Page 1

• Easy-to-Build • All Wood Hand-Launched Glider

• 2-Channel Radio Required

(mini servos recommended)

BEFORE STARTING CONSTRUCTION, READ THROUGH THIS INSTRUCTION

MANUAL. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS

CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modification. In no

case shall Dynaflite's liability exceed the original cost of the purchased kit. Further, Dynaflite reserves

the right to change or modify this warranty without notice. In that Dynaflite has no control over the

final assembly or material used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled product. By the act of using

the user-assembled product, the user accepts all resulting liability. If the buyer is not prepared to

accept the liability associated with the use of this product, return this kit immediately in new and

unused condition to the place of purchase.

SKTRP03 Printed in USA Entire Contents © Copyright 1996

WARRANTY

Page 2

PROTECT YOUR MODEL.

YOURSELF & OTHERS BY

FOLLOWING THIS

IMPORTANT SAFETY

PRECAUTION

Your Skeeter is not a toy, but a sophisticated working

model that functions very much like a full-size

airplane. Because of its realistic performance, the

Skeeter, if not assembled and operated correctly,

could possibly cause injury to yourself or spectators

and damage property.

To make your R/C modeling experience totally

enjoyable, we recommend that you get experienced,

knowledgeable help with assembly and during your

first flights. You'll learn faster and avoid risking your

model before you're truly ready to solo. Your local

hobby shop has information about flying clubs in your

area whose membership includes qualified instructors.

2. You must take time to build straight, true and strong/

3. You must properly install all R/C and other

components so that the model operates properly on

the ground and in the air.

4. You must test the operation of the model before the

first and each successive flight to insure that all

equipment is operating correctly. You must also make

certain that the model has remained structurally sound.

NOTE: We, as the kit manufacturer, can provide

you with a quality kit and great instructions, but

ultimately the quality and flyability of your finished

model depends on how you assemble it; therefore,

we cannot in any way guarantee the performance

of your completed model and no representations

are expressed or implied as to the performance or

safety of your completed model.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,300

chartered clubs across the country. Through any one

of them, instructor training programs and insured

newcomer training are available. Contact the AMA

at the address or toll-free phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie,IN 47302

(800) 435-9262

Fax (317) 741-0057

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the drawings or plan. In those instances you

should assume the written instructions are correct.

INTRODUCTION

Congratulations on your purchase of the Dynaflite

Skeeter. The Skeeter is an attractive, easy to build, all

wood polyhedral Hand Launched Glider (HLG). With

its 55-1/2" inch wingspan and Selig 3021 airfoil, the

Skeeter is a real winner. You will have many hours of

fun with this little ship and never have to chase a

Hi-Start. The Skeeter is easy to build and cover with its

liteweight all balsa conventional construction. The

polyhedral wing, along with simple 2-channel (elevator

and rudder) control make for gentle, forgiving flights.

The Skeeter, with its ideal proportions, is perfectly suited

for small flying sites. So go a head... en joy, and don't let

those little flying sites get in the way of your fun!

At Dynaflite we take pride in offering kits that are

simple and straightforward to build and provide value

for your modeling dollar. Although the Skeeter is small

and easy to build, we recommend seeking the help of

an experienced modeler if this is your first kit. Your local

hobby shop or model club are prime sources of

modeling information.

2

Page 3

Please inventory and inspect all parts carefully

before starting to build! If any parts are missing,

broken or defective, or if you have any questions

about building or flying this model, please call us at

(217) 398-8970 and we'll be glad to help. If you are

calling for replacement parts, please look up the

part numbers and have them ready when calling.

REQUIRED ITEMS

#1 Hobby Knife Handle (XACR4305)

#11 Blades (Qty. 100 - HCAR0311) or

(Qty.5-XACR2911)

Hand or Electric Drill

Drill

Bits:

3/16",

and a 10-24

tap

1/2"

and

9/64"

(or #26)

*0n our workbench/ we have four 11" Easy-Touch™

Bar Sanders/ equipped with #50/ #80/ #150 and

#220-grit sandpaper. This setup is all that is required

for almost any sanding task. Custom sanding blocks

can be made from balsa for sanding hard-to-reach

spots. We also keep some #320-grit wet-or-dry

sandpaper handy for finish sanding before covering.

