Page 1

DPA 4245 / DPA 4260 POWER AMPLIFIER

Features

OWNER’S MANUAL

• 2 x 450 watts output power capacity DPA 4245

• 2 x 600 watts output power capacity DPA 4260

• floating 100 V / 70 V / 25 V power outputs (isolated outputs)

• low impedance outputs (direct outputs)

• bridged mode operation, switchable

• all outputs are protected against idling and short-circuit

• mains supply 230 V AC 50/60 Hz

• POWER REMOTE function

• service mains switch

• active ventilation via 2 temperature-controlled DC-fans

• electronically balanced inputs

• routing switch for parallel linked operation

• input gain controls

• integrated audio limiters

• power-on switching noise suppression

• protection circuitry: DC/HF, Back-EMF, output voltage overload limiters, initial inrush current limiter,

output peak current limiter

• 18 dB/oct. LO-cut filter at 45 Hz

• SIGNAL and LIMIT indication for optical monitoring

• thermal overload protection for the heat sink and the internal power supply, with PROTECT-function

• inputs transformers for balanced, floating operation are optionally available

• XLR-type and binding post clamping input connectors

• 19" frame size, 3 HU

15

Page 2

CONTENTS

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

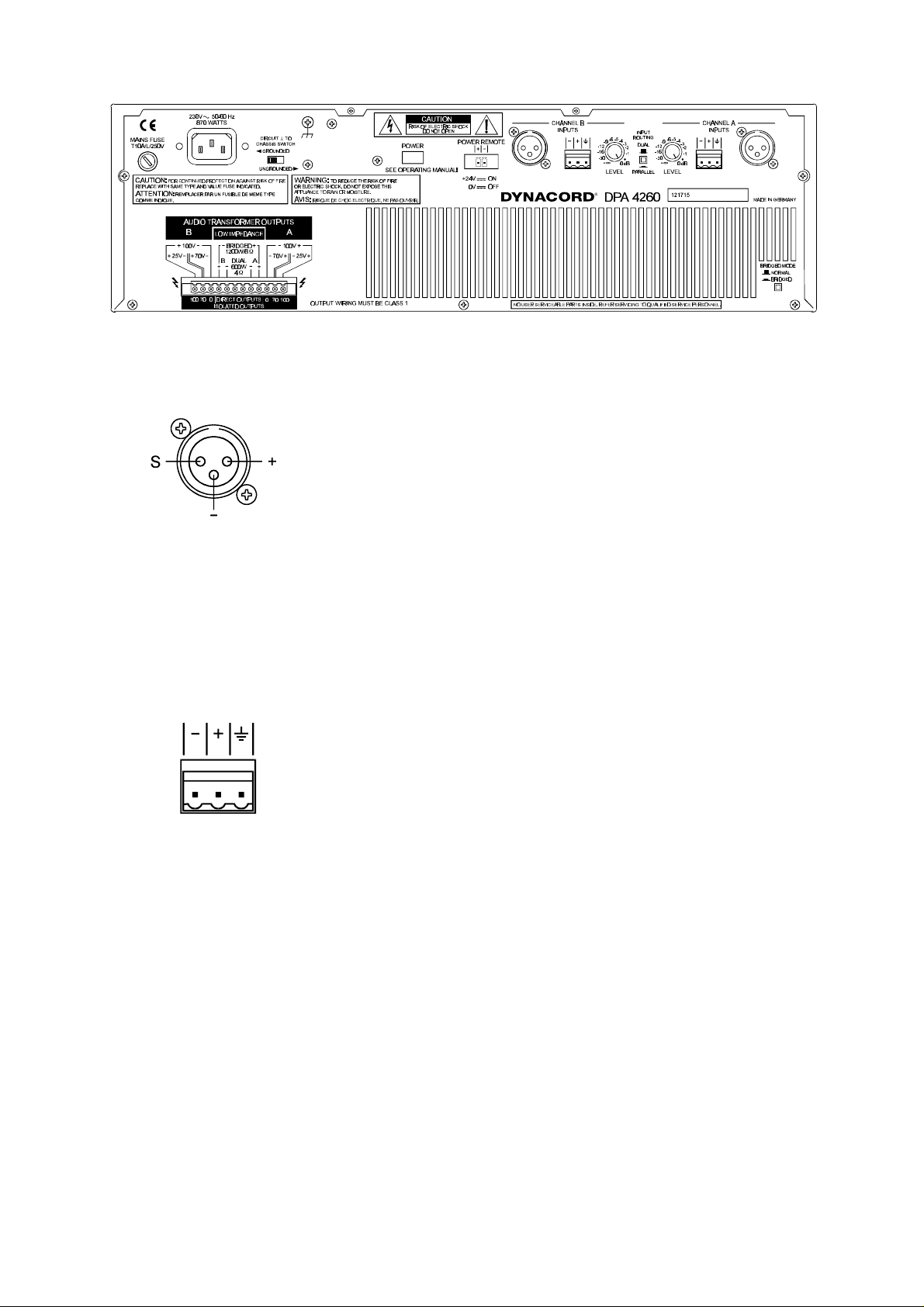

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

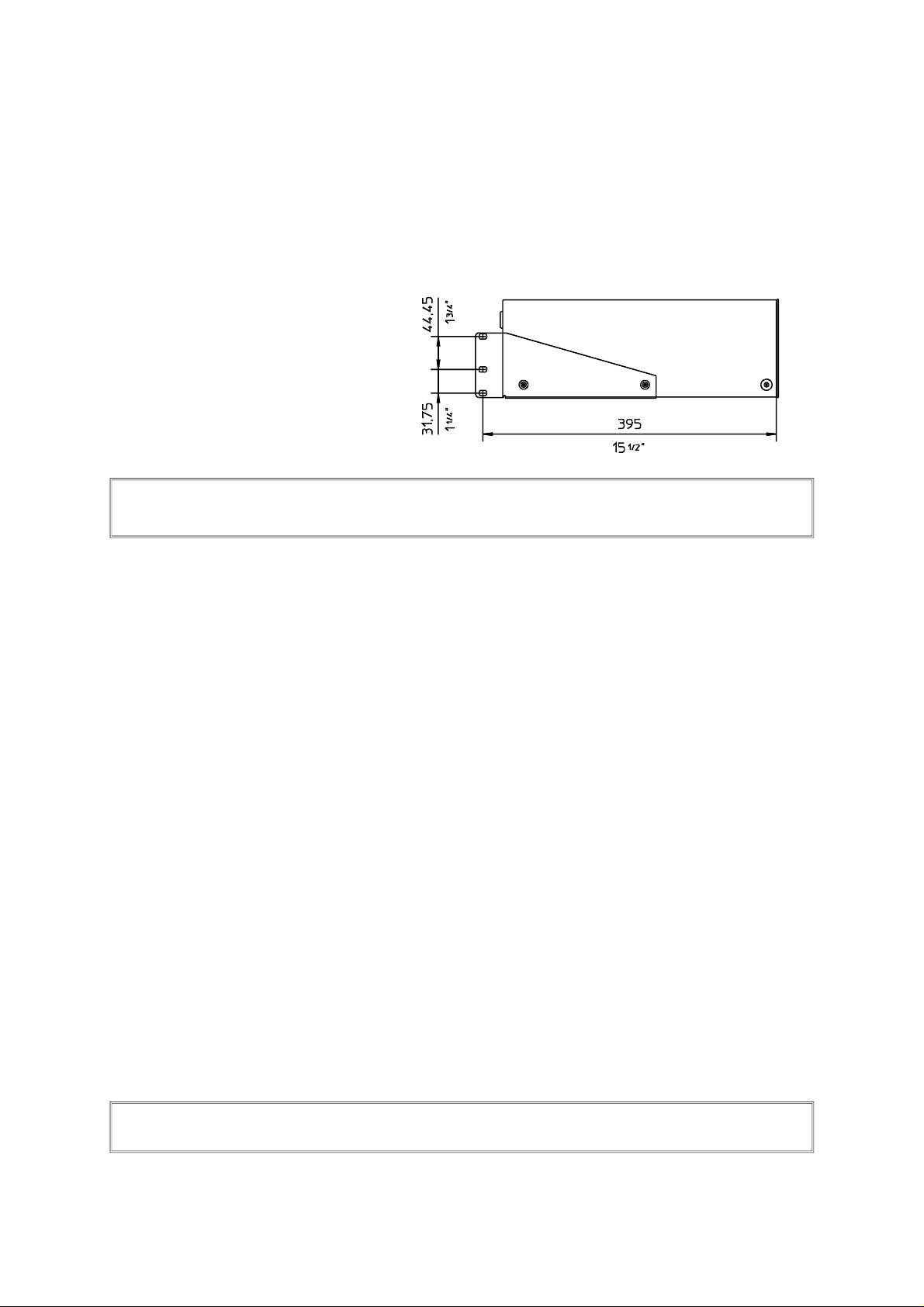

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol, within an equilateral

triangle is intended to alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclosure that may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and maintance (servicing) instructions in the literature accompanying the

appliance.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a damp cloth.

