dymax UVCS User Manual

UVCS LED Light-Curing Conveyor Systems

User Guide

UVCS Conveyors Outfitted with BlueWave® LED Flood Arrays

■ Instructions for Safe Use

■ Setup and Operation

■ Maintenance

■ Ordering Spare Parts and Accessories

2

UVCS LED Light-Curing Conveyor Systems User Guide

About Dymax

UV/Visible light-curable adhesives. Systems for light curing, fluid dispensing, and fluid packaging.

Dymax manufactures industrial adhesives, light-curable adhesives, epoxy resins, cyanoacrylates, and activator-cured adhesives.

We also manufacture a complete line of manual fluid dispensing systems, automatic fluid dispensing systems, and light-curing systems.

Light-curing systems include LED light sources, spot, flood, and conveyor systems designed for compatibility and high performance

with Dymax adhesives.

Dymax adhesives and light-curing systems optimize the speed of automated assembly, allow for 100% in-line inspection, and increase

throughput. System designs enable stand-alone configuration or integration into your existing assembly line.

Please note that most dispensing and curing system applications are unique. Dymax does not warrant the fitness of the product for the

intended application. Any warranty applicable to the product, its application and use is strictly limited to that contained in the Dymax

standard Conditions of Sale. Dymax recommends that any intended application be evaluated and tested by the user to insure that desired

performance criteria are satisfied. Dymax is willing to assist users in their performance testing and evaluation by offering equipment trial

rental and leasing programs to assist in such testing and evaluations. Data sheets are available for valve controllers or pressure pots upon

request.

3

UVCS LED Light-Curing Conveyor Systems User Guide

Contents

Introduction .................................................................................................................................................... 4

Introduction to the User Guide ....................................................................................................................................... 4

Where to Get Help .......................................................................................................................................................... 4

Safety .............................................................................................................................................................. 4

General Safety Considerations ........................................................................................................................................ 4

Specific Safety Considerations ......................................................................................................................................... 5

Safety Symbol Index ........................................................................................................................................................ 5

Dymax Light-Curing System Safety Considerations ......................................................................................................... 5

Product Overview ........................................................................................................................................... 7

Description of UVCS LED Light-Curing Conveyors ............................................................................................................ 7

Assembly and Setup ........................................................................................................................................ 8

Unpacking and Inspecting Your Shipment ....................................................................................................................... 8

Parts Included .................................................................................................................................................................. 8

Conveyor System Setup .................................................................................................................................. 9

Conveyor Setup ............................................................................................................................................................... 9

Mounting the LED Flood Array(s) .................................................................................................................................... 9

Interconnect Cables ......................................................................................................................................................... 9

Operating the Conveyor ................................................................................................................................ 10

Operating the LED Light ................................................................................................................................ 12

Operating Modes ........................................................................................................................................................... 12

Choosing an Operating Mode ........................................................................................................................................ 12

Adjusting Intensity ......................................................................................................................................................... 13

LED Operation ............................................................................................................................................................... 14

Validation ...................................................................................................................................................................... 14

Cleaning and Maintenance ........................................................................................................................... 15

Belt-Tracking Adjustment .............................................................................................................................................. 15

Conveyor Belt Replacement .......................................................................................................................................... 15

Inspect and Replace Fuses ............................................................................................................................................. 17

Troubleshooting ............................................................................................................................................ 18

Spare Parts and Accessories .......................................................................................................................... 20

Spare/Replacement Parts .............................................................................................................................................. 20

Options/Accessories ...................................................................................................................................................... 21

Specifications ................................................................................................................................................ 22

Specifications................................................................................................................................................................. 22

Definition of Terms ....................................................................................................................................... 24

Warranty ...................................................................................................................................................... 25

Index ............................................................................................................................................................. 26

4

UVCS LED Light-Curing Conveyor Systems User Guide

Introduction

Introduction to the User Guide

This guide describes how to assemble, use, and maintain Dymax UVCS LED light-curing conveyor systems

safely and efficiently.

Intended Audience

Dymax prepared this user guide for experienced process engineers, technicians, and manufacturing personnel.

If you are new to UV light sources and do not understand the instructions, contact Dymax Application

Engineering to answer your questions before using the equipment.

Where to Get Help

Dymax Customer Support and Application Engineering teams are available in the United States, Monday

through Friday, from 8:00 a.m. to 5:30 p.m. Eastern Standard Time. You can also email Dymax at

info@dymax.com. Contact information for additional Dymax locations can be found on the back cover of this

user guide.

