Page 1

Series PAFS-1000 Averaging Flow Sensor

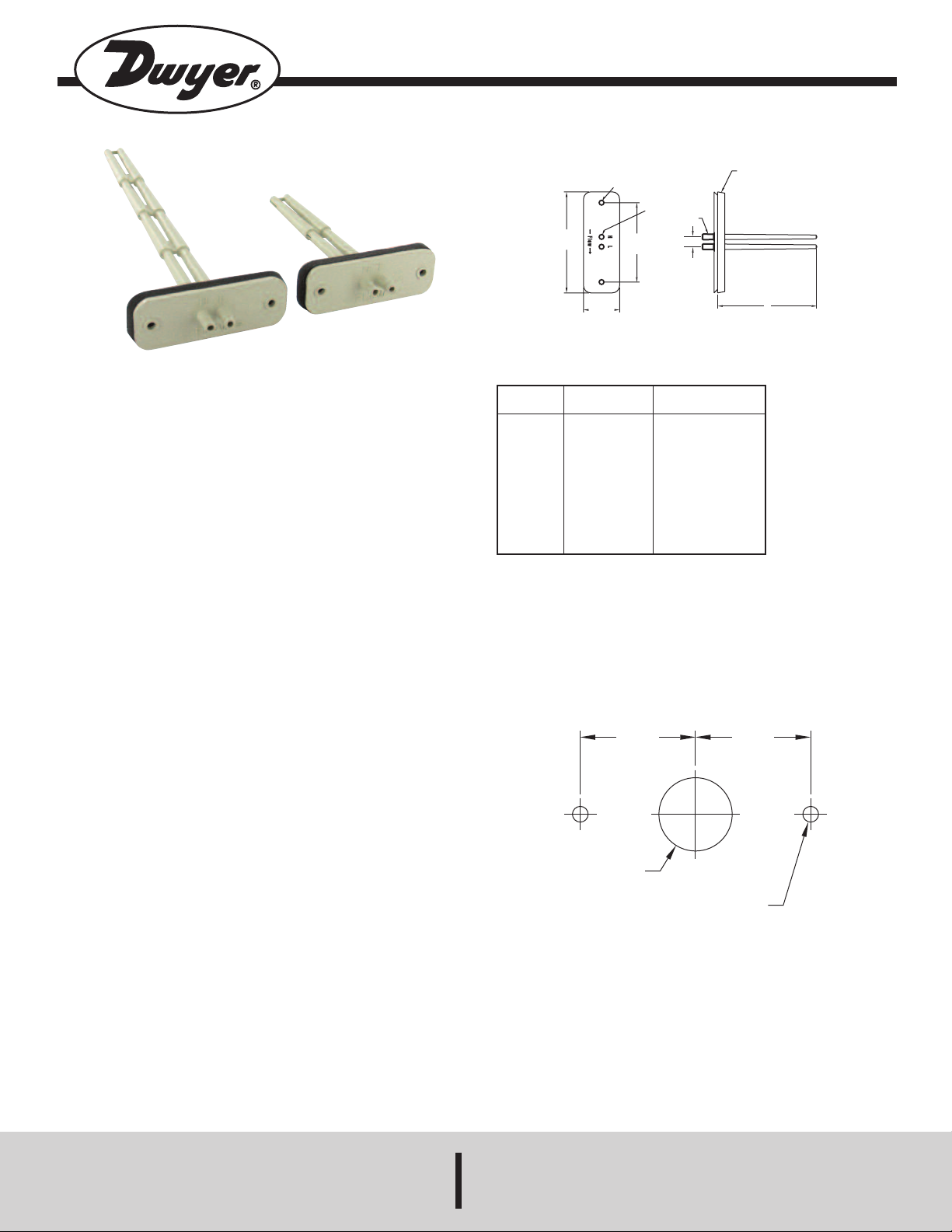

3-1/2

[88.90]

1-1/4

[31.75]

2-3/4

[69.85]

FOAM GASKET

1/8 THK

[6.35 THK]

A

PUSH-ON

CONNECTIONS

FOR 3/8

POLY TUBING

[9.53 OD]

MOUNTING HOLES

2XØ3/16 [Ø4.76]

7

/16

[

11.11]

1-3/8˝

[35]

1-3/8˝

[35]

7/8˝ [22] DIA

CLEARANCE HOLE

(2) 3/16 DIA HOLE FOR

SELF TAPPING SCREWS

Specifications -Installation and Operating Instructions

he Series PAFS-1000 Averaging Flow Sensor from Dwyer Instruments, Inc. is

T

deal for sensing differential pressure in the inlet section of variable air volume

i

erminal units and fan terminal units. Units can also be used to sense differential

t

pressure at other locations in the main or branch duct systems.

