Page 1

POWER AMPLIFIER DPA 4411

Features

OWNER’S MANUAL

Power amplifier with 4x100 W output power capacity according to IEC 283-3

19" - rack size (3 HU) unit that provides the following functions:

• Mains operation 115/230 V AC and operation with emergency power supply of 24 V DC

• Output transformers for balanced, floating 100 V loudspeaker networks: 70 V, 50 V or

4 ohms for low-impedance operation can be selected

• All outputs are protected against idling and short-circuit

• Integrated Remote Module for control and monitoring using the PROMATRIX Manager DPM 4000

• Electronic level controls, electronically balanced inputs and electronically balanced MONITOR output

• Input transformer for balanced, floating inputs can be retrofitted

• Monitor output transformer for balanced, floating MONITOR output can be retrofitted

• Routing switch for parallel operation of the amplifier’s inputs

• Integrated Standby Power Supply

• Mains function switch - POWER

• Ground lift switch

• Remote-Start function for mains and battery operation with inrush current limiter protection

• Power-on noise attenuation

• Status-LED indicators: operation (READY), STANDBY, thermal overload (PROTECT)

and GROUND FAULT at the power outputs

• Fault notification according to DIN EN 60849 via the PROMATRIX Manager DPM 4000

• TEST-switch for systems with average-switching or GROUND FAULT RESET

• LED meters with a range from -13 dB to 0 dB plus CLIP indication

• Mains voltage selector switch 115/230 V AC

• Active, temperature-controlled ventilation

• Modules for pilot tone surveillance and ground fault surveillance according to DIN VDE 0800 are

optionally available

19

Page 2

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintance (servicing) instructions in the

literature accompanying the appliance.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a damp cloth.

7. Do not block any of the ventilation openings.

Install in accordance with the manufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

9. Only use attachments/accessories specified by the manufacturer.

10. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third grounding prong.

The wide blade or the third prong are provided for your safety. When the provided plug does not fit into your outlet, consult an

electrican for replacement of the absolete outlet.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the risk of

electric shock, do not perform any servicing other than that contained in the Operating

Instructions unless you are qualified to do so. Refer all servicing to qualified service

personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to be obeyed when

servicing the appliance.

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is opened, needs to be

operated and is connected to the mains

3. Switch off the power before retrofitting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal enclosure),

respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not connected

to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symb ol (Note) is only permissible

when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced have to be strictly

obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

Note:

SAFETY COMPONENT (HAS TO BE REPLACED WITH ORIGINAL PART ONLY)

