Page 1

Bulletin H-22-OSW

Model OSW-100 Wall Mount Occupancy Sensor

Specifications - Installation and Operating Instructions

The Model OSW-100 Wall Mount Occupancy Sensor is

an infrared sensor designed to automatically control a

HVAC ventilation system. A unique dual delay processor

eliminates false triggers due to short-term occupancies. The

Model OSW-100 has a wide 110° viewing angle to capture

movement up to 49.2 ft (15 m) away.

INSTALLATION

Do not install where the detector is exposed to direct

sunlight or directly above strong sources of heat.

4-27/64

[112.32]

2-39/64

[66.28]

1-25/32

[45.24]

SPECIFICATIONS

Infrared Sensor: Dual Element.

Range: 49.2 ft (15 m).

Detectable Speed: 0.33 to 9.8 ft/sec (0.1 to 3.0 m/sec).

Control Output Rating: SPDT, 0.2A @ 30 VDC.

Ambient Operating T emperatur e: -4 to 140°F (-20 to 60°C).

Power Consumption: Standby: 5 mA, Operating: 18 mA.

Mounting Height: 5.9 to 11.8 ft (1.8 to 3.6 m).

Power Requirements: 22 to 26 VAC/DC.

Weight: 3.2 oz (90.7 g).

Agency Approvals: CE.

Do not install in areas that have any obstruction

(plants, large pieces of furniture, curtains, etc.) which

may block the detection.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

MOUNTING

CEILING MOUNT

WALL MOUNT

NC COM NO

FAN COIL CONTROLLER

24 VAC/DC

24V

ON/OFF INPUT

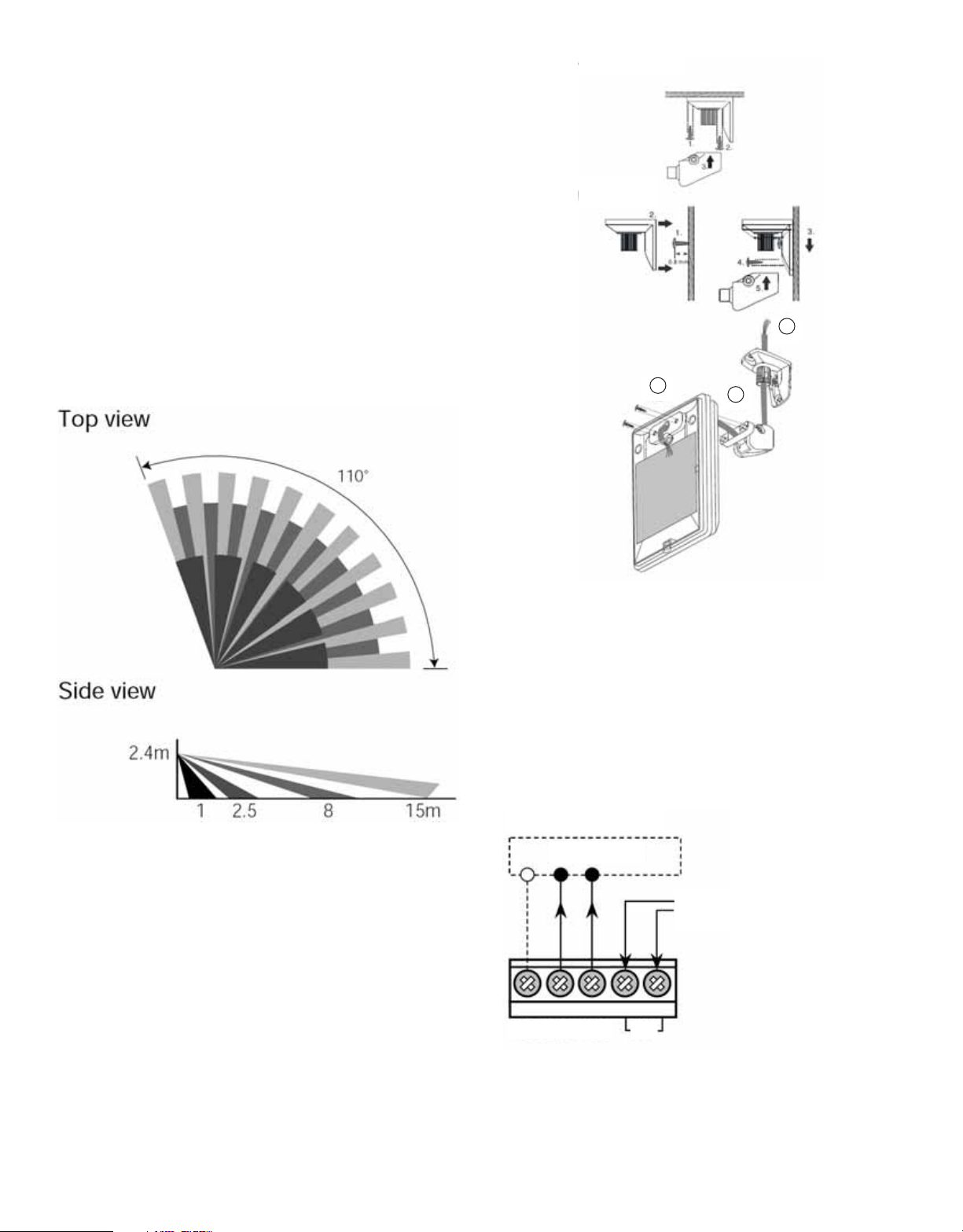

The OSW-100 is designed to be mounted to a wall or

corner.

