuselage side in the exit

slot with 30-minute epoxy and microballoons or just

thin CA. If you use thin CA, fill the slot around the guide

tube with lightweight balsa filler such as Hobbylite".

Q 10. Use your bar sander and 80-grit sandpaper to

sand the exit tube and filler flush with the fuselage side.

1-1 13. Cut, but do not glue, a strip of 1/16" x 3"

balsa to fit on the bottom balsa sheeting joining the

aft edge of the bottom ply sheeting as shown on the

plan. Taper the aft edge of the sheet. Glue it

in

position. Use your bar sander and 80-grit

sandpaper to sand the bottom sheeting even with the

fuselage sides and plywood sheeting.

Q 14. Make the tail skid from a piece of leftover

1/8" plywood. You can glue it now to the bottom

sheeting in the location shown on the plan or you

can wait until after you cover the fuselage.

11

Page 12

U 15. Make sure the front of the fuselage sides, top

and bottom are flush with the front bulkhead D.

Securely glue the balsa nose block in position with

medium or thick CA.

U 16. Shape the nose block with a razor plane or a

hobby knife, followed by progressively finer grits of

sandpaper, to match the contour of the fuselage

shown on the plan.

U 17. If you have drilled holes in bulkheads A and B

for the antenna guide tube, install the guide tube. Cut

a hole in the bottom of the fuselage near the aft end

so the guide tube can exit. Glue the tube in position.

Fill the gaps around the tube at the exit and sand it

flush with the bottom sheeting after the filler dries.

Q 2. Use the remainder of the 3/16" x 1/4" x 24"

balsa stick you used to build the fin and an

additional 3/16" x 1/4" x 24" balsa stick, to build

the rudder framework. Cut the pieces to the correct

length. Pin them in their location over the plan

glue them together with medium

IJ 3. Use the remainder of the 3/16" x 1-3/8" x

24" balsa sheet you also used for the tip of the fin to

make the

position with medium CA.

Q 4. Cut the rudder ribs from the remainder of the

1/16" x 3/16" x 24" balsa stick you originally used

for the fin ribs. Glue them in position with medium CA.

U 5. Remove the T-pins. Lift the rudder from the

plan and peel off the wax paper. Lightly sand the

rudder to remove any glue bumps and high spots. If

you use a sanding block, be careful not to snag the

1/16" ribs with the edges of the sandpaper.

Q 6. Round the bottom of the rudder as shown on

the plan. Taper the rudder toward the trailing edge

to a thickness of approximately 3/32" or round the

trailing edge the same as the leading edge of the fin.

base

of the rudder. Glue the base in

CA.

and

Q 1. Position the rudder portion of the plan

your building board. Cover it with wax paper.

over

Perform steps 7, 8 and 9 only if you are going to

build a functional rudder.

U 7. Cut the hinge slots in the rudder in the location

shown on the plan. Shape the leading edge of the

rudder to a "V" as shown on the plan.

12

Page 13

HINGED RUDDER

1/16" X 1/2" BALSA SHEETS

EVEN WITH AFT EDGE OF "V"

ON LEADING EDGE OF RUDDER

Q 8. Cut two 1 /2" x 7" strips from the remainder of

the 1/16" x 3" balsa sheet you used to sheet the fin.

Glue the strips to both sides of the leading edge of

the rudder with medium CA so the front edge of the

1/16" strips are even with the aft edge of the "V as

shown on the plan.

Perform steps 10, 11 and 12 only if you are

building a fixed rudder.

FIXED RUDDER

1/16" X 1/2" BALSA SHEETS

EVEN WITH LEADING EDGE

OF RUDDER

Q 10. Cut two 1/2" x 7" strips from the remainder

of the 1/16" x 3" balsa sheet you used to sheet the

fin. Glue the strips to both sides of the leading edge

of the rudder with medium CA so the front edge

the 1/16" strips are even with the leading edge

of

of

the rudder.

Q

11. Sand the ends of the 1/16" strips so they are

even with the top and bottom of the rudder.

U 12. Use medium CA to glue the rudder to the fin.

Use a straightedge to make sure you glue the rudder

on straight.

Tne optional fin tip filler constructed in the next three

steps enhances your Bobcat's appearance.

Q 9. Mark the location of the hinges on the rudder

where shown on the plan. Cut the hinge slots. Cut

three hinges to the size shown on the plan from the

supplied CA hinge strip. Test fit the rudder to the fin

with the hinges. If necessary, adjust the width or

position of hinge slots that don't align.

Q 13. Cut two 1/16" x 1/16" x 1" strips from a

piece of leftover 1/16" balsa. Glue them to the top

trailing edge of the fin above the rudder with medium

CA. The strips should be inset from the outer skin of

the rudder by 1/16" but must not obstruct the hole in

the pushrod guide tube for the elevator cable.

13

Page 14

Q 3. Use a hobby knife and a straightedge to bevel

one end of the 3/16" x 1-3/8" x 3-3/4" balsa

sheet to make the stab center. Glue it to the stab LE

and TE with medium CA in the location shown

the plan.

Q 4. Cut the stab ribs from a 1 /16" x 3/16" x 24"

balsa strip. Glue them in position with medium CA.

on

LJ 14. Make two fin tip fillers from leftover 1/16"

balsa sheeting. Glue them to the trailing edge of the

fin so there is 1/16" clearance between the fillers

and the top of the rudder (if you have built a

non-functioning rudder, the fillers should extend all

the way to the rudder tip). Make the fillers oversize

so you can sand them to exact shape after you glue

them in position.

U 15. Sand fillers so they are even with the fop of

the fin and the TE of the rudder.

Q 1. Position the stabilizer portion of the plan over

your

building board. Cover it with wax paper.

Q 5. Remove the T-pins. Lift the stab from the plan

and peel off the wax paper. Lightly sand the stab to

remove any glue bumps and high spots. With such a

lightweight structure it is necessary to even only the

high spots, so don't weaken the structure by sanding

too much.

Q 6. Use the remainder of the 3/16" x 1-3/8"

balsa sheet you used for the fin tip and rudder base

to make the

hinges. Cut the hinge slots and bevel the leading

edge to a "V" as shown on the cross section. Taper

the elevator toward the trailing edge to a thickness

of 3/32" or just round-off the trailing edge.

U 7. Test fit the elevator to the stab with four more

hinges cut to the size shown on the plan from the

hinge strip. If necessary, adjust the width

position of the hinge slots so they align.