The “H” port senses total pressure and the “L” port senses static pressure. The

difference between these signals is the differential, or velocity pressure.

odels offer up to ten sensing points and lengths of 3-5/32˝ to 23-29/32˝ (8.02 to

M

0.72 cm) to accommodate box sizes of 4˝ to 30˝ (10.16 to 76.20 cm).

6

INSTALLATION

The Series PAFS-1000 utilizes 1/4˝ ID, 3/8˝ OD tubing. First check that there are

no sharp bends in the tubing at any connection. Bends and creases may leak over

time as the tubing ages.

Connect the “H” Port to the high input on the differential pressure gage, transmitter,

or switch.

Connect the “L” Port to the low input on the differential pressure gage, transmitter,

or switch.

Approximate K factors for models:

PAFS-1002: 1.32

PAFS-1003: 1.39

PAFS-1004: 1.46

PAFS-1005: 1.46

PAFS-1006: 1.58

PAFS-1007: 1.67

PAFS-1008: 1.78

PAFS-1009: 1.88

PAFS-1010: 2.01

PAFS-1011: 2.14

DIMENSIONS

Number of

odel

M

PAFS-1002

PAFS-1003

PAFS-1004

PAFS-1005

AFS-1006

P

AFS-1007

P

AFS-1008

P

PAFS-1009

PAFS-1010

PAFS-1011

SPECIFICATIONS

Service: Air and compatible gases.

Wetted Materials: ABS/polycarbonate (UL94-5V).

Temperature Limits:

Operating: 40 to 120°F (4 to 49°C);

Storage: -40 to 140°F (-40 to 60°C).

Connection: 1/4˝ (6 mm) ID, 3/8˝ (10 mm) OD tubing.

Mounting Orientation: Integral flange with gasket.

Weight: 1 oz (28 g).

Sensing Points

1

2

3

4

5

6

7

8

9

10

Sensor

Length

3-5/32˝ (8.02 cm)

5-13/32˝ (13.73 cm)

-21/32˝ (19.55 cm)

7

-29/32˝ (25.26 cm)

9

2-1/2˝ (31.75 cm)

1

14-3/4˝ (37.47 cm)

17-1/8˝ (43.50 cm)

19-13/32˝ (49.29 cm)

21-21/32˝ (55.01 cm)

23-29/32˝ (60.72 cm)

MOUNTING DETAILS

Bulletin PAFS-1000

It may be necessary to calibrate in order to insure an accurate measurement.

You can do this by completing a traverse of the duct or fan to determine the delta

P sensed by the PAFS vs. the actual flow.

MOUNTING

1. Install the unit horizontally to assure accurate velocity readings for units ranging

from 3-5/32˝ to 9-29/32˝. If using a unit longer than the PAFS-1005, which is 929/32˝, vertical mounting is recommended.

2. Determine the duct’s flow direction and install the Series PAFS-1000 based on

the unit’s flow arrow imprint.

3. Cut a 7/8˝ hole in the ducting to accept the unit.

4. Attach using two self-tapping screws inserted in the 3/16˝ mounting holes.

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 12/13 FR# 72-443834-00 Rev.1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

MAINTENANCE

Sensing orifices must be kept free of dust accumulation or debris. Occasional

cleaning may be required.

Upon final installation of the Series PAFS-1000 Averaging Flow Sensor, no routine

maintenance is required. A periodic check of system calibration is recommended.

The Series PAFS-1000 is not field serviceable and should be returned if repair is

needed (field repair should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization number before

shipping.

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...