Assembly and Operations Manual

Z10000 Broadband Buffer Amplifier

®

Elecraft

K2 Version & Universal Version

Version 3.2.1 / 05 January 2009

7236 Clifton Road

Clifton Virginia 20124

Telephone: (703) 830-0368

Fax: (703) 830-0711

http://www.cliftonlaboratories.com

Assembly and Operations Manual

Z10000 Broadband Buffer Amplifier

Elecraft® K2 Version & Universal Version

Version 3.2.1 January 2009

(c) 2006, 2008, 2009 Jack R. Smith d/b/a/ Clifton Laboratories.

Last Revised 05 January 2009

1.0 Introduction and Specifications

1.0 Introduction

Clifton Laboratories’ Z10000 IF sampler buffer amplifier is available in two versions:

• Z10000-K2 model—A version optimized to be used with an Elecraft K2 transceiver,

with bandpass response shaping for a 4915 KHz IF;

• Z10000-U or “Universal” model—The same PCB as the Z10000-K2, but without the

frequency-dependent parts. The Z10000-U is broadband.

The Z10000 is intended to provide a high impedance interface to Clifton Laboratories’

Z90 and Z91 SpectraScan Panadapter, but may also be used as a general purpose buffer

amplifier.

1.2 Specifications

The Z10000-K2 and –U models share many specifications:

Parameter Common to Z10000-K2 and Z10000-U

Physical size Approx 1.4” (35 mm) x 1.25” (32 mm). Height

approx 0.2” (5 mm) plus clearance for wiring.

Mounting hole: clearance for 4-40 machine

screw.

Power Requirements +12V at approx 20 mA. On board regulator

permits operation with 30V maximum supply

voltage.

Connectors None. Direct wire (coaxial cable) connection

via solder pads. User may install headers (0.1”)

spacing if so desired.

Gain User settable via programming resistor.

Different maximum and minimum for –K2 and

–U models.

Output Impedance 50 ohms; short circuit protected.

Active Devices 78L09 voltage regulator

AD8007 amplifier

Reverse Isolation Typically 80 dB at 4.915 MHz; depends on

cable routing as stray coupling becomes

important at this level of isolation. Less

isolation at higher frequencies. See Section

1.3.3.

Harmonic Distortion

nd

and 3rd

(2

harmonic)

rd

3

order

intermodulation

distortion

Typically 80 dB below carrier; depends on

gain setting and input level

Typically -70 dB below output for signal levels

found in receiver input stages. IP3 depends

on gain setting and frequency, typically +30

dBm.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 1

Input Signal Level DC not to exceed 25 volts; AC input level

depends on gain setting; typically used with a

less than 100 mV PP input.

Parameter Z10000-K2 Z10000-U

Bandwidth Flat within ±1 dB over

200 KHz range

centered on 4915

KHz. Rolled off above

6 MHz and below 4

MHz.

Input Impedance Depends on bias

isolation resistor

setting; used to

provide extra roll off

and loss;

recommended

values range from 1 K

to 4.7K ohm

Gain Depends on R905 &

R907 values. Typical

maximum gain at

4915 KHz is +9 dB,

typical minimum gain

is -18 dB

1.3 Typical Performance Measurements

Depends on gain. If

set for +6 dB net gain,

usable bandwidth >

100 MHz. (See typical

performance plot)

Low frequency

response extends to

1

below 50 KHz.

Depends on

frequency and

attachment

technique. Greater

than 1.5 K ohm to 10

MHz, (See typical

performance plot)

Depends on R907

value. Typical

maximum gain at 5

MHz is +14 dB, typical

minimum gain is -4 dB

The data presented was taken with several Z10000 amplifiers.

• Unit 1

—A production model Z10000-U buffer amplifier equipped with connectors

2

for easier testing, set for net 10 dB gain (nominal

). R905 = 4.7K and R907 = 95.3

ohms. A 49.9 ohm surface mount resistor was installed across the test amplifier’s

input to provide for 50 ohm nominal input impedance.

• Unit 2

—A production model Z10000-K2 buffer amplifier, set for a nominal loss of 9.5

dB. (The K2 has significant gain ahead of the recommended Z10000 connection

point; hence to provide net 0 dB from K2 antenna port to Z10000 output requires

the buffer amplifier to operate with signifcant negative gain (loss).

• Unit 3

—A prototype Z10000-U ampllifier, set for 6.7 dB nominal net gain.

1.3.1 Frequency Response and Gain

1

It is possible to extend the Z10000’s low frequency response to 3 KHz by replacing all 0.22µF

capacitors with 1.0µF. The Z10000-U used in the test data presented has this modification.

2

The theoretical gain for the tested configuration is 9.9 dB, representing 15.9 dB amplifier

gain, followed by 6 dB loss resulting from the series 49.9 ohm output series resistance.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 2

The data presented in this manual was taken with two vector network analyzers; a

Hewlett Packard model 8752B and an HP model 87510A. Both VNAs assume the device

under test is terminated with the network analyzer’s impedance, 50 ohms (The 8752B is a

75 ohm test set and is used with minimum loss 75:50 ohm matching pads for all

measurements presented.) Since the buffer amplifier’s impedance significantly exceeds

50 ohms, a

nearly doubling (+6 dB gain) into a high impedance load. To prevent this effect from

distorting the gain results, all amplifiers under test have their input is terminated with a

49.9 ohm shunt resistor.

At 5 MHz, Unit 1’s measured gain is 9.78 dB, only 0.12 dB less than theoretically predicted.

The 3 dB bandwidth extends from 3 KHz to 174 MHz.

false gain will be observed due to the network analyzer’s output voltage

Unit 2, presented below, shows the effect of the K2-specific frequency shaping

components. Both above and below the K2 IF frequency (4.9 MHz), the Z10000-K2’s gain

rolls off. At the desired 4.9 MHz, the net gain is -9.6 dB, necessary to offset the K2’s postmixer ampllifier gain when a net 0 db transfer gain is desired.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 3

1.3.2 Input Impedance

The buffer amplifier’s input

impedance is dominated by

two elements; the bias isolation

resistor (4.7 KΩ in the test

amplifier) and shunt

capacitance (the shunt

capacitance of the PCB

traces, connecting wires to the

amplifier and the amplifier’s

input capacitance.)

The measured data presented

at the right (from Unit 3) should

be considered as

representative of an amplifier

with short (a few inches)

coaxial cable input leads.

1.3.3 Reverse Isolation

The buffer amplifier’s

reverse isolation is a

function of frequency, as

illustrated in the amplifier

measurements presented

at the right for Unit 1. At 8

MHz, the measured sample

exhibited 115 dB reverse

isolation.

Reverse isolation is also

affected by how the

amplifier is housed, lead

dress, shielding, etc.