7. Do not block any of the ventilation openings.

Install in accordance with the manufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

9. Only use attachments/accessories specified by the manufacturer.

10. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any

way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third grounding prong.

The wide blade or the third prong are provided for your safety. When the provided plug does not fit into your outlet, consult an

electrican for replacement of the absolete outlet.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the

Operating Instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to be obeyed when

servicing the appliance.

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is opened, needs to be

operated and is connected to the mains

3. Switch off the power before retrofitting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal enclosure),

respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not connected

to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symbol (Note) is only permissible

when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced have to be strictly

obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

Note:

SAFETY COMPONENT (HAS TO BE REPLACED WITH ORIGINAL PART ONLY)

16

Page 3

DESCRIPTION

Especially designed for permanent installations, the DPA-Series power amplifiers offer performance-consistent and reliable operation of PA-systems with 2 individual loudspeaker lines, each. Therefore,

DPA-Series power amplifiers are most suitable for company intercom, alarm and background music

transmission installations in offices and commercial areas, congregation and sport centers, schools,

houses of worship, hotels, hospitals, shopping malls and super markets, cruise ships, and other similar

applications.

Each power amplifier incorporates two high-performance output transformers. Next to 100 V, 70 V, and

25 V floating outputs, the direct outputs provide the possibility to also drive loudspeaker systems with

low-impedance down to a minimum of 4 ohms. Simultaneous operation of low-impedance speaker

systems and floating loudspeaker lines on a single output channel of the power amplifiers is possible as

well.

The integrated 45 Hz LO-cut filter with 18 dB/oct. slope protects the connected loudspeaker lines from

unwanted ultra-low frequencies.

Comparator circuitry constantly monitors the input and output signals of the power amplifiers and activates

their internal limiters whenever non-linear operation is encountered which reliably protects the connected

loudspeaker systems against overload conditions and clipping, saturation of the power supply transformers, and overvoltage at the outputs. The DPA-Series power amplifiers’ transmission and sound qualities

are absolutely superb. The employed comprehensive dimensioned power supply units with low-interference toroidal transformers ensure that the stated nominal performance specifications are accomplished,

even in most demanding and critical installations. Since the DPA-Series power amplifiers do not employ

V/I-Foldback-Limiter circuits, operation on complex loads up to ±90° phase angles is possible without a

problem.

Quick optical information on the power amplifiers’ momentary operational status is provided through easily

readable LED indicators, individually showing whether a channel is ready for operation, a signal is present

at the output, if any of the limiter circuits and/or one of the protection circuits has been activated.

The inputs are electronically balanced and carried out as XLRF-type and as binding post clamping

connectors as well. Parallel linking the two connector types at the input provides the possibility to utilize

the carried-through signals to feed additional power amplifiers, without the necessity for special split-cables. Both inputs can be optionally retrofitted with input transformers. Through Input Routing switches it is

possible to configure the DPA-Series power amplifiers for stereo, parallel-monaural, or bridged-mode

operation.

The dB-scaled level controls – extremely precise and good to operate potentiometers – are located on

the rear of the appliances. A Ground-Lift switch which helps eliminating ground noise loops by separating

the amplifier circuit ground from the common ground of the enclosure is also to be found on the rear

panels. Conveniently connecting the loudspeaker lines to the power amplifiers is provided through a

binding post strip, where all voltages – 25 V, 70 V, 100 V – and the low-impedance output are present on

individual screw-clamp connectors. The rear panel service mains switches allow turning the power

amplifiers’ power on directly. Using the provided power remote input, remote-start is also possible.

Consistent thermal stability of the power amplifiers is obtained through extremely silent running fans which

are automatically switched stepwise depending on the amplifiers’ operation mode. The front-to-rear air

circulation guarantees trouble-free operation in rack-shelf enclosures of any size.

Several other features of the DPA-Series power amplifiers are revealed within this owner’s manual.

Therefore, please take the time to carefully and entirely read the provided information.