20

Page 3

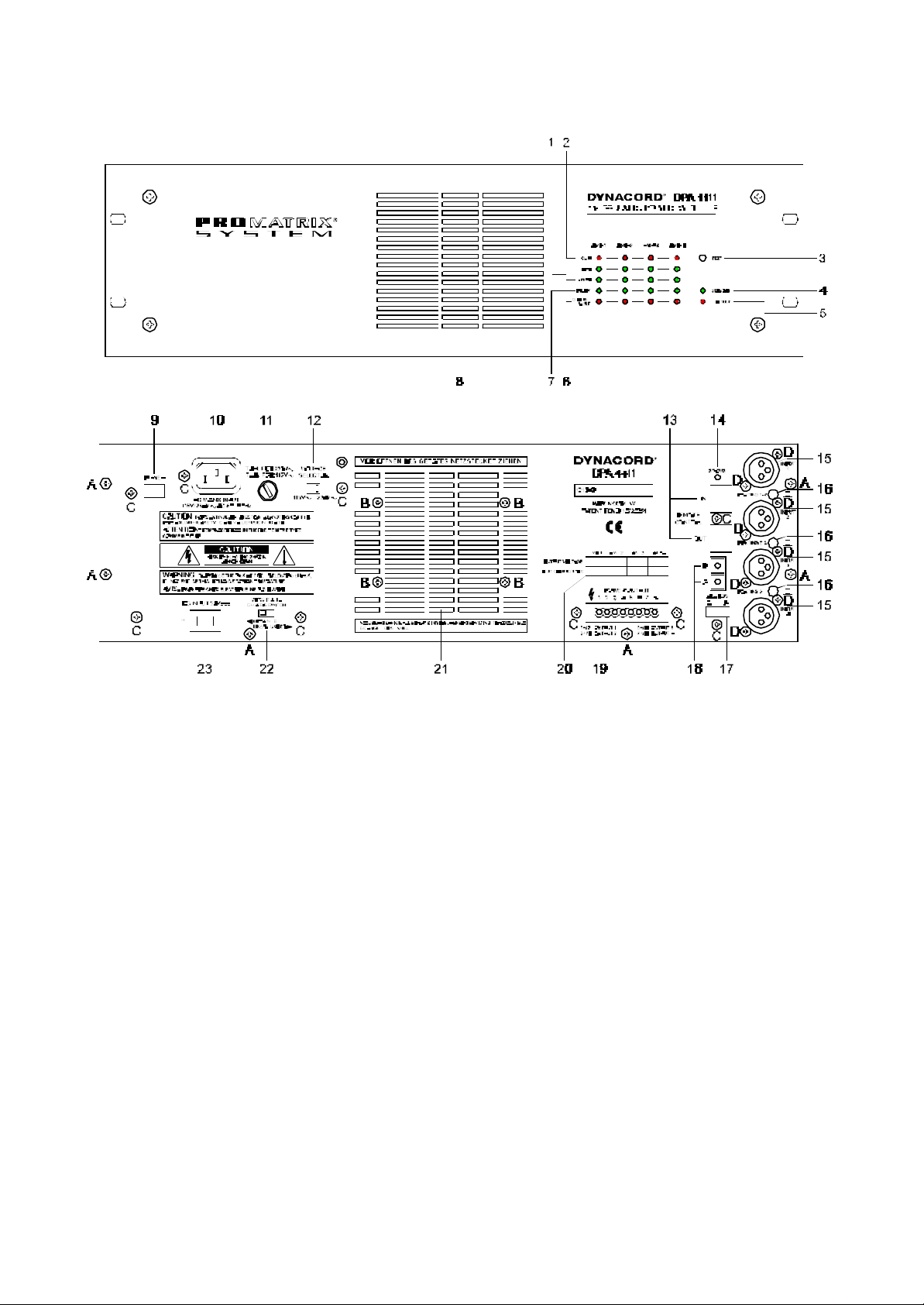

Indicators, Controls And Connections

1 LED meters with a range from -13 dB to 0 dB

2 CLIP indicators

3 TEST button for checking and reset function

4 STANDBY indicator

5 PROTECT indicator

6 GROUND FAULT indicator

7 READY indicator

8 Air inlets

9 POWER ON switch

10 AC MAINS INPUT connector

11 Mains fuse

12 VOLTAGE SELECTOR switch

13 REMOTE CONTROL connectors

14 STATUS indicator

15 INPUT connectors 1-4

16 ROUTING switch for INPUT 1-4

17 Device address label field

18 ADDRESS selector switch

19 POWER OUTPUT

20 Device output configuration label field

21 Air outlets

22 CIRCUIT ⊥ TO CHASSIS SWITCH

23 DC INPUT 24 V =

A Rear plate screws: 6 oval-head sheet-metal screws 3.5 x 6.5 zinc-coated DIN 7981

B heat-sink-mounting: 4 oval-head sheet-metal screws 3.5 x 9.5 zinc-coated DIN 7981

C PCB-mounting: 9 oval-head screws M3 x 12 nickel-plated DIN 7985

D socket-mounting: 8 oval-head screws PT-KA 30 x 8 WN-1412EJOT black, zinc-coated

21

Page 4

Table of Contents

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Indicators, Controls And Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1. Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. Before Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Mains Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Battery Operation 24 V DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5. Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 POWER OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 POWER OUTPUT for the connection of 100 V loudspeaker systems . . . . . . 25

5.3 POWER OUTPUT for the connection of low-impedance loudspeaker systems 25

5.4 POWER OUTPUT 100 V - Double Output Power . . . . . . . . . . . . . . . . . . . . . . 26

5.5 MONITOR Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6. Integrated Remote Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7. Indicators And Fault Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 STANDBY Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 READY Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 PROTECT Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.4 GROUND FAULT Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.5 Meter Instruments And CLIP Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6 STATUS Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8. Switching The Output Voltage (refer to qualified service personnel only!) . . . . . . . 28

9. Additional Functions And Features (refer to qualified service personnel only!) . . 29

9.1 NRS 90206 Pilot Tone Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2 NRS 90207 Ground Fault Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 NRS 90208 Input Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.4 NRS 90227 Monitor Output Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. 19"-Flightcase Or 19"-Rack System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11. Ground Lift Switch CIRCUIT ⊥ TO CHASSIS SWITCH . . . . . . . . . . . . . . . . . . . . 33

12. Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13. DPA 4411 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14. Specifications For DPA 4411 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.1 NRS 90206 Pilot Tone Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.2 NRS 90207 Ground Fault Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.3 NRS 90208 Input Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.4 NRS 90227 Monitor Output Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

15. Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

15.1 DPA 4411 Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

15.2 NRS 90206 Pilot Tone Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

15.3 NRS 90207 Ground Fault Surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

22

Page 5

1. Utilization

The amplifier DPA 4411 has been specially designed to ensure durable performance and reliable

operation of sound reinforcement systems with several independent loudspeaker lines. The DPA 4411 is

best suited for call and message transmission installations, alert systems, and for general music

applications in industrial enterprises, offices, multi-function halls and sport arenas, schools, churches,

hotels, hospitals, super markets, cruise ships, and similar applications.

2. Installation Notes

When installing or mounting the amplifier, it is important to make sure that unhindered air-flow from the

air inlets on the front to the air outlets on the rear of the appliance is guaranteed (see paragraph 10).

To maintain EMV disturbance-free operation, the use of shielded cable for all input, output and control

lines, except for mains supply and battery cords, is mandatory. When installed inside of metal housings

or rack systems, running unshielded output and control lines is possible. Cable screens have to be

connected to the enclosure or rack system ground potential.

The amplifier has to be protected against:

- dropping or splashing water

- direct sunlight

- high environmental temperatures or direct radiation of heat sources

- high humidity and moisture

- dust

- shock or vibration

It is not permissible to place containers filled with liquids - e. g. vases - ontop of the appliance

When moving the amplifier from cold into warm environments, condensation of its inner parts can

sometimes occur. If so, the appliance can be operated again after gaining the environmental temperature

(approximately after one hour).

If a solid object has fallen or liquid has leaked into the device, disconnect all connectors and get in contact

with an authorized DYNACORD service center. Do not operate the amplifier after such accidents.

When cleaning the amplifier’s outside enclosure, never use any cleaning sprays or detergents, because

of inflamability. The use of those liquids will damage the appliance.

3. Before Initial Operation

3.1 Mains Operation

When operated on mains power, use the included mains cord to connect the amplifier to a 230 V or 115

V 50/60 Hz wall outlet. Connect the cable’s other end to the appliance’s 3-pole machine-type socket (10).

Caution The amplifier is factory-set to 230 V AC . To change the setting to 115 V AC, use the

voltage switch (12).

For the operation with 115 V AC , the mains fuse (11) has to be replaced by an 8 Ampère

slow-blow fuse with the label print “T8AL” (see also paragraph 12).