Accordingly, the isolation

illustrated at the right may

not be achieved in every

instance.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 4

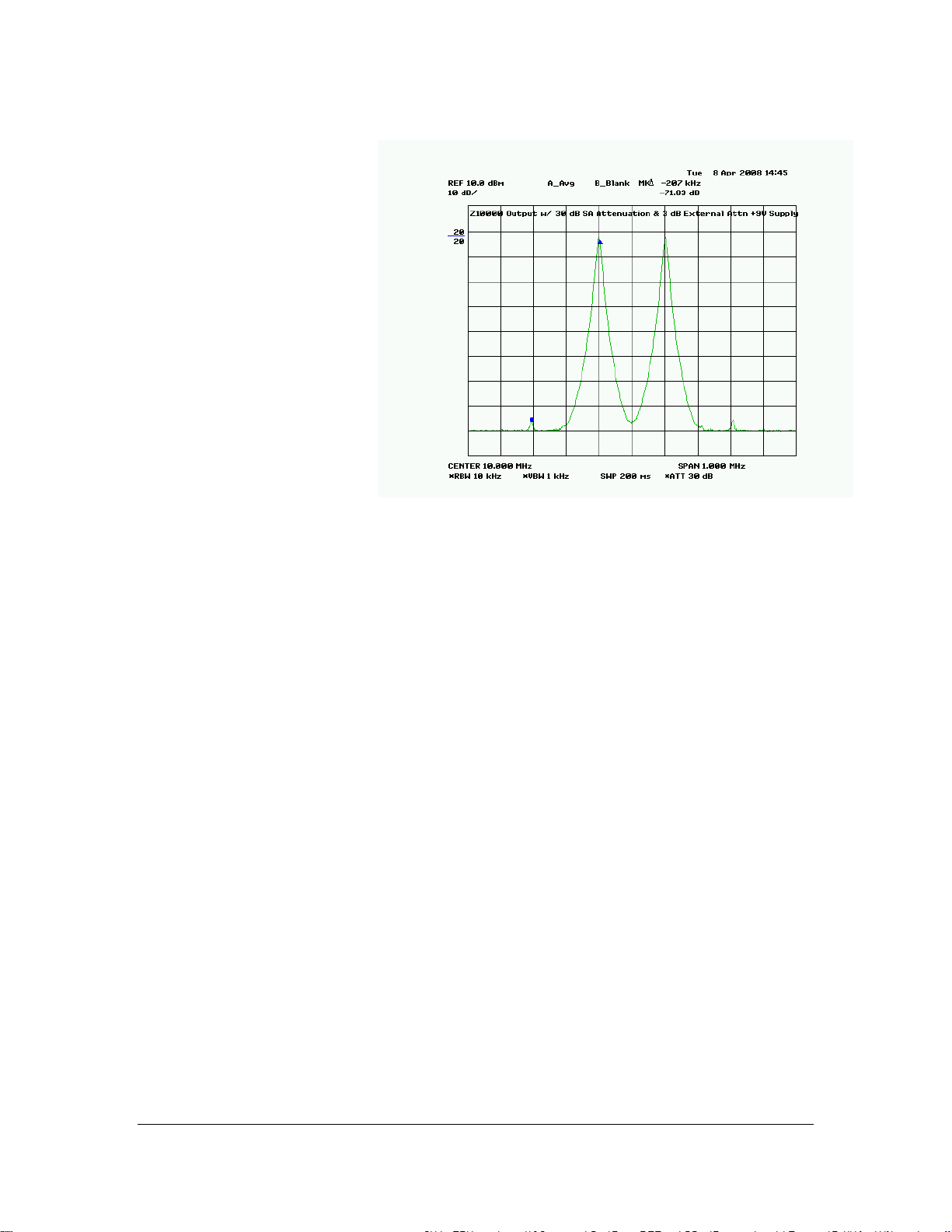

1.3.4 Intermodulation Performance

The illustration at the right

shows the output of Unit 1

with two equal signals (9900

KHz and 10100 KHz) of -10

dBm applied to the amplifier

input. The amplifier output is 0

dBm (a 3 dB attenuator is

applied ahead of the

spectrum analyzer in this

plot.)

The third order

intermodulation product is

-71.8 dBm down from either

tone. With an output based

reference, therefore, the IP3

is thus +35.9 dBm.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 5

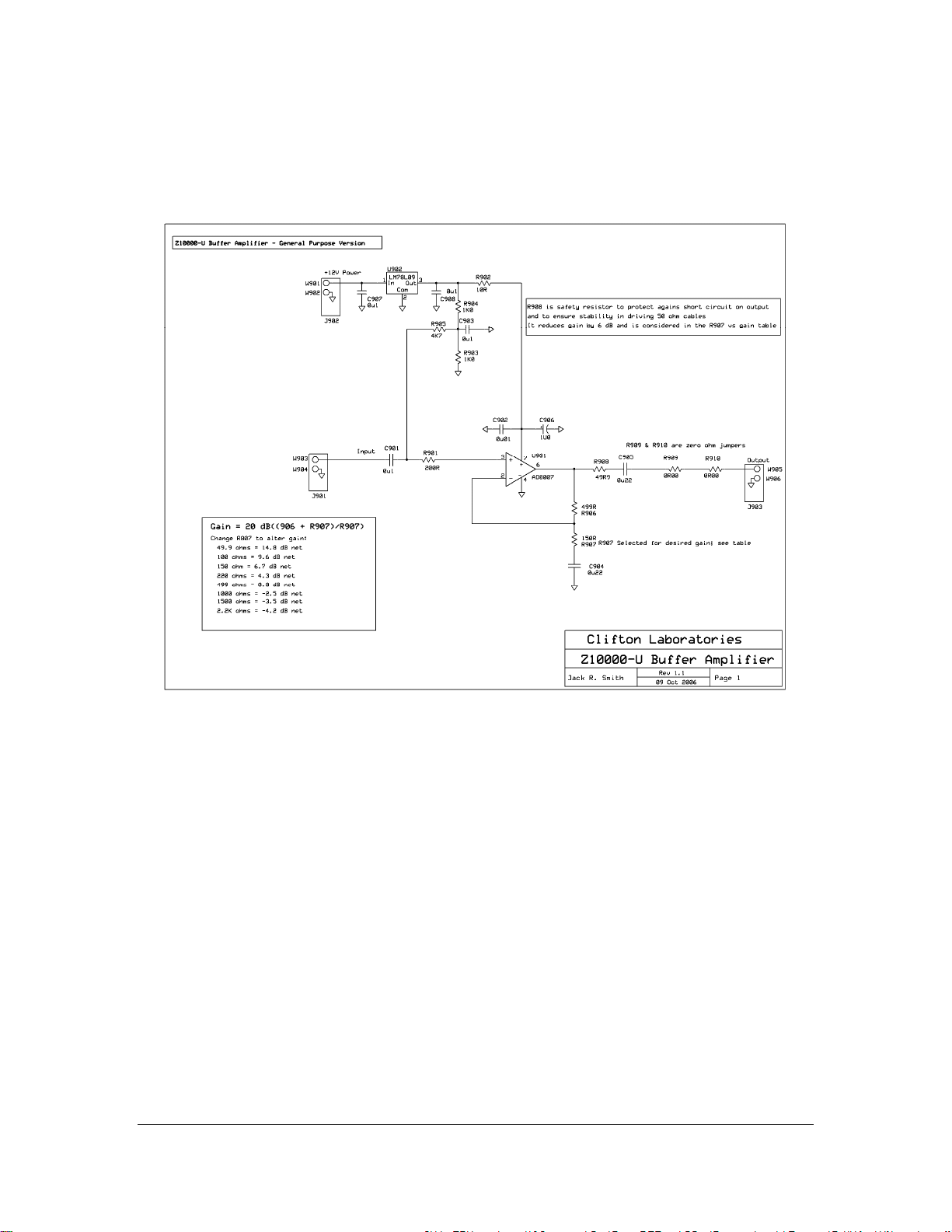

2.0 Schematic and Circuit Description

2.1 Universal Version

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 6

2.2 K2 Version

2.3 Theory of Operation

The operational circuitry of both buffer amplifiers is similar, with differences in component

selection for frequency shaping in the K2 version.

2.3.1 Power Supply.

The AD8007 amplifier is rated at an absolute maximum operating voltage of 12V. In order

to provide a safety margin, and to decouple the amplifier from the power supply, U902,

a three-terminal fixed regulator, provides a source of stable +9V to U901. C907 and C908

provide additional decoupling. U901, the AD8007 amplifier, obtains its power via the RC

decoupling network comprised of R902, C902 and C906.

Since the circuit operates from a single positive power supply, it is necessary to bias

U901’s input to approximately V/2. This is accomplished by the 2:1 voltage divider chain

of R902/R903. C903 bypasses the V/2 reference voltage; whilst R905 increases U901’s

input impedance by isolating C903’s RF ground. R905’s maximum value is determined by

the U901’s input bias current on the positive pin, specified by Analog Devices as 8μA. For

4.7 KΩ, this bias current represents an IR drop of 38 mV. With a DC gain of 4, the

corresponding output DC offset will be about 150 mV. If absolutely necessary for high

input impedance, R905 may be substituted with a higher value resistor, up to

approximately 22 KΩ. However, at frequencies above a few MHz, the input impedance is

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 7

+

dominated by shunt capacitance; increasing R905 should be done only with an

understanding of all the factors affecting the input impedance.

3

2.3.2 Amplifier

U901, an Analog Devices AD8007, is a high performance, low noise current feedback

amplifier, with a gain-bandwidth product exceeding 650 MHz. A current feedback

amplifier is also known as a “transimpedance” amplifier. Analog Devices describes how

a current feedback amplifier works:

First, the negative input of a CFA responds to current; the output voltage is

proportional to that current, hence transimpedance (V(out) = Z(t) I(in)). Instead of

keeping the negative input current small by maintaining high input impedance,

and using feed-back and voltage gain to keep the input voltage difference

small, the CFA keeps the voltage difference small by virtue of its low input

impedance (like looking back into a low-offset emitter follower); and it keeps its

net input current small dynamically by feedback from the output.

When an ideal CFA is driven at the high-impedance positive input, the negative

input, with its low impedance, follows closely in voltage; and the high gain for

error current and the negative feedback through Rf require that the currents

through Rf and Rin be equal; hence V(out) = V(in)[R(f)/R(in) + 1], just like for

voltage-feedback amplifiers. A major difference is that the slew rate can be quite

high, because large transient currents can flow in the input stage to handle rapid

changes in voltage across the compensating capacitor(s). Also, the low

impedance at the negative input means that stray input capacitance will not

substantially affect the amplifier's bandwidth.

U901’s gain (in dB) is determined by the ratio of resistors R906 and R907:

907906

Gain

In the Z10000-K2 version, R905 and C901 form a high-pass RC filter and input attenuator.

Adjusting R905 to values below 4.7K will increase the input attenuation, which is desirable

to achieve the desired amplifier gain when used in a K2.

The Z1000-K2’s output stage also uses RC high pass filtering (R908 & C905) to roll off

frequencies below approximately 5.6 MHz. The AD8007’s output is connected through a

five element low pass filter, consisting of L901, L902, C910, C911 and C912. The low pass

filter sharply rolls off frequencies above 7 MHz.

C910, C911 and C912 are removed in the Z10000-U model and L901 and L902 are

replaced by zero ohm jumpers. In addition, C901 is changed in the Z10000-U to 0u1 and

C905 to 0u22 to provide a flat frequency response down into the 50 KHz range.

R908, 49.9 Ω, allows U901 to drive capacitive loads, such as coaxial cable and also

protects U901 against operation into short circuits. However, the voltage divider effect of

log20

=

10

R

907

RR

3

Clifton Laboratories will provide interested Z10000 owners with the LTSpice model of the

AD8007 and an LTSpice model of the amplifier circuits upon request. SPICE modeling will allow the

user to determine the effects of component changes with a reasonable degree of accuracy.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 8

R908, which is in series with the load, reduces the net available gain into a 50 ohm load

by 6 dB.