Step 1: Install Base Unit

• Determine the location of the sensor according to the

detection pattern shown in Figure 1.

• Screw the base of the mounting bracket to the desired

position on the wall as shown in Figure 2.

• Feed the cable through the hole on the back of the

bracket.

• Loosen the screw on the bottom of the sensor and

remove the cover.

• Feed the cable through the center hole on the back of

the sensor housing.

• Attach the sensor to the mounting bracket.

1

3

2

Figure 1

Determining the Location of the Sensor

Figure 2

Mounting the Sensor

Step 2: Wiring

• Turn the screw for each terminal counterclockwise.

• Connect the cable to the corresponding terminals as

shown in Figure 3.

• NC-COM-NO:

Output for ON-OFF

control of fan coil

operation. Dry contact

signal.

• 24V: Power Supply

(non-polarity)

Figure 3

Wiring the Sensor

Page 3

Step 3: Walk Test

Before beginning test, make certain that the On and Off

delay jumpers (located on the circuit board) are connected

in the “A” positions as shown in Figure 4. If they are not,

follow the procedure under the section titled On/Off Delay

Settings to rearrange the jumpers to location “A.” Replace

the sensor housing and tighten screw.

ON/OFF DELAY SETTINGS

To adjust the On/Off Delay time intervals or adjust sensor for

“Walk Test.”

1. Remove the cover from the sensor.

2. Refer back to Figure 4 to locate the ON/OFF Delay pins

and jumpers on the circuit board.

3. Gently remove the jumpers and reinsert into the desired

pins according to the table below.

A (Walk Test)

ON

0 Sec.

OFF

10 Sec.

4. Replace cover and screw.

Range Adjustment

After installation, the sensor can be manually adjusted to

meet the detection needs of a room.

• Loosen the screw on the mounting bracket and then

carefully move the unit to the desired direction.

• Refer back to the diagram in Figure 1 and adjust the

sensor accordingly.

• Once the sensor is orientated in the desired direction,

hold the unit in place and tighten the screw.

B

10 Sec.

1 Min.

C

30 Sec.

5 Min.

D

1 Min.

10 Min.

E

5 Min.

20 Min.

F

10 Min.

30 Min.

Figure 4

The walk test is used to quickly ensure correct system

wiring, proper functioning of the output, and proper

orientation/location of the sensor.

• Apply power to the unit and allow 45 seconds for the

sensor to warm up. The LED will blink (long blink followed

by short) during warm up.

NOTICE

The LED will blink rapidly if the sensor is improperly wired.

• When the LED stops blinking, the sensor has had

adequate time to warm up and is now in standby mode

(Standby mode is discussed in more detail in the Operation

Mode Section.)

• Walk across the detection zone. The LED will stay lit and

the output will be activated during occupancy detection.

Page 4

OPERATION MODES

A.

STANDBY

DETECTION

B.

RELAY ON

DELAY

C.

1-MINUITE

WAITING

NO

DETECTION

DETECTION

D.

RELAY OFF

DELAY

(RELAY OUTPUT)

The OSW-100 Wall Mount Occupancy Sensor utilizes

several operation modes to eliminate false readings and

conserve energy.

1-Minute Warning Mode

During this mode, the sensor searches for any movement

for one minute past the Relay On Delay Mode.

If occupancy is detected at any point within that one

minute, the output device is activated and the sensor enters

Relay Off Delay Mode.

If occupancy is not detected in that one-minute time frame,

the sensor enters back into standby mode.

Relay Off Delay Mode

During this mode, the sensor’s output is activated for a

preset period of time.

Once this preset time interval is up, the output device

powers off. However, the relay off delay timer will reset with

each motion detection.

This Relay Off Delay Mode allows for energy conservation

by eliminating unnecessary running of the HVAC system.

NOTICE

Occupancy detection may be affected if the unit is operated

within radio frequency electromagnetic field strength of

approximately 3 volts per meter, but the performance of the

instrument will not be permanently affected.

Figure 5

Standby Mode

Before any movement is being sensed, the sensor is in

standby mode.

When the sensor detects occupancy, the LED light turns on

and the sensor switches to Relay On Delay Mode.

Relay On Delay Mode

This adjustable mode allows the user to choose the time

delay before the unit reports that a space is occupied.

The Relay On Delay Mode allows for energy conservation by

bypassing short-term or faulty occupancies. It is followed by

a secondary one minute warning delay.

Storage and Cleaning

The sensor lens is the most delicate part of the Occupancy

Sensor. The lens should be kept clean at all times, care

should be taken when cleaning the lens using only a soft

cloth or cotton swab with water or medical alcohol. Allow

the lens to fully dry before using the sensor. The sensor

should be installed or stored in an area of room temperatur e

between -4 and 140ºF (-20 to 60ºC).

MAINTENANCE

After final installation of the unit, no routine maintenance is

required. The Model OSW-100 is not field serviceable and

should be returned if repair is needed (field repair should not

be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant

application notes. Contact customer service to receive a

return goods authorization number before shipping.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 9/08 FR# R6-443398-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...