When correctly connected and with mains power present the green STANDBY indicator (4) will light. Now,

through sending the corresponding command via the serial interface of the Remote Module, it is possible

to start the amplifier from the PROMATRIX Manager DPM 4000 (see PROMATRIX handbook).

The POWER switch (9) on the rear of the amplifier – for bridging the starting relay – is meant for service

purposes only. It offers the possibility to operate the amplifier without remote start.

Note The POWER switch (9) on the rear of the appliance is for service purposes only. Remote

power-off is not possible with the POWER switch set to ON. In this case, the STANDBY

indicator (4) provides no function.

The DPA 4411 is equipped with a cut-in delay of approximately 3 seconds to efficiently suppress power-on

noise. After this period of time and when no fault was detected, the green READY indicators (7) will light

(see paragraph 7.2).

23

Page 6

3.2 Battery Operation 24 V DC

The amplifier DPA 4411 can either be operated on the AC mains or connected to an external 24 V battery

power source. Switching to battery operation is accomplished via internal relay.

The battery has to be connected to the corresponding socket (23) on the rear panel of the appliance using

insulated AMP flat connectors 6.3x0.8 mm. The amplifier is protected against confusion of poles.

Additional internal protection is provided through two miniature fuses – F502 and F503 – one per each

conductor (+ and -), which are located on the printed board assembly 85272 (see paragraph 12 , diagram

11). For the DPA 4411 the battery cable’s diameter should be at least 2.5 mm2 and the cable length for

the single distance should not exceed 4.0 m (max. drop in voltage < 1V).

Caution Operation of the DPA 4411 is solely allowable using batteries without grounding or

batteries with grounding of the negative pole. Operation with batteries with grounding of

the positive pole is not permissible.

4. Inputs INPUT 1 to INPUT 4

The inputs INPUT 1 to INPUT 4 (15) are electronically balanced. With a sensitivity of 775mV = 0dBu they

are meant for the connection of control amplifiers. For the case that floating inputs are needed, the inputs

are prepared for retrofitting input transformers.

Note If a switch-contact is located between the control amplifier output and the power amplifier

input, switch clicks might become audible during switching. If this is the case, incorporating

input transformers (NRS 90208 - one per input) can solve the problem (see paragraph 9.3)

Parallel operation of INPUT 1 to INPUT 4 (15) is possible when using the ROUTING

switches (16). This allows to connect the input signal through to feed several power

amplifiers with the identical program. Use a permanent marker pen to mark the

needed setting of the ROUTING switches (16) next to the ROUTING switch

push-button symbol.

diagram 1 input socket connection

diagram 2 LF-cable for coupled operation of two DPA 4411

24

Page 7

5. Outputs

5.1 POWER OUTPUT

All power outputs are balanced and floating. When factory-shipped, the outputs are pre-conf igured for the

connection of 100 V loudspeaker systems. Connection is achieved through plugging the supp lied 8-pole

socket into the connection strip (19). Switching the output transformer allows to change the output voltage

to 70 V, 50 V or 20 V (see paragraph 8). When set to 20 V, operation of low impedance speak ers with a

load of 4 ohms is possible.

Caution During operation it is possible that the outputs of the POWER OUTPUT connector may

conduct dangerous voltage (>34 V in peaks). Therefore, observing applicable safety

regulations is mandatory when connecting and installing loudspeaker lines

(see also paragraph 9.2).

5.2 POWER OUTPUT for the connection of 100 V loudspeaker systems

The use of speaker systems with 100 V matching transformers is recommended to reduce the lack in

performance when the distance between amplifier and speaker systems exceeds 50 m. This method also

offers an easy way to distribute the output power. The total power consumption of the maximum amount

of the connected speakers in the network has to match the amplifier’s overall output capac ity of 100 watts

(connection impedance 100 ohms). The connection is accomplished via the 100 V output (19)

(see figure 3).

diagram 3 Connection of 100 V (70 V or 50 V) loudspeaker systems

5.3 POWER OUTPUT for the connection of low-impedance loudspeaker systems

When switching the output to 20 V, low-impedance speaker systems (4-16 ohms) can be connected to

the corresponding output (see diagram 4). Because of line attenuation, the distance between amplifier

and speaker systems should not exceed 50 m. It is of further importance that the overall impedance of

the speakers does not decline 4 ohms and that the individual power handling capacity of each speaker

is not exceeded.

diagram 4 Connection of low-impedance loudspeaker systems

25

Page 8

Free combination of the DPA 4411’s power output voltages, including mixed 100 V and low impedance

(4 ohms) operation, is possible.

5.4 POWER OUTPUT 100 V - Double Output Power

If the output power of one output of the DPA 4411 is not sufficient to feed all cabinets within a speaker

network and dividing the speaker chain is not an option, it is possible to double the output power by

coupling the outputs of two amplifiers. In that case the amplifier inputs have to be paralle led and the

outputs are connected in series. For the connection of inputs, please refer to paragraph 4. For the

connection of the loudspeaker network, refer to diagram 5.

Coupling is possible under the following restrictions: only identical amplifiers or pow er amps can be

connected. Since doubling the output voltage comes along with serial connection, it is necessary to switch

the outputs of both amplifiers to 50 V (see also paragraph 8), resulting again in an overall output voltage

of 100 V. In this case the speaker chain’s minimum load impedance is 50 ohms // 50 nF. The input level

controls of the corresponding channels of the DPA 4411 have to be set to equal values (refer also to the

PROMATRIX handbook).

This results in the following output combinations with a single DPA 4411:

4 x 100 W or 2 x 100 W + 1 x 200 W or 2 x 200 W.

diagram 5 Possible output configuration of the DPA 4411

5.5 MONITOR output

The MONITOR output of the DPA 4411 is configured as monitor bus. It gets connected to the PROMATRIX

Manager DPM 4000 via the serial port REMOTE CONTROL (13). If a floating output is needed, the output

is prepared for retrofitting a monitor output transformer. In this case the extension NRS 90227 is necessary

(see paragraph 9.4). The low-impedance monitor output is electronically balanced. Therefore, the

connected cables may be up to approx. 200 m in length.