U 8. Starting with your bar sander, round the

leading edge and tips of the stab as shown on the

plan. Finish by hand-sanding with progressively

finer grits of sandpaper. Blend the ends of the

elevator to the stab tips for a finished appearance.

elevator.

Mark the location of the

and

Refer to fhis photo while you are building the stab.

Q 2. Use the remainder of the 3/16" x 1/4" x 24"

balsa stick you used for the rudder and two

additional 3/16" x 1/4" x 24" balsa sticks to build

the stab framework. Cut the pieces to the correct

length. Pin them in their location over the plan and

glue them together with medium CA.

L-l 9. Separate the elevator from the stab and

remove the hinges from the stab. Mark a vertical

centerline on the both sides of the stab.

14

Page 15

Some modelers prefer to glue the stab to the fin

after they cover them with MonoKote® film. If this

is your preference, perform the following steps but

use T-pins to temporarily hold the stab to the fin

instead of permanently gluing it in position.

Continue building, skipping the rest of the steps

that can't be done without the stab joined to the

fin. Cover the fin, fuse and stab with MonoKote

film after the parts have been final sanded. Leave

the balsa exposed on the center of the bottom of

the stab where it will contact the fin and the

triangle stab reinforcements. Return to this part of

the manual and glue the stab to the fin. Perform

the steps that you skipped.

Q 1. Drill two 3/32" vertical holes through the

centerline on the stab at the locations shown on

the plan.

U 2. Use a straightedge to draw a centerline on top

of the fin. Place the stab on top of the fin as shown

on the plan. Align the centerlines on the stab with

the leading and trailing edges of the fin and align

the holes in the stab with the centerline on the fin.

Q 4. Remove the stab. Drill 3/32" holes in the top

of the fin (or use your sharpened 3/32" brass tube

to make the holes). Cut two 1" pieces from the

3/32" dowel. Test fit the stab to the fin with the

dowels. Remove the stab and the dowels.

Q 5. Temporarily reattach the elevator to the stab

with the hinges.

LJ 6. Spread a film of 30-minute epoxy on top of

the fin and the bottom of the stab and pack the holes

in the fin with epoxy. Glue the stab to the fin with the

dowels using a 90 degree triangle to make sure the

stab is perpendicular to the fin. Hold the stab in

position with small T-pins and wipe away excess

epoxy with a tissue. Do not disturb the model until

the epoxy has fully cured.

LJ 7. Trim the dowels so they are nearly flush with

the top of the stab. Sand them flush with your bar

sander and 220-grit sandpaper.

U 3. Use the holes in the stab as a "template" to

mark the location of the holes on top of the fin with a

3/32" brass tube sharpened at one end, a ballpoint

pen or a pencil or the 3/32" dowel sharpened to a

point at one end.

Q 8. From the 1/4" x 12" triangle stick, cut two

3-1/4" pieces to reinforce the glue joint between

the fin and the stab. Bevel the ends of the stab

reinforcements for a finished appearance.

Note: The plan shows a 1/4" x 3/16" stick in this

area, but 1 /4" triangle stock is just as strong and

provides a more finished appearance.

15

Page 16

LJ 9. If you are going cover the model before you

glue the stab to the fin, set the triangle fin

reinforcements aside until you are ready to glue

them in place after you cover the fin and stab.

Otherwise, glue the stab reinforcements to the stab

and fin at this time.

A nice-looking fuselage, isn't it? That T-tail is

interesting and pleasing to look at. Clean up your

workbench, vacuum the floor and get out the

wing

plan.

LJ 1. Carefully remove the 1/16" die-cut balsa

wing ribs from their die sheets. If a rib will not easily

come out of the die sheet, do not force

it. Use a #1 1 blade to cut the wood where

necessary. Sand slivers or die-cutting bumps from

the ribs.

LI

4. Use

a 90-degree square to draw a vertical line

on the ribs of the right side panel at the mark you

made. Starting at the innermost rib #2, make a mark

along the vertical line 1 /8" below the top of the rib.

On the next, make a mark 1 /4" below the top of the

rib. Continue marking along the vertical line on the

rest of the ribs in increments of 1/8" until you reach

the sixth and outermost rib, where the mark should

be approximately 3/8" from the bottom of the rib.

U 5. Mark the ribs of the left side of the panel the

same

way.

U 2. Arrange the plan so the center section is over

your building board. Tape it down.

U 3. Gather all the #2 ribs (there are fourteen of

them). One at a time, position a #2 rib over its

location on the plan and use a ballpoint pen to mark

the rib where the aileron pushrod guide tube crosses

it on the plan.

Q 6. Use a 5/32" brass tube sharpened at one end

or a 5/32" drill to cut (or drill) the holes in the ribs

at the marks you made. The sharpened brass tube

cuts the holes more cleanly. Make a 5/32" hole in

the remaining two #2 ribs in the same location as

the hole in the outermost #2 ribs. These are the root

ribs of the outer wing panels.

Q 7. Cover the center section of the wing plan with

wax paper (you'll be gluing soon!).

16

Page 17

1/8" X 3/8" BASSWOOD SPAR

Q 8. Pin a 1/8" x 3/8" x 30" basswood

spar over its location on the plan. Do not attempt to

insert the T-pins through the spar (basswood can be

pretty hard stuff). Insert them over the spar in a

criss-cross fashion as shown.

bottom

RIB

NO.

1

1/16"

BOTTOM SHEETING

1/4" STRIP CUT FROM

1/16" LEFTOVER BALSA

1/16" VERTICAL GRAIN

SHEAR WEB

AFT

BOTTOM TE

Q 9. Pin one of the 1/16" x 1-3/8" x 30" balsa

trailing edge sheets over its location on the plan.

Q

10. Mark the bottom main spar and the bottom

TE where the three #1 ribs contact them.

Q 11. Make the aft bottom center section sheeting

from the 1/16" x 3" x 24" balsa sheet. Glue it to the

bottom spar and bottom TE sheeting.

Q 12. Cut 1/4" strips from leftover 1/16" balsa

sheet to fit under the outer #1 ribs ahead of the

bottom spar. Place the strips over their location on

the plan but do not glue them to the ribs. These are

just shims to temporarily align the ribs while you

build the wing.

Q 14. Use the same 1/16" x 3" balsa sheet you

used for the aft bottom center section sheeting to

make a vertical grain shear web to fit between the

#1 ribs. The web should be centered on the spar and

extend from the bottom spar to the bottom of the

notches in the ribs.

Q 15. Cut the remaining #1 rib in the middle

the top and bottom spar notches. Discard the

front piece.

Q

16.