2.3.3 Gain Setting in the Z10000-U Buffer Amplifier

Note: This section applies only to the Z10000-U amplifier. See later discussion for gain

setting of the Z10000-K2 amplifier.

To vary buffer amplifier’s gain, select R907 using the following table or the provided

graph.

Net Gain (net of R908 series resistance) R907

+15 dB 49.9 Ω

+10 dB 100 Ω

+6.7 dB 150 Ω

+4.3 dB 221 Ω

0 dB 499 Ω

-2.5 dB 1000 Ω

-3.5 dB 1500 Ω

-4.2 dB 2200 Ω

R906 and R901 should not be varied from their design values without a thorough analysis

of the circuit.

The effect of changing R907 upon gain and bandwidth is illustrated in the following plot.

The plot is based upon SPICE simulation of the circuit and is representative of the actual

circuit.

In the –U version, R905

will normally be 4K7Ω.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 9

If it is necessary to operate the Z10000-U with less than -4.2 dB gain, C901 can be

reduced, or in the event extreme gain reductions are required, R905 may also be

reduced to provide an RC voltage divider at the amplifier’s input. Although this will

introduce some RC frequency shaping in the Z10000-U’s frequency response, the

passband tilt will be insignificant when used with a Z90 panadapter.

Section 4.4.2 of this Manual further discusses gain selection considerations for general

receiver connections.

2.3.4 Gain Setting in the Z10000-K2 Buffer Amplifier

There are two connection point options in the K2. Please read the section of this manual

(page 31) describing the connection point options first, as there are different gain

settings required for the two options.

If you go with connection point Option 1

values:

R905 = 2.2K

R907 = 2.2K

If you go with connection point Option 2

values:

, as a starting point, I recommend the following

as a starting point, I recommend the following

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 10

R905: 4.7K Ohms

R907: 220 Ohms (this is a starting point; depending on your sound card gain it may be

necessary to reduce R907 to 100 ohms or even 49.9 ohms for increased net gain.)

Note that as the Z10000’s gain is increased, the clipping point of the amplifier decreases.

Larry, N8LP, reports that with R907 at 120 ohms, the clipping point is -5 dBm. Of course, -5

dBm represents an extremely strong signal, unlikely to be encountered in most K2

environments.

If you decide to use connection point Option 1

, gain setting in the K2 version buffer

amplifier is a bit more complex, because the normal operating mode in a K2 transceiver

requires a negative net gain—in other words, a net loss—of about -14 to -15 dB. Part of

4

the negative gain is obtained by intentional rolloff in C901 and R905.

This combination provides a net gain of about -14 dB. This much loss is required because

the recommended K2 connection point has approximately 18 dB net gain from the K2’s

post-mixer amplifier, Q22 (2N5109). The Z90 is designed for optimum signal level when the

5

net gain between the antenna and the Z90’s input is approximately 0 dB.

When

combined with the approximately 3.5 dB loss of the supplied 4.915 MHz bandpass filter,

setting the Z10000-K2’s gain at -14 dB meets the “net zero gain” requirement. (This

computation assumes the K2 is operating in the “normal” mode, i.e., pre-amp off and

attenuation off.) Don’t worry, by the way, about achieving this “net zero gain” objective

perfectly. A few dB one way or the other is not critical. If you are to err, however, better

results will usually be found if you err on the side of operating the Z10000-K2 with a greater

loss than operating it for higher gain.

Although developed with Clifton Laboratories Z90/91 panadapter, measurements shows

that net 0 dB transfer gain (from K2 antenna input to Z10000 sample output) is an

excellent operating point for the Softrock Lite 6.2 receiver when used as a panadapter or

second receiver. If desired, of course, the Z10000’s gain can be increased as discussed

herein.

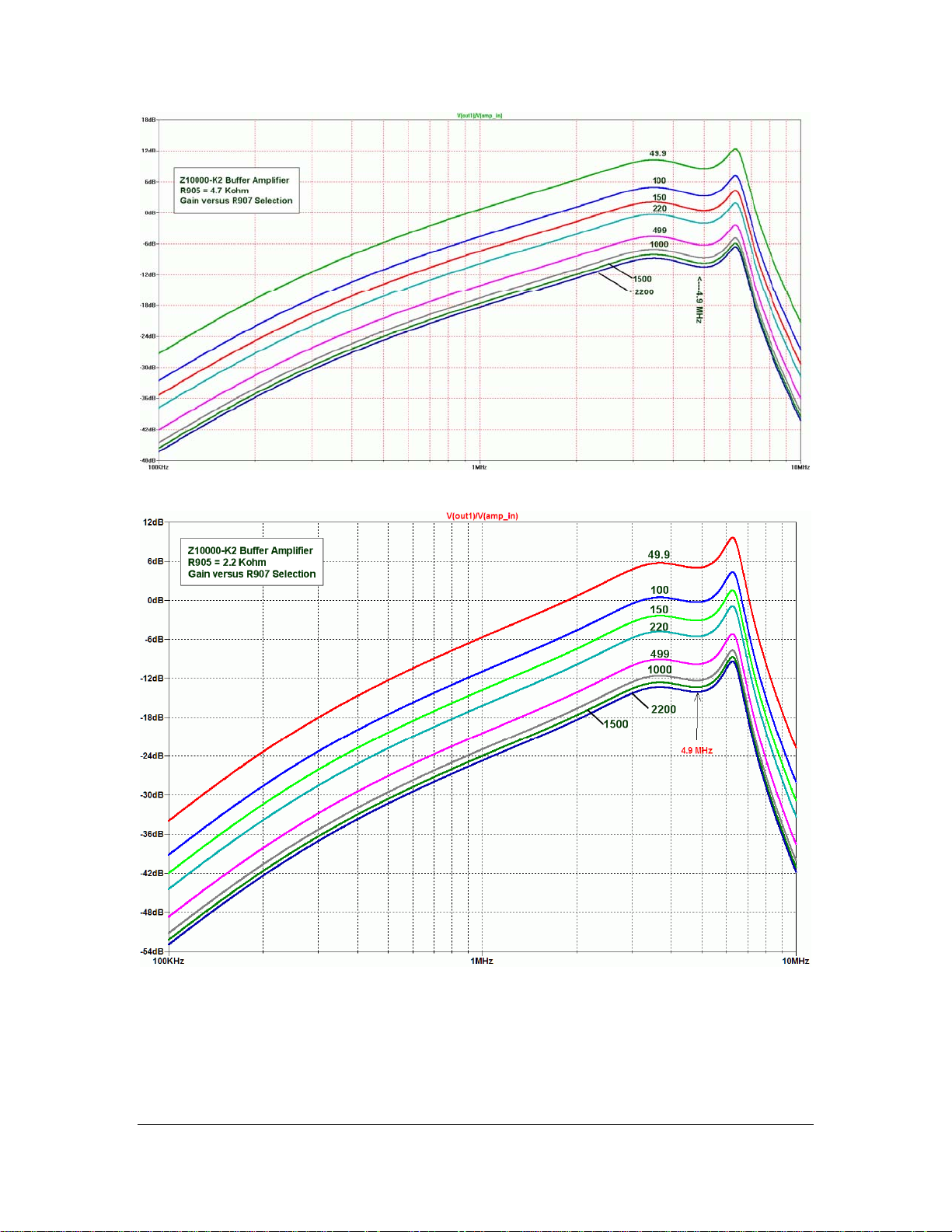

The following three figures show the net gain out of the Z10000-K2 as a function of R907

for three values of R905, 4.7K, 2.2K and 1.1K.

4

It would be possible, of course, to dispense with the buffer amplifier completely and

connect the Z90 to the K2’s IF with a resistive matching pad. However, the resistive matching pad

will not provide isolation as does the Z10000-K2. Although the Z90 has relatively low undesired

emissions from its input connector, the extra isolation of the buffer amplifier provides additional

protection against unwanted signals entering the K2’s IF amplifier chain.

5

In other words, a 1 μV signal at the frequency the receiver it tuned to should yield about a

1 μV signal at 4915 KHz into the Z90.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 11

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 12

3.0 Assembly

3.1 Parts List

The Z10000 parts are packaged in a several small envelopes, depending upon the

option purchased.

All Z10000 kits

• Resistors. All surface mount resistors, for both the –U and –K2 versions. [All R]

• Capacitors for the –U version [All Cap]

• Printed circuit board [PCB]

• Semiconductors (AD8007 and 78L09) [Semi]

K2 Frequency Sensitive Parts

• Capacitors and inductors necessary to shape the amplifier’s frequency

response to peak at 4.9 MHz. [K2 Freq]

:

Internal Mounting

• Parts associated with mounting the Z10000 (either U or K2) inside a receiver. [Int]

• K2-specific internal connectors are supplied where the purchaser selects the

Internal Mounting option and also the K2 frequency sensitive parts. [K2 Con]

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 13

If ordering a Z10000-K2, therefore, you will have several extra capacitors and

resistors that are not used in the –K2 version, as all kits are shipped with the full set of

–U parts.