The PROMATRIX Manager DPM 4000 (see PROMATRIX handbook) offers connection for monitor

amplifiers; which can be set to input-monitoring or output-monitoring for the desired amplifier channel.

6. Integrated Remote Module

The integrated remote module of the power amplifier DPA 4411 provides the following functions:

• input levels of INPUT 1 to INPUT 4 can be set via programmable audio level controls

• reading level values of the audio level controls

• setting level offsets 1 to 4 via virtual controllers

• mute function 1 to 4 (via level controls)

26

Page 9

• mains operation remote control ON/OFF

• battery operation remote control ON/OFF

• monitoring and fault message transmission via the PROMATRIX Manager DPM 4000; in accordance

to DIN EN 60849 standard

− thermal overload of the mains transformer

− thermal overload of power output stages 1 to 4

− monitoring of the functioning of the power output stages 1 to 4 via pilot tone signal (optional, only with

NRS 90206 installed)

− ground fault detection for loudspeaker lines 1 to 4 (optional, only with NRS 90207 installed)

− measuring of input and output level peaks 1 to 4

− measuring of output voltages / levels of the power outputs 1 to 4

− measuring of output currents of the power outputs 1 to 4

− monitoring of connected loads 1 to 4 via current-voltage-measuring

− recognition of amplifier type including user-definable name

− reading of software revision of the remote module

− reading of error flags

− reading of the output configuration

− recognition of extensions NRS 90206 and NRS 90207

• switching the input monitor / output monitor 1 to 4 to the monitor bus

• pilot tone signal ON/OFF (optional, only with NRS 90206 installed)

• ground fault error flags reset

Note Prior to the first operation of the amplifier DPA 4411, you have to set the amplifier address

using the two Hexadecimal Code switches ADDRESS (18) (refer to the PROMATRIX

handbook) and using a waterproof marker pen mark the setting in the ADDRESS label field

on the rear panel of the appliance.

By sending the corresponding command via the serial port REMOTE CONTROL (13) of the remote

module, this function is activated from the PROMATRIX Manager DPM 4000 (see PROMATRIX

handbook).

7. Indicators And Fault Notification

7.1 STANDBY Indicator

When correctly connected and with mains voltage and/or battery voltage present, the green STANDBY

indicator (4) lights.

7.2 READY Indicator

The power amplifier DPA 4411 provides a power-on delay of approximately 3 s to prevent switch clicks

from becoming audible. If after this period of time no faulty condition has been detected, the green READY

indicator (7) lights and the mute-relays pull. When thermal overload of the mains transformer or of one of

the power output stages is detected, the corresponding green READY indicator (7) will not light and the

according mute-relay drops. If, with the NRS 90206 extension installed the pilot-threshold (see paragraph

9.1) is declined, the corresponding green READY indicator (7) goes out but the amplifier stays operational

and a fault message gets transmitted to the PROMATRIX Manager DPM 4000.

7.3 PROTECT Indicator

In case of thermal overload of the mains transformer or of a power output stage is detected, the red

PROTECT indicator (5) will light. During thermal overload of the mains transformer, all mute-relays drop

while during thermal overload of a power output stage, only the according mute-relay drops. After the

mains transformer or the power amplifier have regained their normal temperature, the red PROTECT

indicator (5) automatically goes out and the appliance recovers normal operation mode. The faulty

condition could have been caused by either overload, too high environmental temperature, or by an error

in the ventilation system. A fault-message is transmitted to the PROMATRIX Manager DPM 4000.

27

Page 10

7.4 GROUND FAULT Indicator

If, with built-in NRS 90207 a ground fault condition at one of the power outputs occurs, the corresponding

red GROUND FAULT indicator (6) lights and a fault-message is transmitted to the PROMATRIX Manager

DPM 4000. The power amplifier keeps up normal operation during the occurrence of this fault-type. After

solving the problem, the GROUND FAULT indicator (6) can be reset by pressing the TEST button (3) or

by sending the corresponding command via the serial port of the PROMATRIX Manager DPM 4000 (see

PROMATRIX handbook) (see paragraph 9.2).

7.5 Meter Instruments And CLIP Indicators

The green LED-indicator -13 dB and 0 dB (1) as well as the red LED-indicator CLIP (2) allow the precise

monitoring of output levels, providing the possibility to securely prevent distortion and clipping that could

lead to damaging the connected loudspeaker systems.

- When during program peaks the red CLIP-LED (2) lights briefly, the maximum distortion-free output

is gained.

- Whenever the CLIP-LED (2) lights continuously, the amplifier is driven into overdrive and the input level

should be reduced.

- Overload or short-circuit at the output is the cause for the green LED-indicator (1) to be out or only briefly

lit while at the same time the red CLIP-LED (2) blinks. In that case, please check the impedance of the

connected load.

Caution During normal operation, the red CLIP-LED (2) should hardly light and if, than

only very briefly !

7.6 STATUS Indicator

The yellow STATUS-LED (14) that is located on the rear of the appliance lights briefly during normal

operation when the DPM 4000 addresses a query to the amplifier. For further information, please refer to

the PROMATRIX handbook.

8. Switching The Output Voltage (refer to qualified service personnel only!)

The DPA 4411 offers output voltages of either 20 V, 50 V, 70 V or 100 V. The output voltage is

factory-preset to 100 V. Switching the output voltage to 20 V, 50 V or 70 V should only be carried out by

qualified DYNACORD service personnel.