Test

fit the aft

section sheeting at the marks you made that indicate

its location. If necessary, trim the front of the rib so it

joins the center web and its notches align with the

other #1 ribs (you will probably have to trim about

1 /32" off the front of the rib).

piece

of

rib

#1

on the center

of

U 13. Glue the outer #1 ribs (with the holes you

made) on top of the 1/16" aft bottom center section

wing sheeting with medium CA. Use a small 90

degree triangle to hold the ribs vertical as you apply

the glue.

17. Glue the center rib #1 in position

medium CA.

17

with

Page 18

LJ 18. Glue all the #2 ribs to the spar and TE with

medium CA. Use a small 90 degree triangle to keep

the ribs vertical as you apply the glue.

Q 19. Read the Tip that follows. Glue the 5/16" x

30" hardwood leading edge dowel to the ribs with

medium CA.

U 22. One at a time, remove the T-pins from the

bottom TE sheeting. Replace them in the rear of the

ribs to hold the aft end of the wing panel to your

building

glue the top TE sheeting in position without

interfering with the T-pins.

Q 23. Test fit and final shape the 1 /4" x 6" tapered

balsa trailing edge stock so it is the same height and

has the same taper angle as the "notched section" of

the #2 ribs and there will be enough room to inset

the 1/8" x 3/16" x 4" basswood stick so it will be

even with the TE.

board.

This

will

allow

you

to

Tip: Spray the

dowel

with CA Accelerator before

you position it on the fronts of the ribs. This

way the CA will be sure to cure immediately,

reducing the time you have to hold the dowel

in position.

Q 20. Test fit the 1/8" x 1/8" x 30" basswood

turbulator spars in the notches of the ribs. Glue

them in place with medium or thin CA.

Q 21. Glue a die-cut 1/16" gusset to the bottom

sheeting and outer rib #2 at both ends of the wing

panel.

Q 24. Use medium CA to glue the trailing edge

stock to the end of the #1 ribs and the bottom TE

sheeting. Cut a notch in the bottom TE sheeting for

the 1/8" x 3/16"x 4" basswood stick. Glue it

position as shown in the photo.

Note: The 1/8" side of the stick should contact the

plan while the 3/16" sides should be vertical.

U 25. Use the 1/16" x 3" balsa sheet to make six

vertical grain shear webs to fit between the #2 ribs of

the left side of the panel. Glue all the shear webs -

except the shear web between the outer set of #2

18

in

Page 19

ribs - to the bottom spar and ribs with medium CA.

Set the outermost shear web for the last set of #2 ribs

aside for now. Remove the crossed T-pins that are in

the way, but reinstall them through the shear web after

you glue it in place.

Q 26. Cut and glue five shear webs in the right side

of the center wing panel the same way.

Q 27. Position the 1/16" x 1-3/8" x 30" balsa

upper TE sheet on the ribs. Mark the location of the

1/8" x 3/16" basswood stick and cut a notch in the

TE sheet. Glue the TE sheet in position with medium

or thick CA.

Q 28. Test fit the 1 /8" x 3/8" x 3" basswood top

spar in the notches of the ribs. If necessary, adjust

the notches and the tops of the shear webs so the

spar is fully seated into the ribs. Glue the spar in

place with medium or thick CA.

Q 29. Use the remainder of the 1/16" x 3" balsa

sheet to cover the top center section of the wing

between the top spar and the top TE.

LJ 31. Sand the ends of the spars and TE's and LE

so they are flush with the end ribs.

BUILD THE AILERON SERVO

COMPARTMENT HATCH

Q

1.

From

the

1/16" x 3-7/8" x 5-7/8"

sheet, cut and glue a 1 /2" wide strip to fit between

the #1 ribs against the LE. The grain should run

lengthwise.

plywood

Q 30. Remove the T-pins. Lift the panel from your

building board and peel the wax paper off the wing.

The 1/16" shims you placed under the front of the

#1 ribs should fall off.

Q 2. Cut a 1/4" x 1/4" hatch tongue from the

same 1/16" plywood sheet. Glue it to the top of the

bottom spar as shown in the Bottom View Of Servo

Tray

sketch

on the

plan.

Q 3. Cut the hatch from the 1/16" plywood sheet.

There should be approximately a 1/8" gap between

the sides of the hatch and the #1 ribs. You can see

the hatch in the following photo.

19

Page 20

t-1 4. Cut two more 1 /4" x 1 /4" tabs and one 1 /4

x 2" strip to secure the hatch. Glue the 2" strip to the

top (inside) of the hatch. Glue the 1/4" tabs to the

2"

strip.

U 5. Test fit the hatch over the aileron servo

compartment. The tabs on the hatch fit on top of the

bottom spar and the tab on the spar supports the

back of the hatch.

Q 8. Cut the 2" basswood grooved slider block into

two 13/16" long pieces.

Q 9. Make the servo tray from the remaining

1/16" plywood sheet. For now, cut only the outside

edges. Do not cut to fit your servo until the next step.

Start by making the tray slightly too long and slightly

too wide so you can little by little "fine tune" it for the

best fit by sanding the edges. Test fit the servo tray

between the #1 ribs with the slider blocks but do not

glue any of the parts at this time. With the blocks on

either side of the servo tray, the assembly should fit

tightly between the ribs.

Q 6. Hold the hatch in position and drill a 1/16"

hole through the hatch and the 1/16" x 1/2"

plywood hatch retainer (named "cleat" on the plan).

Remove the hatch and enlarge the hole in the hatch

only with a 3/32" drill bit. Temporarily secure the

hatch to the wing with a #2 x 3/8" screw (not

included).

Q 7. Glue two strips cut from 1/16" balsa to the

bottom of both #1 ribs. The strips should align

with the sides of the hatch with an approximately

1/32"gap.

U 10. Remove the servo tray and cut out the middle

to fit your servo. Make sure that the slider blocks will

not interfere with the mount portion of your servo

and the rubber grommets. Mount your servo to the

tray and reposition the assembly in the wing without

using any glue. The exact position of the servo will

be determined when you connect the servo the

aileron control cables.

There, the center section is ready to join to the outer

panels. Oops, we'd better build the outer panels then!

20

Page 21

Build the right wing panel first so your progress

matches the photos.

0 1. Arrange the wing plan so the right wing panel

is over your building board.

U LJ 2. Mark ribs #3, 4, 5 and 6 where the aileron

pushrod

guide

tube

crosses

them. Cut

or

drill

a

5/32" hole 3/8" above the mark on the ribs.

