Page 1

TM

TM

• EASY TO BUILD...EASY TO FLY

• FORGIVING FLIGHT CHARACTERISTICS

LARGE WINGSPAN • LIGHT WING LOADING

READ THROUGH THIS INSTRUCTION MANUAL FIRST. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

.049 POWERED MOTOR GLIDER

Instruction Manual

Dynaflite guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modification. In no

case shall Dynaflite's liability exceed the original cost of the purchased kit. Further, Dynaflite reserves

the right to change or modify this warranty without notice. In that Dynaflite has no control over the

final assembly or material used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled product. By the act of using

the user-assembled product, the user accepts all resulting liability. If the buyer is not prepared to

accept the liability associated with the use of this product, return this kit immediately in new and

unused condition to the place of purchase.

POCKP03 Printed in USA Entire Contents © Copyright 1996

WARRANTY

Page 2

Introduction.....................................................2

Precautions......................................................3

Preparations...................................................3

Required

Setting

Required Supplies & Tools................................4

Optional Accessories.......................................4

Building

Common Abbreviations...................................5

Types

A Note About Cyanoacrylate Glue...................6

Metric Ruler................................................... 6

Build

Build

Build The Fin, Stabilizer & Elevator...................8

Finish The Tail Surfaces....................................8

Build

Build

Build

Prepare

Join The Inner Wing Panels............................17

Join The Outer & Inner Wing Panels...............18

Finish

Build

Build

Prepare

Join

Sheet The Bottom Of The Fuselage..................22

Install The Firewall........................................22

Install

Sheet The Top Of The Fuselage.......................24

Mount The Landing Gear...............................26

Mount

Align

Align

Align

Covering........................................................30

Prepare The Model For Covering....................30

Covering

How

Covering

Final Construction...........................................33

Shape The Flying Surfaces.............................33

Join

Hinge The Control Surfaces............................34

Accessories

Up

Shop..............................................4

Notes................................................5

Of

Wood...............................................5

The

Tail

Surfaces

The

Rudder.............................................7

The

Wing...............................................10

The

Inner

The

Outer

The

Panels

The

Wing............................................

The

Fuselage..........................................

The

Formers

The

Fuselage

The

Fuselage

The

Servos & Pushrod

Your

Engine.......................................27

The

Tail

Group......................................28

The

Stab..............................................28

The

Fin

................................................29

Tips

...............................................30

To

Cover

Your

Sequence

The

Tail

Surfaces

......................................3

......................................7

Wing

Panels

..........................10

Wing

Panels

.........................15

For

Joining

.........................................19

Sides

Sides.................................20

Model

.......................................32

To

......................17

...........................19

Guides...............23

.............................30

The

Fuselage

............33

18

19

Fuelproofing.................................................34

Final Hook

Connect

Finish

Balance

Set The Control Throws..................................38

Preflight.........................................................39

Charge

Ground

Gather

Range

Engine

Flying

Find A Safe

Takeoff.........................................................41

Flight...........................................................41

Landing.......................................................42

Congratulations and thank you for purchasing the

Dynaflite Piece 0' Cake. The Piece 0' Cake is a

"powered sailplane" or "motor glider" and is an ideal

model to learn radio controlled flying - especially if

you are not able to locate an experienced flight

instructor and must try it on your own. Because of its

large wingspan and light wing loading, the Piece 0'

Cake is a gentle model that will give you time to think

and react. For the same reasons/ you must reserve

first flight attempts for a calm day - more on that in

the "Flying" section at the end of the manual. The

Piece 0' Cake does not require a powerful engine.

Any .049 will do the job - all the engine has to do is

provide a little thrust and the large wing will do

the rest!

The way you fly the Piece 0' Cake is to let it climb (it

will

do

from you) and fly it around rather like a sailplane.

This doesn't sound like much action but don't worry; if

you're a beginner you'll be busy. Most important,

you'll develop the hand/eye coordination required to

fly traditional sport/trainers. Enough said. Please read

the rest of the preliminary information thoroughly,

then let's get started!

2

Ups & Checks................................35

The

Servos.......................................35

Installing

Your

The

Check

Your

Check

Safety

............................................................41

that

The

Radio..............................36

Model

......................................38

Batteries

Tools..........................................39

The

Precautions...............................40

Place

almost

.....................................39

The

Model..............................39

Radio.................................40

To

Fly

................................41

by

itself

with

just

a little guidance

Page 3

Your Piece 0' Cake is not a toy, but a sophisticated

working model that functions like a full-size airplane.

Because of its performance, if you do not assemble

and operate the Piece 0' Cake correctly, you could

possibly injure yourself or spectators and damage

property. To make your R/C modeling experience

totally enjoyable, we recommend that you get

assistance with assembly and your first flights from

an experienced, knowledgeable modeler. You'll

learn faster and avoid risk to your model before

you're truly ready to solo. Your local hobby shop has

information about flying clubs in your area whose

membership includes qualified instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,300

chartered clubs across the country. We recommend

you join the AMA, which will provide you with

insurance coverage at AMA club sites and events.

AMA Membership is required at chartered club

fields where qualified flight instructors are available.

3. You must install all R/C and other components so

that the model operates properly on the ground and

in

the

air.

4. You must test the operation of the model before the

first and each successive flight to insure that all

equipment operates correctly. You must also make

certain that the model has remained structurally sound.

NOTE: We, as the kit manufacturer, can provide you

NOTE: We, as the kit manufacturer, can provide you

with a quality kit and great instructions, but

with a quality kit and great instructions, but

ultimately the quality and flyability of your finished

ultimately the quality and flyability of your finished

model depends on how you assemble it; therefore,

model depends on how you assemble it; therefore,

we cannot in any way guarantee the performance

we cannot in any way guarantee the performance

of your completed model and no representations are

of your completed model and no representations are

expressed or implied as to the performance or

expressed or implied as to the performance or

safety of your completed model. Please inventory

safety of your completed model. Please inventory

and inspect all parts carefully before starting to

and inspect all parts carefully before starting to

build! If any parts are missing, broken or

build! If any parts are missing, broken or

defective or if you have any questions about

defective or if you have any questions about

building or flying this model, please call us at

building or flying this model, please call us at

(217) 398-8970 and we'll be glad to help. If you

(217) 398-8970 and we'll be glad to help. If you

are calling for replacement parts, please look up the

are calling for replacement parts, please look up the

part numbers and have them ready when you call.

part numbers and have them ready when you call.

Contact the AMA at the address or toll-free phone

number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(800) 435-9262

Fax (317) 741-0057

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the photos or plan. In those instances the text

should be taken as correct.

2. You must take time to build straight, true and strong.

REQUIRED ACCESSORIES

These are the items not included with your kit that

you will need to purchase separately. Items in

parentheses (OSMG2691) are suggested part

numbers recognized by distributors and hobby

shops and are listed for your ordering convenience.

GPMis the Great Planes® brand, TOP is the Top

Flite®

brand and

2 or 4 Channel Aircraft Radio System with

2 standard servos and a square battery*

Q .049 Engine with appropriate fuel and glow

plug clip

3

HCA

is

the

Hobbico®

brand.

Page 4

Engine Mount (DAVG3005)

Propellers - Refer to your engine's instructions

for proper size

1 roll of Covering Film; See Covering Tips

(page 30)

1 /4" Latex Rubber Padding (HCAQ1000)

1/16" Foam Wing Seating Tape (GPMQ4422)

(2) 1-1/2" Wheels (GPMQ4243)

(2) 3/32" Wheel Collars (GPMQ4302)

#64 Rubber Bands (1 /4 Ib box - HCAQ2020)

(4) #2 x 3/8" Screw for mounting your engine

Self-Adhesive Lead Weight (GPMQ4485)

*lf your radio includes a "flat" style battery for the

receiver, ask your hobby dealer if you can swap it

for a square style. The square style battery fits in the

fuselage better than a flat one.

SETTING UP SHOP

CA Activator - (GPMR6035)

30-Minute Pro Epoxy - (GPMR6047)

#1 Hobby Knife Handle (XACR4305)

#11 Blades (Qty. 100 - HCAR0311) or

(Qty.5-XACR2911)

Hobbico (or similar) Builders Triangle

(HCAR0480)

Medium T-pins

Wax Paper

Electric Drill

Drill

Bits:

Masking Tape

String for aligning the stabilizer

#1 Phi Hips Screwdriver

Top Flite Covering Iron (TOPR2100)

A building board that you can stick pins into

(see "Setting Up Shop")

1/16",

(HCAR5150)

3/32"/

1/8"/

3/16

11

If this is your first model there are a few supplies and

tools that you should gather before you begin. The

most important item is a flat table that you can build

your models on. You can turn a solid core door into

a building table, but avoid hollow core doors

because they warp easily. If possible, locate your

building table in an area that is not in the way of

other projects or household activities. Cover your

building table with a board that you can stick pins

into. The back of a 2' x 4' ceiling tile works well or

you can cut a piece to fit your table from a 4' x 8'

sheet of Celotex insulation board available from a

home improvement store.

REQUIRED SUPPLIES

AND TOOLS

These are the building tools and adhesives that you

will need to build your Piece 0' Cake.

We recommend Great Planes Pro™ CA and Epoxy

2 oz. Thin CA Adhesive - (GPMR6003)

2 oz. Medium CA+ Adhesive (GPMR6009)

OPTIONAL ACCESSORIES

You can build your Piece 0' Cake without these items

but they will make the job much easier and provide you

with better results. These are things you will accumulate

as your building "career" progresses anyway.

Razor Plane (MASR1510)

Single-Edge Razor Blades (100, HCAR0312)

CA Applicator Tips (HCAR3780)

Hot

Sock™

(for your covering

6-Minute Pro Epoxy (GPMR6045)

Trim Seal Tool™ (TOPR2200)

Heat Gun (TOPR2000)

Straightedge (Fourmost Non-Slip, FORR2149)

Denatured or IsopropyI Alcohol (for epoxy

clean-up) '

HobbyLite™ Balsa Filler (HCAR3401)

Epoxy Brushes (GPMR8060)

CA Debonder (GPMR6039)

Powered hand tool with Sanding Drum and

Cut-off Wheel

Bar Sander or Sanding Block and Sandpaper

(coarse, medium, fine grit)*

Microballoons Filler (TOPR1090)

4

iron,

TOPR2175)