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

- for opening the appliance, please remove the 9 screws on the top of the appliance that lock the cover

plate.

- the four output transformers 356762 are located on the left hand side of the appliance. They are

numbered 1, 2, 3, and 4; starting from the rear cover plate of the appliance.

- for changing the output voltage (see diagram 6) you have to unsolder the orange wire attached to the

transformer’s soldering tab 19 (100 V) and solder it instead to the required soldering tab (70 V, 50 V or

20 V).

- closing the appliance: use the 9 screws M3 x 6 DIN 7500 to reattach the cover plate.

diagram 6 Switching the output voltage at the

output transformers 356762

diagram 7 Output configuration settings of the

amplifiers (rear view)

28

Page 11

Note After changing the output voltage, use a waterproof marker pen to note the correct, newly

set value on the label-field OUTPUT VOLTAGE (20) on the rear of the appliance.

Additionally note the corresponding output configuration (see diagram 5) on the label OUT

CONFIG TYPE (20).

According to the description in diagram 7, adjust the switches S801 and S802 on the printed

board assembly 89019.2 that are located next to the transformers on the bottom of the

appliance’s enclosure (refer also to paragraph 5.4 ).

diagram 8 Printed board assembly 89019.2 showing the position of the switches S801 and S802

9. Additional Functions And Features (refer to qualified service personnel only!)

9.1 NRS 90206 Pilot Ton Surveillance

Using the extension-kit NRS 90206 provides continuous monitoring (surveillance) of the individual

amplifier channels. This is achieved by sending an ultra low-level 19 kHz pilot tone through the device. It

enters the signal path post level controls, runs through the amplification stages and gets filtered out and

evaluated at the output. In case the result of this evaluation shows that the pilot dropped beneath a defined

threshold or is missing at all, the corresponding READY indicator AMP 1 - 4 (7) goes out but the power

amplifier upholds its normal operation. A fault-message is transmitted to the PROMATRIX Manager DPM

4000 (see PROMATRIX handbook). The extension-kit NRS 90206 comes as a plug-in board assembly

and consists of a 19 kHz tone-generator and four selective 19 kHz receivers with evaluation stage.

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

9.1.1 To Install The NRS 90206 Proceed As Follows (see diagram 9):

- for opening the appliance, please remove the 9 screws on the top of the appliance that lock the cover

plate.

- the NRS 90206 gets retrofitted on the printed board assembly 89019.1, which is located behind the input

printed board assembly 81331, in the front area, attached to the left side panel of the amplifier (in front

view).

- Be sure to first insert the included board-guides before installing the printed board assembly, assuring

the correct position of their guide grooves. The release lever of the guides marked “A” points to the top,

while the one of the guides marked “B” points downwards.

- the NRS 90206 extension-kit needs to be inserted with its printed side pointing to the top, until it firmly

locks in place. Make sure that the power resistors R917 to R920 that are located underneath the

NRS-printed board assembly do not touch this board.

- closing the appliance: use the 9 screws M3 x 6 DIN 7500 to reattach the cover plate.

29

Page 12

diagram 9 Printed board assembly 89019.1 showing the position of the modules NRS 90206 and

NRS 90207

9.1.2 Checking The Function Of The NRS 90206:

With built-in NRS 90206 and powered-on amplifier, the READY-indicators (7) have to light. Us e the check

and reset-button TEST (3) to check the functioning of the pilot tone surveillance. When holding the

TEST-button pressed, the 19 kHz tone-generator is switched off, the READY-indicators (7) go out and a

fault-message is being transmitted to the PROMATRIX Manager DPM 4000 (see PROMATRIX handbook). Approximately 3 seconds after releasing the TEST-button, the READY-indicators (7 ) have to light

again.

9.2 NRS 90207 Ground Fault Surveillance

The VDE regulation DIN VDE 0800 has to be obeyed when planning and operating 100 V sound

reinforcement systems. Especially 100 V alert systems have to be in accordance with all protection

measures for class 3 appliances.

We recommend the use of the ground fault surveillance module NRS 90207 for floating speaker network

installations, offering surveillance of the network insulation. Error registration: A ground fault message

signals that a damaged cable has been detected – possibly resulting in an upcoming cable interruption –

or a wrongly connected cable, possibly resulting in malfunctioning. The information “ground fault” is

memorized as long as the amplifier is powered on or a loaded battery is connected, even for short-term

( > 5 s) ground faults. The fault-message is transmitted to the PROMATRIX Manager DPM 4000 (see

PROMATRIX handbook).

The NRS 90207 extension comes as a plug-in printed board assembly and consists of a monito ring circuit

with error-storage and display-driver for four 100 V outputs.

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

9.2.1 To Install The NRS 90207 Proceed As Follows (see diagram 9):

- for opening the appliance, please remove the 9 screws on the top of the appliance that lock the cover

plate.

- the NRS 90207 gets retrofitted on the printed board assembly 89019.1, which is located behind the input

printed board assembly 81331, in the front area, attached to the left side panel of the amplifier (in front

view).

- Be sure to first insert the included board-guides before installing the NRS 90207, assuring the correct

position of their guide grooves. The release lever of the guides marked “C” points to the top, while the

one of the guides marked “D” points downwards.

- the NRS 90207 extension-kit needs to be inserted with its printed side pointing to the top, until it firmly

locks in place. Make sure that the power resistors R917 to R920 that are located underneath the

NRS-printed board assembly do not touch this board.

- closing the appliance: use the 9 screws M3 x 6 DIN 7500 to reattach the cover plate.