Q Q 3. Cover the plan with wax paper. Pin a

1 /8" x 3/8" x 24" balsa bottom outer spar over its

location on the plan. Since the spar is balsa, you can

stick T-pins through it.

Q Q 4. Cut the wing tip dihedral gauge template

(located on the back cover) along the outer dotted

line. Use rubber cement or spray adhesive to glue

the template to a piece of balsa, thin cardboard (the

kind from cereal boxes) or plywood. Accurately cut

the gauge to the solid outline of the template. You

can see the gauge in the photo at the next step.

TRIM 1/16" FROM THE TOP OF RIBS

6 AND 7 BEHIND THE SPAR

1/16"

REMOVE

Q Q 6. Use a #11 blade to trim 1/16" off the top

of ribs #6 & #7 behind the spar.

LJ LJ 5. Use the wing tip dihedral gauge to

accurately bevel the end of a 3/16" x 5/8" x 24"

balsa aft spar. Pin the spar to your building board

over its location on the plan so the root end aligns

with the plan.

Note: For the best fit between the aft spar and root

rib #2, bevel the spar as seen from the top view to

account for the forward sweep of the trailing edge.

LJ U 7. Test fit and use medium CA to glue ribs #3

through #10 to the bottom spar and the aft spar. Use

a small 90 degree triangle to hold the ribs

perpendicular as you glue them.

LJ U 8. Position root rib #2 over its location on the

plan. Use the dihedral gauge to hold it at the correct

angle and glue it to the bottom spar and the aft spar

with medium CA.

21

Page 22

Q Q 9. Glue the 5/16" x 24" hardwood dowel

leading edge to the ribs. Use the dihedral gauge to

make sure rib #2 it is at the correct angle when you

glue the dowel to it.

Q Q 10. Glue the 1/8" x 1/8" x 24" outer

turbulator spars in the notches of the ribs. Use the

dihedral gauge to make sure rib #2 it is at the

correct angle when you glue the spars to it.

Q Q 11. Make six shear webs from the 1 /16" x 3"

x 24" balsa sheet to fit between the sets of ribs from

#2 out to #7. Cut or drill a 5/32" hole 7/16" from

the bottom of the web where the aileron cable guide

tube passes through.

LJ LJ 15. Use your bar sander to angle the end of

the 5/8" x 1 -3/4" x 24" balsa trailing edge stock

so it fits against rib #2 when placed against the aft

spar. When you have achieved the correct angle on

the end of the trailing edge stock, cut it where shown

on the plan. Glue it to the aft spar and #2 rib. The

approximately 18" of remaining trailing edge stock

will be the aileron.

Q Q

12. Do not glue the shear web between ribs

#2 and

between the ribs with medium CA.

Q Q 13. Test fit the 1/8" x 3/8" x 24" balsa top

outer spar in the notches of the ribs. If necessary

adjust the notches and the tops of the shear webs so

the spar is fully seated into the ribs. Glue the spar in

place with medium or thick CA. Use the dihedral

gauge to hold rib #2 at the correct angle when you

are gluing it to the spar.

Q Q 14. Use medium CA to glue three 1/16"

die-cut balsa gussets to the ribs and aft spar where

shown on the plan.

#3, but glue the rest of the shear webs

O Q 16. From the 1/16" x 3" balsa sheet you used

for the shear webs, cut and test fit the sheeting for

the aileron pushrod guide tube exit that fits on top of

ribs #6 and #7. It is okay if the sheeting extends past

the ribs by approximately 3/32" or so. Glue the

sheet in position.

U U 17. Remove the T-pins from the wing panel.

Lift it off your building board and peel the wax

paper off the panel. Look for glue joints that don't

look strong and reinforce them with medium CA.

Pay special attention to the glue joints between the

shear webs and the spars.

22

Page 23

Q Q 1. Use a razor saw to trim the spars and

leading edge dowel so the ends are nearly flush

with rib #2 at the root of the panel and rib #10 at

the tip of the panel. Sand the ends of the spars and

leading edge dowel flush with the root and tip ribs.

Q Q 2. Sand the end of the 5/8" x 1-3/4" x

approximately 18" balsa aileron so it accurately

matches the end of the trailing edge stock you glued

to the wing.

U LJ 3. Place a piece of leftover 1/16" balsa

between the end of the aileron and the trailing edge

stock to act as a spacer. Cut and sand the tip end of

the aileron so it is flush with tip rib #10.

U U 5. Use a hobby carving knife or a razor plane

to roughly carve the tip to the approximate shape.

Final shape the tip with progressively finer grits of

sandpaper to blend it to the wing and the shape

shown on the plan. When you get to the final stages

of shaping the tip, place the aileron on the wing

help guide you in shaping the aft end of the wing tip.

USE THE DIMENSIONS SHOWN BELOW

TO BEVEL THE AILERON

1/8"

9/32"

U U 6. Mark the locations of the hinge slots on the

aileron and the aft trailing edge of the wing. Cut the

hinge slots. Make sure the height of the hinge slots on

the aft TE and the aileron are the same so the aileron

will be centered when you join it to the wing with the

hinges. Bevel the leading edge of the aileron as

shown

in

the

sketch.

Test

fit

the

aileron to

the

wing

with the hinges.

Hey, you've

completed the first wing panel already!

to

Q Q 4. Cut the 7/8" x 1 -3/8" x 12" tapered wing

tip stock into two 6" pieces. Use medium CA to glue

one of the tips to the panel joining them together while

they are both laying flat (so the tip curves down) on

your building table covered with wax paper.

Q 7. Arrange the plan so the left wing panel is over

your building board. Return to step 2 at Build The

Outer Wing Panels on page 21 and build the left

wing panel. Don't forget to switch to the left wing

panel so you don't build two rights!

23

Page 24

U 1. Sand all three wing panels with fine-grit

sandpaper to remove glue bumps. Blend all the ribs

to the spars, LE and TE. Smooth all surfaces.

U 2. Use a small 90 degree triangle or square to

draw a 1/8" wide slot centered between the spars

on the #2 ribs on both outer wing panels.

U

6.

Test

join the

wing

panels

with

the

dihedral

braces and adjust the slots in the ribs or the length of

the braces so the spars and LE's align and the wing

panels fit together without gaps.

First join the right outer panel to the center panel so

your progress matches the photos.

U 3. Use a sharp #1 1 blade to cut the #2 ribs

along the lines and remove the balsa for the

dihedral brace.

U 4. Mark and cut the slots on the #2 ribs at both

ends of the center wing panel the same way.

Q 5. Remove the die-cut 1/8" plywood dihedral

braces from their die sheets and remove slivers or

die-cutting irregularities with your bar sander.