When working with capacitors particularly, do not removed the individual parts

from their color-coded packaging until you are ready to use the component, as

their values are not marked on the part and cannot normally be visually

distinguished. Hence, if you mix up the capacitors, you will have to measure their

values with a capacitance meter.

Also, do not confuse 100 ohm 1% resistors (identified as 1000) with 1.0K ohm 1%

parts, identified as 1001.

Note that the schematic identifies parts with the multiplier as the “decimal” point.

For example a 1K ohm resistor is identified as a 1K0, and a 49.9 ohm resistor as 49R9.

Common Components - K2 and Universal Models

Envelope

Typical Photo Designation Value Marking Number Qty

C902 0u01 Not marked All Cap 1

C903 0u1 Not marked All Cap 1

C904 0u22 Not marked All Cap 1

C906 1u0 Not marked All Cap 1

C907 0u1 Not marked All Cap 1

C908 0u1 Not marked All Cap 1

R901 200R 2000 All R 1

R902 10R 10R0 All R 1

R903 1K0 1001 All R 1

R904 1K0 1001 All R 1

R906 499R 4990 All R 1

R908 49R9 49R9 All R 1

U901 AD8007 AD8007ARZ Semi 1

U902 LM78L09 KA78L09AZ Semi 1

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 14

Envelope

Typical Photo Designation Value Marking Number Qty

Z10000-K2 Only

Z10000-U Only

C901 8p2 Not marked K2 Freq 1

C905 5600pF Not marked K2 Freq 1

C910 1200pF Not marked K2 Freq 1

C911 1200pF Not marked K2 Freq 1

C912 1200pF Not marked K2 Freq 1

L901 1u5 K2 Freq 1

L902 1u5 K2 Freq 1

C901 0u1 Not marked All Cap 1

C905 0u22 Not marked All Cap 1

L901 0 ohm jumper All R

L902 0 ohm jumper All R

Gain Setting Parts - For both Z10000-K2 and Z10000-U

See manual to determine proper value

Resistor Supplied for Selection

R905 4K7 4701 All R 1

R905 2K2 2201 All R 1

R905 1K1 1101 All R 1

Resistor Supplied for Selection

R907 49R9 49R9 All R 1

R907 100R 1000 All R 1

R907 150R 1500 All R 1

R907 220R 2200 All R 1

R907 499R 4990 All R 1

R907 1K0 1001 All R 1

R907 1K5 1501 All R 1

R907 2K2 2201 All R 1

External and Mechanical Parts

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 15

Both Z10000-K2 and Z10000-U

Z10000-01 RG178 2 ft INT

Z10000-02 Bulkhead Connector INT

Z10000-03 6" red wire INT

Z10000-04 1/2" MF 4-40 standoff INT

Z10000-12 fish paper INT

Z10000-08 Printed circuit board

Z10000-10 4-40x1/4" machine screw INT

Z10000-11 4-40 hex nut INT

Z10000-12 3/32" x .5" red heat shrink tubing INT

Z10000-13 3/32" x .5" black heat shrink tubing INT

Z10000-14 3/32" x .5 green heat shrink tubing INT

Z10000-16 3/16" x 2" heat shrink tubing INT

Z10000-K2 Only

Z10000-05 8-pin female header All R

Z10000-06 3-pin female header All R

Z10000-07 3-pin male header All R

Multiple part values are provided for R905 and R907, to be selected by the builder as

discussed in the text.

Printed instructions are not supplied; this manual is to be downloaded from the Clifton

Laboratories web site.

Heat shrink tubing supplied may differ in diameter, length and color from the values in

the above parts table.

3.2 Working with Surface Mount Components

If you are unfamiliar with installing surface mount components, you should review this

section of the Assembly Manual. The surface mount components in this kit are

considered “large” by industry standards, and should not represent difficulty if you have

prior kit assembly experience, either surface mount or through-hole.

3.2.1 Tools

I use the following tools in assembling surface mount printed circuit boards:

Tool Comments Approximate

Cost

I use curved nose forceps

to hold parts while

soldering. I prefer the

pattern 7-SA forceps with

gently curved tips, but the

angular pattern 6-SA may

be preferred by some.

These are by Technik and

are non-magnetic stainless

$9.00 each MSC part

Source

number:

7-SA

pattern:

88348099

6-SA

pattern:

88348081

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 16

Tool Comments Approximate

Cost

steel.

I find clip-on magnifiers

essential to view small

parts. I keep both 1.75 x

and 3.5 x magnification

types at hand.

The 3.5 x magnifiers have a

working distance of 4”, so

it gets you “up close and

personal” with the parts!

(I’m not a fan of the

headband style

magnifiers, but personal

tastes differ in this regard.)

Of course, if you don’t

wear glasses, a different

style magnifier will be in

order.

Small diameter solder is

essential. I use either 0.015”

diameter or 0.022”

diameter solder. If you can

find it, I find solder with a

slight amount of silver (3%

typically) produces a

better appearing joint.

My 0.015” solder is Kester

“44 rosin, 63/37 eutectic

mixture. My 0.022” solder is

(believe it or not) Radio

Shack 62/36/2, with 2%

silver.

If the pad being soldered

to is at all tarnished, a

touch of solder flux will

clean it up. Some like to

use flux regardless of the

pad condition. I prefer a

pen-type dispenser.

$20 each MSC part

$15 for ½

pound

Kester

$4 Mouser

Source

numbers:

1.75X:

06533202

3.5X:

06533236

Mouser

part

number

533-236337-07

part

number:

533-0951

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 17

Tool Comments Approximate

Cost

Solder wick can’t be beat

for cleaning up unwanted

solder, or for removing

solder from a pad after a

part is changed. For small

surface mount parts, I like

narrow solder wick, 0.025

to 0.030.”

Finally, you need

something to hold the PCB

in place whilst you work on

it.

I use a Panavise #301 (with

nylon jaws) for small

boards and a Panavise

#324 board holder for

larger projects.

$2.50 Mouser

$45 for the

standard

Panavise

$85 for the

PCB holder

Source

part

number:

5878-80-15

#324 PCB

Holder is

Mouser PN:

591-324

#301

Standard

Panavise is

Mouser PN:

591-301

Mouser: http://www.mouser.com/ (excellent line of electronic parts and no

minimum order size)

http://www1.mscdirect.com/ (Tools of variety almost unimaginable and it’s

MSC:

all in stock. No minimum order, prices may be a bit on the high side, but I’ve never

bought a tool from them that I’ve been disappointed in. Their customer service is among

the best I’ve seen.)

The tool not

quite useful for many purposes around the electronics

workbench, but when it comes to holding surface mount

parts, I’ve found them to excel at being “parts

launchers” with the ability to shoot a small surface mount

component across the room in an instant.

This tools list assumes you have a suitable soldering iron. I

use two Hakko 936 soldering stations. For integrated

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 18

to use—self-closing forceps. These tools are

circuits such as U801/U901, I use a 0.032” diameter long taper conical tip. For larger

surface mount and through-hole parts, I use a 1/8” screwdriver tip. My experience is that

a lower power soldering iron isn’t adequate, and one of much greater power is too

much. Whether this is a true Goldilocks optimum or just my personal preference remains

to be determined.

If you are thinking of purchasing a new soldering station, I recommend the Hakko Model

936.

3.2.2 Installing Surface Mount Components

3.2.2.1 Integrated Circuits

U901 is a reasonably easy to install surface mount IC, if you have the correct tools and

follow a few simple steps.

Before starting, remember to apply proper anti-static procedures. Study the IC’s

marking and the PCB layout so that you know the correct orientation.

The idea is to hold the IC in place by soldering two diagonal corners in place and

then solder the remaining pins. Start by applying a sparing

one of the corner pads. Then apply a similar amount of solder to the diagonal

corner pad. Place the IC on the PCB, correctly oriented, with pins centered on

the pads. While holding

the IC in place, touch the

soldering iron to the first

tinned pad, tacking the

IC’s pin in place. The

small figure shows an

AD8007 after the

diagonal pins have been

tack soldered in place.

Note how the pins are

centered over the PCB

pads.

Check the orientation of the IC, verifying that it

is properly centered over the pads. If you don’t

get this right now, it will be far more difficult to

correct when the second pin is soldered in

place. When you are satisfied that the IC is

centered on its pads, touch the other diagonal

tinned pad with your soldering iron.

amount of solder on

Double check that the IC has not shifted during

the earlier steps and that the IC’s pins are

centered on their respective pads. Then solder

the remaining pins to their pads. Depending on

how the PCB was constructed, it may have sufficient solder plating so that

additional solder is unnecessary—simply touching the soldering iron to the pin and

pad flows enough solder to form a reliable joint. If this isn’t

possible with your PCB, then apply a small

form the joint.

After each time you touch the solder to the soldering iron,

check the end of the solder for a blob or ball. If you find the

solder has formed a ball, cut it off at an angle to form a

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 19

amount of solder to

pointed end. Otherwise, it will be difficult to control the amount of solder

deposited.

After soldering, check for bridged pins or shorts to ground. Clean up any

problems with solder wick.

3.2.2.2 Passive Components

To install a passive component,

use a similar approach:

Lightly tin one pad.

With angled forceps (or

your favorite tool) hold

the part in place and

solder the part to the

tinned pad with a light

touch of the soldering

iron. This will anchor the

part in place. Notice how

nicely Technik pattern 7A

forceps hold the part in

place without obscuring

vision or blocking the

soldering iron.

