Page 1

ViewRite

Magnetic Liquid Level Indicator

Instruction Bulletin No. 204129

Thank you for purchasing the Dwyer ViewRite Magnetic Level Indicator . Please read this document prior to installing your

ViewRite and store it where it may be readily referred to for familiarization and maintenance purposes. If you require any

additional information, you are welcome to call Dwyer at the number shown below.

1-219-879-8000

Record the Part Number of your ViewRite here to use when ordering spare or replacement parts:

Part Number:____________________

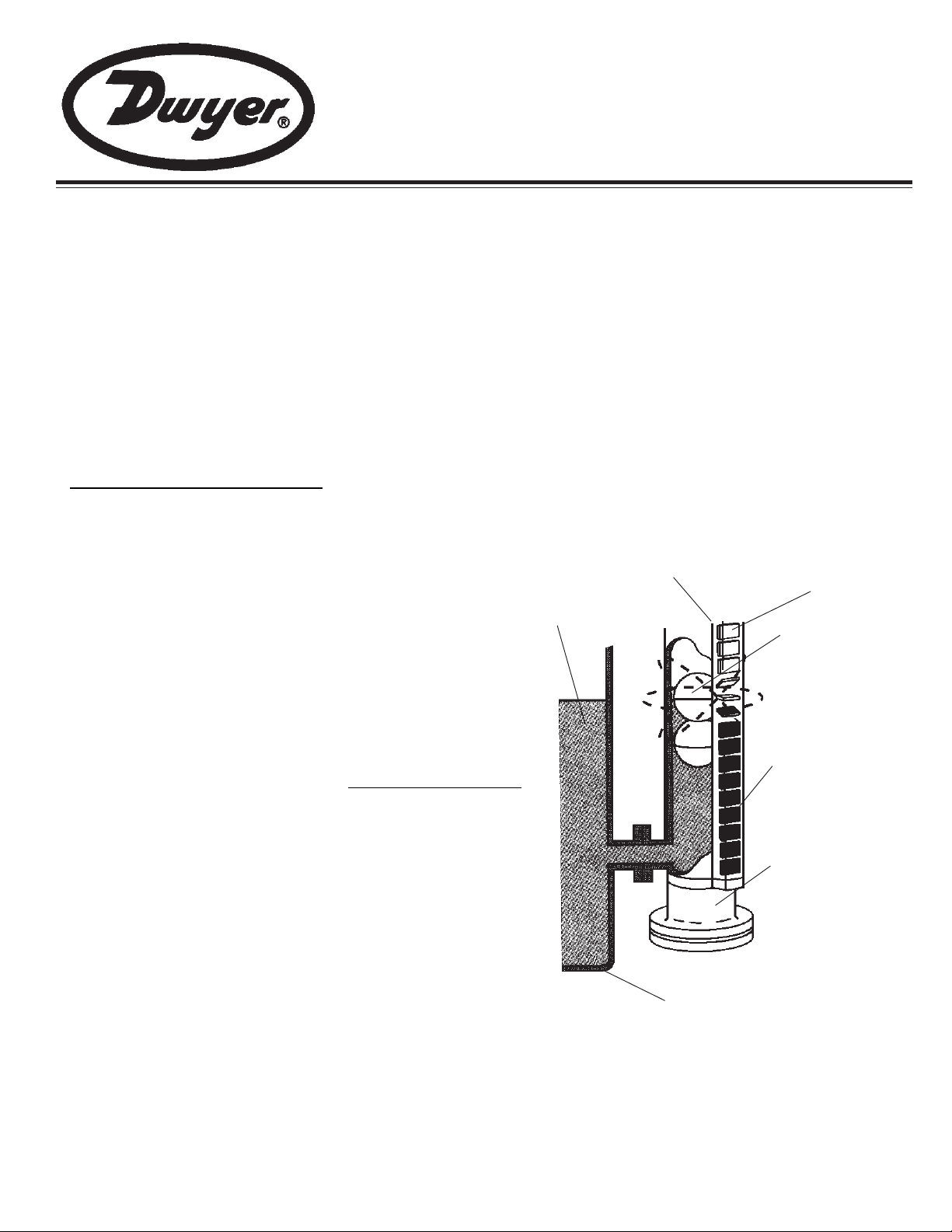

ViewRite Operating Principle

The liquid level of a tank is made visible, even at great distances,

through the use of a shock and vibration-proof magnetic level indicator

that employs “flags” arranged within a specially constructed external

housing: the flag assembly . The two sides of each pivoting flag are

marked with contrasting colors. A permanent magnet is encapsulated

inside each flag and forms a secure magnetic interlock with the

adjacent flags. As the liquid level rises, a float equipped with a

permanent magnet causes each of the flags to begin rotating in turn.