Position the dihedral braces over the drawing on the

plan and mark the "root" and "tip" ends of the

dihedral braces as shown.

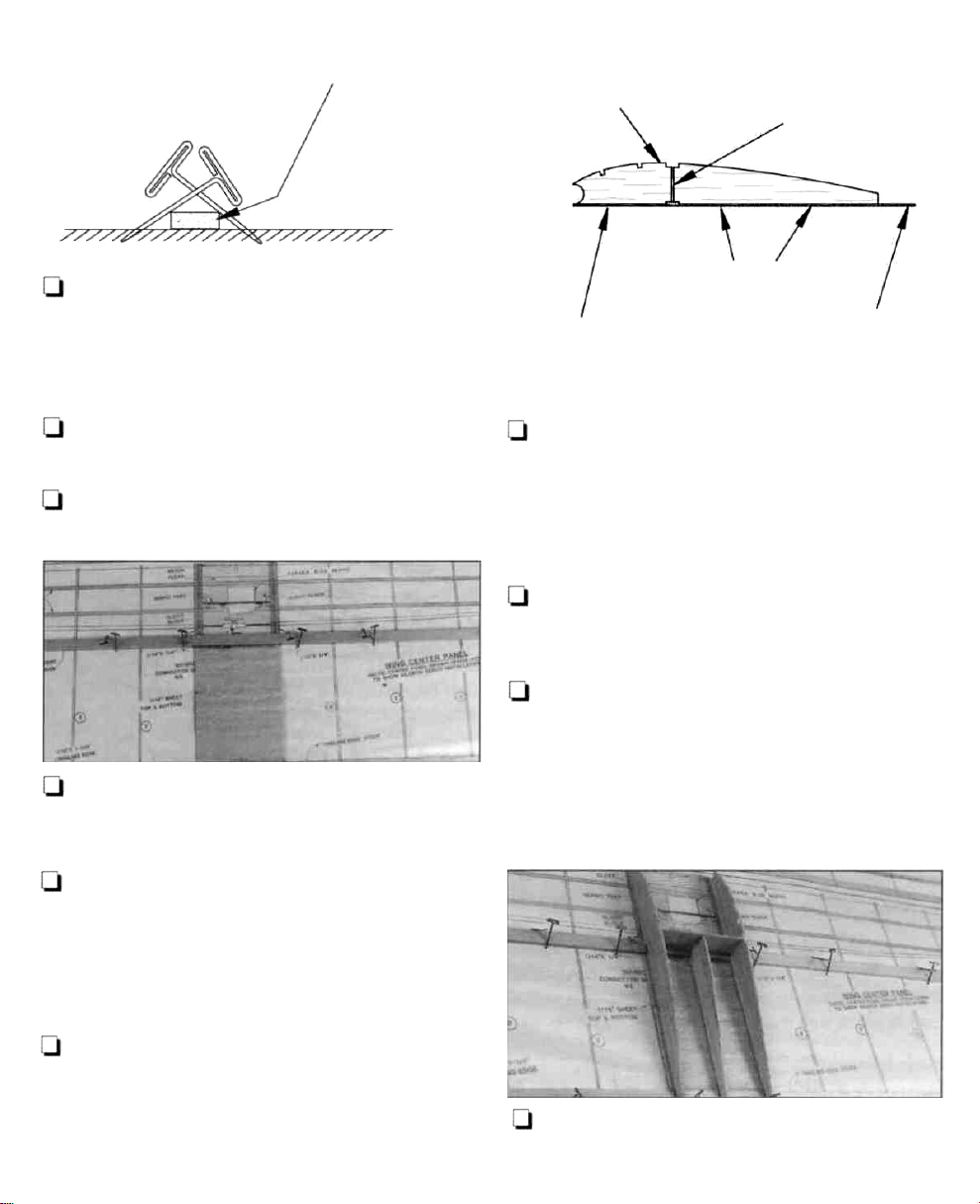

Refer to this photo for joining the wing panels.

U U 1. With the outer panel temporarily joined to

the inner panel, raise the outer panel with a balsa

stick, a stack of balsa sheets or something similar, so

the tip at the last rib is 3/4" above your building

table. Temporarily clamp the panels together with Cclamps, spring clips or clothespins so you will know

where to put them when you are actually gluing.

Note: If your aileron servo is mounted in the wing at

this time, make sure the cord and connector are not

sticking out of the bottom. The center section must

rest flat on your table while you join the outer panel.

24

Page 25

U LJ 2. Remove the clamps and separate the panels.

Lay a piece of wax paper on your building table. Mix

a batch of 30-minute epoxy. Coat the joining surfaces

with 30-minute epoxy. Join the inner wing panels with

the dihedral brace. Refrain from using excess epoxy

so the shear webs will fit later. Place the wing on your

building table. Immediately proceed to the next step.

o o 3. Place a weight on the center section to hold it

down. Prop up the outer panel so the tip is 3/4"

above your table. Clamp the wing halves together

the same as you did in the first step.

Q Q 4. Wipe

not disturb the wing until the

Q 5. Return to step 1 and join the left panel to the

center section the same way.

away

excess

epoxy before

epoxy

is fully cured.

it

cures.

Do

U 3. Make sure the holes in the joining #2 ribs of

both wing panels align so you can route the outer

aileron cable guide tube. If the holes do not align,

open them up with a hobby knife.

Note: These instructions are written for connecting

the ailerons with Great Planes* Flexible Cable

Pushrods, though Sullivan

Gold-N-Push Rods are shown on the plan. If you

decide to use the Sullivan Gold-N-Rods, the

instructions are the same for installing the guide

tubes, but connect the clevises and ball links as

shown on the plan.

U LJ 1. Roughen the outside of a Great Planes 36"

Flexible Cable Pushrod guide tube (not included,

GPMQ3702) with coarse sandpaper so the glue will

stick. Route the guide tube through the holes in the

ribs of the right wing panel.

U U 2. Use a #11 blade to cut an approximately

1/2" diameter circular notch in rib #1 where the

guide

tube

passes.

connector to clear the rib without interfering. See the

photo at step 5.

This

will

allow

the

solder

U 1. Use epoxy to glue the four shear webs you cut

earlier to the plywood dihedral braces and spars on

both sides of the joining wing panels. It does not

matter whether you glue the shear webs to the front

or back of the shear webs, but do it the same way

on all four webs for symmetry.

Q 2. Sand-off glue bumps and blend the spars and

LE's and TE's of the joining wing panels.

