Page 1

Piston-Type Flow Switches

P4 Series

Installation . . .

Unless otherwise specified, the units are factory-calibrated with water mounting in vertical position, with lead wires

up. Observe proper direction of liquid flow, as marked "IN" and "OUT" on housing.

Be careful to keep foreign material out of units during installation. Use of 50 micron filtration is recommended. All

plastic NPT threads should be installed, using a suitable thread sealant, such as Teflon tape or Permatex "No

More Leaks". Sealant must be kept out of unit during installation.

Avoid over-tightening when connecting piping to unit, which is constructed of plastic material. Connection of

metallic piping to plastic units is not recommended.

- Warning -

These flow switches are plastic, straight-thread, O-ring

sealed instruments. Over-tightening will result in breakage!

Port Adapter Fittings . . .

Install plastic adapters with O-rings (supplied) directly into "IN" and "OUT" ports of the flow switch before installing

unit. CAUTION: Do not exceed 20 inch-pounds maximum torque when installing adapter fittings. Hold wrench

flats on adapters as indicated below when installing unit in piping to prevent additional torque accumulation

between adapter and body. (Note: Port adapter fittings must be purchased separately.)

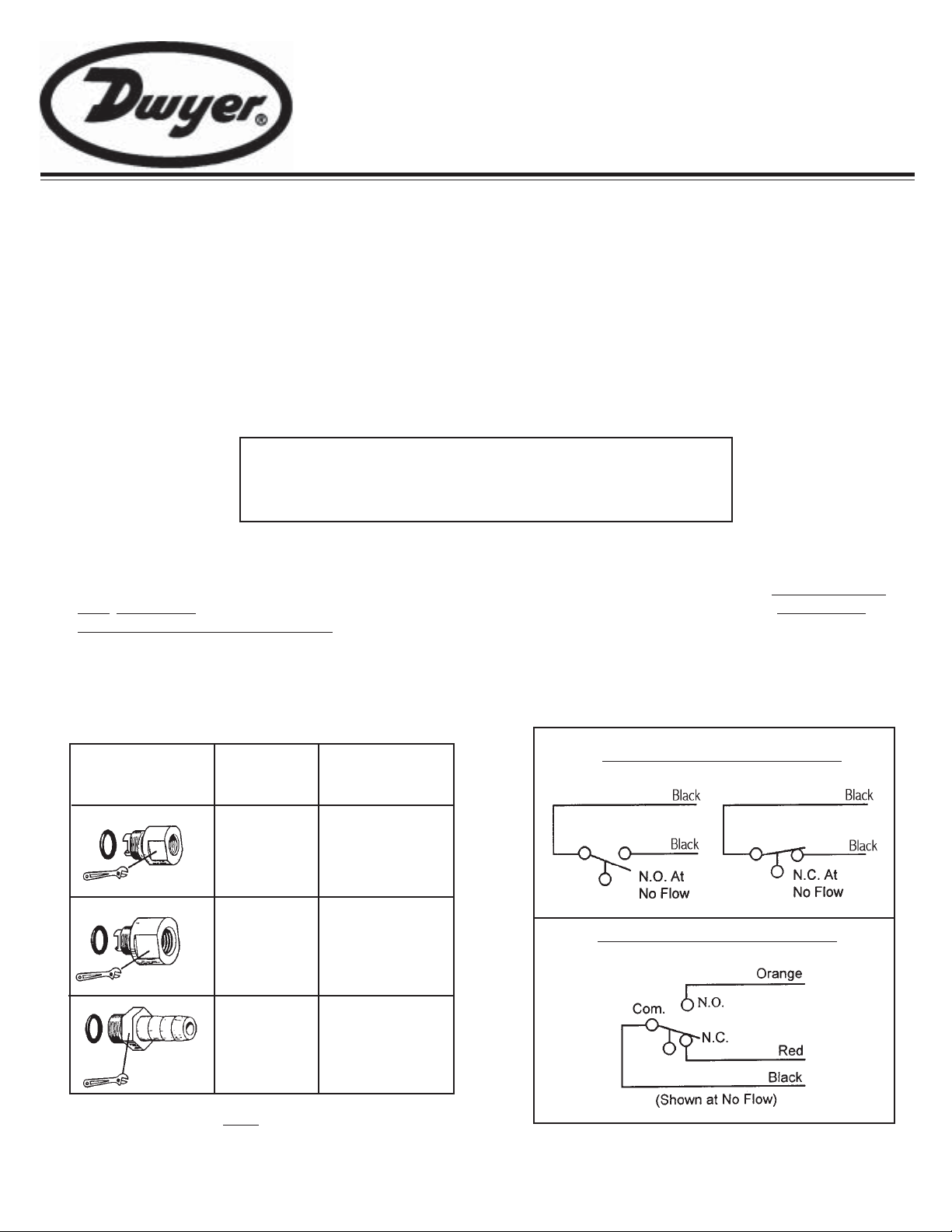

Typical Wiring Diagrams . . .

Port Adapters . . .

P4 Models with SPST Switches

P4 Models with SPDT Switches

Adapter

Adapter

Size

1/8" NPT*

1/4" NPT*

Model

Numbers

P4-98

P4-94

1/2" Barb **

Notes

* Wrench flats provide for proper assembly

** Accepts 1/2" I.D. flexible hose

P4-92

Page 2

Specifications . . .

Wetted Materials

Housing and Piston

O-Ring

Spring

Other Wetted Parts

Operating Pressure, Maximum

Operating Temperature

Set Point Accuracy

Set Point Differential

Switch, See "Switch Ratings"

Inlet / Outlet Ports

Electrical Termination SPST

Electrical Termination SPDT

®

Ryton

Viton

- R4

®

316 Stainless Steel

Epoxy

250 PSIG @ 70°F

0°F to 225°F (-17°C to +107°C)

±15% Maximum

20% Maximum

SPST or SPDT, 20 VA

9/16" - 18 UNF - 2B Thread

No. 18 AWG, 24"L. Sarlink Zipcord Lead Wires

No. 18 AWG, 24" L., PVC Lead Wires

Maintenance . . .

The only maintenance normally required

is occasional cleaning when excessive contamination is present in the liquid.

Switch Ratings

Maximum Resistive Load

VA

Volts

0 - 30

20

120

240

The switch mechanism is an hermetically-sealed

reed switch for pilot duty only. Refer to electrical

data above or consult Factory.