Additional resources are available to ensure a trouble-free experience with our products:

■ Detailed product information on www.dymax.com

■ Dymax adhesive Product Data Sheets (PDS) on our website

■ Safety Data Sheets (SDS) provided with shipments of Dymax adhesives

Safety

WARNING! If you use a Dymax LED light-curing conveyor system without first reading and

understanding the information in this user guide, injury can result from exposure to UV light. To

reduce the risk of injury, read and ensure you understand the information in this user guide before

assembling and operating the system.

General Safety Considerations

All users of Dymax UVCS LED light-curing conveyor systems should read and understand this user guide before

assembling and using the system.

To learn about the safe handling and use of light-curable formulations, obtain and read the MSDS for each

product. Dymax includes an MSDS with each adhesive sold. In addition, fluid product MSDS can be requested

on the Dymax website.

5

UVCS LED Light-Curing Conveyor Systems User Guide

CAUTION! Always wear protective goggles or face shield when working near UV light. Never

look directly at light!

WARNING! Always observe safety requirements! Do not open the cover of the LED Array or

Power Supply. There are no user serviceable parts inside.

Specific Safety Considerations

Dymax UVCS LED light-curing conveyor systems are designed to maximize operator safety and minimize

exposure to light-curing energy. To use the unit safely, it must be set up and operated in accordance with the

instructions in this user guide. Please also read and understand the safety considerations unique to lightcuring systems as described below.

Safety Symbol Index

The following symbols are displayed on the curing system. Please see below for their meanings.

Refer to Manual

Warning!

Eye Protection Required

Warning! UV Light Hazard

Electrostatic Sensitive Device

WARNING! Looking directly at the UV light emitted by an LED flood array can result in eye

injury. To prevent eye injury, never look directly at the high-intensity light and always wear

protective goggles (provided).

Dymax Light-Curing System Safety Considerations

Operators must understand these three concepts to use the LED light source safely: light exposure, hightemperature surfaces, and bright, visible light. Each is described below.

Light Exposure

The BlueWave® LED Flood’s PrimeCure® and RediCure® models emit energy in the UVA portion of the

spectrum while the VisiCure® model emits energy in the visible portion of the spectrum. UVA light is generally

considered the safest of the three UV ranges: UVA, UVB, and UVC. Although OSHA does not currently regulate

visible or ultraviolet-light exposure in the workplace, the American Conference of Governmental Industrial

Hygienists (ACGIH) does recommend Threshold Limit Values (TLV’s) for ultraviolet light.

6

UVCS LED Light-Curing Conveyor Systems User Guide

Figure 1. Light Spectrum

The strictest interpretation of the TLV (over the UVA range) for workers’ eyes and skin is 1 mW/cm2 (intensity),

continuous exposure. Unless workers are placing bare hands into the curing area, it is unusual to exceed these

limits. To put 1 mW/cm2 limit into perspective, cloudless summer days in Connecticut regularly exceed

3 mW/cm2 of UVA light and also include the more dangerous UVB light (primarily responsible for suntans, sun

burns, and skin cancer) as well.

Checking the Workstation

The human eye cannot detect “pure” UV light, only visible light. A radiometer should be used to measure stray

UV light to confirm the safety of a UV light-curing process. A workstation that exposes an operator to more

than 1 mW/cm2 of UVA continuously should be redesigned.

Protecting Operators

Light-curing technology can be a regulatory compliant, “worker-friendly” manufacturing process when the

proper safety equipment and operator training is utilized. There are two ways to protect operators from UV

exposure: shield the operator and/or shield the source.

Shield the Operator

UV-Blocking Eye Protection - UV-blocking eye protection is recommended when operating UV light-curing

systems. Both clear and tinted UV-blocking eye protection is available from Dymax.

UV-Blocking Skin Protection

Where the potential exists for UV exposure upon skin, opaque, UV-blocking clothing, gloves, and full-face

shields are recommended.

Shield the Source of UV

Any substrate that blocks UV light can be used as a shield to protect workers from stray UV light. The following

materials can be used to create simple shielding structures:

Rigid Plastic Film — Transparent or translucent/UV-blocking plastics (typically polycarbonate or acrylic) are

commonly used to create shielding where some level of transparency is also desired.

7

UVCS LED Light-Curing Conveyor Systems User Guide

Flexible Film — Translucent UV-blocking, flexible urethane films can be used to quickly create workstation

shielding. This UV-blocking, flexible urethane film is available from Dymax, call for assistance.

High-Temperature Surfaces

Surfaces exposed to high-intensity curing lights will rise in temperature. The intensity, distance, exposure

time, cooling fans, and the type/color of the surface can all affect the actual surface temperature. In some

cases, exposed surfaces can reach temperatures capable of producing a burn or causing damage to a

substrate. In these cases, care must be taken to ensure either a more moderate surface temperature or

appropriate protection/training for operators. No infrared radiation is produced by these LED systems, so

surface temperatures will be lower than with conventional lamp systems. Empirical testing should be used to

verify the exact temperature rise in each application.