1-11- 3. Cut a 1/2"

between ribs #6 and #7 where the guide tube

pass through. Be careful not to make the slot too far

aft or the clevis will interfere with the guide tube and

limit aileron throw. The aft end of the slot should be

approximately 1-1/4" from the aft edge of the aft

spar. Route the guide tube through the slot and

the tube so it protrudes from the sheeting (on top

the wing) about 3/8".

long

slot

in

the

sheeting

25

will

cut

of

Page 26

Q Q 4. Glue a 1/16" balsa strip to the inside of

the sheeting on both sides of the slot to keep the

sheeting from splitting.

Q Q 5. Cut the "servo end" of the tube about 3/4"

from rib#1.

Q Q 6. Glue the guide tube in the slot with

microballoons and epoxy. Glue the tube to the ribs

with medium CA.

Q Q 7. After the microballoons and epoxy filler

has fully cured, use your bar sander and 220-grit

sandpaper to sand the guide tube and the filler flush

with the sheeting. See the photo at step 13.

Q Q 10. Cut the threads off a Great Planes 2-56

(1/16") Threaded Coupler (included with the Great

Planes Flexible Cable Pushrod set) so that 5/16" to

3/8" of the threaded portion remains. Silver solder

the threaded coupler to one end of the aileron cable.

Thread the coupler all the way into the dual end ball

link (included with this kit).

Q Q 11. Route the cable through the guide tube.

Align the ball link socket with the ball link on the

servo but do not snap it on.

Q Q 12. Connect a small control horn (included

with this kit) to a Great Planes 2-56 Solder Clevis

(not included, GPMQ3810). Place the control horn

on the aileron as shown on the plan next to the cable

protruding from the wing.

Note: The control horn should be 1/8" aft of the

aileron pivot point (as shown on the plan) for aileron

differential.

LJ U 8. Remove the aileron servo. Temporarily

install a Great Planes 1/16" Ball Link (not included,

GPMQ3842) onto the servo arm or wheel of your

servo. Reinstall the servo - the sliders should not yet

be glued in place so you can determine the location

of the servo after the exact location of the cable and

ball link socket have been set.

Q Q 9. Reinstall the aileron servo with the ball link

on the servo arm.

Q Q 1 3. With the aileron neutral, mark the cable

where to cut it so you leave enough extra to securely

solder it into the clevis. Remove the clevis from the

control horn. Cut the cable at the mark you made.

26

Page 27

Q Q 14. Silver solder the clevis to the cable. If you

find it difficult to cut the cable with wire cutters, use a

MultiPro with a cut-off wheel or tin the cable in the

area where it is to be cut with wire cutters.

LJ U 15. Place the control horn on the aileron. Drill

1/16" holes in the aileron for the horn mounting

screws. Remove the aileron and use a pin to poke

holes in the aileron where the control horn will be

mounted. Saturate the area and the holes for the

horn mounting screws with thin CA. Sand the area

smooth.

Q 1. Connect the aileron servo to your receiver and

turn on your radio. Center the aileron servo with

your transmitter and make sure both ailerons are

neutral. You can still do this without snapping the

ball

socket

onto

the

ball

by

just

fitting

the

ball

socket

over the ball, but not snapping it on. It is easiest to

center the aileron servo and ailerons now while the

ball linkage is easily accessible rather than at the

flying field when you will have disconnect the ball

link and remove the servo to make an adjustment.

LJ 2. Connect the ball link to the servo arm or wheel

on your aileron servo with the small nut included with

the ball link. Use thread locking compound or epoxy to

make sure the nut is secure.

U Q 16. Mount the control horn to the aileron with

two #2 x 1/2" screws. Fit the aileron to the wing

with the hinges and connect the clevis to the control

horn.

Q Q 17. Place the ball socket over the ball link but

do not snap it on. Adjust the ball socket on the

threaded coupler so the aileron is neutral.

U 18. Return to step 1 and connect the other aileron

the same way. Do not snap the ball socket onto the

ball link until instructed to do so.

U 3. Mix a batch of 30-minute epoxy and glue the

sliders to the #1 ribs. Adjust the sliders so you can

connect the ball socket to the ball on the servo without

bending the aileron cable out of its way. Snap the ball

socket onto the ball. Do not disturb the assembly until

the epoxy is fully cured.

U 4. If you have to make any adjustments to the

aileron servo or connection, make them now before

you sheet the rest of the center section. You can

easily remove the servo from the compartment after

you sheet the center section by sliding the servo tray

out, but it is easier to access the ball and socket now.

Q 5. Use the remainder of the 1/16" sheeting to

sheet the top center section of the wing forward

the main spar.

27

of

Page 28

Back to

time for covering!

Q 1. Cut two 1 /4" x 4" strips from leftover 1 /8"

plywood. Glue them together with medium CA to

make the servo

U 2. From the strips you glued together, cut two

servo rails that will fit between the fuselage sides in

the servo compartment.

0 3. Position your servo(s) on the rails in the fuselage

as shown on the plan. Raise or lower the rails so the

servo arms (or wheels) will align with the pushrods but

make sure the servos will not interfere with the

forward wing dowel. There is enough room for

standard size servos but most advanced fliers will use

mini or micro servos for the least amount of weight.

the fuselage for a little while. It will soon be

rails.

1— 7. Use silver solder to solder a Great Planes

Standard Solder Clevis (not included with this kit,

GPMQ3810) onto the elevator cable (included with

the Great Planes Flexible Cable Pushrod set

previously recommended). Connect the clevis to the

second or third hole of a small nylon control horn

included with this kit.

Q 8. Route the cable through the guide tube and

position the control horn on the elevator as shown

on the plan.

U 9. Use the control horns as a template to drill two

1/16" holes to mount the control horns to the rudder

and elevator with 2-56 x 1 /2" screws in the location

shown on the plan. Connect the rudder pushrod and

elevator cable to the control horns.

LJ 4. Make sure there is enough space between the

rails so you can remove the servos. Glue the rails to

the fuselage sides with medium or thin CA.

Q 5. Mount the servos to the rails with the

screws, grommets and brass inserts included with

your radio system.

Q 6. Cut the elevator and rudder (if you have a

moveable rudder) guide tubes so they extend

approximately 1 /4" forward of bulkhead C.

Q 10. At the servo end, cut the elevator cable and the

rudder pushrod to the correct length. Connect them to

the servos with your favorite type of connector. On our

prototype we used Great Planes Screw-Lock" Pushrod

Connectors (not included, GPMQ3870).

28

Page 29

U 11. Glue the outer pushrod guide tubes to the

bulkheads with thick or medium CA.