This action exposes the contrasting (fluid level indicating) color on

the other side of the flag. As the float and liquid level rise, each flag

below the level of the float completes a 180 degree rotation, while

remaining magnetically interlocked with the other lower flags.

Together, the rotated flags display a band or column of color, the

height of which corresponds with the liquid level within the tank. An

exclusive feature of the ViewRite is the patented magnetic guide

that is integrated into the flag assembly. This magnetic attraction

ensures that the float is always aligned for optimum performance

and exactness, regardless of any shock, vibration, or rapid change

to the level of fluid in the tank.

Flag Channel

Liquid

Magnetic Flags

(Plain Side Out)

Magnetic

Float

Magnetic Flags

(Colored

Side Out)

Weldment

Standard and Mini-ViewRites are supplied with the floats packed

either separately , or securely strapped to the unit. The float supplied

with each unit has been designed to the specific gravity of the fluid

being monitored, so that the permanent bar magnet will always seek

and indicate the fluid surface. Because of the attraction of the

permanent bar magnet in the float and the patented magnetic guide,

the ViewRite flag assembly can be rotated to a position which will

allow for optimum viewing.

Tank

(See the Maintenance Section on page 4 for instructions on how to rotate your

ViewRite flag assembly.)

- 1 -

Page 2

Important!

Read the following instructions completely - BEFORE installing the ViewRite.

Installation Precautions and Preparation

Failure to observe these precautions could affect the operation of your unit.

1. When locating the tank ports for the ViewRite, make sure that no strong magnetic fields or magnetic materials

(such as railings, protective cages, I-beams, etc.) will be any closer than 6 inches (153 mm) from the ViewRite.

2. Make necessary efforts to ensure that all tank-side modifications and equipment; i.e., the mating flanges, NPT

ports or shut-off valves (if used) will align properly with the connections. Improper alignment could

cause distortion and may damage welds and compromise the integrity of the ViewRite and/or the tank.

3. After any necessary tank modifications are completed, the tank should be cleaned to remove contaminants. This

will ensure that the installation is free of foreign particles; especially those which could be magnetic and which

could impair the performance of the ViewRite.

4. Do not begin the installation of the ViewRite until all necessary tools and materials are obtained. (Such as

mating flange gaskets, bolting hardware, etc. )

5. Gasket material typically supplied with the standard ViewRite unit is either Viton or nitrile rubber, Garlock 3000

style. Higher pressure units are typically supplied with FlexitallicTM gaskets.

6. All supplied flag assembly clamps are intended to be installed with a torque on the clamp screw not to exceed

5 lb.-inches.

Installation

Caution

Handle the ViewRite with care to avoid damaging the threaded areas, flange surfaces, etc.

For Standard ViewRites (Alloy and Mini)

1. Remove the protective packing materials from your ViewRite.

2. Position the unit horizont ally on a level surface.

3. Unpack the float assembly or, with the aid of a wire-cutter or similar device, remove the strapping that secures

the float to the exterior of the ViewRite Unit.

- 2 -

Page 3

Warning

D0 NOT : 1) Hold the V iewRite in a vertical position or 2) Drop the float assembly into the unit. Avoid this or

any action which could damage or dent the float. Such damage could cause the float to crush under normal

working pressures.