Solder the remaining

pad(s). If necessary

rework the first pad

connection.

It does not take a large amount of solder to properly attach a surface mount

component. A correctly installed part will be flush against the board and have a small

filet at the end caps.

3.2.3 Removing Defective Parts

In almost every instance, trying to salvage a surface mount part installed wrong is a

waste of time. A 1% 1206 size surface mount resistor, for example, costs about 2 cents in

100 lots. It’s much easer to use a pair of cutters and snip the part in half. (Resistors and

capacitors are ceramic based—they shatter when cut.)Then use solder wick to remove

the two halves. Clean up the pads with additional applications of solder wick.

To remove a multi-pin IC, a similar approach can be used—carefully cut the part into

pieces with cutters, exercising care to avoid damaging traces or the PCB. A hot air gun

can also be used to simultaneously liquefy the solder at all IC pins. The IC can then be

lifted free of the PCB. Care must be taken, of course, to avoid damaging nearby parts

with the heat gun.

An alternative IC removal approach is ChipQuik (DigiKey PN SMD1-ND, approximate

price $15). ChipQuik’s kit includes special flux and a low temperature melting point solder

that mixes with the normal solder and allows the chip to be removed without extensive

heating.

Because I do so much surface mount work, I’ve purchased a Hakko 950 SMT tweezer

handpiece and several blades. Although not cheap, it’s an excellent tool, like all other

Hakko products I’ve purchased.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 20

3.2.4 Most common error

The most common error I make in installing a surface mount resistor or capacitor is to not

center the part on the pads, resulting in the metalized end of the component shorting to

ground, where it bridges the pad’s isolation. This error can be completely avoided by

carefully centering the part and holding it in the correct position whilst soldering one end.

It’s much easier to fix this type of error before soldering the second end!

With integrated circuits, the most common error is to bridge solder across adjacent pins.

In most cases, applying solder wick will remove the bridge and leave the pins correctly

soldered in place.

3.2.5 Teflon Coax

The coaxial cable supplied with this kit is RG178, with Teflon outer jacket and center

insulation. Teflon will not melt during normal soldering operations, unlike, for example,

RG174, with a center conductor insulation that melts if you look at it crossways. However,

RG178 requires some special handling:

Most wire strippers do not work well with Teflon. I use a Hakko FT800 thermal wire

stripper. Before acquiring the FT800, I used either a special micrometer-type wire

stripper or an X-Acto knife. It is extremely easy to cut through the shield or the

center condutor when stripping the coax, so apply light pressure when cutting.

RG178 is small (about 0.078” [1.8mm] diameter) so be careful when stripping it.

The shield is comprised of #38 AWG wire, which is tiny. It’s easy to wind up with

small pieces of shield in places where you don’t want them, so look over your

work with a magifying glass for stray bits of shield.

Likewise, the center conductor is #30 AWG and it’s very easy to cut through it

when stripping the center insulation.

Gently does it when using the X-Acto knife. Let the sharpness of the blade do the

work, and do not apply more than the absolute minimum pressure necessary.

You might practice stripping the jacket and center conductor on the free end of

the cable to get a feel for how easy or difficult it will be for you before doing it

“for real.”

Cutting the cable with a bit of excess length is not a bad idea as it may save you

from redoing a lot of work if your first attempt at stripping the cable fails.

You have only one opportunity to cut the connector end of the cable. The old

carpenter’s rule of “measure twice, cut once” applies with force here. Replacement

cables are $15 from Clifton Laboratories.

After soldering the RG178 to the input and output printed circuit board pads, be careful

not to apply excessive mechanical force to the cables. It’s easy to rip the pad off the

printed circuit board or break the cable where it is soldered. It’s also easy to wind up

with a stray wire from the shield floating around and shorting the input and output pads.

Any stray bits of shield wire should be carefully removed.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 21

4.0 Assembly

4.1 Component Placement

Locate the appropriate PCB and orient yourself with the board. Identify the top and

bottom. The top has silk screening as well as solder masking.

The photograph shows an earlier version of the PCB. Later PCBs correct the silk screen

error identifying R907 as R8

production circuit boards may be slightly smaller than in the photographs.

This photograph shows parts placements for both

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 22

07, and slightly rearrange other silk screen legends. In addition,

the -K2 and -U versions of the Z10000.

The bottom PCB surface is solder masked but not silk screened. Please use the following

annotated photograph for parts placement.

The photograph below shows the parts placement for the -K2 version and, with respect

to C902, C906, C907 and C908, the -U version as well.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 23

The Z10000-U differs on the bottom assembly in several respects from the -K2 version:

Low pass filter capacitors C910, C911 and C912 are not used.

L901 and L902 are not used. Instead, 000 ohm jumpers are installed in their place.

The photograph shows the most recent (2008) PCB board. C906 in the photograph is a

tantalum electrolytic capacitor. Normally a ceramic capacitor is supplied with the

Z10000, although a tantalum electrolytic may be provided in some instances.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 24

The assembled Z10000 top view photo below is identical in appearance for both the -U

and -K2 models, as the differences are only in component values.

The board shown uses plug-in headers for test purposes. Your board will normally use

direct wire connections to the power, input and output pads, although you are, of

course, free to use header pins if so desired.

The photo below shows the bottom view of an assembled Z10000-U.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 25

4.2 Component Installation

The assembly instructions are almost identical for both the K2 and Universal board. Where

appropriate, the following instructions will identify the differences.

Before starting construction, it is necessary to select the gain programming resistor (R907)

and the input resistor (R905). In the case of an Elecraft K2 transceiver and Option 1

connection point, the recommended values are R905=2.2K, R907=2.2K For Option 2

connection, the starting point should be R905=4.7K, R907=220 ohms. For assistance in

determining the programming resistor value read Sections 2.3.3, 2.3.4 and 4.4.2 of this

document.

If the internal installation option is purchased, locate the fish paper6 (black, stiff

paper) and the printed circuit board. Align the 1/8” hole in the fish paper with the

PCB’s mounting hole and trim the fish paper to approximately the same size as

the buffer amplifier PCB using scissors or an X-Acto knife. Return the fish paper to

a safe location.

Now the surface mount parts on the top are installed:

[Semiconductor Package] Install U901 (AD8007) using the technique discussed

earlier.

[K2 Freq –K2; All Cap for -U] Install C901 (0.1 uF for –U; 8.2pF for –K2, both

unmarked)

[All Cap] Install C903 (0.1 µF, unmarked)

[All Cap] Install C904 (0.22 µF, unmarked)

[All R] Install R901 (200 Ω, marked 2000)

[All R] Install R902 (10 Ω, marked 10R0)

[All R] Install R903 (1 KΩ, marked 1001)

[All R] Install R904 (1 KΩ, marked 1001)

[All R] Install R906 (499 Ω, marked 4990)

[All R] Install R908 (49.9 Ω, marked 49R9)

[K2 Freq for –K2; All Cap for -U] Install C905 (5600 pF for –K2; 0.22 µF for -U, both

unmarked)

[Select R905 from [All R] following instructions at Sections 2.3.3, 2.3.4 and 4.4.2]

Install R905

[Select R907 from [All R] following instructions at Sections 2.3.3, 2.3.4 and 4.4.2]

Install R907

Flip the board upside down and install the remaining surface mount components:

[All Cap] Install C902 (0.01 µF, unmarked)

[All Cap] Install C906. (1.0 µF, unmarked)

[All Cap] Install C907 0.1 µF, unmarked)

[All Cap] Install C908 (0.1 µF, unmarked)

If you are building the –K2 version, install the frequency-sensitive parts [these parts are not

included with the –U version]:

[K2 Freq] Install L901 (1u5 inductor)

6

Why this is called “fish paper” remains a mystery. The best I can find is a conversation with

a ham in his 70’s (K8AQC) said that when he was a young man, the old time electricians called it

“fish oil paper” which leads him to believe that the insulating paper at the time was coated with

fish oil, and then heated and rolled. That’s the most plausible explanation I’ve heard for the name.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 26

[K2 Freq] Install L902 (1u5 inductor)

You may find the two inductors a bit more difficult to install than the resistors or

capacitors due to the way the leads are formed. After soldering one end in place, check

the associated pads for an inadvertent short circuit to ground. Both pads associated with

each inductor should be an open circuit to ground when checked with an ohmmeter.

Repeat the ohmmeter check after soldering the second end of each inductor.

[K2 Freq] Install C910. (1200pF, unmarked)

[K2 Freq] Install C911 1200pF, unmarked)

[K2 Freq] Install C912 (1200pF, unmarked)

If you are building the –U version, install the filter bypass parts:

[All R] Install L901 bypass (Zero-ohm jumper)

[All R] Install L902 bypass (Zero-ohm jumper)

The two zero-ohm jumpers are slightly small for the pad spacing but will work if you

carefully center the parts on the pads. After soldering one end of each zero ohm jumper

in place, check for an inadvertent short to ground. Both ends of both pads should be

open circuit to ground when measured with an ohmmeter. Check again after soldering

the second end of each zero ohm jumper.