IMPORTANT BUILDING NOTE: During construction!

you

will

be using a number

various assemblies. Ample material is included but

you should study the plans/ then make an effort to cut

the longest pieces you will need first. Label the pieces

as you cut them for later reference. By doing this

now, you won't have to splice pieces together later,

of balsa

sticks

to frame

Medium T-pins (HCAR5150)

Wax Paper

Clothespins

Masking Tape

1 /2 oz. Thin CA Adhesive - (GPMR6001)

1 /2 oz. Medium CA+ (GPMR6007)

4 oz. Aliphatic Resin (Wood Glue) (GPMR6161)

6-Minute Pro™ Epoxy (GPMR6045)

Bar Sander (GPMR6170) or Sanding Block and

Sandpaper (coarse/ medium, fine grit*)

1 roll film covering plus trim colors

Covering Iron

Straightedge (Fourmost Non-Slip/ FORR2149)

BET READY TO BUILD

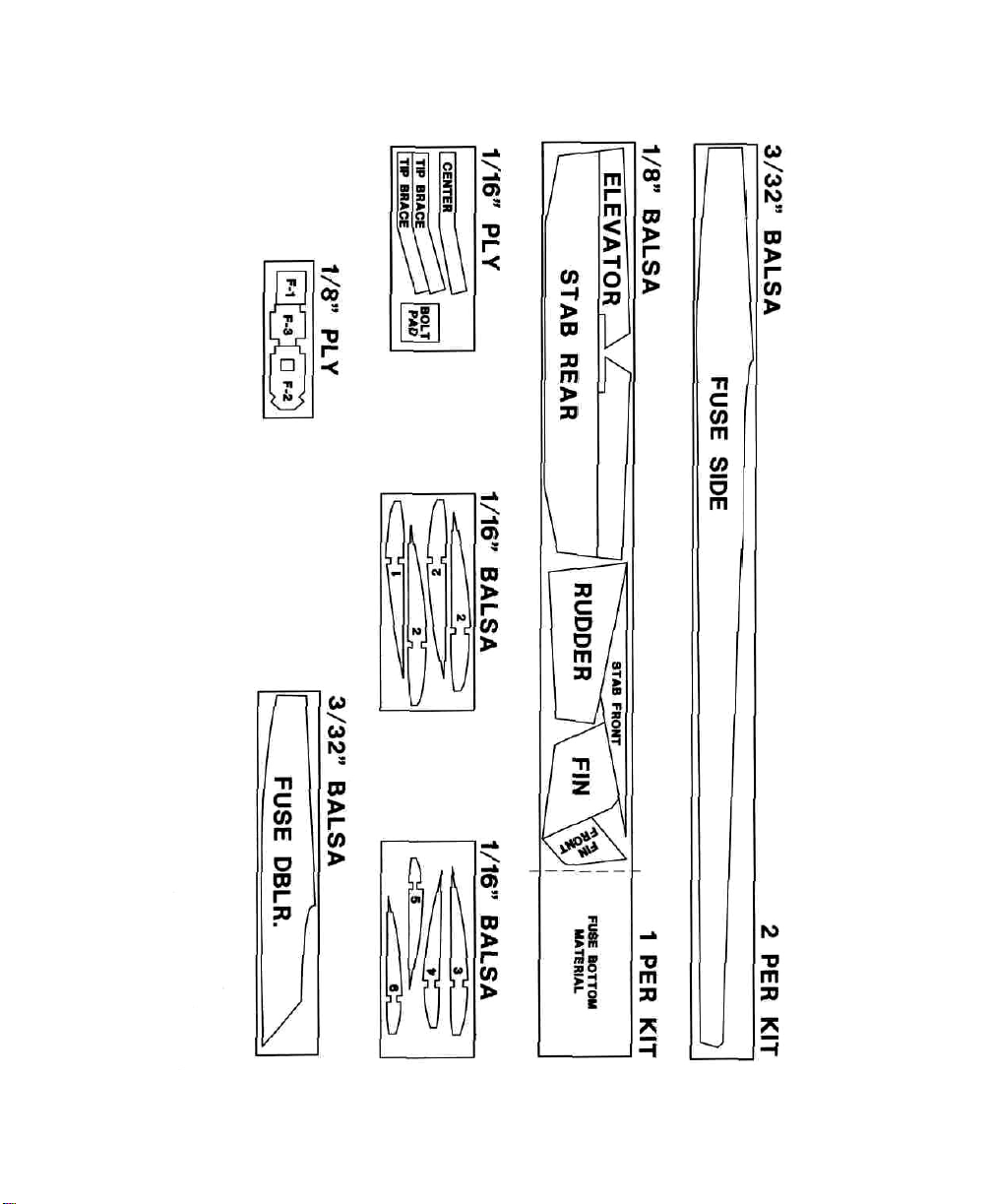

1. Unroll the plan sheet. Reroll the plan inside out

to make it lie flat.