17

Page 4

Installation Notes

Generally, it is important to install the power amplifier in a way, that ensures unhindered front-to-rear air

circulation.

When installing the power amplifier in a closed rack-shelf system, please make sure that adequate air-flow

is guaranteed. The space between the rear panel of the amplifier and the inner wall of the rack-case has

to be at least 60 mm x 330 mm. A free space of at least 100 mm above the rack-shelf system is needed

to provide sufficient air circulation. Since, during operation, the temperature inside the rack system could

easily rise up to 40° C, the maximum allowable ambient temperatures of the rest of the incorporated

modules and appliances within a specific rack-shelf system have to be taken into careful consideration.

When mounting the power amplifier inside of a closed rack system, it is recommended to use special rack-rails or

optionally available rack-mount ears

NRS 90235 (112733) to prevent bending

of the appliance’s front panel.

Note For maintained trouble-free operation of the appliance, the maximum admissible ambient

temperature of +40°C is not to be exceeded.

The amplifier has to be protected from:

- water drops or splashes

- direct sunlight

- high ambient temperatures and the direct radiation of heat sources

- high humidity and moisture

- heavy dust

- massive vibrations

Moving the amplifier from a cold into a warm environment can result in the occurrence of condensation

on inner parts. Operating the appliance is only permissible after it has accommodated to the altered

temperature (approximately after one hour).

Should any foreign solid parts or liquids inadvertently intrude the enclosure, immediately unplug the device

from the power source and have it checked at a DYNACORD service center, before further use.

Cleaning the appliance should not be performed using chemical solvents or sprays, as this might damage

the finish and could even cause hazard fire.

Before The First Operation

Before switching the amplifier’s power on, the included mains cord has to be connected to a 230 V - 50/60

Hz wall outlet. On the appliance itself, the cord has to be connected to the 3-pole mains socket.

To remotely start the amplifier, it is necessary to connect an external 24 V power source to the terminal

strip POWER REMOTE. Providing correct connection and with an external power supply being present,

the POWER ON indicator will light and the power amplifier is ready for operation.

The mains switch POWER on the rear of the appliance is meant for service and maintenance purposes

only. Through bridging the mains switching relay this option provides the possibility to operate the amplifier

without an external 24 V power supply connected.

Caution The mains switch POWER on the rear of the appliance is only meant for maintenance.

Remotely switching off the device is not possible when the POWER switch is engaged.

The DPA-Series power amplifiers employ power-on switching delays of approximately 2 seconds.

18

Page 5

Inputs INPUT CHANNEL A&B

With an input sensitivity of 775 mV = 0 dBu and an input impedance of 20

k ohms, the electronically balanced inputs – INPUT CHANNEL A&B – are

meant for the connection of control amplifiers, audio controllers, mixing

consoles, etc.

Peripheral pieces of audio equipment are either connected via the XLRtype input connectors or using the parallel-linked binding posts. For the

latter option you can utilize the supplied screw-plugs. Thus, carrying the

audio signals through to feed additional power amplifiers can be conveniently achieved without the need for special split-cables.

PIN 1: SHIELD

PIN 2: a, +

The XLR-type input connectors’ pin-assignment is in accordance to the

IEC 268 standard:

PIN 3: b, -

In case the controlling device does not supply balanced output connectors,

it is also possible to configure the connectors for unbalanced operation.

Therefore, the common ground (pin 1) has to be connected to the (–) input

(pin 3). The audio signal is now solely fed through the (+) input (pin 2).

So, to be able to entirely make use of all the advantages the electronically

balanced input stage offers – like the suppression of humming and

interference noise – it is beneficial to re-establish balanced input connection whenever possible.

In case floating inputs are needed, the inputs are ready to be retrofitted

with input transformers; one optional available extension kit NRS 90208

(308840) per channel is necessary.

Instructions On How To Install NRS 90208 Extension Kits

• unplug the power amplifier from the mains

• detach all screws holding the cover plate of the appliance

• lift and remove the cover plate

• disconnect the flat-wire cable of the printed board assembly 81340/1

• detach all screws holding the printed board assembly 81340/1

• remove the printed board assembly 81340/1 and unsolder the resistors R106 … R109

• attach insulators to the input transformers according to the corespondent marks on the printed board

assembly

• re-assemble the appliance by performing all steps described in the opposite order

19

Page 6

figure: block diagram input channel A

figure: printed board assembly area

channel A – transformer retrofitting

Level Control

dB-scaled rotary controls for adjusting the power amplifier’s overall amplification. This control should be positioned between the 0 dB and the -6 dB

marks to prevent distortion in source devices. The labeling indicates the

actual attenuation applied to the internal specified factor of amplification.