30

Page 13

9.2.2 Checking The Function Of The NRS 90207:

With built-in NRS 90207 and powered-on amplifier, the READY-indicators (7) have to light. When using

an external switch to shortcut one pole of the 100 V speaker network via a 47 k ohms resistor and the

safety earthing conductor for approximately 5 seconds, the corresponding GROUND FAULT indicator (6)

has to light. The fault-message is transmitted to the PROMATRIX Manager DPM 4000 (see PROMA TRIX

handbook). After releasing the external switch, indication and message have to stay present. Use the

TEST-button (3) to reset the ground fault surveillance function.

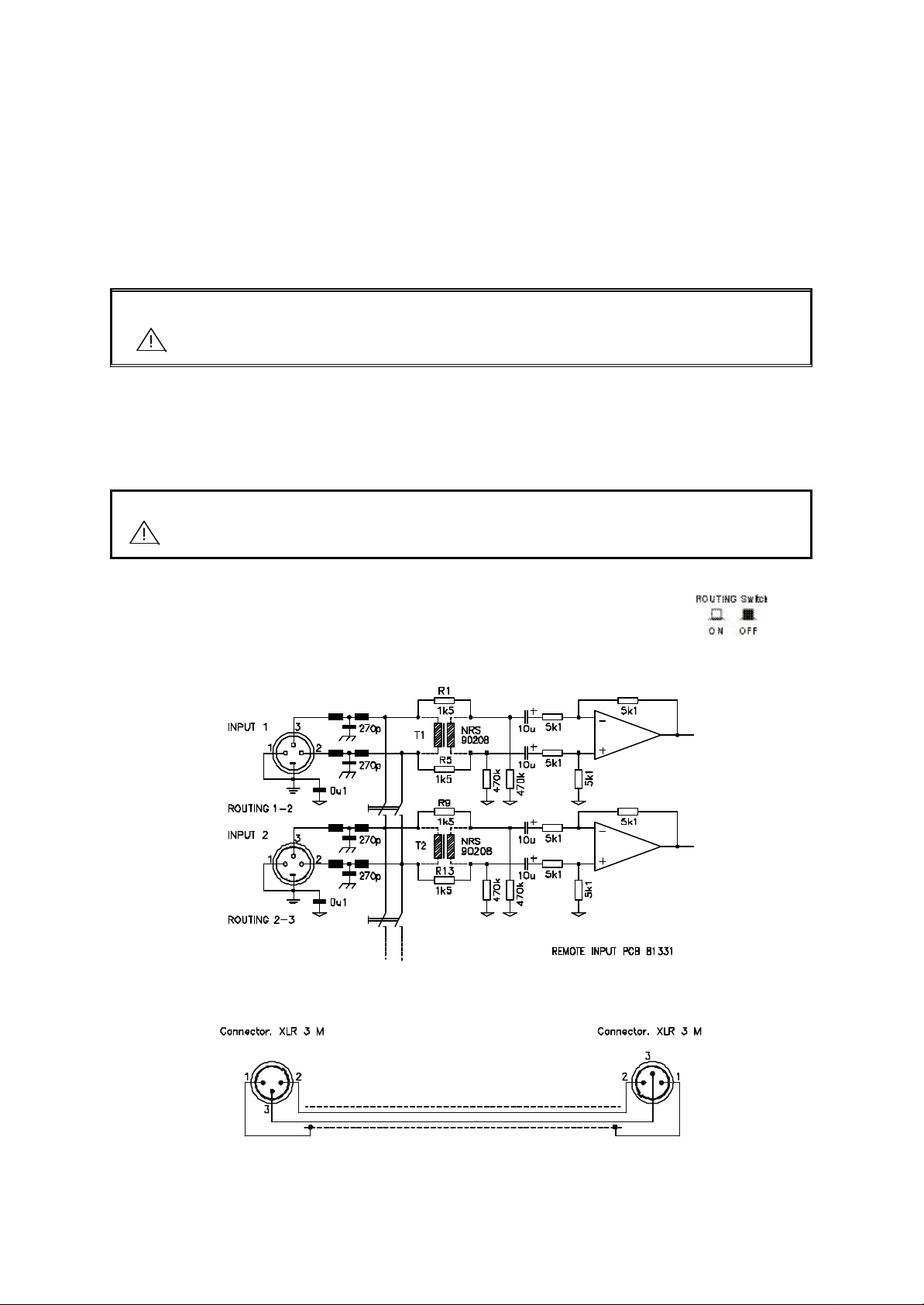

9.3 NRS 90208 Input Transformer For Floating, Balanced Inputs

In case floating inputs are needed, the inputs of the DPA 4411 are prepared for retrofitting input

transformers; a separate NRS 90208 extension-kit is needed per input.

Note If a switch-contact is located between the control amplifier output and the power amplifier

input, switch clicks might become audible during switching. If this is the case, incorporating

input transformers can solve the problem.

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

9.3.1 Retrofitting The NRS 90208 On The Printed Board Assembly 81331:

- for opening the appliance, please remove the 9 screws on the top of the appliance that lock the cover

plate

- detach the rear panel by removing the screws marked “A” to “D” (refer to the picture of the rear panel

on page 21).

- remove the input printed board assembly 81331 : (see diagram 10)

remove the 8 screws marked “D” that tighten the input sockets and detach the 6 flat cables CN1 to CN6.