Page 5

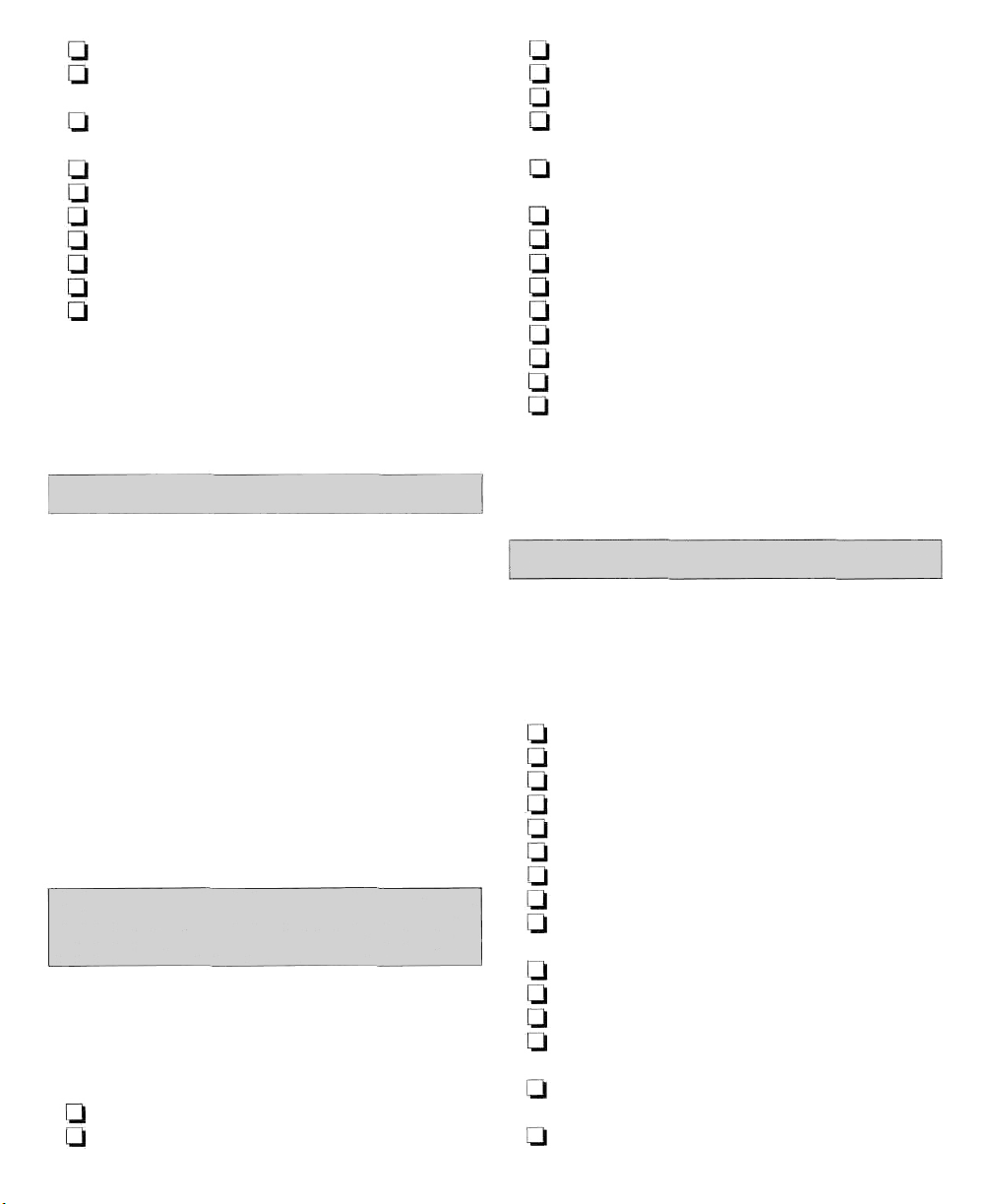

*A flat, durable, easy-to-handle sanding tool is a

necessity for building model airplanes. Great Planes

makes a complete range of Easy-Touch™ Bar Sanders

and replaceable Easy-Touch adhesive-backed

sandpaper. For the Piece 0' Cake all that is required

is the short 5-1/2" Bar Sander (GPMR6169) and

two assortment packages of adhesive-backed

sandpaper (GPMR6189).

For future reference, here's a list of Easy-Touch Bar

Sanders and adhesive-backed sandpaper:

5-1/2" Bar Sander (GPMR6169)

11 "Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

Machine screws are designated by a number,

threads per inch and a length.

For example 2-56 x 3/8"

When you see the term "test fit" in the

instructions, it means you should first position the

part on the assembly without using any glue,

then slightly modify or "custom fit" the part as

necessary for the best fit.

Whenever

either 30-minute epoxy or 6-minute epoxy. When

30-minute epoxy is specified, it is highly

recommended that you use only 30-minute epoxy

because you will need either the working time

and/or the additional strength.

just

"epoxy"

is

specified

you

may

use

COMMON ABBREVIATIONS

Assortment pack of 5-1/2" strips (GPMR6189)

12' Roll of adhesive-backed sandpaper,

80-grit (GPMR6180)

150-grit (GPMR6183)

220-grit (GPMR6185)

• There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length.

For example #2 x 3/8"

Fuse = Fuselage

Stab = Horizontal Stabilizer

LE = Leading edge (front)

TE = Trailing edge (rear)

Ply = Plywood

" =Inches

Balsa Basswood Plywood

5

Page 6

The most popular type of glue modelers use for

general construction of R/C models is cyanoacrylate

or CA glues. Modelers build with CA because it

cures fast (immediately in some cases) and the

pieces do not have to be clamped or pinned together

as they do with traditional adhesives. CAs do,

however, have their own set of special procedures

and precautions that you should follow. Always use

CA in a well ventilated area. Open some windows

or place a fan in the room to circulate the air. Do not

lean directly over your work when you use CA and

look away while it cures or "sets off." CA can cure

immediately upon contact with skin so if you

accidentally bond your fingers, do not use vigorous

motion to separate them. Use CA Debonder

(GPMR6039) or acetone (nail polish remover) or

soak your fingers in warm water for a few minutes.

Never point the tip of a CA bottle toward your face

and be especially careful when you unclog a CA tip.

Hobbico CA Applicator Tips (HCAR3780) are highly

recommended and will help keep the bottle from

clogging. Keep paper towels or tissues close by to

immediately absorb excess CA dropped on your

model or work area. Read all the warning labels on

your CA bottle.

glue to one part, then join it to another. Thick CA is

great for glue joints that don't fit perfectly or parts

that require a little time for positioning before the

glue cures. You will encounter many other conditions

that require one or the other types of CA. For the

Piece 0' Cake all you really need is thin and

medium CA.

CA Accelerator is a chemical that you can spray

over uncured CA to make it cure immediately. A mist

spray of accelerator will do the job. Do not inhale

the vapors! Some modelers "preprime" the parts to

be glued with accelerator, join them, then add the

CA. This way the CA is guaranteed to cure

immediately. This prepriming is especially handy

when you use thin CA because it will cure before all

of the glue soaks into the wood away from the glue

joint. We do not recommend you build your entire

model with this method. Use accelerator only when

necessary. Often, overspray from accelerator used

hours or even days earlier on nearby glue joints will

cause the CA you use on the next step to cure

prematurely and unexpectedly - so be careful!

There are different viscosities of CAs intended for

different conditions you will encounter when you

build. Thin CA is great for "tack-gluing," for glue

joints that fit well and for parts that are already

joined but need to be permanently bonded. Medium

CA is used for general construction where you apply

Inch Scale

0"

1"

0

10

20

2"

30

40

3"

50

60

70

Metric Scale

4"

80

90

100

6

5"

110

120

130

6"