Input Routing

If the switch is set to parallel/mono, the input connectors CHANNEL A and

CHANNEL B are electrically linked for direct parallel operation. With only

a single audio signal source connected, both channels are driven, while

their volume levels are still individually controlled via the level controls A

and B.

If the switch is set to its dual/stereo position, channels A and B are

separately amplified (two channel or stereo mode).

Power Outputs A&B

The loudspeaker cables are connected to the power amplifier through high-performance binding posts –

with the necessary screw-plugs being supplied. For connection purposes, it is possible to remove the

12-pole terminal plug. Cables with a maximum diameter of 2.5 mm2 can be utilized. To provide flexible

connections, all floating output voltages – 25 V, 70 V, and 100 V (ISOLATED OUTPUTS) – as well as the

low-impedance output (DIRECT OUTPUTS) of both channels are directly accessible.

figure: power outputs of the DPA 4260

20

Page 7

Power Outputs – AUDIO TRANSFORMER OUTPUTS

The two integrated output transformers convert the power amplifier’s nominal output voltage to the

commonly used loudspeaker line voltage standards – 25 V, 70 V, and 100 V. These voltages are

simultaneously present at the correspondent floating outputs of the binding post strip. The two power

amplifier channels can be operated using any possible output voltage combination. Simultaneous

operation of low impedance loudspeaker systems and floating loudspeaker lines on a single power

amplifier channel is possible as well.

Caution It is possible that during operation shock-hazard output voltages can be present at the

power output connectors (>34 V peak value). Therefore, the connected loudspeaker

lines have to be installed in accordance to applicable security standards and regulations.

When installing and operating 100 V-loudspeaker networks, compliance to the VDE

regulation DIN VDE 0800 is mandatory.

Especially, if a 100 V-loudspeaker network is included in alarm system applications, all

security standards have to be in accordance to the security class 3 standard. Before the

first operation of the power amplifier, the loudspeaker terminal strip has to be covered

using the supplied protection cover.

Power Outputs - Isolated Outputs 70 V and 100 V

To reduce line attenuation effects when the distance between power amplifier and loudspeaker systems

exceeds 50 meters, it is recommended to employ loudspeaker systems with 100 V or 70 V line

transformers, which also allows conveniently distributing the output power to the individual loudspeaker

systems.

It is possible to connect as many loudspeaker systems until the total power consumption of the

loudspeaker network equals the nominal power handling capacity of the power amplifier; while not

declining the nominal load impedance of the power amplifier outputs.

For details on nominal power handling capacity and nominal load impedance of the amplifier’s individual

power outputs, please refer to the specifications in the appendix.

figure: example configuration – DPA 4260 with 100 V loudspeaker systems – maximum load

using 30 W / 100 V and 60 W / 100 V loudspeaker systems

21

Page 8

Power Outputs - Isolated Outputs 25 V

The floating 25 V output is mainly used for driving low impedance loudspeaker systems (4 - 16 ohms).

Because of the effect of line attenuation, the distance between power amplifier and loudspeaker systems

should not exceed 50 meters. It is further important that the total impedance of the entire loudspeaker

network does not decline the nominal load impedance of the 25 V output. For details on the nominal load

impedance of the 25 V output, please also refer to the specifications in the appendix.

figure: example configuration – DPA 4260 with 8 ohms and 16 ohms loudspeaker systems at

maximum load

Power Outputs – DIRECT OUTPUTS

In addition to the output transformer equipped outputs and for driving low impedance, high performance

loudspeaker systems, the power amplifier’s direct, low impedance outputs are carried out as well, offering

a minimal load impedance of 4 ohms. Each power amplifier channel is capable of simultaneously driving

loads at the direct output and at the isolated output. But it is of major importance that the overall power

consumption of the connected loudspeaker systems or lines does not exceed the output power capacity

of the power amplifier.