Q 12. Wrap your receiver and battery pack in

foam rubber. Mount them in the fuselage where

shown on the plan. Mount the on/off switch in a

location that will not interfere with the pushrods or

the radio system.

We recommend you cover your Bobcat with Top Flite

MonoKote iron-on model covering film. If this is one

of the first times you have covered a model, refrain

from attempting a complicated trim scheme. Add

stripes, graphics and various designs to your Bobcat

cut from different colors of MonoKote film. Iron them

directly over the base color. Try only a single color

base (usually a lighter color such as white or yellow)

with perhaps a single stripe, your AMA number or

even some stick-on graphics. A simple trim scheme

will get you in the air faster and look much better

than an ambitious a trim scheme that makes your

model too difficult to cover.

Q 1. Inspect the wing, fuselage and tail surfaces for

glue joints that don't look strong. Reinforce them with

thin or medium CA. Make sure the fuselage bottom

is securely glued to the fuselage sides in the area of

the tow hook anchor.

Q 2. Temporarily fit the 3/16"

through

the fuselage. If necessary, adjust the shape of the

fuselage sides and the aft plywood fuselage

where they fit over the

U 3. Remove pushrods, wing dowels, control horns

and any other hardware that may interfere with

covering.

Q 4. Fill dents, scratches and glue joints on the

surface of the model that may show through the

covering with HobbyLite filler. Sand the fuselage so it

is smooth and even.

the

holes

in

the

fuselage.

wing.

wing dowels

Test

fit the

wing

on

top

Here is a "rule of thumb" to keep in mind before you

begin: Where possible, apply the covering so all

seams face downward or rearward. You can do

this by covering the bottom (of the wing, fuse, stab,

etc.) first.

Never cut the covering after you iron it to the

wood except near the tips. Modelers who do

this may weaken the structure which could

cause it to fail during flight.

Tail Surfaces:

1. Stabilizer bottom right and left half

2. Stabilizer top

3. Fin right, then left side

4. Rudder

5. Elevator

29

Page 30

Fuselage:

1. Bottom*

2. One side, then the other

3. Top forward, then aft of the hatch

4. Top aft

of wing

5. Hatch

* Many modelers cover the forward bottom section of

the fuselage with two layers of covering or glass cloth

and paint the forward bottom section for better

protection during landings.

Wings:

1. Center panel bottom, then top

2. Outer panel bottoms, then tops

3. Ailerons

4. Hatch

If you decided to cover your Bobcat before you

glue the stab to the fin, return to page 15 and

follow the instructions to glue the stab.

U 2. Lay the center section of the wing on your

building table. Place weights on top of it to hold it

down. Twist the trailing edge upward while you heat

the covering until the wrinkles disappear. Let the

covering cool. Measure the distance between the

trailing edge of the wing at the tip and your building

table. It should be 1/4". You may also have to heat

the bottom of the outer wing panel.

U 3. Add washout to the left outer panel the same

way. Make sure the center section of the wing is flat

and warp free as described in step 1.

Q 1. Due to the lightweight structure of the Bobcat

and the shrinkage of the covering, the wing and stab

can warp or twist. Correct the twists by carefully

twisting the part in the opposite direction. Heat the

covering with your iron or heat gun until the part is

flat and free of warps.

Add "washout" to the wing tips. Washout is where

the trailing edge of the wing at the tip is twisted

upward. This gives the wing tip a lower angle of

attack than the rest of the wing, which will reduce

the tendency for the wing to "tip stall."

Use the instructions below to hinge the ailerons,

elevator and rudder (if you have built a steerable

rudder). Hinge the elevator first because it's

the easiest.

CUT THE COVERING

AWAY

FROM THE SLOT

U 1. Use your hobby knife and a sharp #11 blade to

remove a small strip of covering from the hinge slots.

30

Page 31

TEMPORARY PIN

TO KEEP HINGE

CENTERED

CUT

CUT

RUBBER

BAND

T-PIN

LJ 2. Join the elevator to the stab with the hinges. If

the hinges will not stay centered, stick a pin through

the center of the hinge. Remove the pins after the

hinges are glued in place.

Q 3. There should be a small gap between the

control surfaces (just enough to see light). A small

gap is desirable so you do not inadvertently glue the

parts together.

Q 4. Carefully apply 4 drops of thin CA to both

sides of the hinges. Keep a cloth handy to wipe

away excess CA. If you spill a few drops of CA

on the covering, you can use CA Debonder

(GPMR6039) to remove it or carefully peel it off with

a hobby knife after it fully cures.

Do not use accelerator on any of the hinges. Do not

glue the hinges with anything other than thin CA

and do not attempt to glue one half of the hinge at

a time with medium or thick CA. They will not be

secure and the controls could separate while the

model is flying.

STRAIN RELIEF

INSIDE FUSELAGE

ANTENNA HOLDER

AT

THE

TOP

OF

VERTICAL STABILIZER

THE

Q 2. Route the receiver antenna through the guide

tube (if you installed one) or make a strain relief and

an antenna hook from a cut-off servo arm as shown

in the sketch.

U 3. Cut a hole in the covering over the wing dowel

holes in the fuselage. Install the dowels and glue

them in position with medium CA.

Q 4. Apply 1/16" thick Great Planes Single-Sided

Foam Tape (GPMQ4422) to the wing saddle of

the fuselage.

Q 5. Drill a #36 (or 7/64") hole through the

fuselage bottom and the tow hook anchor. From the

top, enlarge the hole

anchor only with an

1/4"

deep in the tow hook

11/64"

(or

5/32")

drill

to

accept the 6-32 blind nut for the tow hook.

TOW HOOK ANCHOR

6-32 BLIND NUT

Q 5. Let the CA fully cure. Carefully Rex the elevator

several times to check the movement.

Q 6. Hinge the rest of the controls the same way.

Q 1. Reinstall the pushrods and connect

the servo control horns the same way you did

during construction.

FLAT WASHER

6-32

NUT

NO. 6 TOW HOOK

Q 6. Install the tow hook as shown in the sketch and

secure the blind nut and the hex nut with thread lock.

31

Page 32

This section is important and must NOT be omitted.

A model that is not properly balanced will be

unstable and possibly unflyable.

Q

1.

Accurately mark the balance point on the

bottom of the wing near both sides of the fuselage

with tape or a felt-tip pen. The balance point is

shown on the plan and is 3" (77mm) aft of the

leading edge.

LJ 2. Place the wing on the fuselage. Hold it in place

with two or four #64 rubber bands. When it is time to

fly your Bobcat, you should secure the wing with at

least eight rubber bands crossing the last two.

