Page 1

User Guide

Guide D’Utilisation

Bedienungsanleitung

Guida per l’utente

Guía del usuario

Guia do Usuário

Rhino

M1011

www.dymo.com

Page 2

A

B

C

D

F

G

H

I

K

L

M

J

N

E

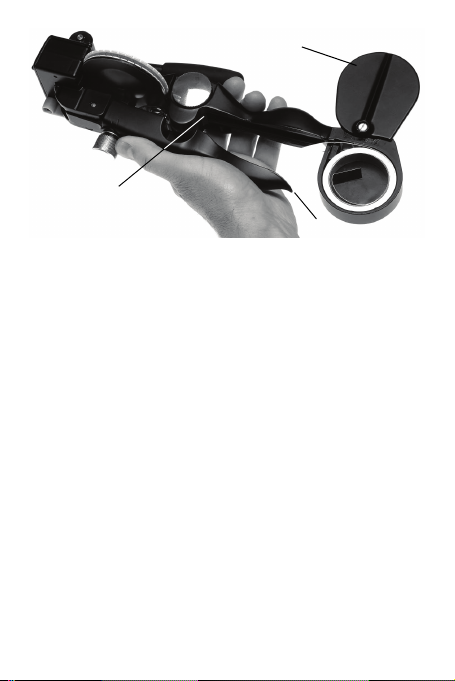

A Tape cassette door H Character selection window

B Tap e ro lle rs I Cutting handle

C Tape advance knob J Embossing adjustment screw

D Start line K Cable tie slot entrance

E Tape pawl L Hole punch entrance

F Embossing handle M Tape exi t

G Embossing wheel N Trailer length guide

2

Page 3

About Your New Label Maker

With your new DYMO M1011 label maker, you can create metal labels.

The label maker uses DYMO 12 mm (1/2") tape.

Metal tapes are available as follows:

• Aluminium with adhesive (35800)

• Aluminium without adhesive (31000)

• Stainless Steel (32500)

You can also use a Reverse Image Wheel with the DYMO M1011 label

maker. Th is wheel allows you to print mirror script labels that meet

special requirements in the industry. Mirror labels are used on moulds or

casts for metal or rubber injection, silicon casting, fiber glass

applications, and so on.

Visi t www.dymo.com for information on obtaining tapes for your

label maker.

3

Page 4

Loading the Tape

A

B

F

The DYMO M1011 is set to emboss non-adhesive aluminium tape.

To load the tape roll

1. Hold the label maker in your left hand.

2. Open tape cassette door (A).

3. Inse rt roll of tape allowi ng the end t o extend ab out 5 cm (2" ) through

the label slot.

4. Close the tape cassette door.

5. Feed the tape between the two rollers (B).

6. Squeeze the embossing handle (F) half-way (one click) several times

to ensure the tape is visible at the tape exit.

4

Page 5

Cutting the Label

I

M

To c ut the labe l

1. Squeeze the embossing handle half-way, several times until the tape

extends from the front of the tape exit (M) by at least 2,5 cm (1").

Before cutting the tape, make sure the end of the tape extends

!

beyond the edge of the cutting assembly so you can easily pull the

label out. Otherwise, a tape jam may occur.

2. Lift the cutting handle (I) gently until it is vertical to cut the label.

5

Page 6

Embossing the Label

G

H

F

Avoid turning the embossing wheel at the same time you are

!

squeezing the embossing handle. This can damage the character wheel.

To emboss a label

1. Turn the character selection wheel (G) until the desired letter is

centered in the window (H).

2. Squeeze the embossing handle (F) firmly.

3. Release the embossing handle fully before selecting the

next character.

To add space between words

♦ Squeeze embossing handle (F) half-way (one click) or turn the label

advance knob clockwise (one click per space).

6

Page 7

Embossing on Stainless Steel Label

J

You may need to adjust the labelmaker to emboss properly when using

stainless steel tape.

To adjust for stainless steel label

1. Turn the adjustment screw (J) clockwise 3/4 to 1 turn.

2. Emboss the text as described in “Embossing the Label” on page 6.

When you return to using aluminum tape, you may need to reverse

this adjustment.

7

Page 8

Retracting the Label

E

C

You may want to retract the tape, for example, if the tape advanced too

far or to center the text on the label.

To retract the label

1. Pull back the pawl (E).

2. Turn the tape advance knob (C) counter-clockwise.

8

Page 9

Removing the Label

A

To remove the label

1. Retract the tape as described in “Retracting the Label” on page 8.

2. Open the tape cassette door (A) and remove the label.

Use caution when removing stainless steel tape that may have

!

sharp edges.

3. Reload the tape as described in “Loading the Tape” on page 4.

9

Page 10

Centering the Text on the Label

N

I

D

The trailer length guide (N) has positioning marks for a short (S) or long

label (L). Use the marks on the guide to center the text on your label.