Q 2. Remove all parts from the box. As you do,

determine the name of each part by comparing if

with the plans/ instruction manual and parts list

included with this kit. Using a felt-tip or ballpoint

pen/ lightly write the part name or size on each

piece to avoid confusion later. Use the die-cut

patterns shown on page 4 to identify the die-cut

parts and mark them before removing them from the

sheet. Save all leftovers. If any of the die-cut parts

are difficult to punch out/ do not force them! Instead,

cut around the parts with a hobby knife. After

punching out the die-cut parts/ use your bar sander

or sanding block to lightly sand the edges to remove

any die-cutting irregularities or slivers.

LJ 3. As you identify and mark the parts/ separate

them into groups/ such as fuse (fuselage)/ wing/ fin,

stab (stabilizer) and hardware.

3

Page 4

DIE-CUT PATTERNS

4

Page 5

BUILD THE WING

U 1. Start the wing by placing the wing portion of

the plans on the building board. Cover the plans

with wax paper or plastic wrap. This is to prevent

the wing from becoming glued to the plans.

Q 2. Pin the bottom .040" x 15/16" sheet trailing

edge over the drawings.

NOTE: .040" is the thinnest of the sheeting.

Q 3. Pin the 1/8" x 3/16" hardwood bottomspars

over the drawings.

MAIN PANEL / TIP SEPARATION

Q 4. Glue the .040" bottom sheet between the spar

and the trailing edge sheet. Refer to the sketch above.

Q 5. Glue the ribs in place from the center to the tip as

shown on the plans. We will cut the ribs later for the

polyhedral braces. The ribs should fit as shown above.

VERTICAL GRAIN SHEAR WEB

U 7. Cut the shear webs from the 1/16" x 3" balsa

sheet. Glue the shear webs into place between the

ribs. Be sure the grain runs vertically.

NOTE: Do Not install the shear webs where the

polyhedral braces will be installed later.

Q 8. Sand the shear webs so they are flush with the

top of the spar.

Q 9. Glue the 3/16" x 1/4" leading edges to the

front of the ribs.

Q 6. Test fit the top 1 /8" x 3/16" spar into place. If

it doesn't fit properly, enlarge the notches in the ribs

so the spar fits completely in the notch. This is

important so the .040" LE sheet will blend with the

rear portion of the rib. Glue the spar in place with

thin CA.

U 10. Carve and sand the leading edge top to

blend into the ribs. You will probably need to take

the wing off the building board.

5

Page 6

Q 11. Carve and sand the trailing edge sheeting to

accept the upper trailing edge sheeting.

Q 12. Lay the wing back down on the work surface.

Apply thick CA to the area where the top TE is about

to be installed.

Q 13. Install the top TE. Use pins to secure the parts

until the glue dries.

Q 14. With the wing still pinned down, install the

top LE sheet. Cut the .040" x 3" balsa sheeting to the

approximate length. If you haven't put on LE

sheeting with CA before, use the following method:

Apply thick CA to the top spar, ribs and leading

edge. Place the LE sheet into place, and start pinning

down... LET DRY!

Ul 15. Once dry, trim off excess wood at W1, W2

and

the

LE.

Q 16. Prepare the wing for the Polyhedral.

Beginners Note: To avoid difficulties, read this step

through BEFORE cutting and sanding! Refer to the

dimensions on the plans. With each center panel flat

on the work surface, lift the tips so that the bottoms

of

rib

W6

are

2-3/4"

off

the

table.

With

the

tips

blocked up, carefully sand the roots of each tip

panel so they are flush with W2. The final fit should

be tight with no gaps. Take your time while sanding,

removing small amounts at a time.

U 17. Referring to the plans, sand the center and

tip panels to shape as shown.