140

150

Page 7

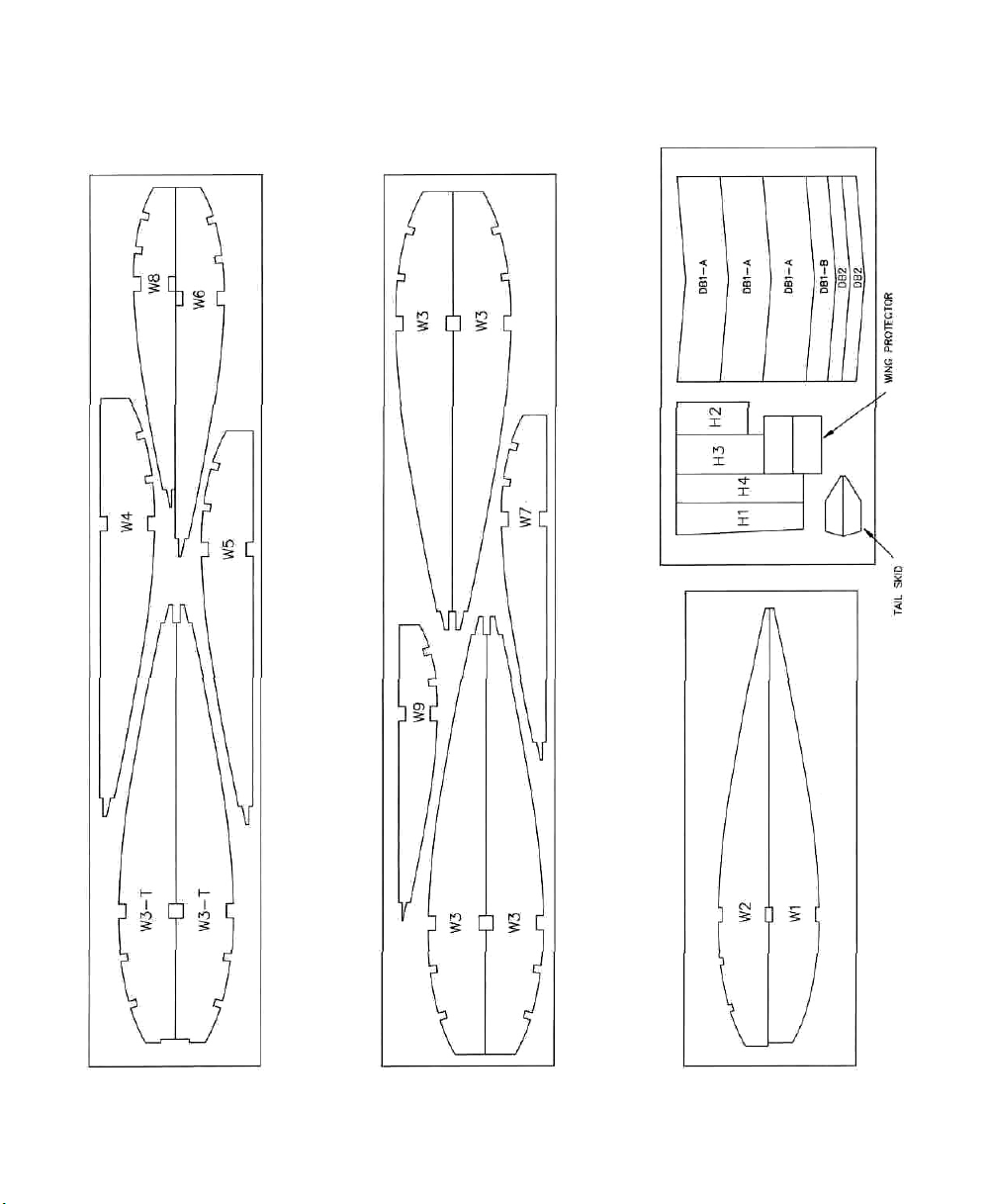

DIE-CUT PATTERNS

7

Page 8

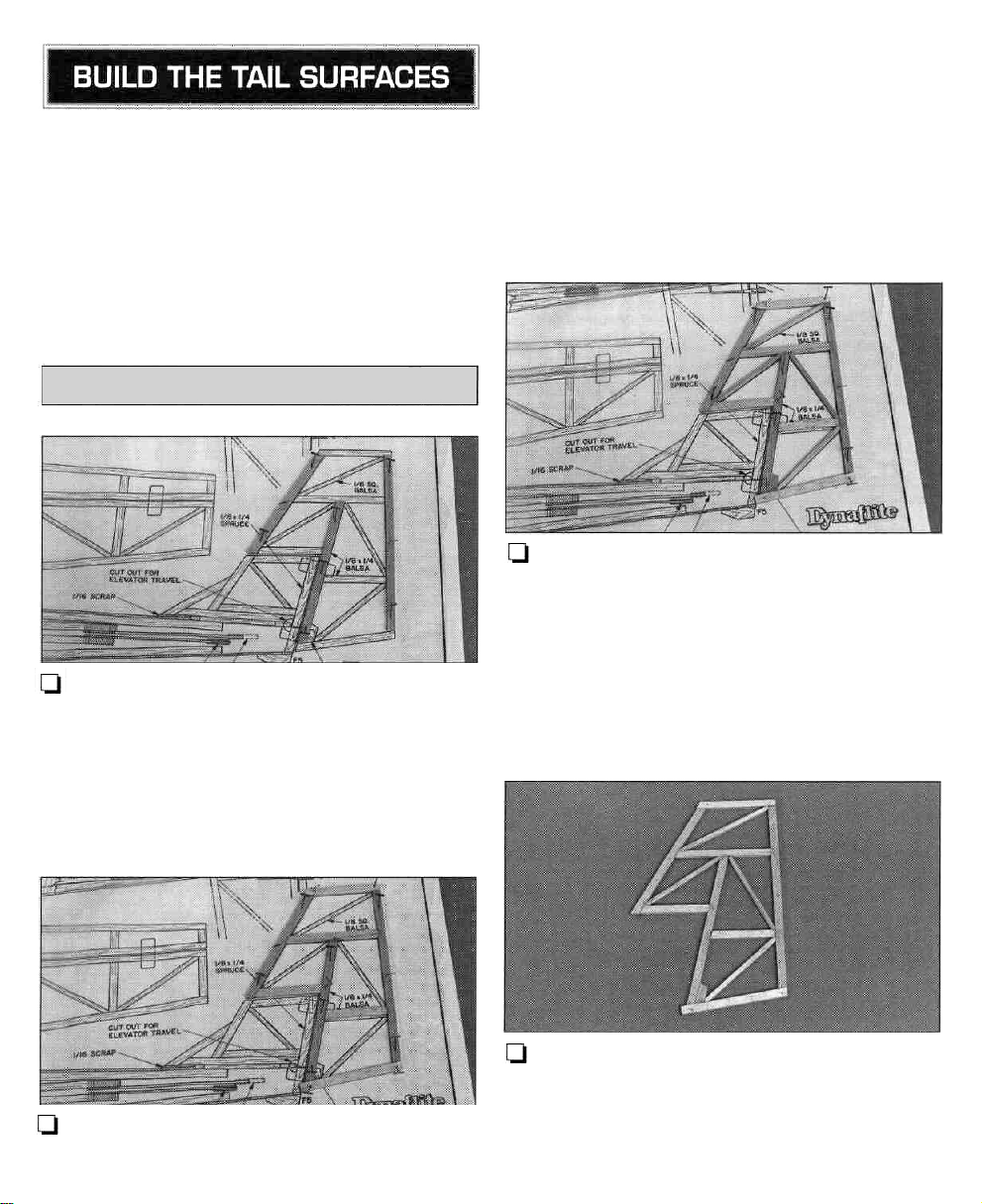

Place your building board on top of your flat

building table. Unroll the plan sheet, then reroll it the

opposite way so it will lay flat. Position the rudder

and fin drawing over your flat building board. You

may separate the wing portion from the plan, or fold

the plan in half to make it easier to work with. Cover

the rudder and fin drawing with wax paper so the

glue will not stick to the plan.

BUILD THE RUDDER

position with medium CA. Where possible, cut the

sticks slightly too long so you can trim them to exact

length as you complete the assembly. You can cut the

tip and bottom pieces too long, and trim them after

you remove the rudder from the plan.

L-l 3. Make the rudder horn mount plate from the

1/8" x 1/4" balsa stick, then glue it in position with

medium CA. Accurately cut the "braces" from a

1/8" x 1/8" x 36" balsa stick, then place them in

the frame and glue them in position with thin CA.

LJ 1. Accurately cut the three vertical rudder pieces

including the leading edge (LE), rudder post (the

middle part) and the trailing edge (TE) from a 1 /8"

x 1/4" x 36" balsa stick. Then pin them over their

locations on the plan with small T-pins. Many

modelers find that they can more accurately cut

small balsa sticks with a single-edge razor blade

instead of a hobby knife.

LJ 2. Cut the five horizontal rudder pieces from the

same 1/8" x 1/4" balsa stick, then glue them in

LJ 4. Remove the T-pins, then lift the rudder from

your building board and peel off the wax paper.

Reinforce glue joints that don't look strong with

medium CA, then set the rudder aside and continue

with the rest of the tail pieces.

8

Page 9

BUILD THE FIN,

STABILIZER & ELEVATOR

Q 1. Use the remainder of the 1/8" x 1/4" balsa

stick plus three more 1 /8" x 1 /4" x 36" balsa sticks,

and the remainder of the 1/8" x 1/8" balsa stick

plus a second 1/8" x 1/8" x 36" balsa stick, to

build the fin, stab and elevator the same way as the

rudder. Remember, where possible it's easier if you

cut the sticks slightly long so you can trim them to

exact length after you remove the assembly from

your building board. After you complete each

assembly, remove it from your building board and

reinforce any glue joints that don't look strong with

medium or thin CA.

Note:

Make

sure

you

use

the

1/8" x 1/4" x 3-1/2"

basswood stick for the fin trailing edge. Make the

stab center from the 1 /8" x 1" x 2-3/4" balsa sheet.

Cut the angles to match the leading edge first, then

trim the stab center to the length shown on the plan.

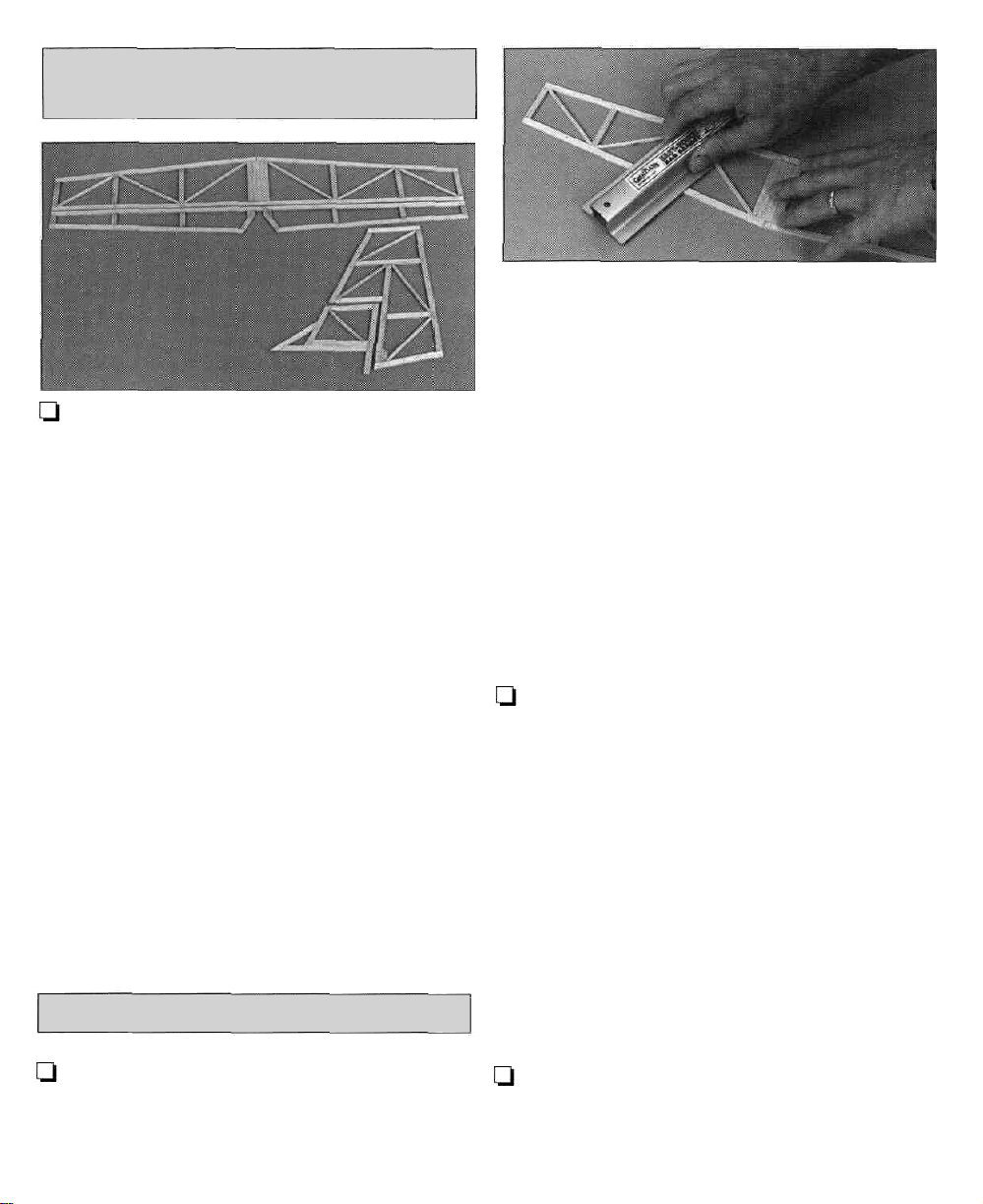

A note about sanding "built-up" tail surfaces:

Use care when you sand a lightweight balsa

structure made up of "sticks." The part flexes and

moves while you sand, and it can be difficult to

keep your sanding block flat so you do not snag

any of the small braces, or over-sand one area

and make it thinner than another. Due to the

design and slow flying speed of the Piece 0' Cake,

a perfectly smooth finish is not necessary. For this

model, the purpose of sanding is just to remove

any glue bumps or uneven edges. Stop sanding

when you have reduced most of the high spots.

Use a large sanding block or a flat bar sander,

and

do

not

apply

much

pressure

Enjoy it's not a racing plane - it's a floater.

Q 2. Use a ballpoint pen to lightly mark the location

of the hinges on the control surfaces where shown

on the plan.

while

you

sand,

FINISH THE TAIL SURFACES

LJ 1. See the note below/ then use your bar sander

or a sanding block and 220-grit sandpaper to even

the edges and blend the LE's, TE's and "braces" of

all the tail surfaces so they are flat and smooth.

Q 3. Use a hobby knife with a #1 1 blade to

carefully make the hinge slots. The first several cuts

should be just deep enough to make a shallow slit to

establish the hinge slot location.

9

Page 10

CUT HINGE SLOT

WITH HOBBY KNIFE

AND No. 11 BLADE

After the first shallow cuts, make several more cuts

going slightly deeper each time. Move the knife from

side to side and widen the slot as you cut.

Q 6. Carefully separate the elevator from the stab.

Then use a ballpoint pen and a straightedge to

lightly draw a line 1/16" from the leading edge on

both sides of the elevator.

7/16"

3/4"

MAKE SIX 7/16" X 3/4" HINGES FROM

THE 2" X 9" HINGE STRIP PROVIDED

Q 4. Cut six hinges from the hinge material

supplied as shown in the sketch. Snip the corners off

so the hinges go into the slots easier.

Q 7. Use the lines as a guide to bevel the leading

edge of the elevator to a "V" with a hobby knife or a

bar sander and 220-grit sandpaper.

LJ 8. Bevel the leading edge of the rudder the same

way you did the stab.

Q 9. Use your bar sander and 220-grit sandpaper

to round the perimeter of the tail surfaces as shown

on the plan (except of course, the edges that are

joined by hinges).

There, that was a "piece o' cake," wasn't it? Set the

tail surfaces aside for now while you build the wing

and the fuselage.

U 5. Test join the elevator to the stab, and the

rudder to the fin with the hinges. Adjust the hinge

slots if necessary so the control surfaces fit well.