For all versions:

Now install the remaining through-hole parts:

[Semi] Install U902. This is a 78L09 3-terminal regulator in a TO-92 package. Note

the orientation of the device as shown in the silk screen outline. You will have to

form the leads to fit the hole. Assess how much vertical clearance is needed

above the PCB. In the –K2 version, press U902 into place so that the body is

approximately 1/8” (3mm) from the top of the PCB. If necessary to have a lower

profile in your particular installation, you may leave the leads longer and bend

the regulator as necessary, avoiding, of course, shorting the leads together.

Otherwise, follow the –K2 installation practice.

The Z10000 is supplied with a length of RG178 coaxial cable with an attached cable jack

bulkhead connector. This cable is to be cut as necessary for your installation, with the

connector on the output and the remaining cable to be for the input connection.

Clifton Laboratories offers an optional 3’ RG174 cable with a male SMA connector on

one end and a male BNC connector on the other end. This cable is not part of the

Z10000 buffer amplifier kit.

Since the Z10000-U may be employed in a variety of receivers or transceivers, explicit

installation instructions cannot be provided. Clifton Laboratories suggests the K2

installation guidelines provided below be used to develop your own installation strategy.

For installation in a K2, prepare the supplied coaxial cable and power hookup wire as

follows.

Examine your K2:

Before cutting the coaxial cable, remove the cover on your K2 and determine where

you wish to mount the SMA bulkhead output connector. Study the photographs in this

manual to understand where the buffer amplifier will be mounted. In a normal

installation, it will be placed next to the noise blanker board, or the place where the

noise blanker board would be installed if your K2 has that option.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 27

The following photograph shows the normal K2 installation location. The buffer amplifier

mounts on a ½” (12.6 mm) male-female aluminum standoff that replaces one of the

screws holding the K2 main board in place.

Now that you know where the buffer amplifier will be located, determine where the

output SMA connector will be installed.

My K2 has the optional KPA100 100 watt output stage but does not have the K60XV 60

meter band / transverter board. This leaves two open holes (XVTR IN and XVTR OUT) in my

K2, which are the correct size for the SMA bulkhead connector:

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 28

Note that the RCV. ANT. hole is a bit large to properly hold the SMA connector.

If you need to punch or drill a hole in your K2 for the SMA connector, the connector

nominal outer diameter is ¼” (6.4mm). Both nuts require a 5/16” wrench.

Using the cable or a piece of string, determine the cable length required from the SMA

connector mounting position to the buffer amplifier board. In my K2, the length of

required output cable is approximately 6” (152 mm), but yours may vary, and you may

also wish to route the cable differently than I did.

This is a critical dimension, in that if cut too short, you will require a replacement cable.

After cutting the cable, reserve the cut-off piece for the input connection.

Now, determine the length of cable required for the input connection. In the K2,

assuming the Z10000-K2 is installed in the normal location, the input coaxial cable will be

approximately 5 inches (125 mm) long. You should determine if this length is adequate

for your installation and preferred routing.

After you have determined the correct input cable length, cut a section of RG178 to that

length.

Bob, K7HBG, has provided the following drawing showing where he located the SMA

bulkhead in his K2, which is equipped with all possible options and hence has no unused

holes.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 29

Bob notes that the 6mm (¼”) (internal diameter) lock washer just fits in between the "D"

chassis bracket and the 160 Meter board so it is necessary to carefully measure the hole’s

location.

Bob’s K2 with the

buffer amplifier in

place. Note the

SMA connector

mounting in the

space between the

160 meter board

and the edge of

the back panel.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 30

The SMA bulkhead connector is supplied with one lockwasher intended to be used on

the outside of the enclosure, between the nut and panel. Bob suggests using a second

internal tooth lockwasher on the inside. If you follow this suggestion, a ¼” (6mm) internal

tooth lockwasher can be obtained at any hardware store.

K2 Connection Options

Option 1

The Z10000-K2 was originally developed and tested with the connection point shown in

the schematic below. This connection point has two advantages and one

disadvantage:

Advantages:

• Connects at a low impedance point, and takes advantage of the K2’s low noise

• Allows use of a 3-pin plug connector that minimizes modifications to the K2 and

Disadvantage:

• The K2’s BFO leakage backwards through the IF chain places an unwanted “pip”

post-mixer amplifier, Q22.

allows easy removal of the Z10000-U for maintenance, if necessary.

in the spectrum analyzer. (See section 4.6 of this manual for a discussion of why

the K2 has BFO leakage.)

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 31

Option 2

Larry, N8LP, has developed an alternative connection option; take the IF sample at R80,

Q22’s 680 ohm base resistor.

This connection point also has advantages and disadvantages:

Advantages:

• Reduced BFO leakage back into the panadapter. This is because the BFO

Disadvantages:

• Less gain from the K2’s low noise post-mixer amplifier. This will reduce the overall

• Requires soldering to the PCB parts and is not as easily reversible as Option 1,

To illustrate the difference in BFO leakage, Larry has supplied three screen images

captured with an LP-PAN panadapter and the Z10000-K2 buffer amplifier connected at

Option 1 and Option 2 points.

With the K2’s Preamp OFF

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 32

leakage is reduced by the post-mixer amplifier’s isolation, which is around 30 dB.

usable sensitivity of the K2/panadapter combination. On most bands, and with

most antennas, when used with the LP-PAN, this reduction in sensitivity will likely

not prove significant.

With the K2’s Pre-amp ON

The images show a significant reduction in BFO leakage, on the order of 30 dB.

When the K2’s pre-amp is off, the noise floor is higher, by around 10 dB. This is because

the low noise post-mixer amplifier gain is not available in Option 2. Larry has increased

the Z10000-K2’s gain slightly to offset part of the loss of the post-mixer amplifier gain, but

the Z10000-K2 is optimized for isolation, not noise figure. Hence the composite noise figure

of K2, Z10000-K2 and LP-PAN is not as good under Option 2. However, operating the K2

with its internal pre-amp on significantly improves the composite noise floor of the

K2/Z10000/LP-PAN combination.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 33

In Option 2, Larry recommends building the Z10000-K2 with the following gain setting

resistor values:

R905: 4.7K Ohms

R907: 220 Ohms (this is a starting point; depending on your sound card gain it may be

necessary to reduce R907 to 100 ohms or even 49.9 ohms for increased net gain.)

Note that as the Z10000’s gain is increased, the clipping point of the amplifier decreases.

Larry reports that with R907 at 120 ohms, the clipping point is -5 dBm. Of course, -5 dBm

represents an extremely strong signal, unlikely to be encountered in most K2

environments.

Use these values only if you use Option 2; do not use these values if you connect using

Option 1.

Each connection option is separately described.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 34

Input Connections for Option 1

Note: The photographs show RG174 cable, not the RG178 cable supplied. The stripping

dimensions and installation instructions remain the same.

Strip the outer jacket back about ½”

(12 mm) using an X-Acto or sharp

hobby knife, being careful not to nick

the braid. See Section 3.2.5

concerning working with Teflon cable.

Slip the center conductor through the

braid and form a pigtail as illustrated.

Strip approximately 1/8” (3 mm) from

the center conductor and lightly tin

the bare wire.

Lightly tin the end of the braid to a

length of about 1/8” (3 mm)

Locate the 3-pin male header plug in

Envelope 13. [supplied only with the –

K2 version]

Lightly tin the short side pins. (This is a

good use for the locking forceps, by

the way!)

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 35

Locate the length of green small

diameter heat tubing in Envelope 11

and slip it over the center conductor.

It may be necessary to trim the heat

shrink tubing.

Solder the center conductor to one of

the outside pins of the 3-pin male

header plug.

Slide the heat shrink tubing to be flush

with the header plug plastic base and

apply heat to the tubing to shrink it

into place.

[note – colors changed after photos

taken]

Locate the length of black heat shrink

tubing in Envelope 11 and slip it over

the stripped and twisted braid. Trim

the tubing’s length to fit.

Solder the braid to the center pin of

the 3-pin male header plug.

Slide the heat shrink tubing to be flush

with the header plug plastic base and

apply heat to the tubing to shrink it

into place. Don’t worry if some of the

braid near the jacket is still exposed.

[note – colors changed after photos

taken]

Strip approximately 1/8” from the red

hookup wire and lightly tin it. Solder

the tinned end to the remaining pin of

the 3-pin male header plug.

Locate the length of red heat shrink

tubing in Envelope 11. Slide the heat

shrink tubing over the red wire to be

flush with the header plug plastic base

and apply heat to the tubing to shrink

it into place.

[note – colors changed after photos

taken]

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 36

Locate the length of larger diameter

heat shrink tubing in Envelope 11. It

may be of any color.

Cut a length of about 1” (25 mm) and

slip it over the coaxial cable and

hookup wire, sliding it down to the

plug end. Ensure that the braid is

completely covered by tubing.

The connector end of the assembly

should resemble the photograph, with

no bare shield showing.

Apply heat to shrink the tubing.

Cut short lengths of the remaining

large diameter tubing and apply to

form the coaxial cable and hook up

wire into a cable assembly. Leave the

last 2” (50 mm) free.

Strip the free end of the coaxial cable

to a length of about 3/16” to ¼”

(4.5mm to 6mm)

Remove the center conductor

insulation for about 1/16

Prepare the braid as shown in the

illustration.

Strip the free end of the hook-up wire

to a length of about 3/16” (4.5mm).

The photograph shows RG178.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 37

”

(1.5mm).

Route the connections on the top of

the PCB as shown in the photograph.