CUT RIB AS SHOWN

Q 18. Working with the left wing, cut through and

remove 1/16" of rib W2 just behind the spar. This

will make a slot for the polyhedral brace to fit into.

Test fit the die-cut 1/16" ply polyhedral brace in

place as shown on the plans. The polyhedral brace

should contact the top and bottom spars along it's

entire length and the front edge of W2 should touch

the back of the polyhedral brace. If the polyhedral

brace fits, remove the brace and glue the wing tip to

the center panel with CA. If the polyhedral brace

does not fit, slightly adjust its angle with your

sanding block.

Q 19. Using 6-minute epoxy, glue the polyhedral

brace into place. Clothespins work well as clamps

while the epoxy cures. When the epoxy has cured,

glue rib W2 to the polyhedral brace with medium

CA. Repeat steps 18 and 19 for the right wing.

6

still

Page 7

Q 20. Joining the wing panels: Using the same

techniques outlined in steps 16 thru 19, prepare, fit

and glue the two wing panels together using the

die-cut 1/16" ply dihedral brace.

U 6. Hinge the elevator to the stabilizer. Start by

cutting the hinges from the 2" x 9" strip of hinge

material to a size of 1/2" x 1". Snip off the corners

of the hinges for easier insertion.

NOTE: The measurement for blocking up the wing

panels for this step is 3 ".Refer to the plans.

Q 21. Using .040" balsa, sheet the center of the

wing on top. Leave the lower bottom forward section

unsheeted where we will need to get to the W1 ribs

to install the hold down dowel.

Q 22. Glue the 3/16" x 1/2" balsa tip sheets

into place.

Q 23. Sand the wing so the airfoil looks like the

drawing on the plan labeled "typical rib section".

Shape the wing tips as shown on the plan.

BUILD THE TAIL GROUP

U 1. Remove the die-cut stabilizer, elevator, fin and

rudder from their die-cut sheets. Refer to the die-cut

layout for identification.

Q 2. Start assembly by joining the stab front to the

stab. Using your sanding block, remove any die-cut

irregularities. When they mate to your satisfaction,

use CA to glue the two parts together. Sand the joint

to obtain a smooth surface.

Lt 7. Now use your knife to cut the slots into the

stab and elevator at the hinge locations shown on

the plans. CAUTION: Do this slowly. The wood is

thin. It is best to use many small cuts to get the

required depth. Test fit the hinges by joining both

parts. Make sure the bevel will allow the elevator to

move adequately up and down. Do not glue the

hinges in place until the model is covered.

Q 8. Sand the stab to the approximate airfoil shape

as shown in the cross section on the stab drawing.

Q 9. Glue the rudder front to the rudder.

U 10. Bevel the leading edge of the rudder

Q 11. As before/ install the hinges to the fin and rudder.

Q 12. Sand the fin and rudder to a nice thin

airfoil shape. Set these parts aside and move on to

the fuselage.

BUILD THE FUSELAGE

Q 3. Tape the elevators to the stab.

U 4. Cut a piece of leftover spar material to fit into

the tie bar area between the elevators. When it fits

to your satisfaction glue it in place. Be careful not to

glue the elevator to the stabilizer!

Q 5. Remove the elevator from the stab and bevel

its LE as shown in the cross section on the plan. This

will allow for proper movement.

Q 1. Cover the fuselage section of the plans with wax

paper or plastic wrap. Start the fuselage by aligning a

die-cut 3/32" balsa doubler over the inside of a diecut 3/32" balsa fuse side. Align the doubler at the

front and top. When everything is aligned, glue the

doubler to the fuse side by applying thin CA around

the perimeter of the doubler. Be sure to make both a

left and a right side.

7

Page 8

Q 2. Glue the 1/4" sq. top and bottom longerons

into place.

Q 3. Drill or cut and file a 1 /2" hole in the center of

F3. This will allow the pushrods to pass through it.

Lay the sides over the plans and mark the location of

the F2 and F3 fuselage formers.

1/8" THICK

Q 4. Taper the 1 /4" sq. longerons at the rear of the

fuselage with a sanding block so when the

bulkheads are installed the tail will pull together to

measure about 1/8" thick.

Q 10. Starting at the nose/ cut and glue 3 pieces of

1/8" balsa bottom sheeting as shown on the plans.

[-ll1.

Glue

the

1/16"

place. Do not sheet the top yet, we will need to

install the pushrods first.