10

Page 11

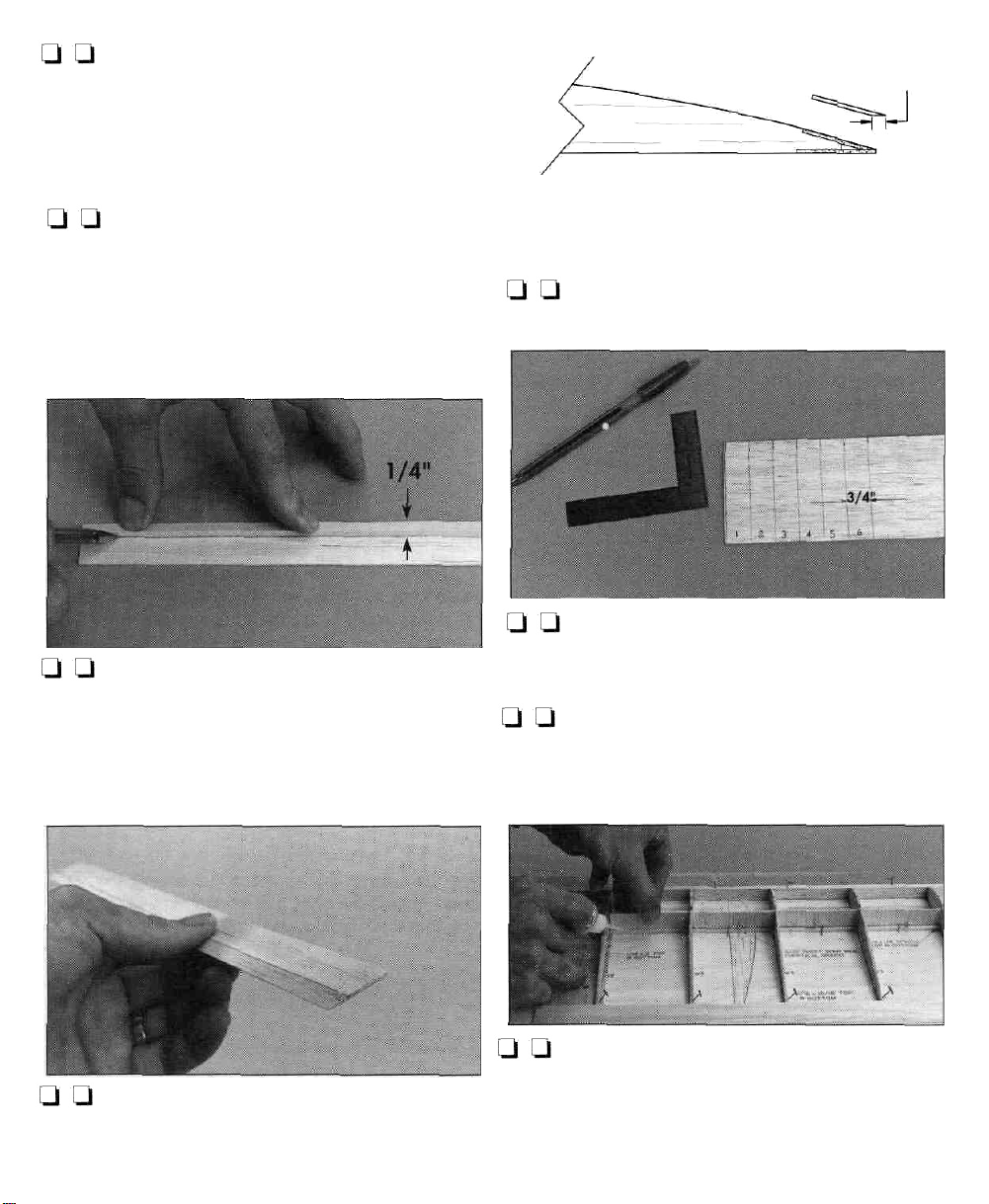

BUILD THE INNER WING PANEL

U 1. Before you remove the the die-cut 3/32" balsa

ribs and the die-cut 1/16" plywood parts from their

die sheets, mark them with a ballpoint pen as shown

on page 7. If you plan on covering the wing with

transparent film, neatly mark all the ribs in the same

location, or mark them in an inconspicuous location

so the marks will not be seen through the covering.

Q 2. Carefully remove all the ribs and the plywood

parts from their die sheets. If a rib will not easily

come out of the die sheet, do not force it but use a

sharp #11 blade to cut the wood where necessary.

Use a bar sander and 220-grit sandpaper to remove

any slivers or die-cutting irregularities.

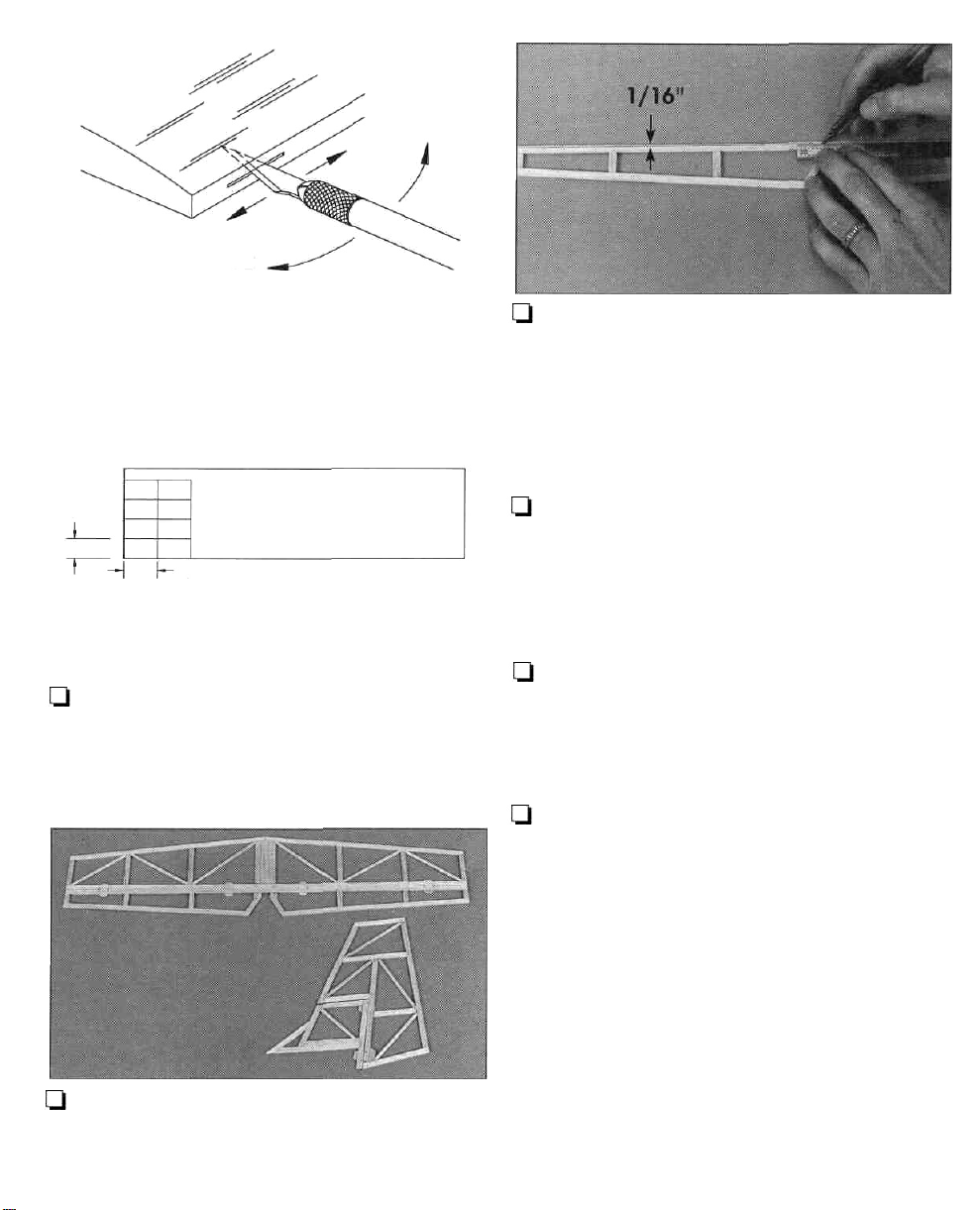

Ql Q 3. Build the right inner wing panel first so

your progress matches the photos. Cut the wing

portion from the plan, or fold the plan so the right

wing panel is on top. Lay the right wing plan over

your building board, then cover it with wax paper.

U U 5. Accurately cut a 1/16" x 15/16" x 36"

balsa sheet to a length of 1 8". Then pin it in position

over the trailing edge of the plan so the root end

aligns with the centerline.

LJ LJ 6. Use a straightedge and a hobby knife to

cut halfway through one W1 rib and one W3-T rib

along a line connecting the aft edge of the spar

notches. Cut another line 1 /16" ahead of the first on

both ribs. Make the slots on the side of the rib that

will be visible when you glue the ribs in position. The

ribs in the photo are for the right wing panel. It is

easier to align

they are in one piece instead of cutting all the way

through. These slots are for the plywood joiners and

will be cut all the way through later.

these

ribs and glue

them

in

position

if

T-Pins

Spar

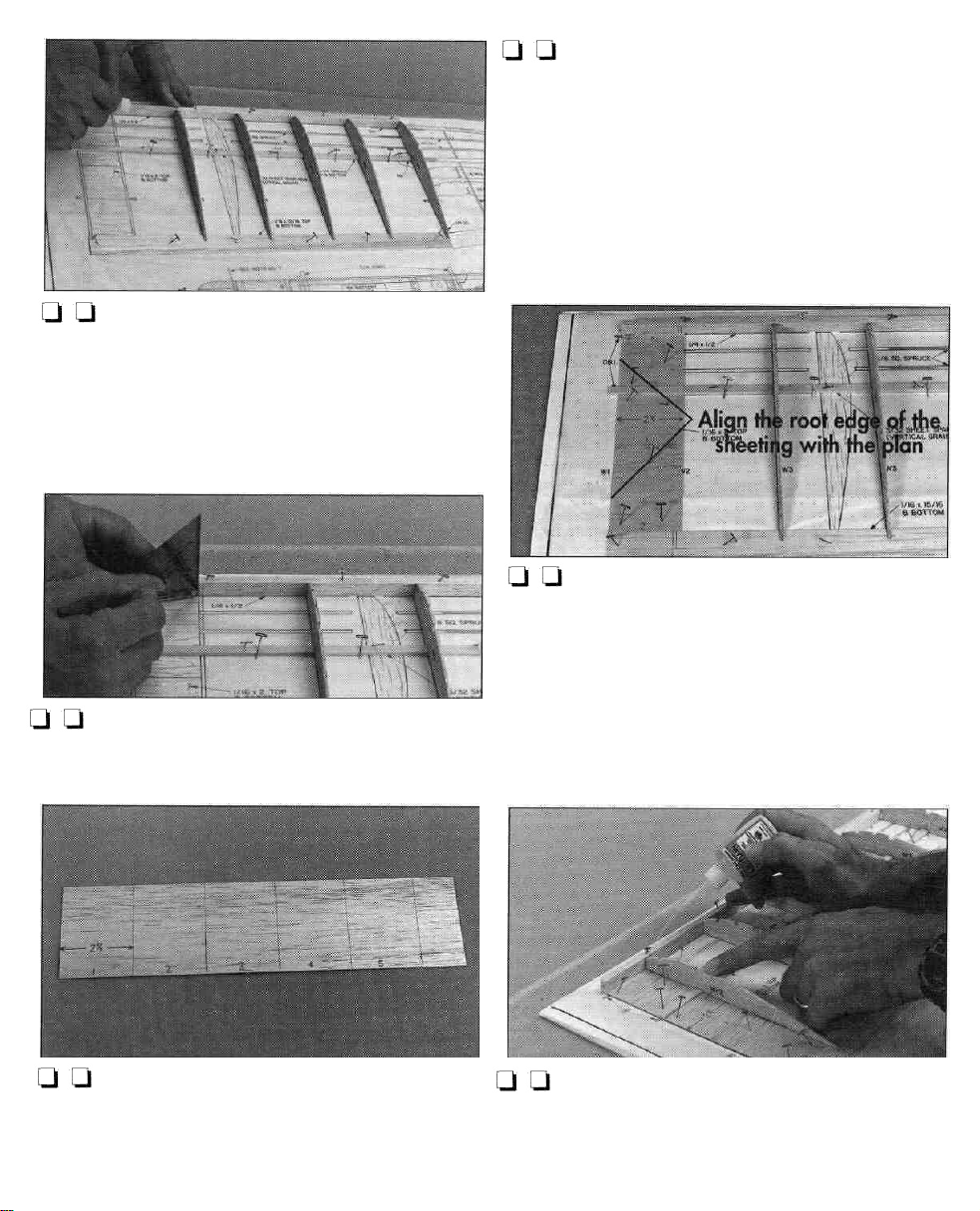

U U 4. Pin a 1/8" x 1/4" x 18-1/4" basswood

bottom spar over its location on the plan so the root

end accurately aligns with the centerline of the wing

at rib W1 on the plan. Do not insert T-pins through

the spar but install them in a "criss-cross" pattern.

