Page 1

Adjusting Space on Label Ends

DYMO 1570

For more blank spaces before and after messages: Turn the tape feeder (B) .

For less blank spaces: Turn the tape feeder (B) in reverse, emboss the message, turn feeder

forward, and cut.

To center a message: Advance completed label 3 spaces (5 space for 1530 Office Mate I)

Squeeze tape cutter.

Troubleshooting

Label shows letters instead of blank space: Squeeze handle half way until you hear a click,

then release.

Letters too light: Squeeze harder by holding the upper end of the handle.

Tape jam: In the unlikely event the tape does not feed properly, remove the tape wheel, discard

left over tape ends, and replace the wheel.

Preparing Problem Surfaces

Use non-residual solvents (i.e., alcohol, acetone) to clean oily or greasy surfaces. If the surface is

rough or porous, coat it with a sealer (i.e. shellac, lacquer). Once stuck, water will not affect the

label. Do not apply labels to surfaces exceeding 140 F.

Page 2

1. Load Tape

Expose 3" of the tape, open the tape compartment (A), and insert so that ‘U’ shape opening in the

tape cartridge points down. Insert the tape into the feed slot and thread forward until visible.

Close the tape compartment to lock in the tape.

2. Advance Tape

By turning the feeder (B) or with several half-squeezes (squeeze until click sound is audible) of

the handle (F), advance the tape 1/4" past front of embosser.

3. Emboss Letters

Turn the wheel (E) until the desired letter aligns with selector. Squeeze the handle (F) firmly and

repeat for each letter. To space between words, half-squeeze handle until click is heard.

DO NOT HOLD WHEEL WHILE EMBOSSING.

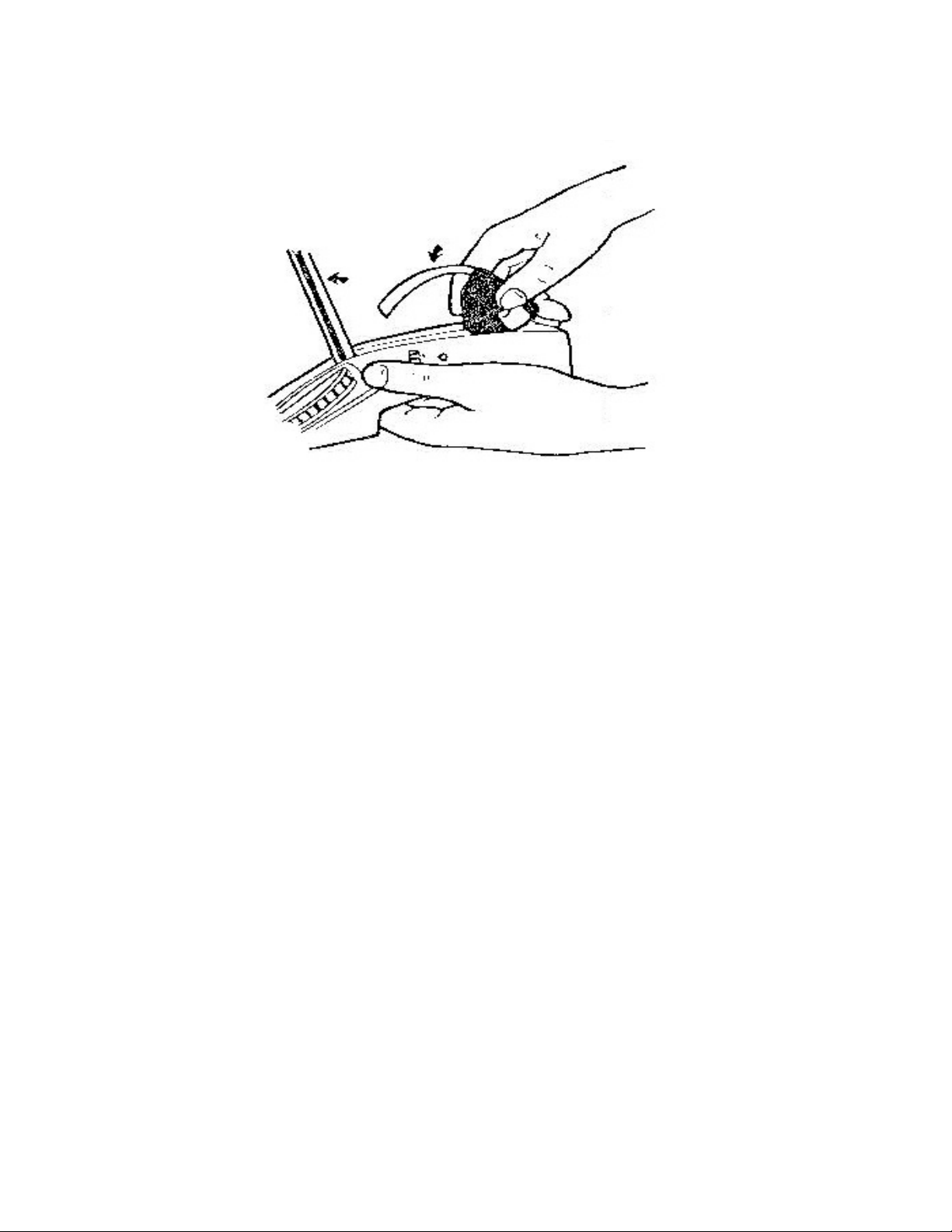

4. Cut Tape

Squeeze the cutter (C) and remove excess tape from the end of the embosser.

5. Apply Label

Pull the end of the tab to strip the backing. Apply tape to a clean dry surface.

6. Change Wheel

Push wheel right to left and remove. Snap in the new wheel.

DO NOT SQUEEZE HANDLE WHILE CHANGING WHEEL.

Loading...

Loading...