Solder the hookup wire to the +V side

of J902, i.e., the non-grounded side of

J902.

Solder the coaxial cable center

conductor to the non-ground side of

J901. Solder the coaxial cable shield

to the grounded pad at J901,

trimming its length if necessary to

ensure that the braid does not cause

a short circuit to the input or any other

component. Check the center

conductor resistance to ground with

an ohmmeter. It should read as an

open circuit.

Input Connections for Option 2

Note: Since Option 2 results in hard wiring the Z10000 to connection points in the K2,

before

described in Section 4.3 of the manual.

Cut a length of the coaxial cable

approximately six inches (150 mm)

long. Strip both ends of this piece of

coaxial cable to expose

approximately 0.5” (12 mm) of the

center conductor. Solder it to J903;

the ground shield to the ground

connector of J903 and the center

conductor to the non-grounded pad.

Route the connections on the bottom

of the PCB as shown in the

photograph.

Strip 0.25 inches (6 mm) from both

ends of the short length of red hookup

wire. Solder the hookup wire to the +V

side of J902, i.e., the non-grounded

side of J902.

Strip the free end of the long coaxial

cable with the SMA connector to

expose 0.5” (12 mm) of the center

conductor. Solder the coaxial cable

making the connections described below, follow the check out procedures

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 38

center conductor to the non-ground

side of J901. Solder the coaxial cable

shield to the grounded pad at J901,

trimming its length if necessary to

ensure that the braid does not cause

a short circuit to the input or any other

component. Check the center

conductor resistance to ground with

an ohmmeter. It should read as an

open circuit.

Connect the free end of the short

coaxial cable to R80. The shield

goes to the ground side of R80,

and the center conductor to the

base pin side of R80, as illustrated

in the photograph to the right.

Connect the red hookup wire as

illustrated.

Output Connection Under Option 1

If you have not already done so,

locate the length of coaxial cable

with the SMA bulkhead connector

and cut it to the length you have

determined, following the earlier

instructions.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 39

Strip the free end of the coaxial

cable to a length of about 3/16”

to ¼” (4.5mm to 6mm)

Remove the center conductor

insulation for about 1/16

Prepare the braid as shown in the

illustration.

The photograph shows RG178.

Solder the coaxial cable center

conductor to the ungrounded

pad at J903.

Solder the coaxial cable shield to

the grounded pad at J903,

trimming its length if necessary to

ensure that the braid does not

cause a short circuit to the input or

any other component. Check the

center conductor resistance to

ground with an ohmmeter. It

should read as an open circuit.

At this point, your completed

buffer amplifier should resemble

the photograph.

”

(1.5mm).

4.3 Checkout

Note: If you are following Option 1, the Z10000 is a free standing board, with plug-in

connections. If you follow Option 2, the board is hard wired into the K2. In this case,

these measurements should be made before soldering the Z10000-K2 into the K2.

Before applying power, make the following resistance checks. The data presented is

taken with a Fluke 189 digital multi-meter and different meters may provide differing

readings. However, any significant variance from these values should be investigated

for potential problems. The negative meter lead should be connected to a ground

point on the Buffer Amplifier PCB. The test point (TP) Key numbers are depicted in the

photograph below.

Measuring Point TP Key Reading Comments

J902 (+12 V input)

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 40

1

2.5 K This value may vary considerably from

Measuring Point TP Key Reading Comments

ohmmeter to ohmmeter.

J901 input pad

J903 output pad

U901, pin 7 (Vcc)

U901, pin 6 (output)

U901, pin 4

(ground)

U901, pin 3 (+

input)

U901, pin 2 (- input)

2

3

4

5

6

7

8

infinite Should be infinite to ground as DC is

blocked by C901

infinite Should be infinite to ground as DC is

blocked by C905.

2.0 KΩ Reading dominated by R903/904

voltage divider impedance.

5 MΩ Should be high impedance; hundreds

of KΩ at least.

0 Ω

5.9 KΩ This value may vary considerably from

ohmmeter to ohmmeter.

5 MΩ Should be high impedance; hundreds

of KΩ at least.

If the Buffer Amplifier meets these measurements, apply +12 V DC to the power input,

with the negative return to the PCB ground. Measure the input current. It should be

approximately 20 mA, and readings significantly over this value should be

investigated.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 41

4.4 Installing the buffer amplifier

This section discusses installing the Buffer Amplifier in the K2 and other receivers and

transceivers. Although specific detail is provided regarding the K2, installation in other

equipment is up to the user, following the guidelines in this document.

Note: Although I’ve made the Buffer Amplifier installation as “no holes” as possible, you

may find it necessary to add a small hole to fit the SMA connector to the K2’s back panel

for the signal output.

4.4.1 Elecraft K2 Transceiver-Option 1

The K2 connection concept following Option 1 is illustrated in the following figure.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 42

Elecraft has conveniently provided the three connections the Buffer Amplifier needs

(signal sample, ground and +12 V) at J12, the noise blanker connection socket, on three

consecutive pins, no less. The following sections describe how the Buffer Amplifier is

connected and installed, whether the noise blanker board is present or not. The Buffer

Amplifier, if installed as described, will not interfere with the noise blanker’s operation,

should it be installed.

If your K2 does not

the steps described at Section 4.4.1.1.

have the optional noise blanker board installed, please first complete

4.4.1.1 Units without the Optional Noise Blanker Board

Locate the 8-pin female header socket provided with the K2 Buffer Board kit in Envelope

13. This socket will be installed at position J12 in the K2’s RF board. These installation steps

mimic Elecraft’s noise blanker installation instructions, except for those steps associated

with the noise blanker itself.

Turn the K2 off and disconnect the power (either external supply or internal

battery)

Remove the top and bottom covers, but not the heat sink panel.

Install the 8-pin female header socket on the RF board at location J12. Do not

solder it in place yet; just mechanically install it from the top of the RF board.

Solder one pin near the middle of the connector. It’s important that the

connector seats firmly against the PCB, so apply down pressure on it whilst

soldering the pin. If the socket is not flush with the PCB, reheat the pin whilst

applying downward pressure. Make sure the socket is not tilted up on one end or

the other, but contacts the PCB for its full length.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 43

Do not make any other changes in your K2. If you later purchase the noise

blanker board, it will not be necessary to remove the 8-pin socket, as it is identical

with the socket installed in connection with the noise blanker board. (Of course,

the other changes to the RF board required for the noise blanker installation will

be necessary at that time.)

Follow the installation instructions as for rigs with the noise blanker board, except

that the 3-pin male header plugs directly into the newly installed 8-pin socket at

J12. Pin 1 of the 3-pin header plug goes to Pin 1 of the 8-pin socket at J12.

4.4.1.2 Units with the Optional Noise Blanker Board

Turn the K2 off and disconnect the power (either external supply or internal

battery)

Remove the top and bottom covers, but not the heat sink panel.

Remove the noise blanker board by removing the 4-40 screw from the stand-off

and unplug the noise blanker board.

Turn the noise blanker board upside

down and locate the 8-pin male

header, P1.

There is no definitive way to install the three-place female header socket onto the noise

blanker PCB. Two ways that have been successful are:

Variant Procedure A

With an X-Acto knife, trim away the

plastic from the male header pins 1,

2 and 3, leaving the pins soldered in

place. To help hold the pins in

place whilst soldering, you may find

it useful to slip the provided 8-pin

female header partway over the

noise blanker board’s pins.

Solder the provided 3-pin female

header socket to the three header

pins, with the socket parallel to the

noise blanker PCB, at right angles to

P1’s pins.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 44

Another view of how the three-pin

socket is solder to the modified

noise blanker header.

Variant Procedure B

Bob, K7HBG, describes how he installed the three-pin female header on the bottom of his

noise blanker board:

1. I used a small razor saw to carefully cut through the insulating strip of

the board male header (P1) between pins 3 and 4. I then lifted the

cut loose insulating strip from the board surface and slid this strip up

the pins toward their tops and left it there to hold the pins at the

proper spacing and attitude on the chance I melted the solder

holding a pin to the board. I did not but felt better for the

precaution.

2. I then rotated the solder tabs of the 3 pin female socket strip until

they were 90 degrees from where they were originally and flat on to

the male connector pins. I gripped the pins a bit out from the

connector body in order to allow the pin blades to rotate without

undue stress on the metal in the bend area. This seemed to work

well to position the ears flat against the male header pins. I tried

connecting the female connector to a male header before and

after pin bending to see if I could detect any loosening of the

contact pin force. I could feel no degrading of the pin grip.

3. I made sure that I didn't over do the amount of solder on each pin. I

ended up with a good fillet of solder between flat and pin.

4. One more thing to watch for is to keep the solder and female

connector pins below the level of the rest of the male connector

(P1) insulating strip so that the board plugs into its fem connector

(J12) on the K2 RF board as before the mod.

A thought here. A fella might want to angle the female connector away from the

board just a bit so that the 3 pin male header with its coax and heat shrink misses

R3’s lead.

Plug the 3-pin male plug into the

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 45

newly installed socket. Orient the

plug so that the pin with the green

heat shrink tubing (coax center

conductor) plugs into position 1. (If

the plug is accidentally inserted

backwards, it will not damage

either your K2 or the Buffer

Amplifier. Of course, the Buffer

Amplifier won’t work.)