Q Q 7. Test fit four W3 ribs and one W3-T rib to

the bottom spar and bottom TE over their locations

on the plan. If necessary, adjust the notches in the

ribs so they fit the spar and bottom TE. Then use a

builder's triangle to make sure the ribs are

perpendicular as you glue them in position with thin

or medium CA.

11

Page 12

Q Q 8. Position a 1/4" x 1/2" x 18" balsa

leading edge over its location on the plan so the

root aligns with the centerline of the wing. Securely

pin the LE to the building board so it tightly contacts

the wing ribs. Then glue it in position with thin CA.

Q Q 11. Trim the 2-1/8" x 6" sheet you just made

so it fits between the bottom main spar and the

bottom trailing edge sheet. Accurately trim the root

edge of the sheet (the left edge if you are building

the right wing panel, the right edge of the sheet if

you are building the left wing panel) so it aligns with

the centerline of the wing. It's okay if the other edge

of the sheet extends past rib W2. Pin the sheet in

position but do not glue it to the wing yet.

U U 9. Mark the location of rib W2 on the leading

edge and trailing edge.

Q Q 10. Cut three 2-1/8" wide strips from the

1/16" x 3" x 30" balsa sheet. Glue two of the strips

together to make the 2-1/8" x 6" aft bottom

sheeting that fits behind the bottom spar.

Q Q 12.

fit between the leading edge and the bottom spar so the

root end accurately aligns with the wing centerline.

Note: It is important that the root edges of the

bottom sheeting accurately align with the wing

centerline because those edges will be used as a

guide to determine the position of rib W-1.

Q Q 1 3. Use the lines you marked as a guide to

glue rib W-2 in position with medium CA. Then glue

the forward and aft 1/16" bottom center section

sheeting to the spar, LE, TE and rib W-2.

12

Trim

the

third

1/16" x 2-1/8" x 3"

sheet

to

Page 13

Q Ql 14. Remove the T-pins from the bottom TE

sheeting. Then replace them in the aft end of the ribs

to hold the rear of the wing panel securely to your

building board.

1/4" BEVEL

Q Q 15. Test fit the other half of the 1/16" x

15/16"

x 36" trailing edge

sheet

that

you

cut

to

a

length of 18" in step 5. If necessary, adjust the

notches in the ribs so the aft edge of the upper TE

will align with the aft edge of the lower TE.

LJ U 16. Use a 1/8" x 1/4" x 18-1/4" basswood

spar as a guide to make a line 1 /4" from one edge

of the upper TE sheet with a ballpoint pen. See the

sketch at step 18.

BEVEL THE UPPER TE TO FIT

THE LOWER TE.

LJ LJ 18. Glue the upper TE to the bottom TE and

ribs with medium CA.

LJ LJ 19. Use a builder's triangle or square and a

ballpoint pen to mark, then cut, six 3/4" vertical-grain

shear webs from the 3/32" x 3" x 15" balsa sheet.

Q [-I 20. Test fit but do not glue the shear webs

between the ribs. If necessary, trim each shear web

so the top spar will fully seat in the notches of the

ribs and contact the tops of the webs.

LJ U 17. Use the line as a guide to bevel the aft

edge of the sheet with your bar sander and 220-grit

sandpaper.

LJ U 21. Use medium CA to glue five of the shear

webs in the center of the bottom spar between all

the ribs. You will have to temporarily remove the

T-pins, then reinsert them through the shear webs to

hold the wing to your building board.

13

Page 14

Q Q 22. Test fit, then glue/ the 1/8" x 1/4" x 18-

1 /4" basswood top spar to the ribs and shear webs

with medium CA.

LJ LJ 23. Cut a notch about 1/8" from the end of

two 1/8" x 1/8" x 16-1/2" basswood inner

turbulator spars. The notches should go halfway

through the end of the turbulator spars.

U LJ 24. Glue the turbulator spars into the ribs so the

notches at the ends of the spar extend approximately

1/32" to 1/16" past rib W2. Trim the ends of the

turbulator spars so they are even with tip rib W-3.

Q Q 26. Cut along the dotted line of the wing root

and wing tip dihedral gauge templates on the back

cover of the manual. Then glue the templates with

spray adhesive or rubber cement to a piece of balsa

wood or thin card stock (such as from a cereal box).

Use a #11 blade and a straightedge to accurately

cut the templates from the card stock along the solid

outline to make the dihedral gauges.

Q LJ 27. Test fit rib W-1 and if necessary, adjust

the notches so it fits between the top and bottom

spars. Accurately align the bottom of W-1 with the

bottom sheeting. Then use the wing root dihedral

gauge hold W-1 at the correct angle and glue it in

position with medium CA.

U LJ 25. Cut a small triangular piece from the end

of the 1/4" x 1/4" x 15" balsa stick to make a

gusset, then glue it in position with medium CA.

LJ Q 28. Remove the T-pins, then lift your wing

from your building board and peel off the wax

paper. Inspect the wing panel and add CA to glue

joints that don't look strong.

LJ Q 29. Trim, then fit, but do not glue the sixth

shear web that you already cut, between ribs W-1

and

W-2.

14

Page 15

Q Ql 30. Use your bar sander and 150-grit

sandpaper to sand the ends of the spars, bottom

sheeting/ LE and TE's so they are even with rib W1

and W3-T.

Q Q 31. Use a sharp #11 blade to remove the

portion of balsa between the lines you partially cut

on ribs W1 and W3-T.

TIP: How To Use A Razor Plane

We highly recommend a razor plane to shape the

LE's because it is the safest, fastest and most accurate

method to remove large quantities of balsa.

A. Adjust your razor plane so it removes about

1 /64" or less balsa at a time.

B. Position the LE of the wing panel at the edge of

your work bench so it is supported and the bench

does not interfere with the razor plane.

C. Hold the razor plane at an angle to the grain

direction as shown in the photo.

D. Work slowly and inspect your work frequently before you know it you will have shaved the LE

down quite far.

Q Q 32. See the "Tip" that follows. Then use a

razor plane, a hobby knife with a carving blade, or

a #11 blade to roughly carve the leading edge

according to the sketch. Note: Leave the leading

edge at least 1/16" high in front of ribs W1 and

W2 to accommodate the top sheeting. You will final

sand the LE after you join the inner panels to the

outer panels and glue the top sheeting in position.

Ul Ul 33. Use a bar sander and 220-grit sandpaper

to carefully remove any glue blobs and blend all the

ribs, spars, TE and LE.

Q 34. Arrange the plan so the left inner wing panel

is over your building board. Cover it with wax

paper. Return to step 4 and build the left inner wing

panel the same way as the right. Don't forget to

switch to the left wing panel plan so you do not

build two right panels.

15

Page 16

BUILD THE OUTER

WING PANELS

Start with the right outer wing panel so your

progress matches the photos.

Q Q 6. Position a 1/4" x 1/2" x 18" balsa

leading edge over its location on the plan so the

root aligns with the centerline at W3-T. Securely pin

the LE to the building board so it tightly contacts the

wing ribs. Then glue it in position with thin CA.

Ui l—l 1. Cover the outer panel of the right wing

plan with wax paper. Use the "crossed T-pin"

method to pin a 1/8" x 1/4" x 18-1/4" basswood

bottom spar in position so the root end aligns with

the centerline at W-3.

l-l Q 2. Accurately cut a 1/16" x 15/16" x 36"

balsa sheet to a length of 18". Pin it in position over

the plan so both ends extend past the ends of the TE

on the plan. You will sand the ends of the TE

sheeting flush with the end ribs later.

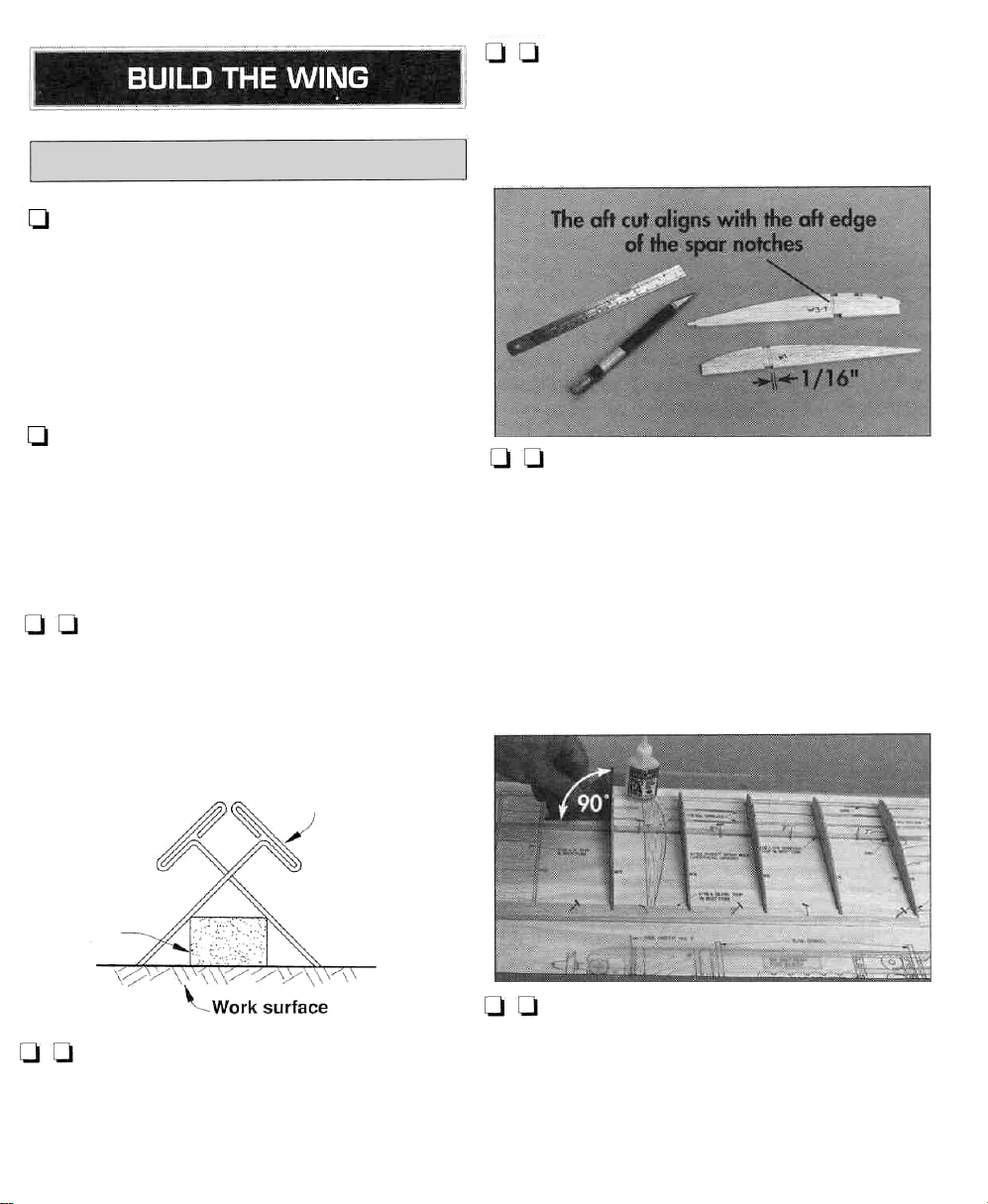

Q Ul 3. Use a straightedge and a hobby knife to cut

halfway through one W3-T rib to accommodate the

1/16" dihedral brace the same way as you did at

step 6 on page 11. Make the slot on the side of the

rib that will be visible when the rib is in position.

Ul LJ 7. Remove the T-pins from the bottom TE

sheeting. Replace them in the aft end of the ribs to

hold the rear of the wing panel securely to your

building board.

Q Q

8.

Test

fit the other half of the 1 /16" x 15/16"

x 36" trailing edge sheet. If necessary, adjust the

notches in the ribs so the aft edge of the upper TE

will align with the aft edge of the lower TE.