Bright, Visible Light

The bright, visible light energy emitted by curing systems can cause eyestrain if proper eye protection or

shielding is not used. The proper use of tinted eye protection and/or opaque/tinted shielding can be utilized to

reduce eyestrain and address this concern.

Summary

UV-light sources can be more “worker friendly” than many commonly accepted industrial processes, provided

the potential concerns are addressed. Both the lower working temperature and lack of spurious frequency

transmission that this system produces make it even more user friendly. Contact your Dymax representative

for information regarding the proper use of Dymax light-curing systems.

Product Overview

Description of UVCS LED Light-Curing Conveyors

Dymax UVCS LED light-curing conveyor systems use high-intensity light sources for fast curing of light-curable

materials. UVCS bench-top conveyors can be outfitted with BlueWave® LED flood systems available in one of

three different wavelengths (365 nm, 385 nm, or 405 nm). The flood system consists of two main components:

an LED flood array and a power supply that contains the user interface. Only one LED flood array can be

connected to a power supply at a time via the interconnect cable. The power supply is designed to be

interchangeable and can be used with any of the three different wavelength LED flood arrays. Up to four LED

flood arrays can be mounted on the conveyor.

BlueWave® LED flood systems feature an intensity adjustment, allowing the output intensity level to be

adjusted from 10 to 100% to meet process and adhesive requirements. LED technology within the BlueWave®

LED Flood System allows for instant on/off activation without the need for a warm-up period, and is also rated

for continuous operation. A switch on the conveyor is provided to keep the LED array always active.

Fans in the LED flood power supply and array provide cooling and must not be covered or blocked. Fan Filters

must be maintained regularly to ensure reliable operation. Thermal sensors in the LED flood power supply and

array shut the unit down to protect the components if the internal temperature exceeds maximum limits.

Please refer to the BlueWave® LED Flood System User Guide for further description and explanation.

8

UVCS LED Light-Curing Conveyor Systems User Guide

WARNING! If you block the air flow from the LED flood array or the power supply vents,

equipment damage and malfunction can result. To prevent damage and malfunction, ensure 1"

[2.54 cm] of clearance is provided around the power supply and at least 6" [15.24 cm] of clearance

is provided around the cooling fan inlets to allow the free flow of air.

All UVCS conveyors have adjustable belt speeds and lamp-to-belt distance to address a variety of application

requirements. Standard height clearance is 4 inches; optional risers increase clearance to either 6 or 10 inches.

When combined, the UVCS conveyors’ consistent intensity, fast curing, and adjustable line speeds create an

optimized light-curing process that enables high throughput.

Features & Benefits

Features

Complete UV shielding

Built-in exhaust fan and stack

Controlled and consistent cure times

Integral vacuum hold-down and cooling system

Accepts parts up to 12" x 36"

Accurate digital belt control and readout

4", 6", or 10" vertical clearance available

Adjustable array-to-belt distance

12" belt width (guides available to channel parts into

center 6")

Bench-top conveyor (with optional transportation carrying

cart)

Assembly and Setup

Unpacking and Inspecting Your Shipment

Your UVCS LED light-curing conveyor will arrive in one or two crates. Inspect the crates and boxes for damage

and notify the shipper of box damage immediately.

Open each box and check for equipment damage. If parts are damaged, notify the shipper and submit a claim

for the damaged parts. Contact Dymax so that new parts can be shipped to you immediately.

Check that the parts included in your order match those listed below. If parts are missing, contact your local

Dymax representative or Dymax Customer Support to resolve the problem.

Parts Included

■ BlueWave® LED Flood System(s) - LED Array, Power Supply, Power Cord, Interconnect Cable

■ UVCS Conveyor with Acrylic Tunnel Shield

■ Adapter Plate and Cradle Assembly

■ UVCS LED Light-Curing Conveyor Systems User Guide

■ UV Protection Goggles

9

UVCS LED Light-Curing Conveyor Systems User Guide

Conveyor System Setup

Conveyor Setup

1. If purchased, uncrate and assemble the optional Conveyor

Mounting Cart prior to unpacking the Conveyor.

2. Remove the protective coverings from the Conveyor. Place

the Conveyor on the Conveyor Mounting Cart or on a

convenient work surface. Install the Exhaust Ventilation

Stack on the Blower Motor’s Outlet Flange. Secure the

Exhaust Ventilation Stack with the 3 fasteners provided.