Amps AC

.4

.17

.08

Note

Amps DC

.3

.13

.06

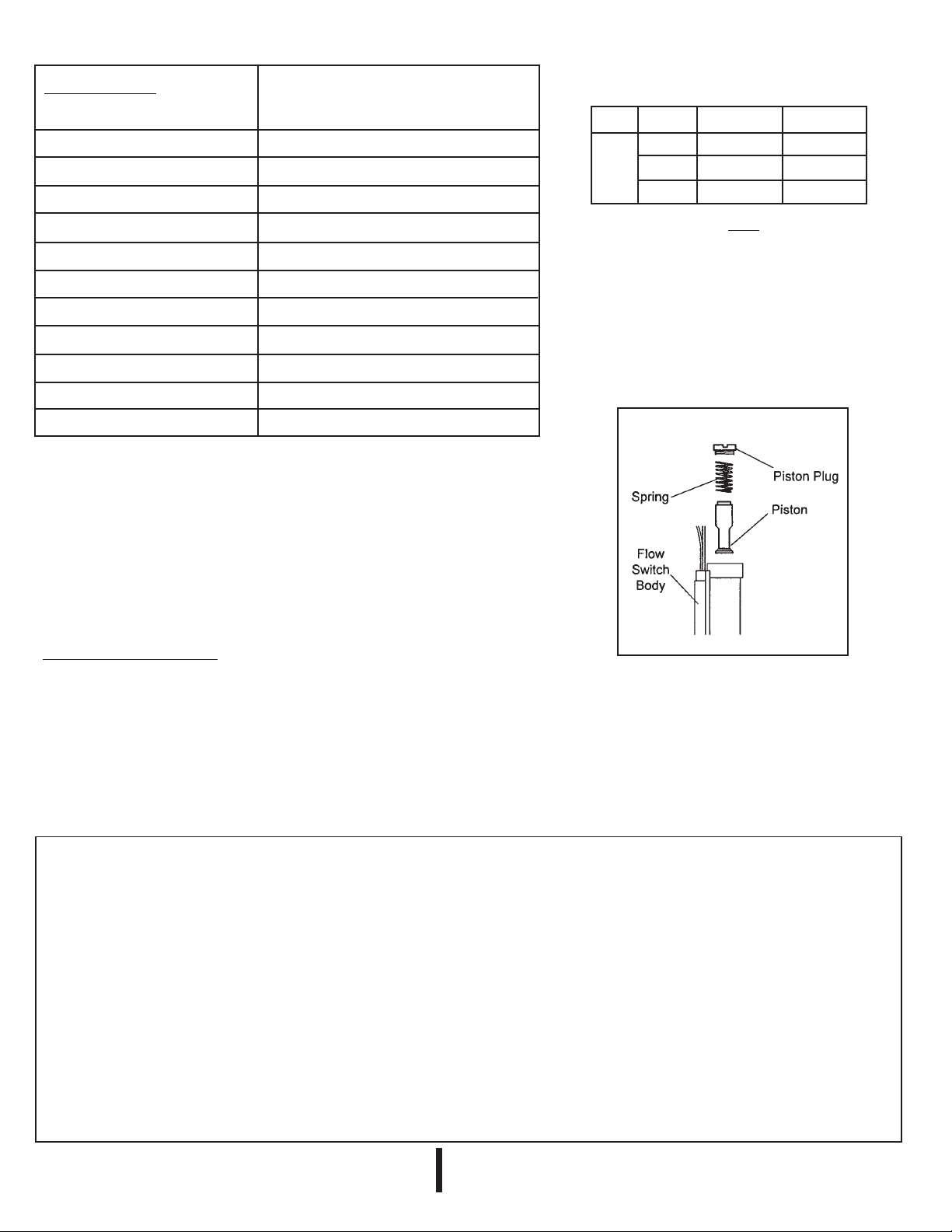

To disassemble the flow switch for cleaning: With system shut down and no liquid in

piping, remove: 1) Piston Plug 2) Spring

3) Piston

It is not necessary to remove the unit from the system. Reassemble unit in reverse order;

i.e., #3 - #1 above. Use care when handling spring to prevent distortion.

MAINTENANCE/REPAIR

Regular maintenance of the total system is recommended to assure sustained optimum performance. These devices are not field repairable and

should be returned to the factory if recalibration or other service is required. After first obtaining a Returned Goods Authorization (RGA) number,

send the unit freight prepaid to the following. Please include a clear description of the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

Product must be maintained and installed in strict accordance with the

National Electrical Code and Dwyer product catalog and instruction

bulletin. Failure to observe this warning could result in serious injuries

or damages.

For hazardous area applications involving such things as (but not

limited to) ignitable mixtures, combustible dust and flammable materials,

use an appropriate explosion-proof enclosure or intrinsically safe

interface device.

The pressure and temperature limitations shown on the individual

catalog pages and drawings for the specified flow switches must not

be exceeded. These pressures and temperatures take into

consideration possible system surge pressures/temperatures and

their frequencies.

Selection of materials for compatibility with the media is critical to the

life and operation of Dwyer products. Take care in the proper selection

of materials of construction, particularly wetted materials.

DWYER INSTRUMENTS,INC.

P .O.BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Important Points!

Life expectancy of switch contacts varies with applications. Contact

Dwyer if life cycle testing is required.

Ambient temperature changes do affect switch set points, since the

specific gravity of a liquid can vary with temperature.

Dwyer Products have been designed to resist shock and vibration;

however, shock and vibration should be minimized.

Filter liquid media containing particulate and/or debris to ensure the

proper operation of our products.

Electrical entries and mounting points in an enclosed tank may

require liquid/vapor sealing.

Dwyer Products must not be field-repaired.

Physical damage sustained by the product may render it

unserviceable.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Loading...

Loading...