Q Q 9. Use a 1 /8" x 1 /4" basswood spar to mark

the guide line, then bevel the edge of the upper

TE sheet.

Q Q 10. Glue the upper TE to the bottom TE and

ribs with medium CA.

Q Q

11.

Test

fit,

then

glue,

the 1 /8" x 1

basswood top spar to the ribs with medium CA.

/4" x 18-1

/4"

Q Q 4. Test fit ribs W3-T through W9 to the bottom

spar and bottom TE over their locations on the plan.

If necessary, adjust the notches in the ribs so they fit

the spar and bottom TE.

C.] Ql 5. Set rib W3-T aside and glue all the ribs

except W3-T in position with thin or medium CA.

Use a builder's triangle to make sure the ribs are

perpendicular to the work surface as you glue them.

LJ LI 12. Cut a 1/8" x 1/8" x 36" balsa stick into

two 18" long

outer turbulator spars in the notches of ribs W4

through W9 so the ends align with W9.

16

pieces.

Test

fit,

then

glue,

the

two 18"

Page 17

Q Q 13. Fit rib W3-T to the outer panel and

accurately align it over its location on the plan. Use

the wing tip dihedral gauge to set W3-T at the correct

angle, then glue it in position with medium CA.

Q Q 14. Make a gusset from the end of the

1 /4" x 1 /4" x 15" balsa stick. Glue it with medium

CA at the position shown on the plan.

Q Q 15. Remove the T-pins. Lift your wing from

your building board and peel off the wax paper.

Inspect the wing panel and add CA to glue joints

that don't look strong.

Q Q 16. Make a 3/32" x 3/4" shear web from

the same balsa sheet you used to make the other

shear webs (originally a 3/32" x 3" x 15" sheet).

Then fit but do not glue it between ribs W3-T

and

W4.

Q Q 20. Cut the 3/4" x 12-1/4" balsa triangle

stock into two 6-1/8" pieces to make the wing tips.

Use medium CA to glue a tip to W9 so the aft edge

of the triangle wing tip aligns with the aft edge of

the

TE.

U U 21. Roughly carve the wing tip with a razor

plane or a hobby knife, then final shape the tip and

blend it to W9 with a bar sander and 150-grit

sandpaper.

Q Q 1 7. Use your bar sander and 150-grit

sandpaper to sand the ends of the spars, LE and TE's

so they are even with rib W3-T and W9.

LI Q 18. Use a sharp #11 blade to remove the

portion of balsa between the lines you cut with a

straightedge on rib W3-T.

Q Q 19. Roughly shape the LE the same way you

did for the inner wing panels.

U U 22. Use a bar sander and 220-grit sandpaper

to carefully remove any glue blobs and blend all the

ribs/ spars/ TE and LE.

Q 23. Arrange the plan so the left outer wing panel

is on your building board. Cover it with wax paper.

Return to step 1 and build the left wing panel the

same way as the right. Don't forget to switch to the

left wing panel plan so you do not build two right

panels.

17

Page 18

PREPARE THE PANELS

FOR JOINING

LJ 1. Use your razor plane or a hobby knife to

shave the sharp corners of the leading edge of one

of the wing panels. Round and final shape the

leading edge with a bar sander and 150-grit

sandpaper according to the cross section on the

right wing panel drawing on the plan. Shape the

remaining wing panels the same way.

Note: The Piece 0' Cake is a motor glider, not a

high performance acrobatic model - it's named the

"Piece 0' Cake" after all! It is not critical that you

shape the leading edges with the greatest precision.

You probably would not notice a difference in the

flight performance of a Piece 0' Cake with an

accurately finished leading edge and a Piece 0'

Cake with a leading edge roughly carved to shape

with a hobby carving knife. This isn't to say that you

should not always strive for building accuracy and a

good finish, but don't worry if your LE's don't look

perfect. Building a straight fuselage and flat, warp

free wings are areas where you should concentrate

most of your building efforts.

U2. Use a sanding block or your 5-1/2" bar

sander and 220-grit sandpaper on all four wing

panels to remove any glue blobs and blend all the

ribs to the spars/ LE and TE.

JOIN THE INNER WING PANELS

to decrease the height of the dihedral brace if needed

so it fits between the top and bottom spar.

Q

2.

Test

fit

the

dihedral brace in the

panel. Without using any glue, join the panels with

the dihedral brace and the shear webs you cut

earlier, then temporarily clamp them together with

C-clamps, spring clips or clothespins. Make sure the

tops of ribs W1 and the bottom sheeting of both

wing panels align.

01 3. Test fit a 1/16" die-cut plywood forward

dihedral brace DB1-B between the W1 ribs and the

leading edges. The top of DB1-B should be 1/16"

below the LE's to accommodate the 1/16" top center

section wing sheeting that will be added later.

Q 4. After making any adjustments required so the

wing panels fit together and align, separate the wing

panels. Remove the dihedral braces and the shear

webs.

other

wing

LJ

1.

Test

fit a

1/16"

die-cut

brace DB1-A in the left wing panel. Use a bar sander

plywood

center

dihedral

U 5. Gather a stack of books, balsa blocks or

something similar to prop up the end of one of the

wing panels 3-1/2".

LJ 6. Lay a piece of wax paper on your building

table. Mix a batch of 30-minute epoxy. Coat all the

joining surfaces with 30-minute epoxy, then join the

inner wing panels with the dihedral braces and

install the balsa shear webs. Place the wing on the

wax paper on your building table. Immediately

proceed to the next step.

18

Page 19

LJ 7. Clamp the wing halves together. Then prop up

one of the tips so it is 3-1/2" above your table.

Q Q 4. Clamp the wing halves together. Then prop

up the tip so it is 3-1 /2" above your table.

1 8. Wipe away excess epoxy before it cures and do

not disturb the wing panel until the epoxy if fully cured.

JOIN THE OUTER AND INNER

WINGPANELS

Q Q

1.

Test

fit the left outer

inner panel with DB1-A , DB-2 and the shear webs.

If needed, adjust the dihedral brace so they fit.

Temporarily clamp the panels together with C-

clamps, spring clips or clothespins and make sure

ribs W3-T align.

Q Q 2. After making any adjustments required so

the wing panels fit together and align, separate the

wing panels and remove the dihedral brace and the

shear webs.

U U 3. Lay a piece of wax paper on your building

table. Mix a batch of 30-minute epoxy. Coat all the

joining surfaces with 30-minute epoxy, then join the

wing panels with the dihedral brace and install the

balsa shear webs.

wing

panel

to the left

Q Q 5. Wipe away excess epoxy before it cures

and do not disturb the wing panel until the epoxy is

fully cured.

Q 6. Return to step 1 and join the panels of the

other wing half the same way.

FINISH THE WING

Q 1. Final-sand the wings with your bar sander and

320-grit sandpaper and blend the LE's where they

meet at each panel joint.

Q 2. Use the remainder of the 1/16" x 3" x 30"

balsa sheet you used to sheet the bottom center

section of the inner panels to sheet the top center

section of the inner panels.

d 3. Use your bar sander and 220-grit sandpaper

to blend the top and bottom center section to the rest

of the wing.

19

Page 20

LJ 4. Use your bar sander to bevel the top edges of

the die-cut plywood wing protectors. Glue the wing

protectors to the top of the trailing edge of the wing

with medium CA so the inner edges are 3/4" from

the centerline of the wing.

Q 4. Remove the T-pins, then lift F2 from the plan

and peel off the wax paper. Reinforce the glue joints

in the corners with medium CA.

Q 5. Build F3 and F4 from the 1/8" x 1/4" x 24"

balsa stick the same way you built F2.

BUILD THE FORMERS

I—I 1. Arrange the plan so the fuselage drawing is

over your building board. Then cover the drawings

of F2,F3 and F4 with wax paper.

Q 2. Make the two vertical side pieces of F2 from the

1/4" x 1/4" x 15" balsa stick you used for the wing

gussets. Pin them in position over the plan.

LJ 3. Cut the horizontal pieces or F-2 from the same

balsa stick. Glue them in position with thin CA.

PREPARE THE FUSE SIDES

LJ 1. Remove the 3/32" die-cut balsa fuselage

sides from their die sheets. Temporarily pin them

together and use your bar sander and 150-grit

sandpaper to remove slivers or die-cutting

irregularities, and make sure the sides are identical.

LJ 2. Separate the fuse sides, then lay them on your

work bench as a mirror image and mark one as the

right inside and the other as the left inside.

20

Page 21

Q 3. Use a sharp hobby knife and a straightedge to

cut 1 /8" off the front of only the right fuselage side.

CJ 4. Push a large T-pin through the punch marks that

are on the outside of the right fuselage side to transfer

the punch marks to the inside. Use a straightedge to

draw a line with a ballpoint pen connecting the punch

marks that indicate where the formers are located on

the inside of both fuselage sides.

U 6. Glue a 1/4" x 30" balsa triangle stick to the

inside right fuselage side top as shown on the plan.

Note that the stick "ends" approximately 2-1/4"

from the back of the fuselage and you will have to

cut the stick into two pieces at the front of F3. Do not

glue a triangle piece to the fuselage side at the top

of the hatch compartment until instructed to do so.

LI 7. Glue a 1 /4" x 30" balsa triangle stick to the

bottom inside of the right fuselage side as shown on

the plan. The front of the stringer extends all the way

to the front of the fuselage and like the top triangle

stick, is cut into two pieces at the front of F3 and ends

approximately 2-1/4" from the back of the fuselage.

Q 5. Make two 2-1/2" long servo rail supports

from the remainder of the 1/8" x 1/4" balsa stick

you used to make fuselage formers F3 and F4. Glue

the supports to the inside of both fuselage sides in

the location shown on the plan and in the photo.

Q 8. Glue two more 1/4" x 30" balsa triangle

sticks to the inside of the left fuselage the same way

as the right.

JOIN THE FUSELAGE SIDES

Q 1. Test fit but, do not glue, all three formers to the

right, then the left fuselage side. If necessary, adjust the

45 degree angle on the corner of each former so the

sides of the formers fully contact the fuselage sides.

21

Page 22

LI 2. Position former F2 on the right fuselage side so

the aft edge aligns with the guideline you made. Use

a builder's triangle to hold the former perpendicular

to the fuse side. Glue it in position with thin CA.

Q 3. Glue former F3 to the right fuselage side the

same way.

D 4. Without using any glue, join the left fuselage

side to the right fuselage side. Then place the

assembly over the top view of the fuselage plan.

Q 5. Align F2 and F3 and the fuselage sides

between F2 and F3 with the plan. Align F2 and F3

with the guide lines on the left fuselage side, then

hold the fuselage to the plan so the sides are

parallel. Check and double check that everything

aligns. Finally, use thin CA to tack glue the formers

to the left fuselage side.

Q 6. Inspect the fit and alignment of the fuselage

sides and the formers, then securely glue the formers

to the fuselage sides with medium CA.

Q 8. Accurately align F4 with the guidelines you

drew and align the top and bottom of the aft

fuselage sides. Glue F4 in position with thin CA.

Q 9. Remove the rubber bands. Temporarily clamp

the ends of the fuselage together with a piece of

1 /8" x 1 /4" balsa to simulate the spacing of the fin

TE. If necessary, trim the triangle sticks at the aft

ends so they do not interfere.

LI 10. Position the 1/8" x 1/4" balsa spacer and

the clamp so the top of the fuselage aft of F3 will

fully contact the plan. Align the top of the fuselage

sides aft of F3 with the plan, then pin the fuselage

sides to your building board over the plan.

Ql 7. Position former F4 between the fuselage sides.

Hold the rear of the fuselage sides together with a

few small rubber bands.

Q 11. Use a builder's triangle to align the front of

the fuselage over the plan, then use thick balsa

blocks (you may use the cowl blocks) pinned to the

building board to hold the front of the fuselage in

alignment over the plan.