For removing the printed board assembly 81331 you have to unscrew the two screws on the side panel

- before installing the input transformer, make sure to unsolder the resistors for T1: R1/R5, for T2:

R9/R13, for T3: R17/R21, for T4: R25/R29 and clean the corresponding eyelets

- place the input transformer onto the printed board assembly 81331, so that the markings on the board

and on the bottom part of the transformer are aligned. As a protection against short-circuit, place the

supplied insulating disk between the printed board and the transformer

- before re-installing the printed board assembly 81331, reconnect the flat cables CN1 to CN6. Keep in

mind that the plug of the cable leading to CN1 (AMP1+2) is marked. Now, reconnect the printed board

assembly 81331 to the amplifier’s side panel, using two screws M3 x 12

- installation of the rear panel:

first, connect the POWER OUTPUT printed board assembly to the rear panel, using two screws marked

“C”. Make sure not to squeeze any wires. Now, you can slide the rear panel underneath the four

lock-fish-plates of the input sockets. In doing so, mind that the acknowledge button of the ROUTING

switches need to be pulled through the corresponding openings

input sockets are tightened with two screws marked “D”, each

the power supply printed board assembly 85272 gets tightened using two screws marked “C”; mind the

acknowledge button of the CIRCUIT ⊥ TO CHASSIS SWITCH.

tighten the Remote Control printed board assembly with two screws marked “C”; mind the yellow

STATUS-LED

tighten the mains-input printed board assembly 86243 using three screws marked “C”; tighten the mains

connector (10) and the mains selector switch (12) with individual screws and self-securing nuts M3

reinstall the rear panel using 6 screws marked “A”

tighten the heat sink using four screws marked “B”

- closing the appliance: reconnect the cover-plate using 9 screws M3 x 6 DIN 7500

31

Page 14

diagram 10 Printed board assembly 81331 showing the position of the input transformers NRS 90208

9.4 Monitor Output Transformer NRS 90227 Offering A Floating, Balanced MONITOR Output

In case a floating MONITOR output is needed, the monitor amplifier’ output is prepared f or retrofitting an

output transformer. Herefore, you will need the extension kit NRS 90227.

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

9.4.1 To Install The NRS 90227 Proceed As Follows: (see diagram 10)

- for opening the appliance , please remove the 9 screws on the top of the appliance that lock the

cover plate.

- de-install the input printed board assembly 81331 following the description in the paragraph 9.3.1.

- disconnect the resistors R95, R96, R97 and R101 before installing the monitor output transformer.

- mount the monitor output transformer on the printed board assembly 81331; in doing so, polarity is

of no importance, since the transformer is balanced.

reinstall the input printed board assembly 81331 following the description in paragraph 9.3.1.

- closing the appliance : use the 9 screws M3 x 6 DIN 7500 to reattach the cover plate.

10. 19"-Flightcase Or 19"-Rack System Installation

Caution Operating the DPA 4411 without cover-plate is not admissible.

When incorporating the DPA 4411 into a 19" flightcase or 19" rack system, make sure to leave room for

sufficient air-flow. Between the amplifier’s rear plate and the inside-wall of the surround ing enclosure has

to be at least 60 mm x 330 mm of space until up to the enclosures top or its ventilation gaps. At least 100

mm of space should be left above a rack system to guarantee sufficient air circulation. S ince, during the

operation of the DPA 4411 the environmental temperature within the rack closet may increase by about

10° C, minding the maximum allowable temperature values for other equipment that is ins talled into the

same rack system or enclosure is of major importance.

Note For trouble-free operation of the appliance, the maximum environmental temperature

of +40 °C is not to be exceeded.

32

Page 15

11. Ground Lift Switch CIRCUIT ⊥ TO CHASSIS SWITCH

Using the ground lift switch CIRCUIT ⊥ TO CHASSIS SWITCH (22) lets you separate the audio signal

ground from the enclosure ground (safety earthing). This helps to solve problems with hum or noise without

jeopardizing safety standards. If several units with ground lift switch are installed in a co mmon enclosure

or rack system, it is recommended to set the ground lift switches of all devices but one to “ungrounded”.

Set to “ungrounded”, the impedance between signal ground and enclosure is: 100 k ohms // 100 nF. It is

necessary to maintain the immunity from EMV.

12. Fuses

Location Pos. Used for Value Dimensions Standard

Fuse switch (11)

Fuse switch (11)

Board 86243

Board 85272

Board 85272

Board 85272

Board 85272

Board 85272

Board 85272

F601

F601

F602

F502

F503

F504

F505

F506

F507

Mains fuse 230 V~ AC

Mains fuse 115 V~ AC

Mains fuse AC

Battery fuse 24 V DC

Battery fuse 24 V DC

Power-AMP 1

Power-AMP 2

Power-AMP 3

Power-AMP 4

T4AL 250V

T8AH 250V

T1AL 250V

25AL 32V

25AL 32V

T6.3AL 250V

T6.3AL 250V

T6.3AL 250V

T6.3AL 250V

5 x 20 mm

5 x 20 mm

8.5 x 8.45 mm

Flat type fuse

Flat type fuse

5 x 20 mm

5 x 20 mm

5 x 20 mm

5 x 20 mm

IEC 127

IEC 127

IEC 127

DIN 72581-3

DIN 72581-3

IEC 127

IEC 127

IEC 127

IEC 127

Changing The Fuses F502 And F503 (see diagram 11):

Caution Unplug the mains cord and disconnect batteries before opening the appliance!

The battery fuses F 502 and F503 are located on the mains (power supply) printed board assem bly 85272

behind the AMP-battery connectors. In case they need to be replaced, commence as follows:

- open the appliance by removing the 9 screws that lock the cover-plate

- remove the mains input printed board assembly 86243 that is located at the rear inner wall.

Therefore, unplug the yellow/green ground conductor form the corresponding connector at the rear

inner wall. To remove the AMP-plug, press its lock-piece

- now, you have to remove the 3 screws of the mains-input printed board assembly 86243 marked “C”

(refer to the picture of the rear panel on page 21).

- disconnect the 6-pole flat cable between the two relays on the mains-input printed board ass embly

86243 that is connected to the male multi-point connector B602

- now, the hinged mains-input printed board assembly 86243 can be turned up. In doing so, be careful

not to damage any wiring or other parts

- the fuses F502 and F503 are now easy to get to and can be removed to the top

- for re-installing the mains-input printed board assembly 86243, proceed in opposite order:

tighten the mains-input printed board assembly 86243 with the 3 screws marked “C”, where each,

the mains plug (10) and the mains selector switch (12) need to be connected using individual screws

and self-securing nuts M3.

