Page 1

Technical Data Sheet

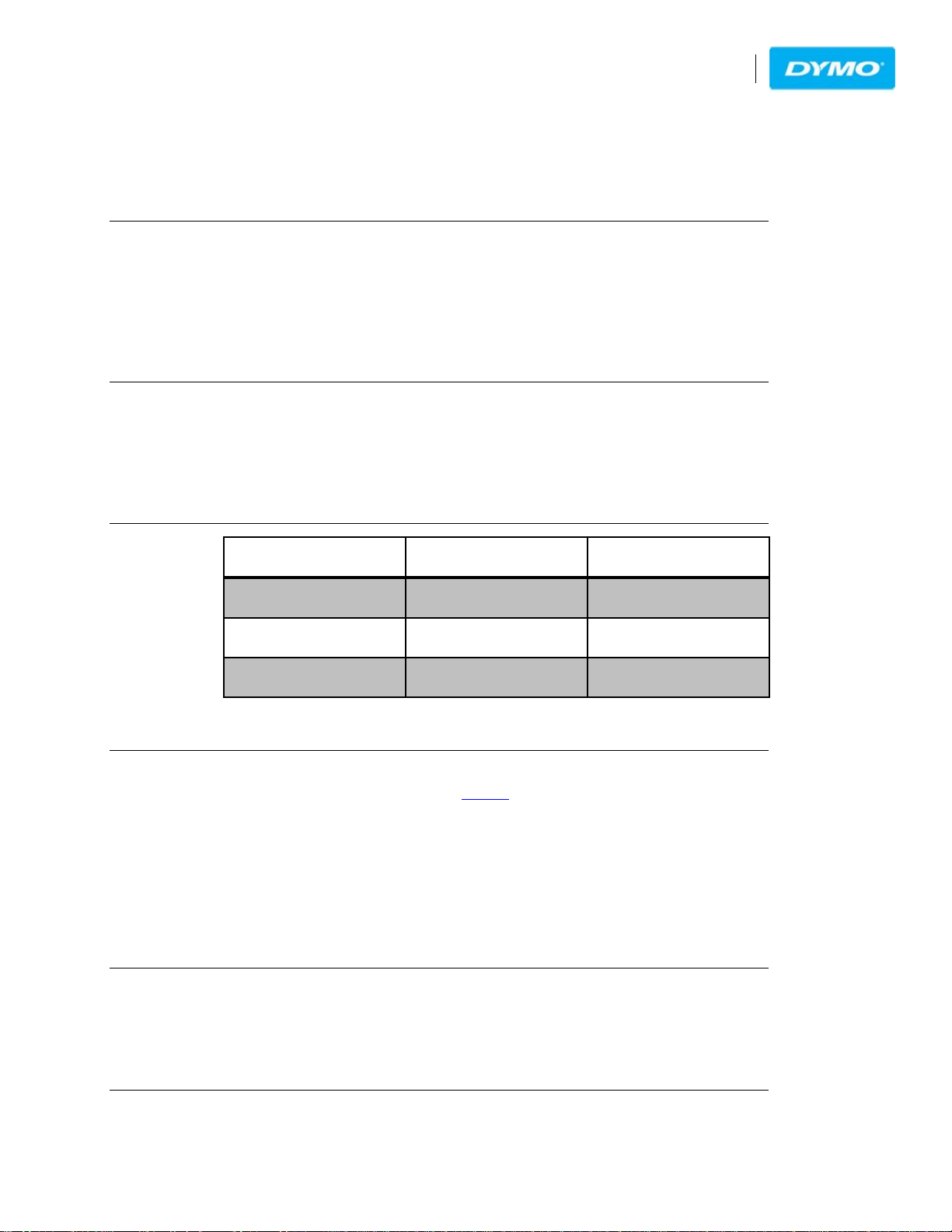

Print Color

Tape Color

Available Widths (in, mm)

Black

White

¼, 6mm; ⅜, 9mm; ½, 12mm;

¾, 19mm; 1, 24mm

Black

Clear

¼, 6mm; ⅜, 9mm; ½, 12mm;

¾, 19mm; 1, 24mm

Black

Metallic

¼, 6mm; ⅜, 9mm; ½, 12mm;

¾, 19mm; 1, 24mm

DYMO Industrial Permanent Polyester (PET) Tape

Description

Polyester (PET) tape used for thermal transfer printing. It is formulated with a

permanent acrylic adhesive and is mainly used for general ID, inventory and

warehouse marking, and the marking of connectivity panels. This tape adheres to

smooth and rough surfaces, however is not recommended for use on curved or

rounded surfaces. This tape is halogen free.