22

Page 23

U 12. Use your bar sander and 150-grit sandpaper

to sand the bottom of the fuselage sides aft of F3 so

the formers and fuselage sides are even. Make sure

the clamp and the 1/8" x 1/4" spacer in the back

of the fuselage sides will not interfere with the

bottom sheeting (we had to replace the paper clamp

shown in previous photos with a clothespin and

shorten the balsa spacer).

SHEET THE BOTTOM OF

THE FUSELAGE

Q

1.

Test

fit,

then glue the

balsa sheet to the bottom of the fuselage so the front

edge "ends" in the middle of F3.

1/16" x 2-1/4" x 20"

U 4. Use the mark as a guide to cut the angle for the

right thrust at the front of the fuse bottom with a

straightedge and a hobby knife. Test fit, then use

medium CA to glue the forward fuse bottom in position.

Q 5. Use your bar sander with 150-grit sandpaper

to sand the edges of the forward fuse bottom so they

are even with the fuselage sides.

INSTALL THE FIREVVALL

U 2. Remove the T-pins, then lift the fuselage from the

plan. Reinforce the joint between the aft fuse bottom

and the triangle stock from inside the fuselage with

thin CA. Use a hobby knife, then your bar sander with

150-grit sandpaper, to trim the excess bottom sheeting

so it is flush with the fuselage sides.

Q 3. Position the 1/16" x 2-1/4" x 11-1/4"

plywood forward fuselage bottom on the fuselage.

Mark the front of the right fuselage side on the fuse

bottom.

Q 1. Cut two of the remaining pieces of 1 /4" triangle

stock to the correct length. Glue them to the top of the

hatch area in the front of both fuselage sides.

Q 2. Cut, then glue the remaining pieces of 1/4"

balsa triangle stock to the sides, then to the bottom

of the front of the fuselage.

Q 3. Glue the die-cut 1/16" plywood H1 forward

hatch compartment top in position. Cut and glue the

last piece of 1/4" triangle stock underneath it. The

top and bottom triangle pieces are a little difficult to

make fit perfectly because of the "double taper"

required in the comers, but don't worry - most of

the strength is gained along the sides of the triangle

pieces.(See the photo that follows.)

23

Page 24

LJ 4. Use a large sanding block and 150-grit

sandpaper to sand the triangle pieces, fuselage

sides, fuselage top and fuselage bottom so they are

all flat and even.

Q 5. Glue the 1/8" plywood firewall F1 to the front

of the fuselage with 30-minute epoxy. Use masking

tape to securely hold the firewall to the front of the

fuselage until the epoxy fully cures.

LJ 6. Use your bar sander and 150-grit sandpaper

to sand the edges of the firewall flush with the

fuselage sides, top and bottom.

Q 1. Use the 1/8" x 3/8" x 12" plywood stick to

make two servo rails that rest upon the servo rail

supports between the fuselage sides. Fit but do not

glue the servo rails in position, then place your

servos on the rails.

Q 2. Place servo wheels or short servo arms on

your servos, then position the servos so the arms or

wheels will not interfere. Adjust the servo rails so

they are parallel and allow enough space for you to

remove the servos. Carefully (without gluing the

servos to the rails) glue the rails to the rail supports

with medium CA.

Q 3. Remove the servos, then securely glue the rails

to the rail supports and the fuselage sides with

additional medium CA.

Reinstall

the

servos,

then

drill

1/16" holes through the rails and mount the servos

with the wood screws included with your radio.

Q 4. From the remaining piece of the 1 /4" x 1 /4"

balsa stick, make a forward and an aft pushrod

guide tube support to fit between the fuselage sides

in the location shown on the plan. Test fit the

supports to make sure they are the correct length.

FRONT GUIDE

TUBE SUPPORT

2-1/16"

AFT GUIDE

TUBE SUPPORT

1-7/16"

INSTALL THE SERVOS &

PUSHROD GUIDES

Refer to this photo for the following three steps.

TO MATCH

SERVO WHEELS

MAKE FROM 1/4"

DRILL TWO 9/64"

EVENLY SPACED.

X 1/4" BALSA.

HOLES

Q 5. Drill 9/64" holes through the supports in the

locations shown in the sketch. The holes in the front

support should match the spacing of the holes you will

connect your pushrods to in your servo wheels. If you

do not have a 9/64" drill bit, you may use a 1/8"

drill instead, but insert one of the outer guide tubes in

the holes and spin it around to enlarge the hole so the

guide tubes can slide through a little easier.

24

3/8"

Page 25

LJ 6. Reinstall, but do not glue, the guide supports in

the fuselage, then cut the 36" outer guide tubes into

two 23" long pieces. Roughen the outside of the guide

tubes with 150-grit sandpaper so glue will stick. Then

slide them through the slots in the back of the fuselage

and route them through the guide supports.

U 8. Position the aft support so the guide tubes

make a smooth transition from the slots at the back

of the fuselage to the front support. Glue it to the

fuselage sides and F4 with thin CA.

SCREW-LOCK

CONNECTOR

POSITION THE FRONT GUIDE TUBE

SUPPORT SO THE PUSHROD WIRES

ALIGN WITH THE SCREW-LOCK

PUSHROD CONNECTORS.

4-40x1/8" Cap Screw

Pushrod Connector

Servo Arm

Nylon Retainer

PUSHROD

PUSHROD WIRE

Pushrod

U 7. due the guide tubes to the slots in the back of

the fuselage with microballoons and epoxy.

Microballoons are a powder that you can mix with

epoxy to make a sandable filler where a bond is

required. If you do not have microballoons, glue the

tubes to the fuselage sides with medium CA, then fill

the rest of the slot with HobbyLite filler.

LJ 10. Use your bar sander and 80-grit sandpaper

to sand the guide tubes and filler flush with the

fuselage sides.

Q 7. Insert a Screw-Lock Pushrod Connector in both

servo wheels. Slide the 1/16" x 36" pushrod wires

included with this kit through the guide tubes and

accurately align the front support so the wires pass

through the pushrod connectors. Use thin CA to glue

the front support to the fuselage sides.

U 11. Glue the pushrod guide tubes to the supports

with medium CA.

SHEET THE TOP OF THE FUSE

CJ 1. Use your bar sander and 80-grit sandpaper to

sand the tops of the fuselage sides and the tops of

the formers so they are even. Clip clothespins to the

top of the fuselage sides in the wing saddle area,

then place a long straightedge such as a metal ruler

on the saddle leaning against the clothespins.

25

Page 26

Q 2. Place the stab on the back of the fuselage with

a small weight on top of the middle of the stab.

Stand back from the fuselage and view the

straightedge and the stab. If necessary, use your bar

sander with 80-grit sandpaper to carefully sand the

tops of the fuselage sides until the stab aligns with

the straightedge.

Q 5. With the stab in position on the fuselage, use a

ballpoint pen to mark the location of the leading

edge of the stab on the top of the fuselage sides. This

indicates where the top fuselage sheeting "ends."

U 6. Sheet the top of the fuselage with the

1/16" x 3" x 12" balsa sheet between F3 and the

marks indicating the LE of the stab. Apply the

sheeting in "planks" running cross-grain as shown

on the fuselage plan.

U 3. Mark the top of the fuse sides 1/4" from the

end. Use the marks as a guide to cut a notch for the

leading edge of the elevator.

LJ 4. Place the stab and elevator on the fuselage so

the aft edge of the elevator leading edge is 5/16" in

front of the aft end of the fuse. Move the elevator up

and down to adjust the notch if the fuselage

interferes with the elevator LE.

U 7. Use your bar sander and 150-grit sandpaper

to sand the edges of the fuselage top even with the

fuselage sides.

LJ 8. Use medium CA to glue the die-cut 1/16"

plywood H4 aft hatch compartment top to the

26

Page 27

fuselage. Then glue the 1/16" die-cut plywood H3

hatch ledge to the bottom of the aft hatch

compartment top so 3/8" protrudes in front of H4.

Glue a piece of 1/16" leftover plywood to the

bottom of the ledge for the hatch screw.

l-l 9. Trim the 1/16" plywood hatch to it fits

between the front and aft hatch compartment tops.

Don't make it fit too tight; leave a little space for the

iron-on covering.

Q 10. Glue the plywood H2 hatch tab to the bottom

of the hatch so only 1/8" of the tab protrudes past

the front of the hatch. Fit the hatch to the

compartment, then drill a 1/16" hole through the

hatch and the ledge.

when positioned on the fuselage. Use medium CA to

glue the windshield in position. Then sand the edges

flush with the fuselage.

1/8"

FUSELAGE

BOTTOM

1/8"

Q 11. Remove the hatch and enlarge the hole in the

hatch only with a 3/32" drill bit. Reinstall the hatch,

then secure it to the fuselage with a #2 x 3/8" screw.

Sand the edges of the hatch even with the fuse sides.

Q 12. Trim the front of the 9/16" x 2-1/4" balsa

windshield so it does not interfere with the hatch

3-7/8"

3/32"

Q 1. Drill 3/32" holes for the landing gear in the

fuse bottom where shown in the sketch. Bevel the

inner edges of the holes on the fuse bottom so the

landing gear will rest flush.

1—1 2. Cut two 2-1/4" landing gear rails from the

remainder of the 1/8" x 3/8" plywood stick you

used for the servo rails. Fit the landing gear in the

fuselage, then use medium CA to glue the rails to the

fuse bottom behind and in front of the landing gear.

(See the following photo.)

27

Page 28

LJ 3. Use your bar sander with 80-grit sandpaper to

sand the ends of the landing gear rails so they are

flush with the fuselage sides. Bevel the corners for a

neater appearance.

LJ 4. Center the 1/16" plywood landing gear plate

on the landing gear rails. Drill four 1/16" holes

evenly spaced 1/4" from both ends of the plate.

Remove the plate, then enlarge the holes in the plate

only with a 3/32" drill bit.

MOUNT YOUR ENGINE

U 1. Center your engine on the firewall, then mark

the location of the mounting holes. Drill 1/16" holes

at the marks and temporarily mount your engine

with #2 x 3/8" screws (not included).

U 2. Glue both 3/8" x 2" x 1-7/8" cowl side

blocks to the firewall with medium CA.

Q 5. Temporarily mount the landing gear in the

fuselage with the landing gear plate and four #2 x

3/8" screws.

LJ 6. Make four 1/4" x 5/8" landing gear bearing

plates from leftover 1/16" plywood. Use medium

CA to glue them to the fuselage sides next to the

landing gear. Make sure the landing gear is straight

and perpendicular to the fuse bottom.

Q

3.

Test

fit and shape a 3/8" x 1-1/2" x 1-3/4"

cowl bottom block so it fits between the side blocks

on the bottom of the fuselage. Lightly push the

bottom block into the bottom vent tube on the engine

so the tube leaves a mark on the block, then drill a

3/16" hole through the block at the mark. Glue the

block in position with medium CA.

28

Page 29

Q 4. Remove the engine (so it does not get balsa

dust in it), then sand the cowl blocks so they are flush

with the fuselage. Round the front edges of the cowl

blocks for a finished appearance. Start with your

bar sander and 80-grit sandpaper, then finish by

hand-sanding with 320-grit sandpaper. Reinstall

your engine just to see how it looks!

3/8"

5/16"

5/16"

1/8"

F-3

Q 5. Drill 3/16" holes in the fuselage sides at the

locations shown in the sketch for the wing dowels.

Cut the 6-1/2" dowel in half. Use sandpaper to

chamfer the ends of the wing dowels, then test fit

them in the fuselage, but do not glue the dowels in

place until instructed to do so.

U 2. Accurately mark the center of the fuselage top

sheeting at the front over F3 and at the rear. Position

a straightedge on the fuse top and align it with the

centerlines you marked. Then place the stab on the

fuselage and align the centerline of the stab with the

straightedge. Temporarily attach the stab to the

fuselage with T-pins.

Q 1. Remove the elevator from the stab, then mark

the center of the stab. Use a builder's triangle to

mark a centerline on the top of the stab at the mark.