Example: If a loudspeaker system with 8 ohms and a nominal power handling capacity of 300 watts is

connected to the DPA 4260 channel A Direct Output, this equals exactly half of the power amplifier’s

output power capacity since the minimal load impedance for each channel is 4 ohms. That leaves the

possibility to utilizes exactly half of the nominal output power capacity of the channel A 100 V output –

which in this example equals 500 watts/2 = 250 watts – to supply a split loudspeaker line. The total

impedance of the loudspeaker line has not to decline 20 ohms*2 = 40 ohms.

figure: example configuration – DPA 4260 channel A in mixed mode

22

Page 9

Bridged Mode

Doubling the power amplifier’s output power is accomplished by engaging bridged mode operation, where

the two power amplifier output stages are linked for push-pull operation. In other words, a monaural power

amplifier is “created” offering double the output voltage and double the output power capacity of a single

channel. As a result you are provided with floating 50 V, 140 V, and 200 V as well as with a direct output

with doubled nominal output voltage.

If the BRIDGED-MODE switch is engaged, the audio input signal has to be fed via the CHANNEL A input

while the CHANNEL B input is without function. The signal is internally inverted and the power amplifier

stage B is driven by that inverted signal. The power amplifier stage A is still driven by the unaltered

incoming audio signal. Bridged mode operation is possible with using the isolated and/or the direct outputs.

When using the isolated outputs, bridging the (–) binding posts of channels A and B is mandatory,

using short cables with suitable diameter (1.5 mm2 ... 2.5 mm2)!

Careful consideration of the loudspeaker systems’ correct connection is important in preventing phase

correlation problems. Channel A carries the signal “in phase” and therefore has to be connected to the

(+)-pole of the correspondent loudspeaker system while the loudspeakers (–)-pole has to be connected

to the (+)-output connector of channel B. The output voltage of each power amplifier stage A&B is present

at the binding post strip, but utilization is not recommended because of the negative correlation.

figure: output connection in 50 V bridged mode operation

*Caution! The bridging cable has to be at least 1.5 mm2 in diameter.

Driving 4 ohms loads at the direct output is not admissible in bridged mode operation. For details on

nominal load impedance and nominal loads of the individual outputs in bridged mode operation, please

refer to the specifications in the appendix. Also in bridged mode, the nominal load impedance is not to be

declined.

23

Page 10

GROUND Lift Switch

The ground lift switch helps is a perfect means for eliminating possible ground

noise loops. In case the power amplifier is operated together with other

equipment inside of a rack shelf system, the switch should be set to its

GROUNDED position. When using the power amplifier together with other

equipment that operates on different ground potentials, the switch should be

set to UNGROUNDED.

Power On And Remote Control

When the power amplifier is operated via power remote start (standard

operation) an external 24 V power source has to be connected to the POWER

REMOTE terminal strip and the mains switch has to be set to its OFF-position. When correctly connected and with a present supply voltage, the power

amplifier is operational. The fans run for approximately 2 seconds and the

POWER ON-LED on the front panel lights. The mains switch POWER on the

rear of the appliance bridges the mains relay. It is meant for service purposes

only. This allows to operate the power amplifier without the presence of an

external 24 V power source. The current consumption at the POWER

REMOTE input is approximately 25 mA.

Limit Indicator

The indicator lights whenever the integrated limiter is activated. While short

blinking means no problem, the continuously lit LED indicates that the volume

level needs to be reduced to prevent the connected loudspeaker systems

from being damaged by overload.

The audio limiters are capable of controlling overdrive levels of up to 20 dB.

Most other power amplifiers without integrated limiters begin to clip, generating nasty distortion that not only attacks your ears but also lead to damaging

the connected loudspeaker systems by overload. The limiters are activated

only in case of the occurrence of non-linear conditions within the power

amplifier; e. g. signal clipping at the operation voltage limit. The limiters do

not affect the power amplifier’s overall dynamic range.

Signal Indicator

This indicator is lit when the audio signal exceeds –30 dB. In case short-circuits resulting from broken loudspeaker cables are detected or one of the

power amplifier’s protection circuits is activated, the signal indicator is

dimmed.

PROTECT

The PROTECT-LED lights whenever one of the power amplifier’s protection

circuits – thermal overload, RF, DC, Back-EMF – is activated. In PROTECT

mode all loudspeaker lines and output transformers are disconnected via

relays and the power amplifier’s audio inputs are short-circuited to prevent

the connected loudspeaker systems from being damaged. When the power

amplifier enters the PROTECT mode please examine first whether the

appliance is overheated. If this is the case, the front and rear ventilation

louvres are possibly covered, the nominal load impedance has fallen below

the specified minimum value, or a short-circuit occurred at the power output.