To center the text on a long label

1. After cutting the previous label, emboss the text on a new label.

2. Pull the trailer length guide (N) to the forward position.

3. Advance the tape until the last embossed letter is opposite the L on the

guide. The label has a leader/trailer of approximately 5 cm (2") and the

text is centered.

4. Lift the cutting handle (I) to the vertical position to cut the label.

To center the text on a short label

1. Retract the tape until the tape edge is at start line (D).

2. Emboss the text on your label.

3. Advance the tape until the last embossed letter is opposite the S on the

guide. The label has a leader/trailer of approximately 3 cm (1.5") and

the text is centered.

4. Lift the cutting handle (I) to the vertical position to cut the label.

10

Page 11

Applying Self-Adhesive Labels

Self-adhesive aluminum tape sticks permanently to any smooth, clean,

and dry surface.

To apply self-adhesive tape

1. Peel off the protective backing taking care not to touch the adhesive.

2. Press the label in place.

3. Apply firm pressure along the entire length to ensure good contact.

11

Page 12

Punching Holes in Non-Adhesive Labels

L

K

I

You can choose to punch one or two holes in non-adhesive labels so that

the labels can be attached using screws, nails, rivets, and metal or plastic

wires or ties. You can also punch a cable tie slot in one or both ends of the

label.

To punch a hole

1. Insert one end of the cut label into the hole punch slot (L).

2. Lift the cutting handle (I) to the vertical position to punch a hole.

To punch a cable tie slot

1. Insert one end of the cut label into the cable tie slot (K) with the

letters facing down. The letters must face down to ensure the bridge

of the slot is on the same side of the label as the characters.

Make sure to allow enough room for the tie-buckle before

!

and/or after the letters. A cable tie slot positioned on top of the

characters or a punched hole may cause the tape to jam.

2. Lift the cutting handle (I) to the vertical position to punch the slot.

12

Page 13

Changing the Wheel

G

You can replace the character wheel with a Reverse Image Wheel.

To change the wheel

1. Remove the tape.

2. Unscrew the screw in the center of the embossing wheel (G) and

remove the wheel.

3. Position the new wheel.

4. Insert the screw in the center and tighten. Do not tighten the screw

too tightly.

13

Page 14

Hints for Trouble Free Operation

Keep the following in mind when using the label maker:

• Letters appear where you want spaces - You are probably squeezing

the embossing handle too hard.

• Letters overlap - The tape is slipping. This can happen when dirt or

grease gets on the rollers. Clean the rollers by using a soft cloth

and alcohol, while turning the tape advance knob back and forth

several times.

• Avoid turning the embossing wheel at the same time you are

squeezing the embossing handle. This can damage the

character wheel.

• When punching a cable tie slot, make sure the label is well inserted

and abutted against the end of the slot. If the label is not inserted to

the end, label jam may occur.

• It is recommended to remove regularly th e label waste from the

waste exit at the bottom of the machine.

14

Page 15

Warranty Registration

This DYMO M1011 has been manufactured under strict quality control

and performance tested before leaving the factory. Within one year after

purchase, DYMO will repair or replace, at its own option, the M1011 free

of charge if sent prepaid by the purchaser to DYMO and found, in DYMO’s

judgement, to be defective in materials or workmanship. No other

warranty or guarantee, expressed or implied, shall be applicable to this

label-writer.

This warranty does not cover repair or replacement necessitated by or

the result of accident, normal wear and tear, alteration, abuse or misuse.

USA and Canada: For repair or replacement, carefully pack the labelwriter and send it prepaid to the DYMO Repair Center, DYMO Corporation,

44 Commerce Road, Stamford, CT 06902 along with a note indicating the

nature of the problem. Your M1011, or a replacement, will be returned

promptly.

Rest of the World: For repairs or replacement, please contact your local

DYMO dealer.

15

Page 16

Distributed by/Distribué par/Distribuido por:

DYMO, Atlanta, GA 30328 ©2010 Sanford, L.P. www.dymo.com

Imported into Canada by/Importé au Canada par Sanford Canada L.P., Oakville, ON L6J 3J3

En México importado y distribuido por: Newell Rubbermaid de México S. de R.L. de C.V.

Av. Vasco de Quiroga 3000 P. Plaza 1, Col. Santa Fe, Del. Alvaro Obregón C.P. 01210, México, D.F.

Newell Rubbermaid Latin America, 273 Ponce de Leon Ave., Scotiabank Bldg. Suite #1405

SANFORD BRANDS VENEZUELA LLC. Rif: J-30560396-0.

Calle Gustav Dalen, Zona Industrial La Hamaca. Maracay Edo. Aragua.

San Juan PR 00917. Atención al consumidor: (787) 622 9017

DYMO bvba, Sint-Niklaas, Belgium

W005234B

Loading...

Loading...