Dynacut MDM Operation Manual

Minimum quantity lubrication system MDM

for external lubrication.

Operation manual.

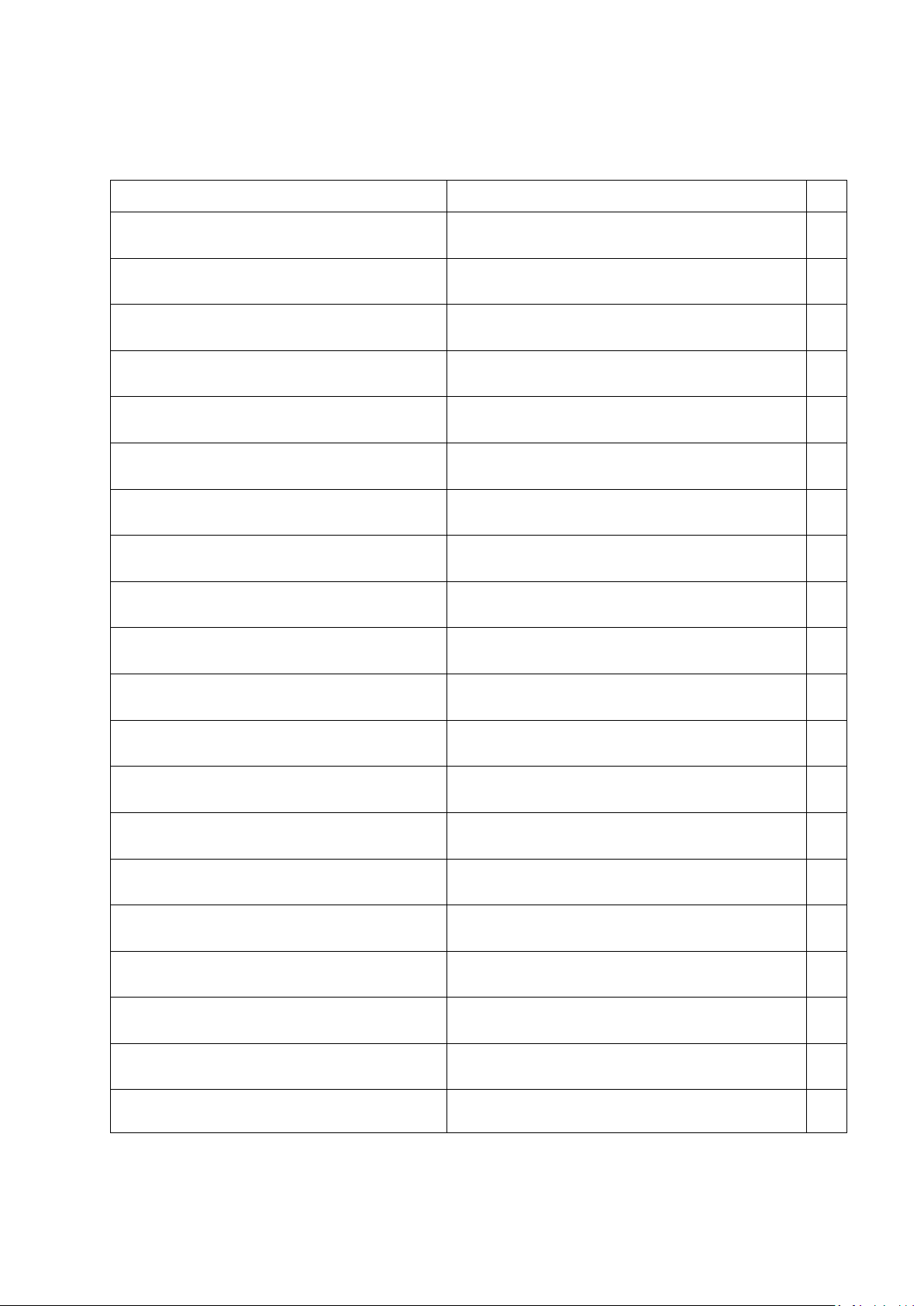

Table of contents

Table of Contents

2

Foreword

3

Instructions for use

4

Intended use

4/5

Safety instructions

5/6

Function description

7

Aerosol generation

7

Layout and function

7/8

Pictorial representation

9

Controls

10

Assembly

11

Initial filling

12

Commissioning

13

Flooding of the transport lines

13

Default

14

Check the settings

14

Switch off the system

15

Maintenance

15

Cleaning

15

Decommissioning

16

Technical specifications

16

Foreword

We would like to thank you for your confidence in our product.