When switching the power amplifier on, the PROTECT-LED lights for approximately 2 seconds. This is normal. It signals that the protection circuitry is

in working order.

Power ON Indicator

This LED lights when the power amplifier is connected to the mains and its

power switch is set to the ON-position. If the indicator does not light although

the power amplifier is switched on, the appliance is not connected to the

mains or the primary fuse is blown.

24

Page 11

Protection Circuitry

The DPA-Series power amplifiers are equipped with extensive protection circuitry:

• initial current inrush limiter

• power-on delay

• RF and DC protection

• Back-EMF protection

• limiters for the audio signals

• output peak-current-limiters

• thermal overload of the heat sink

• thermal overload of the mains transformer

• output voltage overload limiters

High-level signals in the low frequency range can drive the output transformers of power amplifiers that

do not provide audio signal limiters into saturation, resulting in nasty distortion and high thermal load of

the power amplification stage. The audio signal limiters of the DPA-Series power amplifiers are designed

to quickly identify the occurring saturation of the core of an output transformer. The level is dynamically

reduced to a value, that stays just below the point of where the saturation starts. The Limit-LEDs on the

front panel indicate that the limiters have been activated. Despite the protection that is provided through

the audio signal limiters, the Limit-LEDs should not light over a longer period of time. Please, locate the

cause of the faulty operation – e. g. lower the LF-EQ setting at the connected mixing console when at the

same time the input level at the power amplifier is approximately +10 dB above the nominal input level.

The DPA-Series power amplifiers employ integrated Lo-Cut filters at 45 Hz with 18 dB/oct. for each

channel. They protect the loudspeaker systems that are connected via output transformers against

low-frequency audio signals, which, depending on the quality and size of the involved transformers, could

lead to problems with core saturation. In addition to the 45 Hz Lo-Cut filters, the frequency response of

the DPA-Series power amplifiers top margin is set by 30 kHz Hi-Cut filters with 12 dB/oct., preventing

unwanted high-frequency audio signals from being present at the outputs.

25

Page 12

Mains Operation And Leakage Power

The mains power consumption as well as the leakage power is stated for driving the power amplifier at

different levels. All the values were measured at nominal load via the 100 V output with two channels

driven. The shown values differ only slightly when the appliance is operated at different nominal output

voltages or in the Direct Out mode.

mains operation at the

100 V output

DPA 4245

idling 230V 0,34 78 47 — 47 160

normal operation (-10 dB) 230V 2,76 635 490 70 420 1430

alarm (-3 dB) 230V 5,54 1274 1040 352 688 2347

nominal conditions 230V 7,45 1714 1420 700 720 2456

DPA 4260

idling 230V 0,57 131 80 — 80 273

normal operation (-10 dB) 230V 3,66 842 655 101 554 1890

alarm (-3 dB) 230V 7,34 1688 1370 506 864 2948

nominal conditions 230V 9,86 2268 1900 1000 900 3070

U

mains

[V]

I

mains

[A] P

mains [VA]Pmains

[W] P

[W] Pv [W] BTU/hr

out

initial current inrush for both models: < 38 A

P

[VA] = apparent power U

mains

mains*Imains

, P

[W] = active power, P

mains

[W] = output power,

out

Pv[W] = leakage power, 1BTU = 1055.06 W/s

Fuses

location pos. utilization value dimensions standard

rear panel DPA 4245 —- mains fuse 230V~ AC T8A 250V 5 x 20 mm IEC 127

rear panel DPA 4260 —- mains fuse 230V~ AC T10A 250V 5 x 20 mm IEC 127

print 84171/1 F1 power supply T1A 250V 5 x 20 mm IEC 127

print 84171/1 F2 power supply T1A 250V 5 x 20 mm IEC 127

Extension Kits For The DPA 4245 And The DPA 4260:

NRS 90208 balanced input (input transformer for a single channel)

NRS 90235 1 pair of rack-mount ears

26

Page 13

Technical Specifications: DPA 4245, DPA 4260

Amplifier at rated conditions, both channels driven, direct outputs with 8

unless otherwise specified.