DYMO Part Numbers

1805442 18482 18483 18484 1734523

1805440 18508DMO 622289 622290 1805433

1805441 18485 18486 18487 1805434

Available Colors & Sizes

Certifications and & Standards Adherence

- UL Recognized as a component to UL969 (UL File Number MH48389)

All UL information can be found at UL.com under certifications

- To the best of our company’s knowledge we declare that our products meet the most recent

standards of the European Directives considering REACH and ROHS. None of the substances

identified as “substance of concern“ has been and will be contained in the product(s), listed on

this Technical Data Sheet, to a higher level than mentioned in the European Directives

considering REACH and ROHS.

Physical Properties

- Total Thickness: 131 µm +/- 10%

- Dimensional Stability (%): No shrinkage observed on an aluminum panel at 70°C

(158°F) for 24 hrs.

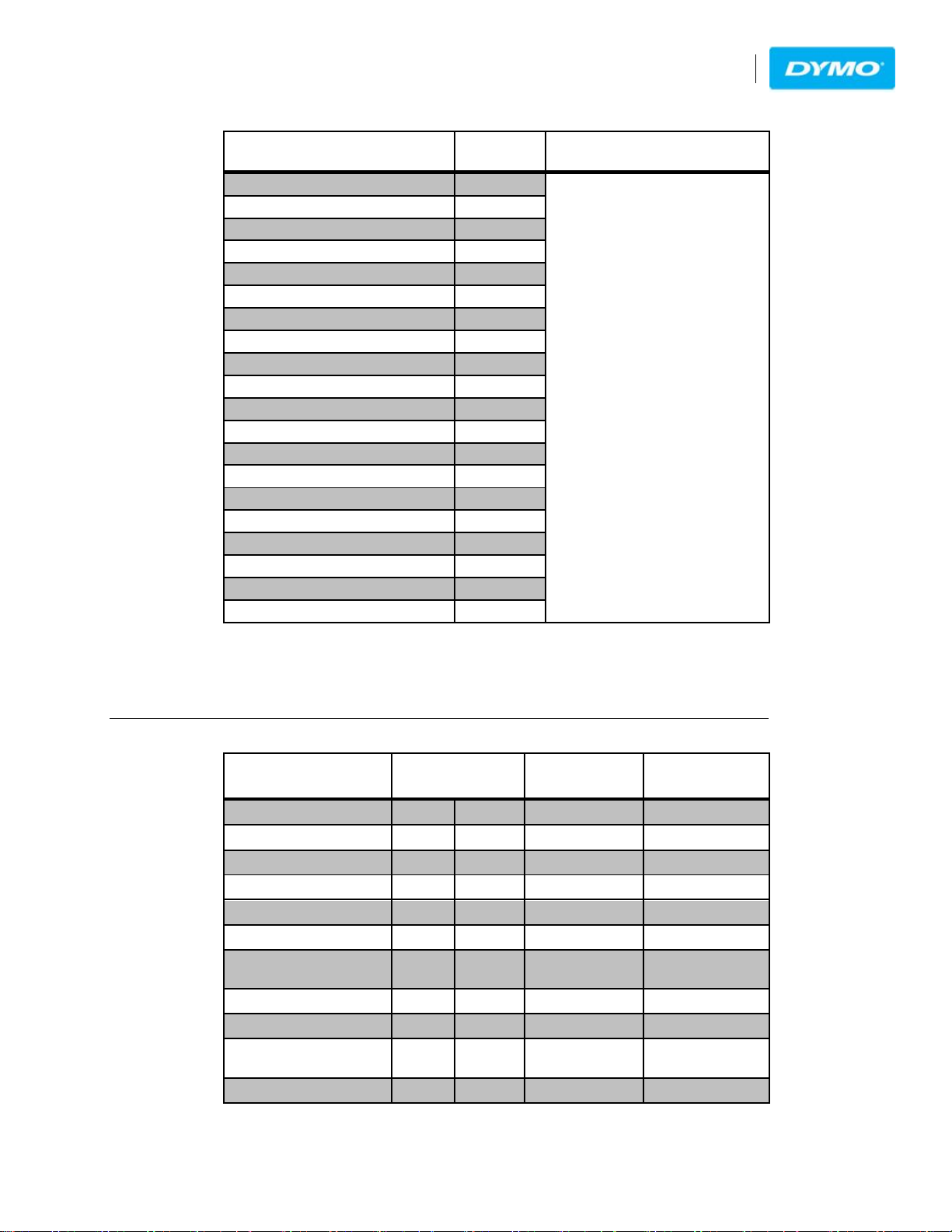

Adhesive Properties (tested per UL969)

Last Updated 11/29/2011

Page 2

Technical Data Sheet

Surface (N/25mm)

72 hrs.

Test Method

ABS

14

FTM-1

Stainless steel

21

Galvanized steel

17

PVC

19

Polycarbonate

20

Anodized Aluminum

25

Polystyrene

26

HDPE

18

Glass

25

Polypropylene

25

Polyethylene Terephthalate

25

Nylon - polyamide

24

Polyurethane paint on Aluminum

25

Polyester paint on Aluminum

26

PE - cross linked

23

EPMD rubber

17

Bare aluminum

25

LDPE

24

Polyimide Kapton

16

Phenolic

21

Surfaces

Temperature (°C)

Max Min

Indoor Use

Outdoor Use

Aluminum

150

-40

x x Galvanized steel

150

-40

x x Stainless steel

150

-40

x x Glass

100

-40

x x Nylon - Polyamide

100

-40

x

x

Polyester paint

100

-40

x

x

Polyethylene

terephthalate

100

-40

x

x

Polyimide

100

-40

x x Polyurethane paint

100

-40

x

x

Acrylonitrile butadiene

styrene

80

-40

x

x

Polypropylene

80

-40

x

x

Adhesion to Surfaces

- Tack (ASTM D 2979): 980gm/cm²

Temperature Ratings (tested per UL969)

Last Updated 11/29/2011

Page 3

Technical Data Sheet

EPDM rubber

60

-40

x

x

Phenolic - Phenol

Formaldehyde

60

-40

x

x

Polycarbonate

60