- reconnect the 6-pole flat cable to the multi-point connector B602

- reconnect the yellow/green ground cord to the ground connector on the rear panel; make sure th at it

sits tight

- closing the appliance: reattach the cover-plate with 9 screws M3 x 6 DIN 7500

33

Page 16

Caution For safety reasons make sure that after reassembling, wires running underneath the

mains-input printed board assembly 86243 are run with a minimum distance

of at least 6 mm.

diagram 11 Printed board assembly 85272 showing the position of the DC-fuses F502 to F507

34

Page 17

13. DPA 4411 Specifications

Power supply on mains operation:

operation voltage 115 V / 230 V~ AC, ±10 %

mains frequency range 50 - 60 Hz

safety class I

mains operation Umains [V] Imains [A] Pmains [VA] Pmains [W] Pout [W] Pv [W]

Standby

0idling

Normal operation (-10 dB)

Alarm (-3 dB)

Nominal conditions

mains initial current inrush < 36 A

230

230

230

230

230

0,016

0,29

1,64

3,25

4,39

3,7

67

377

748

1010

1,5

40

275

585

815

0

0

40

200

400

1,5

40

235

385

415

mains operation U

Standby

0idling

Normal operation (-10 dB)

Alarm (-3 dB)

Nominal conditions

mains initial current inrush < 20 A

Pmains[VA] =apparent power Umains*Imains, Pmains[W] =true power, Pout[W] =output power, Pv[W] =leakage power

[V] I

mains

115

115

115

115

115

[A] P

mains

0,30

0,50

3,28

6,50

8,78

mains

3,5

58

377

748

1010

[VA] P

[W] P

mains

1,5

40

275

585

815

[W] Pv [W]

out

0

0

40

200

400

Power supply on battery operation:

operation voltage 24 V DC, -10/+30 %

battery operation UB [V] IB [A] P

Standby

0idling

Normal operation (-10 dB)

Nominal conditions

battery initial current inrush < 3,9 A

Pi[W] = input power UB*IB, Pout [W] = output power, Pv [W] = leakage power

24

24

24

24

0,06

1,1

7,5

18

i [VA]

1,5

26

180

432

Pout [W] Pv [W]

0

0

40

250

input characteristics: electronically balanced

nominal input level 775 mV = 0 dBu / 10 k ohms

power output characteristics: balanced, floating

nominal output power with mains supply 4 x 100 W (according to IEC 268-3)

nominal output voltage

with mains supply 100 V ( 70 V / 50 V / 20 V )

with battery supply at 24 V DC 79 V ( 56 V / 40 V / 16 V )

nominal load impedance 100 ohms ( 50 / 25 / 4 ohms)

1,5

40

235

385

415

1,5

26

140

182

minimal allowable output impedance:

100 W output power 200 W output power

100 V output

70 V output

50 V output

20 V output

100 Ohm // 250 nF

50 Ohm // 500 nF

25 Ohm // 1000 nF

4 Ohm // 6250 nF

50 V + 50 V output

—————

—————

—————

noise voltage (A-weighted) ≤ -56 dBu

THD at P

A NOMINAL

≤ 1 %

amplification frequency response 60 Hz .. 20 kHz

35

50 Ohm // 500 nF

—————

—————

—————

Page 18

distortion-limited response

(P

A NOMINAL

-3dB, kΣ = 1 %) 60 Hz .. 5 kHz

crosstalk between two channels ≥ 80dB at 1 kHz / ≥ 60dB at 10 kHz

MONITOR output characteristics: electronically balanced

nominal output voltage 2 V = + 8.2 dBu

nominal load impedance 600 ohms

amplification frequency response 60 Hz .. 20 kHz

environmental temperature +5 °C .. +40 °C

technical regulations:

This appliance is in accordance to the following regulations EN 55103-1, EN 55103-2, EN 55022

EN 60065, EN 60555

dimensions (W x H x D) 19“ (483 mm) x 3HU (132 mm) x 345 mm

installation depth without external connectors 340 mm

installation depth incl. external connectors max. 400 mm

weight 22.5 kg

color anthracite

Extension kits for the DPA 4411:

NRS 90206 pilot tone surveillance (for four amplifiers) Order No. 121 639

NRS 90207 ground fault surveillance (for four outputs) Order No. 121 640

NRS 90208 input transformer (per single input) Order No. 121 641

NRS 90227 monitor output transformer Order No. 121 679

14. Specifications For DPA 4411 Accessories

14.1 NRS 90206 pilot tone surveillance (for four amplifiers)

pilot frequency 19 kHz ± 1%

fault recognition threshold ≤ 12 mV

fault message output separate for each output; via

PROMATRIX Manager DPM 4000

14.2 NRS 90207 ground fault surveillance (for four outputs)

input loudspeaker line 20 V / 50V / 70V / 100V

fault message output separate for each output; via

PROMATRIX Manager DPM 4000

voltage strength 1000 Veff

fault recognition threshold ≤ 50 k ohms

14.3 NRS 90208 input transformer (per single input)

transmission range 20 Hz .. 20 kHz

input impedance ≥ 10 k ohms

idling ratio 1:1

primary winding resistance 1420 ohms at 20°C

secondary winding resistance 1420 ohms at 20°C

14.4 NRS 90227 monitor output transformer

transmission range 40 Hz .. 20 kHz

nominal load impedance ≥ 600 ohms

idling ratio 1:1

primary winding resistance 18 ohms at 20°C

secondary winding resistance 18 ohms at 20°C

36

Loading...

Loading...