DPA4245 DPA4260

DUAL MODE Direct Output Isolated Outputs Direct Output Isolated Outputs

Output Definition 8Ω 4Ω 100V 70V 25V 8Ω 4Ω 100V 70V 25V

Load impedance or rated output voltage

Rated Load Impedance 28.5Ω14

isolated outputs only

Maximum Midband Output Power 240W 450W 410W 400W 390W 330W 600W 590W 580W 570W

THD=1%, 1kHz

Maximum Midband Output Voltage 44V 42.4V 108V 74.8V 26.5V 51.3V 49V 109.5V 75.4V 26.7V

THD=1%, 1kHz, RMS, rated load

Rated Output Power 230W 350W 350W 350W 350W 300W 500W 500W 500W 500W

THD <0.2%, 45Hz ... 20kHz,

>10min. according IEC 268-3

Rated Output Voltage 42.9V 37.4V 100V 70V 25V 49V 44.7V 100V 70V 25V

THD<0.2%, 45Hz ... 20kHz

Maximum RMS Voltage Swing 44V 125 V 87V 31V 52V 121V 88V 32V

THD=1%, 1kHz, no load connected

Frequency Response, -3dB, ref.1kHz 45 Hz .... 30kHz 45 Hz.... 22kHz 45 Hz .... 30kHz 45 Hz .... 22kHz

LO-Cut-Filter: 18dB/octave, 45Hz

HI-Cut-Filter: 12dB/octave, 30kHz

Voltage Gain 34 dB 34 dB 42 dB 39 dB 30 dB 35 dB 35 dB 42 dB 39 dB 30 dB

at 1 kHz

Input Sensitivity and Impedance 0dBu ( 775mV) / 20 kOhm

at rated condition

Slew Rate 25 V/µs 30 V/µs

Power Bandwith 45Hz ...50kHz 45Hz .... 25kHz 45Hz .... 50kHz 45Hz .... 25 kHz

THD=1%, ref. 1kHz, half power @ rated

load impedance

THD at rated output power, < 0.05% < 0.1% < 0.2% < 0.3% < 0.05 % < 0.1% < 0.2% < 0.3%

MBW=80kHz, 1 kHz

IMD-SMPTE < 0.08% < 0.1% < 0.3% < 0.5% < 0.08% < 0.1% < 0.3% < 0.5%

60 Hz, 7 kHz

DIM30 < 0.03% < 0.2% < 0.2% < 0.2% < 0.03 % < 0.2% < 0.3 % < 0.3%

3.15 kHz, 15 kHz

Crosstalk < -80dB

ref. 1kHz, at rated output power

Input Impedance 20 kOhm

20Hz ... 20 kHz, balanced

Damping Factor > 300 / > 200 > 300 / > 200

at 100Hz / 1kHz, direct outputs only

Insertion Loss 0.7 dB 0.8 dB 0.9 dB 0.7 dB 0.8 dB 1.1 dB

isolated outputs only

Signal to Noise Ratio > 100 dB

Rated output voltage to noise, A-weighted

loads, isolated outputs with rated load and voltage,

Ω

Ω

1.8

Ω

20

Ω

9.8

Ω

1.25

Ω

27

Page 14

BRIDGED MODE Direct Output Isolated Outputs Direct Output Isolated Outputs

Output Definition 8Ω 200V 140V 50V 8Ω 200V 140V 50V

Load impedance or rated output voltage

Rated Load Impedance —— 57Ω 28Ω 3.6 Ω ——- 40Ω 19.6Ω 2.5 Ω

isolated outputs only

Rated Output Power 560 W 700 W 700 W 700W 600W 1000W 1000W 1000W

THD<0.2%, 45Hz ... 20kHz

Maximum Bridged Output Power 900W 820W 800W 780W 1200W 1180W 1160W 1140W

THD=1%, 1kHz

GENERELLPower Requirements 230V / 50Hz...60Hz

Power Consumption

at 1/8 maximum output voltage @ rated load impedance 690 W 870 W

Protections Audio limiters, High temperature, DC, HF, Back-EMF,

Peak current limiters, Inrush current limiters, Turn-on delay, Output Transformer Saturation Protection

Input Connectors Euro-style, 3pin, detachable or XLR

Output Connectors Euro-style, 12pin, detachable, covered

Cooling Front-to-Rear, 3-stage-fans

Regulations The appliances are in accordance with EN60065, EN50081-1, EN 50082-1

Safety Class I

Operating Temperature Range +5°C ... +40°C

Mounting Depht with Connectors 437 mm

Mounting Depht without Connectors 377 mm

Dimensions (W x H x D) 483mm x 132.5mm x 382mm

Weight (net) 20.5 kg 22.5kg

28

Loading...

Loading...