-40

x x Polyethylene

60

-40

x x Polystyrene

60

-40

x x Polyvinyl chloride

60

-40

x

x

Chemical

# of rubs

Result

Test Method

Fuel

30x

Slight print removal

Crockmeter,

900g weight/arm

Gasoline

30x

No visible effect

Isopropyl alcohol

30x

No visible effect

Ethanol

30x

Slight print removal

Water

30x

No visible effect

Skydrol* LD-4

30x

Moderate print removal

Ethyl acetate

5x

Printing gone

Papanicolau og. 6

30x

No visible effect

Hematoxylin (stain)

30x

No visible effect

Xylene

30x

Printing gone

UV light stability of:

Time

Result

Test Method

Label

30 days

No visible effect on text

and background

Constant UV

light exposure in

Suntester

Adhesive

30 days

No loss of adhesive

properties

Abrasive Object

# of rubs

Result

Test Method

Pencil eraser

30x

No visible effect

Crockmeter,

900g weight/arm

Polystyrene pin

30x

No visible effect

Sandpaper

30x

Moderate print removal

Chemical Resistance (Printed with the Rhino 6000)

Abrasion Resistance (Printed with the Rhino 6000)

UV Light Resistance

Humidity Resistance

- Printed labels adhered to aluminum surface for 30 days at 45°C (113°F), 85% Relative Humidity

with no visible effect on text or background

Last Updated 11/29/2011

Page 4

Technical Data Sheet

Shelf life of label cassette

- Two years stored at 21°C (69.8°F) and 50% Relative Humidity

Notice

- This product is not developed to be used on humans, animals and/or in direct food

contact.

*Skydrol is a registered trademark from Solutia

All of the descriptive information, performance data, and recommendations for the use of DYMO products shall be used only as

a guide and do not reflect the specification or specification range for any particular property of the product. Furnishing such

information is an attempt to assist you and in no event will constitute a warranty of any kind by DYMO or DYMO distributors. All

purchasers of DYMO products shall be responsible for independently determining the suitability of the material for the purpose

for which it is purchased.

Last Updated 11/29/2011

Loading...

Loading...