3. Unpack the LED Flood System(s). Each Flood System includes

an LED Array, Power Supply, Power Cord, and Interconnect

Cables. There may be one or two LED Array systems inside

the crate depending on the conveyor system ordered.

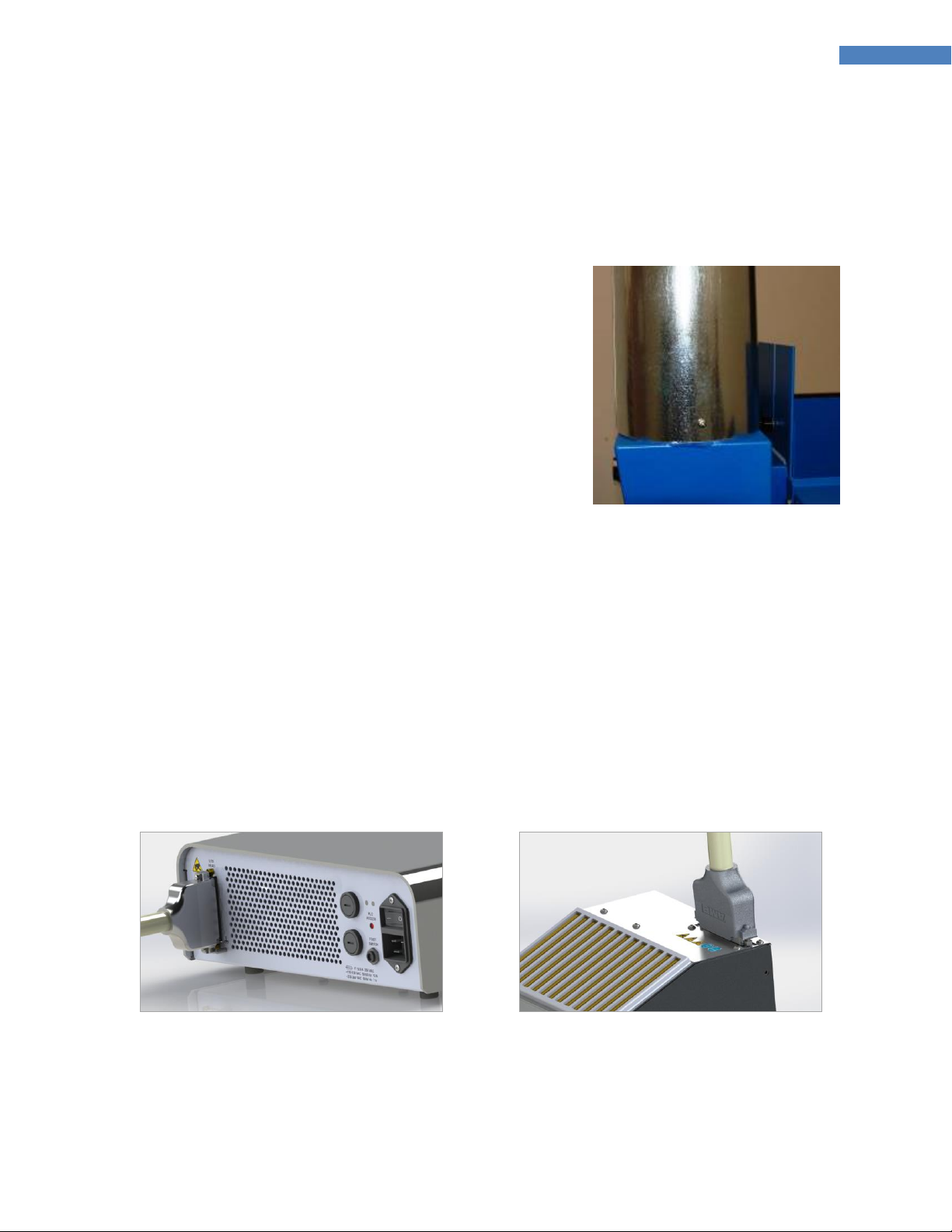

Figure 2. Exhaust Ventilation

Stack

Mounting the LED Flood Array(s)

Up to four LED Arrays can be mounted onto your conveyor. Please reference the quick start instructions

included with your Conveyor Kit for complete set up instructions.

Interconnect Cables

Attach and fasten the 37-Pin Interconnect Cable from the back panel of the Power Supply to the top of the

LED Flood Array.

Figure 3. Interconnect Cable to Power

Supply

Figure 4. Interconnect Cable to LED Flood

Array

The LED Arrays may be controlled using the Activation Switch on the front face of the Conveyor to toggle the

LED Array on and off. This allows the LED to remain on for as long as needed.

Loading...

Loading...