Q 12. Find the 1/2" x 1-3/8" x 1-1/4" block that

fits cross grain in front of the canopy. Sand a bevel

to the approximate angle shown on the plan.

Q 13. Glue the block into place.

Q 14. Sand the front flat and glue the nose block

into place

Ql 15. Glue the tow hook block into place. It fits

between the two 1/4" sq. longerons and against the

bottom sheeting.

U 16. Cut a small exit hole on either side of the fuse

near the tail for the pushrod guide tubes.

balsa

bottom

sheeting

into

LJ 5. Using a small triangle, glue F2 and F3 to the

left fuse side at a 90-degree angle. See section AA

on the plans for bulkhead orientation.

1— 6. Glue the right fuse side to F2 and F3.

Q 7. Pull the fuse together at the tail and glue

into place.

LJ 8. Pull the fuse front together and glue F1 into place.

Ul 9. With your sanding block/ sand the top and

bottom flat to accept the 1/16" and 1/8"

balsa bottom.

U 17. Slide the pushrod guide tubes into the slots at

the rear, then through F3 and F2. Leave the tubes as

they are until you install the radio.

Q 18. Sheet the rear top of the fuse with 1/16"

balsa. Do not sheet the area where the stabilizer will

mount.

Q 1 9. Cut or sand a bevel at one end of the

hatch/canopy block so it will fit with the cross grain

block already installed.

Q 20. Hollow out the hatch/canopy block so that it

just clears F2, and sits flat on the fuselage.

8

Page 9

Q 21. Tack glue the hatch/canopy block into place

with about 4 drops of CA. This will hold it in position

while the front of the fuse is being shaped.

Q 22. Carve and sand the fuselage to a nice round

shape. Section AA and CC shows approximately

what you should try to achieve. Do not carve the

wing or stab mount areas!

Q 23. Glue the 1/8" ply wing bolt mount into

position as shown on the fuselage drawing.

FINAL ASSEMBLY

Q 1. Cut the canopy block loose with your knife. Set

the canopy aside.

Q 2. Place the wing on the fuselage in the position

shown in the plans. Push the leading edge up

against F2.

Q 3. Drill a 3/16" hole through F2 and into the

leading edge and rib W1.

Q 7. Remove the wing and apply 6-minute epoxy to

the front dowel at W1. Before the epoxy cures,

reinstall the wing so it will set in the proper location.

NOTE: Be careful not to glue the wing to the fuselage!

1-1 8. Pin the stabilizer to the fuselage. Sight down

the fuse from the rear making sure the stabilizer is

parallel to the trailing edge of the wing. You may

need to sand the stab mount area so the stab sits flat

on the fuse. When everything looks good, glue the

stab to the fuse with medium CA.

Q 9. Pin the fin to the centerline of the stab. Use a

90-degree triangle to make certain that the fin is

perpendicular to the stab and centered, when viewed

from the back. When satisfied that the fin is centered

and straight, glue it in place using medium CA.

U 10. Use a piece of 1 /4" sq. leftover balsa from the

fuse longerons to cut triangular sticks to fit where the

stab and fin intersect. Glue them in place with CA.

This should finish the basic construction. Cover your

"Skeeter" according to the instructions included with

the covering of your choice.

Ul 4. Before you glue the dowel, let us install the

rear bolt. Start by aligning the wing with the

fuselage. Use a measuring tape to measure the

distance from the wing tip to the tail of the fuselage.

LI 5. When both the left and right sides are equal/

use a #26 or 9/64" drill to drill a hole through the

wing and the 1/8" ply wing bolt mount. See the

fuselage drawing for the proper location.

Q 6. Use a 10-24 tap to thread the wing bolt mount.

Apply a couple of drops of thin CA to the threads to

harden them. When dry, run the tap through the

threads again.

RADIO INSTALLATION

Q 1. At this point the pushrod guides are in place.

You will need to test fit your servos before you cut

the guides to their final length.

9

Page 10

1—1 2. Based on the servo location, cut the pushrod

guide tubes to fit. Leave enough room for the servo

output attachment. Use 1/16" wire for this.

the coupler). Now, measure another 1/2" toward

the elevator on the pushrod wire and make another

mark. Trim the pushrod wire at the second mark.

Z-BEND

Ul 3. When you have the forward part of the

pushrod bent and attached/ slide the wire into the

tube from the front. Then mount the servos using

double-sided tape.