3"

U 2. Measure the throws at the widest part of the

trailing edge of the rudder and elevator. After a few

flights you may change the throws to suit your flight

style or the weather conditions.

We recommend the following control surface

throws:

Ailerons: 1 /2" up and 1 /4" down

Elevator: 1 /4" up and down

Rudder: 3/4" right and left

Q 3. After you set the control throws and position

the pushrod connectors in the correct holes in the

servo wheels, securely fasten the pushrod connectors

to the servos with the nylon fastener on the bottom

of

both connectors. Install the screws that hold the servo

wheels to the

servos.

Q 3. Lift the model with your fingers at the balance

point or make a simple stand as shown in the sketch.

Shift the battery pack and/or the receiver to get the

model to balance. Only if necessary, add additional

weight to the nose or tail to achieve the correct C.G.

Great Planes Adhesive Lead Weights (GPMQ4485)

work well for this task.

Q 1. Center the servos before you measure the

control throws. With the transmitter and receiver

turned on, neutralize the elevator, rudder and

ailerons on the model.

Charge Your Batteries

Follow the battery charging instructions in the

manual that came with your radio control system.

You should always charge your batteries the night

before you fly and at other times recommended

the radio manufacturer.

Ground Check Your Model

Inspect all screws and connectors. Make sure you

install the screw that holds the servo arm onto the

servos and that the servo cords are securely

connected to the receiver. Check the security of the

hinges by lightly tugging on the control surfaces.

32

by

Page 33

Range Check Your Radio

Check the operational range of the radio before the

first flight. Before you turn your radio on the first

thing you always must do is make sure no one else

is on you frequency (channel). Most model flying

fields utilize frequency control so familiarize yourself

with their system. Collapse your transmitter antenna

and turn on the transmitter, then the receiver

(preferably the receiver should never be on by itself).

You should be able to walk at least 100 feet away

from the model and still have control. Have an

assistant stand by your model and tell you what the

control surfaces are doing while you operate them

from the transmitter.

If the control surfaces do not always respond

correctly, don't fly! Find and correct the problem

first. Look for loose servo connections or corrosion, a

defective on/off switch, low battery voltage or a

defective cell, a damaged receiver antenna or a

receiver crystal that may have been damaged from

a previous crash.

The Bobcat is intended for intermediate to

experienced fliers, but here are some flying notes for

those nearer the "intermediate" end of the scale.

If you are at a club site or another area where

there are other fliers present, make sure you

are not on the same frequency. Learn the

frequency control system if one is used.

If you are not an experienced pilot, find an expert to

help you with your first flights. Although the Bobcat

is an easy model to fly, an experienced pilot can

save you lots of time and frustration by helping you

get the Bobcat in the air and back to the ground

safely for the first couple of launches.

Make a couple of trim flights before each flying

session (and especially before the maiden voyage) to

make sure your Bobcat is properly trimmed and the

controls work properly. Fly the trim flights over a

clear, grassy field or strip. Turn on the transmitter

first, then the receiver. Hold the Bobcat by the

fuselage under the wing with the wings level, the

nose pointed slightly down and facing into the wind.

It is important that you hand launch the model with

the wings level and the nose pointing at a spot on

the ground about 50 feet ahead. Have a friend

stand to the side and tell whether the nose is

pointing up or down. If you launch your Bobcat with

the nose up or throw it too hard it will climb for a

few feet, stall and fall nose first straight into the

ground. With the nose pointed down slightly the

sailplane will accelerate until it picks up enough

speed to level off and glide. Launch the plane with a

gentle

push

forward.

be able to launch the Bobcat perfectly so it makes a

long, straight flight path. Don't attempt to climb but

maintain altitude or a gentle descent.

With

a little practice

you

will

Once you are

If a club flying site is not available, find a large, ; can execute gentle turns with a light touch of aileron

grassy area at least 6 miles away from houses, (and rudder if you've built it in). Go light on the

buildings, streets and other R/C activity like boats and ailerons - remember the wing will dip slightly when

cars. Avoid flying R/C models near traffic or areas you apply ailerons. Relax the ailerons just before the

such as parks, school yards, office buildings, etc. that model touches the ground. You can also practice

may attract unrestrained observers, "flaring" by slowly applying up elevator as the

confident with hand launching,

you

33

Page 34

Bobcat nears the ground. It will continue to fly just a

few inches off the ground for a surprisingly long

distance. It is important you don't over-control the

model. Make control inputs slowly and smoothly.

If you are an inexperienced pilot, you should

reserve first flight attempts for calm days when the

wind is five to seven mph or less. Inexperienced

pilots can find it difficult to keep a non-powered

model upwind in heavy wind conditions. A calm

evening an hour or so before sunset is a great time

for a relaxing first flight.

Follow the instructions that came with your

Hi-Start and lay it out directly into the wind. Turn on

your transmitter and receiver. Pull the

Hi-Start approximately twice as far back as the

length of the rubber tubing (pull back 200' if you

have 100' of rubber tubing) or whatever the

Hi-Start instructions state. If you have a scale,

approximately 8 pounds of tension is adequate. You

may use more tension after you are acquainted with

the launching procedure.

Hook your Bobcat to the Hi-Start and hold it above

your head with the wings level. Point the nose slightly

upward and directly into the wind. Give a gentle

push forward and it will climb like a kite. You should

not have to touch the elevator while the Bobcat is

climbing, but you will probably have to work the

ailerons a little bit to keep it going straight. As the

rubber relaxes, the model will level off and the ring at

the end of the Hi-Start will release from the tow hook.

Sometimes a little bit of down elevator is required to

release the Hi-Start. The wind will open the parachute

on the end of the Hi-Start and it will lay the line and

rubber cord on the ground directly facing into the

wind for your next flight.

Keep your Bobcat upwind and perform gentle "S" turns

to acquaint yourself with the feel and response of the

ailerons. Adjust the trims on your transmitter a little at a

time until the plane will fly straight and level. If you are

losing altitude rapidly, do not attempt to turn the model.

Let it approach the ground the same way you did when

you were hand launching it, then land. Always land

upwind! If, on the other hand, you have enough altitude

and you are ready, execute your first 360 degree circle

to the right or the left. Try not to let the model get

behind you so it is always upwind. Be ready for the

nose to drop a little and flight speed to increase.

Toward the middle of the turn, apply a little up elevator

to level the nose or maintain a steady descent (again

the same as when hand launching). The nose will level

as the model turns back into the wind. Be aware that at