With the acquisition of a DYNACUT-MDM minimum quantity lubrication system for external

lubrication, you have decided to use environmentally friendly and economical technology. Our

high-quality minimal-quantity lubrication systems have been designed for use on modern

machine tools. DYNACUT minimum quantity lubrication systems for external lubrication are

built according to the generally recognized rules of technology and comply with the applicable

occupational safety and accident prevention regulations. However, hazards may arise during

their use, which can lead to physical damage to the user or to third parties or to damage to

the machine tool or other property.

In order to ensure trouble-free operation and to avoid dangers, please read this operating

instructions carefully and observe the notes contained therein.

Dynacut UG (haftungsbeschränkt)

Gewerbering 3

48734 Reken

E-Mail sales@dynacut.eu

Homepage www.dynacut.eu

Instructions for use

Texts marked with this symbol indicate special dangers or mark work which requires

special caution.

This manual contains a general description of the system, as well as instructions for installation

and operation. The system also examines the specificity of the system.

Use the table of contents to find the information you need quickly and securely.

This operating manual is an integral part of the system and must be handed over to the new

operator when the system is sold.

Intended use

The DYNACUT-MDM minimum quantity lubrication must only be used and used

according to the instructions given in the operating instructions.

In particular, we would like to point out that hazardous substances of any kind, especially

substances classified as dangerous according to EC Directive 67/548 / EEC, Article 2, paragraph

2, as well as liquids such as chlorinated hydrocarbons, solutions with alcohol contents of more

than 30% Gasoline, nitro lacquers and nitro diluents (solvent mixtures for nitro lakes from

hydrocarbons and esters) and concentrated acids must not be filled into and distributed with

DYNACUT minimal-quantity lubrication systems and components and / or distributed with

them.

The minimum quantity lubrication system described here is intended exclusively for the

external lubrication of machining and forming processes. During external lubrication, the

lubricant is transported directly to the friction point between tool and workpiece via spray

nozzles, which are attached to the machine tool. Depending on the type of processing, one or

more spray nozzles per tool can be used.

The DYNACUT-MDM minimum quantity lubrication system can be used both for the initial

equipment of processing machines and for the retrofitting of processing machines with an

existing cooling lubricant supply.

Any other use or use beyond this is considered to be improper. Dynacut UG is not liable for

damages resulting from this.

The lubricants suitable for use in DYNACUT minimal-quantity lubrication systems for external

lubrication are specially adapted to the high requirements of the technology used in their

chemical and physical properties.

For this reason lubricants suitable for minimum quantity lubrication may be used.

We cannot assume any liability for damage caused by improper use of lubricants or by the use

of lubricants suitable for minimum quantity lubrication.

Safety instructions

Please observe the following safety instructions in order to ensure the trouble-free

functioning of the minimum quantity lubrication system and to avoid damage.

Spraying of lubricants or substances which are released for minimum quantity lubrication

with DYNACUT minimum quantity lubrication systems is not permissible.

Prior to any work on the system, e.g. cleaning or replenishing lubricant, etc., the system must

be disconnected from the compressed air supply and depressurized.

Humans or animals must not be aerosolized. The aerosol must not get into the eyes and should

not be inhaled directly.

We point out that the spraying of mineral oils or mineral oil-containing substances can lead to

health damage.

Any kind of fire e.g. in the form of open flames, sparks, glowing cigarettes, etc., must not get

into the vicinity of the spray jet. The aerosol must not be sprayed on hot surfaces.

The generally valid rules and safety regulations for the work with compressed air and electrical

voltage carrying machinery and equipment must be observed.

The system may only be used in a technically perfect condition as well as in accordance with

its intended purpose, in accordance with safety and driving safety, observing the operating

instructions.

The existing safety devices must not be damaged, immobilized or rendered unusable or

replaced by parts other than those expressly approved by Dynacut UG.

In the event of a fault, the system should be disconnected as soon as possible from the

compressed air and voltage supply, e.g. by actuating the quick coupling on the compressed air

connection and pulling the mains plug.

The unauthorized conversion of the system as well as the use of unauthorized spare parts and

accessories are not permitted.

Used systems must be rendered unusable and then properly disposed of.

Loading...

Loading...