U 3. Carefully turn the fuselage over and lightly

mark the outline of the fuselage sides on the bottom

of the stab. This line indicates where to apply the

covering "up to" and apply glue when it is time to

glue the stab to the fuse.

29

Page 30

Q 4. Align your straightedge with the marks on the

fuse top again, then lightly mark a 1" long centerline

on the fuse top in front of the LE of the stab.

ALIGN THE FIN

Q 1. Position the fin on the stab with the trailing

edge of the fin between the fuse sides.

Q 2. Cut the 3/16" x 3/16" x 6" balsa stick into

two 2-1/2" long pieces. Use your hobby knife to

carve them into triangle pieces (like the 1/4"

triangle stock used in the fuselage), then round the

ends. These are the fin braces.

Q 5. Align the fin with the centerline you marked on

the top of the fuselage, then pin the front of the fin to

the fuse sheeting with one small T-pin. Lightly trace

the outline of the fin on the fuse top and the outline

of the fin and triangle fin braces onto the stab, and

trace the outline of the fin braces onto the fin. These

lines will be guide lines for covering so you can glue

the fin and triangle pieces to bare balsa after you

cover them.

d 6. Cut the notch in the fin the same as you did on

the fuselage to allow the elevator to move up

and down.

Q 3. Temporarily place the fin braces on the fin and

the stab.

LJ 4. Use medium CA to glue a piece of leftover

1/16" balsa to the bottom of the fin in front of the

stab to fill the space.

PREPARE THE MODEL

FOR COVERING

Q 1. Remove the fin and stab from the fuselage.

Inspect the wing, fuselage, and tail surfaces for glue

joints that don't look strong and reinforce them with

thin or medium CA.

30

Page 31

U

2.

Test

fit

the

wing

on the fuselage.

knife and a bar sander with 150-grit sandpaper to

shape the top of F2 and the windshield so the wing fits.

Q 3. Remove the engine, pushrods, landing gear,

hatch, wing dowels and any other hardware that

may interfere with covering.

Use a hobby

does not pull on the airframe as much as MonoKote

film. Therefore, EconoKote film is ideal for lighter

weight structures like your Piece 0' Cake, especially

the tail surfaces.

If this is the first time you have covered a model

refrain from attempting a complicated trim scheme.

Add stripes, graphics, and various designs to your

Piece 0' Cake cut from different colors of EconoKote

film, then iron them directly over the base color.

Self-adhesive trim sheets may also be used. Try only

a single color base (usually a lighter color such as

white or yellow) with perhaps a single stripe, your

AMA number, or even some stick-on graphics. A

simple trim scheme will get you in the air faster and

look much better than a model that was difficult to

cover because of a complicated trim scheme.

U 4. Fill dents, scratches and glue joints on the

surface of the model that may show through the

covering with HobbyLite filler. Slightly round the

top and bottom corners of the fuselage and the

windshield with your bar sander and 220-grit

sandpaper, then sand the fuselage so it is smooth

and even.

COVERING TIPS

We recommend you cover your Piece 0' Cake with

Top Flite EconoKote® iron-on model covering film.

EconoKote film is similar to famous Top Flite

MonoKote® covering film except that EconoKote film

is lighter weight, requires less heat to apply and

HOW TO COVER YOUR MODEL

We will use the stabilizer as an example because

the techniques shown apply to the rest of the

Piece 0'Cake.

Q 1. Here is a "rule of thumb" to keep in mind before

you begin: Where possible, apply the covering so all

seams face downward or rearward. You can do this by

covering the bottom (of the wing, fuse, stab, etc.) first.

Never cut the covering after you iron it to the

wood except near the tips. Modelers who do this

may weaken the structure which could cause it to

fail during flight.

31

Page 32

U 2. Cut the covering for one half of the bottom of

the stab so it is approximately 2" oversize. Use a

straightedge to cut the end that aligns with the lines

you drew that indicate the fuselage. Use a Top Flite

MonoKote Iron with a Hot Sock to securely bond the

covering to the perimeter (LE, TE, tip, middle) of

the stab.

Ll 4. Seal the front, rear and tip of the covering to

the stab. Then heat the covering as you pull and

stretch it around the tip. It takes a little practice to get

all the wrinkles out so don't be discouraged if it

doesn't look perfect on your first attempt (or the

second or third time). You can reheat and stretch the

covering many times. It helps to place the stab on

your work bench or a stand so the tip is over the

edge, and place a weight on top of the stab to hold

it down. This will allow you to pull the covering with

one hand and hold the iron in your other hand.

Q 3. Place the stab right side up on your building

table (preferably on a cutting mat if you have one)

and use a straightedge to trim the covering about

3/32" from the LE, TE and tip, but leave a "handle"

at the corner so you can stretch the covering around

the tip as you heat it.

LJ 5. Cut the excess covering from the tip with a

single-edge razor blade or a sharp hobby knife.

32

Page 33

Ul 6. Cover the other bottom stab half the same way.

LJ 10. Cover the triangular fin reinforcements. Trim

the excess so it "overhangs" the edges by

approximately

way all you have to do is glue the fin reinforcements

to the fin and stab and seal the edges with the iron.

3/32".

Don't

iron

it

down

yet.

This

CJ 7. Cut the covering for one half of the top of the

stab so it is approximately 2" oversize. Before you

iron it down, trim the covering so it aligns with the

lines you marked indicating the fin and triangle fin

reinforcement. This will allow you to glue the fin

reinforcements directly to the bare wood and avoid

cutting the covering directly on the wood after you

iron it down.

LJ 8. Iron the piece of covering you just "custom cut"

to the top of the stab. Then make the other side the

same way and iron it in position.

U 11. Use the same methods described above

to cover the rest of the model using the correct

Covering Sequence.

COVERING SEQUENCE

Tail Surfaces:

1. Elevator bottoms, then tops

2. Fin right, then left

3. Rudder right, then left

Fuselage:

1. 1 /8" Plywood landing gear mounts on the bottom

of the fuselage

2. Bottom behind the landing gear mounts, then in

front of the landing gear mounts

3. One side, then the other

4. Top forward, then aft of the wing saddle

5. Front windscreen area

6. Hatch

7. Landing gear plate (or you could paint it instead)

Q 9. Align the elevator with the stab, then transfer

the hinge slots from the elevator (since they are

visible and you have not yet covered over them) to

the stab by marking them on the covering with a

felt-tip pen.

Wings;

1. Tips

2. Bottom inner panels

3. Bottom outer panels

4. Top inner panels

5. Top outer panels

33

Page 34

SHAPE THE FLYING SURFACES

Q 1. Due to the lightweight structure of the Piece 0'

Cake and the shrinkage of the covering, the wing,

fin, rudder, elevator and stab can warp or twist.

Correct the twists by carefully twisting the part in the

opposite direction of the built-in twist, then heat the

covering with your iron or heat gun until the twist is

removed and the part is flat.

Add "washout" to the wing tips. Washout is where

the trailing edge of the wing at the tip is twisted

upward. This gives the wing tip a lower angle of

attack than the rest of the wing and will reduce the

tendency for the wing to "tip stall."

JOIN THE TAIL SURFACES TO

THE FUSELAGE

LJ

1.

Test

fit the stabilizer and fin to the

make sure none of the covering interferes with the

glue joints and areas that are exposed balsa.

LJ 2. Apply a film of 30-minute epoxy to the

exposed balsa on the bottom of the stab and the

stab saddle area of the aft fuse. Then position the

stab on the fuse. Use the centerlines on the top of the

stab and fuse, and the exposed balsa on the bottom

of the stab, as a guide to align the stab with the fuse.

Use T-pins, weights or clamps to hold the stab to the

fuse until the epoxy fully cures. Use a cloth

dampened with alcohol to wipe away excess epoxy

before it cures.

fuselage

to

LJ 2. Lay the outer panel of the right wing on your

building table. Place a 1/4" piece of balsa under

the wing tip at the trailing edge. Heat the covering

until the wrinkles disappear and the wing will stay

twisted without the shim. You may have to heat the

bottom of the outer wing panel too.

Q 3. Add washout to the left outer panel the same

way. Make sure the inner wing panels are flat and

warp free as described in step 1.

LJ 3. Use epoxy to glue the fin to the stab and fuse.

While you align the fin, use a builder's triangle to

make sure the fin is perpendicular. Use T-pins to hold

the fin in position until the epoxy fully cures. Some

modelers may prefer to glue the fin in position with

medium CA and this is acceptable as long as you

can achieve proper alignment before the CA cures.

CJ 4. Test fit the fin reinforcements to the fin and

stab/ then glue them in position with medium CA.

34

Page 35

Q 5. Use a Trim Seal Tool or a MonoKote Iron

to seal the perimeter of the covering on the

reinforcements to the fin and stab.

the center of the hinge, then join the surfaces and

remove the pins.

Q 3. Confirm that the ends of the elevator align with

the ends of the stab, that the hinges are centered,

and there is a small gap between the stab and

elevator (just enough to see light). A small gap is

desirable so you do not inadvertently glue the

elevator to the stab.

Q 6. If necessary, cut 1/4" strips of covering and

use your Trim Seal Tool to iron the strips in the

"corners" where the bottom of the stab meets the

fuse and the fin meets the top of the fuse.

HINGE THE CONTROL

SURFACES

Make sure you join the elevator to the stab first,

then join the rudder to the fin.

CUT THE COVERING

AWAY FROM THE SLOT

LJ 1. Use your hobby knife and a sharp #11 blade

to remove a small strip of covering from the hinge

slots to expose them.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

0 2. Join the elevator to the stab with the hinges. If

the hinges will not stay centered, stick a pin through

Q 4. Carefully apply 4-6 drops of thin CA to both

sides of the hinges. Keep a cloth handy to wipe

away excess CA. If you spill a few drops of CA

on the covering, you can use CA Debonder

(GPMR6039) to remove it, or carefully peel it off

with a hobby knife after it fully cures.

Do not use accelerator on any of the hinges. Do not

glue the hinges with anything other than thin CA

and do not attempt to glue one half of the hinge at

a time with medium or thick CA. They will not be

secure and the controls could separate while the

model is flying.

Q 5. Let the CA fully cure, then carefully flex the

elevator several times to check the movement.

Q 6. Hinge the rudder the same way as the stab.

FUELPROOFING

Use 30-minute epoxy thinned with alcohol or

fuelproof model airplane paint to coat areas that

may be exposed to raw fuel or exhaust residue.

These areas include the firewall, inside the cowl

sides and bottom, the underside of the hatch, the

landing gear plate (if you did not cover it with

iron-on film), and inside the fuselage around the

wing saddle area.

35

Page 36

CONNECT THE SERVOS

I,.) 1. Use "Z-Bend" pliers or read the following

procedure to make a "Z-bend" in the end of one of

the 1/16" x 36" pushrod wires.

How To Make A Z-Bend In A Pushrod Wire With

Regular Pliers

A. Make a sharp "L-Bend" 1/8" from the end of

the wire.

B. Grip the first bend in your piiers and make another

90 degree bend in the wire 1 /8" behind the first.

C. Hold the "bends" in the pliers, then make a third

bend aligning the first two bends to make the

Z-bend.

Q 2. Use a new #11 blade to cut the covering from the

pushrod guide tube exits in the rear of the fuselage,

then temporarily mount a Screw-Lock Pushrod

Connector to the rudder servo wheel. Slide the pushrod

wire with the Z-bend into the pushrod guide tube

through the back of the fuselage and into the pushrod

connector on the elevator servo. Connect a small

control horn to the pushrod wire.

36

Page 37

RIGHT WRONG

LJ 3. Position the control horn on the right side of

the rudder so the holes in the control horn align with

the hinge gap.

LJ 7. Mount the engine to the firewall.

Q 8. Mount the landing gear in the fuselage with the

mount plate and four #2 x 3/8" screws, then mount a

1-1/2" wheel with a 3/32" wheel collar (not

included, GPMQ4302) on each landing gear wire.

I—I 9. Use a sharp hobby knife to lightly cut a small

strip of covering from the bottom of the fuselage