Reinstall the noise blanker board,

being careful to apply only the

minimum necessary stress to the

newly installed 3-pin socket and

cable assembly. Route the cable as

shown in the photograph.

Remove the 4-40 screw at as shown

in the photograph and install the

provided ½” (12 mm) male/female

4-40 threaded standoff from

Envelope 11. Retain the removed

screw.

Remove the fish paper from

Envelope 12. You should have

trimmed the fish paper to match

the PCB according to the earlier

instructions. If you have not already

done so, do it now.

Mount the Buffer Amplifier board

and fish paper as shown in the

photograph, using the retained 440 machine screw. If you cannot

find the screw, an extra one is

provided in Envelope 11.

The fish paper is placed below the

PCB to insulate the components on

the bottom of the PCB from

contacting the electrolytic

capacitors on the K2’s main board.

The photo shows the fish paper’s

edges near the mounting screw.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 46

Mount the output connector at the

location you have decided on.

Route the SMA connector to that

location and install, using 5/16”

open end wrenches to fit the nuts.

Do not overtighten!

The photo shows my K2’s mounting

position. You may need to use a

different strategy, depending on

the options installed in your K2.

Check your work for possible

problems and correct any problems

found.

Restore +12 V power to the K2 and

proceed to the checkout stage.

4.4.1.3 Post-Installation Checkout

If you have the Z90 or Z91 working, you may use that to check out the Buffer Amplifier.

Connect the Z90/91 to the Buffer Output with the supplied BNC-to-RCA cable. Set the

Z90/91 to 4415 KHz following the instructions in the Z90/91 Operating Manual. Tune your

K2 around the bands and see how the signals display on the Z90/91.

If satisfactory, re-install the K2’s panels you have removed.

If you do not have a working panadapter or other device to connect to the Buffer

Amplifier output port, you may wish to verify the installation through simple tests. For

example, check the +12 V input to the Buffer Amplifier PCB and verify the +9 V regulated

output from U902. You can measure the current drawn by U901 by measuring the

voltage drop across R902. It should be approximately 0.1 volt, corresponding to 10 mA.

If you have a signal generator and an oscilloscope, you can input a strong signal into the

receiver and measure the buffer amplifier output voltage. The K2 connection point is

after the RF preamplifier and post-mixer IF amplifier, so there should be a reasonable

amount of gain ahead of the Buffer Amplifier. By comparing the signal level at the input

to U901 to the output level, you may verify the gain.

4.4.2 Other Receivers and Transceivers

Before installing the Buffer Amplifier in a different transceiver, review the K2 installation

instructions for ideas that might be adapted for your equipment.

While the information presented in this document are believed correct, connecting the

Buffer Amplifier to your receiver should be done only if you are comfortable working on

the equipment and if you have independently assessed the accuracy of this information.

Clifton Laboratories is not responsible for damage to your equipment, whether or not you

follow this document’s recommendations.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 47

The concept is to

connect the Buffer

Amplifier at a point

in the receiver

chain ahead of the

selective filter

stages. Practically

all receivers and

transceivers

manufactured in

the last 20 years are

“up-converting”

style with a first IF in

the 40 MHz to 70

MHz range.

up-converting

receiver,

immediately after the first mixer is a crystal filter of perhaps 20 to 25 KHz bandwidth,

commonly called a “roofing filter.” If the Panadapter is to have maximum utility, it must

be connected ahead of the roofing filter.

7

In an

Determining the optimum connection point requires analysis of the receiver’s schematic

diagram. Ideally, the point of connection will be at a low impedance point (50 Ω is ideal)

so that the Buffer Amplifier’s input impedance will not disturb the receiver’s performance.

Unfortunately, the input impedance of the roofing filter is generally not indicated in the

receiver’s schematic. However, in some cases it can be inferred from other circuit values.

Consider the Racal RA6790/GM receiver’s first mixer area, shown in the above schematic

fragment. The output of the first mixer module goes to the 40.455 MHz roofing filter

module. The filter’s output goes to

a common gate FET amplifier, Q5.

This arrangement strongly suggests

that the mixer’s impedance is

designed for 50 Ω and that the

necessary crystal filter matching is

done internally to the roofing filter.

(The RA6790/GM Technical

Manual specifies the roofing filter

as having a 20 KHz bandwidth, but

is silent on its impedance.) Using

the rough rule that bridging a circuit with impedance 10 times higher is “safe” we

determine that so long as the Buffer Amplifier’s input impedance > 500 Ω we can likely

connect it to FL1’s input port without seriously upsetting the receiver’s performance by

altering the terminating impedance seen by the first mixer. Looking at the impedance

data presented earlier (although it cuts off at 30 MHz, it can be reasonably extrapolated,

as the behavior seems to be that of a simple RC circuit) the buffer amplifier should meet

this requirement, so long as the connection to the Buffer Amplifier is kept short.

7

Elecraft’s K2, of course, is a notable exception to this design philosophy, as it is a single

conversion receiver, with a nominal IF of 4915 KHz.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 48

It’s unlikely that all (most?) receiver

designers will have been so

accommodating as to provide a

suitable low impedance pick-off

point ahead of the roofing filter.

Fortunately, it’s relatively easy to

“neutralize” the Buffer Amplifier’s

input capacitance, thereby

increasing the input impedance.

We’ll start the analysis by

examining a simple model of the Buffer Amplifier’s input circuitry as shown at the right.

This simple model does a

reasonable job at modeling the

Buffer Amplifier’s input impedance,

may be seen by comparing the

computed impedance plot for the

model with the measured input

impedance data presented in

Section 1.3.2.

Looking at the model immediately

suggests a strategy for increasing

the input impedance. Since the

impedance above a few MHz is

dominated by the shunt capacitance C1 (representing the input leads and PCB traces)

we can resonate C1 and C2 with a parallel inductance. In order to obtain a reasonable

size inductor that will operate below its self-resonant frequency, we will normally wish to

add extra capacitance in

parallel with the strays. For a 45

MHz IF, we, based on

experience, use a 300 nH

resonating inductor and a

variable capacitor (usually a

small variable plus a fixed capacitor) of about 30 pF, calculated from the normal parallel

resonance formula. To avoid placing a DC short on the AD8007’s input, the cold side of

the parallel resonant circuit is returned to a bypass capacitor, not directly to ground.

Plotting the resulting input impedance shows that at 45 MHz the input impedance is

increased to about 4 KΩ. The maximum input impedance is limited by L2’s Q and the

R905, the 4.7 bias isolation resistor.

Whether this solution works for any particular receiver requires further analysis. For

example, terminating the mixer output with a frequency selective circuit may impair the

receiver’s IP3 performance as the mixer will not see the same impedance over a wide

range of frequencies.

4.5 Selecting R907

The object in setting the Buffer Amplifier’s gain is to provide just enough gain to optimize

the Panadapter’s performance. To understand how to accomplish this task, we must

consider the Panadapter and receiver as an integrated system.

Clifton Laboratories – Buffer Amplifier Assembly and Operation Page 49

The Z90/91 has a dynamic range of about 55 to 60 dB, depending on bandwidth

selected. Although this is superior to other amateur radio Panadapters, it is does not

approach the typical 100 dB+ dynamic range of a receiver. (The K2’s dynamic range

approaches or even exceeds 130 dB.) Receivers display large dynamic ranges because,

amongst other things, they incorporate automatic gain control systems; as the signal

level increases, lower level stages have their gain is reduced to prevent overloading later

stages. Panadapters and spectrum analyzers do not generally employ AGC systems,

instead relying upon log amplifiers and generous headroom in amplifier design.

Let’s reduce this abstract discussion to practical numbers. Two signals, one of S1 and one

of 40 dB over S-9 differ by about 94 dB, assuming the 1 S-unit = 6 dB standard. The Z90/91

will not accurately display two signals differing by 94 dB. For that matter, neither of my

two HP spectrum analyzers will accurately display two signals with 94 dB difference in

signal strength.

We should consider two cases: Where the stages ahead of the Z10000 Buffer Amplifier

are not subject to the receiver’s AGC and where they are.

In most receivers, AGC is not applied to the RF amplifier stage. The K2, for example,

applies AGC only to the IF stages; the RF amplifier and post-mixer amplifier are run at

fixed gain. (The RF amplifier is switchable in and out, of course, via a front panel switch.)

The standard Racal RA6790/GM has no RF amplifier and AGC is applied to the postroofing-filter amplifier stage.

The user has two options to set the Z10000 Buffer Amplifier’s gain; set it such that the

strongest reasonable signal input to the receiver’s antenna terminal causes the Buffer

Amplifier to output a signal at about -40 dBm, the optimum maximum input level for the

Z90/91. If this signal level corresponds to, say S9 + 40 dB, then the weakest signal that the

Panadapter will display is about 60 dB below that, or S6. This is likely to be perceived

(correctly so) as resulting in a “deaf” Panadapter. It will, however, accurately display

strong signals. A more desirable strategy is to set the Buffer Amplifier’s gain so that the

weakest reasonable signal will produce a discernable “pip” on the Panadapter screen or

computer display. If this threshold is, say, S1, then signal levels much beyond S9+10 dB will

be compressed on the Panadapter’s display.

To determine the correct gain setting resistor (R907) with this strategy, assuming that test

equipment such as a calibrated signal generator and spectrum analyzer are available,