Q 4. Use CA to glue the guide tubes to the fuselage

formers and the rear of the fuse.

LI 5. Trim off and sand the excess guide tubes flush

with the fuse sides.

Bend the wire between the two marks as shown in

the sketch. Remove the clevises from the control

horns and unscrew the clevis from the coupler. Slide

the coupler onto the wire and carefully solder the

coupler to the wire. Reassemble the clevises and

reattach them to the control horns.

Q 8. Mount the battery in the front of the fuse. If

you can fit any foam around the battery, use it to

keep the battery in place.

Ul 9. Glue the 1/16" plywood tongue to the bottom

front of the canopy, as shown on the fuse plan.

Ul 10. To hold the canopy down, simply use a piece

of tape on both sides.

Q 11. Mount the receiver and check the direction of

the control surface movement.

LJ 6. Before attaching the threaded shaft and clevis,

install the control horns using two 2-56 x 5/8"

screws each.

OR

Q 7. Turn on the radio and center the servos.

Thread a nylon clevis onto a threaded solder coupler

at least 10 turns. Attach a clevis/coupler assembly to

the rudder and elevator control horns. Align the

coupler with the pushrod wire (making sure the

rudder and elevators are centered) and mark the

wire at the back of the coupler (where it would enter

Q 12. Check the balance. A good place to start is

on the spar. Move the center of gravity (C.G.) to

your liking - remember if you move the C.G. back

the model will become more sensitive in pitch, to the

point that it snap rolls, so go slowly.

IMPORTANT

If this is your first model we recommend you now enlist

tne help of an experienced modeler and

so

will

assure a more

successful

local hobby dealer or R/C club is a great source of

assistance if you don't already know someone into R/C.

10

Test

Pilot.

first

experience. Your

Doing

Page 11

Airfoil - A curved structure designed to create lift by

the reaction to air moving over its surface.

AMA - Academy of Model Aeronautics

A.R. - Aliphatic Resin glue (wood glue).

Pushrods - Wooden or wire rods which transfer

motion from the electronic servos to the aircrafts

control surfaces.

Rib - A structural member which maintains the

contour of the wing surface.

Rudder - The vertical control surface hinged to the

fin and used to control yaw about the vertical axis.

Bulkhead - A structural member in the fuselage used to

strengthen and establish the shape of the cross section.

CA - Cyanoacrylate glue

C.G. - Center of Gravity

Clevis - Used to attach the pushrods to the control

surfaces through a control horn.

Control horn - A lever projecting from a control

surface which translates motion from the pushrod

and clevis.

Die-cut - Parts of sheet wood that are precut so the

modeler can use them with a minimum of preparation.

Dihedral - The angle formed by the wing panels

where they intersect.

Doubler - Part of the structure that is used to

reinforce a member by lamination.

Elevator - The horizontal moving surface hinged to

the stabilizer. Used to raise and lower the tail in

flight, thus causing the aircraft to pitch about the

lateral axis.

Slope soaring - the art of remaining aloft in a glider

or sailplane by utilizing the vertical components of

air currents caused by wind being deflected up and

down a cliff or hill.

Spar - The principle spanwise structural member of a

wing or stabilizer.

Tierod - Structural member that connects two halves

of a split elevator.

Trailing edge - (TE) The rearmost edge of the wing,

stabilizer, fin, etc...

Towhook - a device used to connect the tow line to

the aircraft during lunch.

DYNAFLITE BUTTERFLY.

.DYFA1010

Fin - The fixed vertical stabilizer

Fuselage - (fuse) The structure of an airplane to

which the wings and tails are attached.

Glider - A heavier-than-air unpowered aircraft.

Leading edge - (LE) The forward edge of a wing,

stabilizer, fin etc...

The Butterfly is a "powered sailplane" or "motor

glider" and is an ideal model for learning to fly radio

controlled models. Because of its large wingspan and

light wing loading, the Butterfly is a gentle model that

will give you plenty of time to think and react. The

Butterfly does not require a powerful engine. Any .10

to .15 cu. in. 2-stroke will do the job - all the engine

has to do is provide a little thrust and the large wing

will do the rest!

11

Page 12

FLIGHT LOG

DATE

COMMENTS

Started Construction

Finished Construction

First Flight

Loading...

Loading...