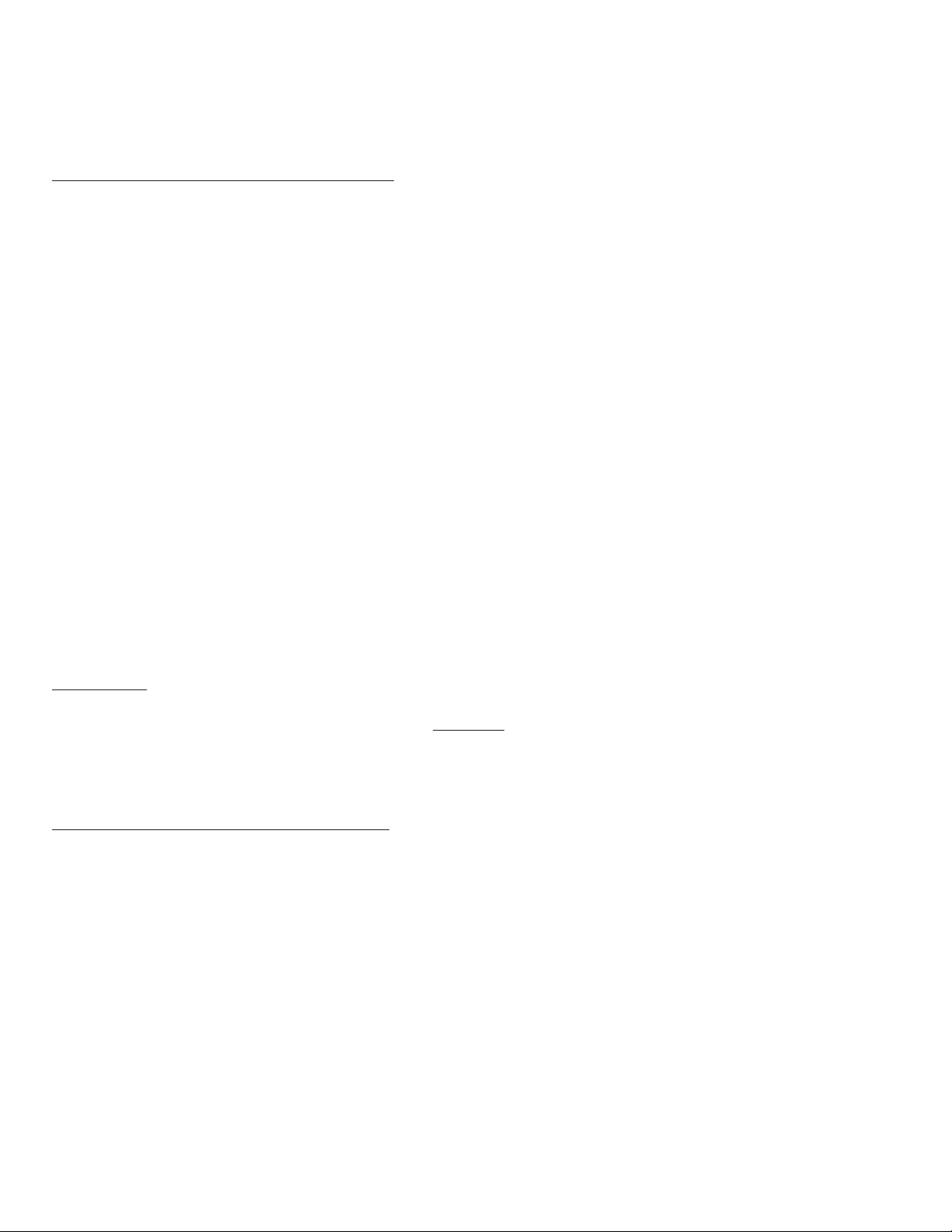

TOP

Weldment

Float

TOP

Weldment

Float

Flange

Flange

Remove Bolts

Standard ViewRite

Remove Bolts

Mini ViewRite

4. Remove the end cap or flange attaching bolts, as indicated in the appropriate drawing. Then remove

the end cap or flange.

5. With the unit still in a horizontal position, insert the float assembly into the weldment, with the “TOP” indication

on the float assembly moving in the same direction as the “UP” arrows that are located on each side of the

externally mounted flag assembly.

6. With the gasket or O-ring properly positioned, reassemble the end cap or flange to the weldment. Tighten the

end cap or flange bolts securely, using the proper recommended torque value as supplied in Figure A, page 4.

7. Slowly raise the top end of the ViewRite, while the bottom end remains on the level surface, permitting the float

to slowly slide to the bottom, avoiding any sudden impact damage to the float assembly.

8. Move the ViewRite to the tank and position the unit with the end marked “TOP” pointing upwards. Install any

necessary mounting gaskets or seals1, and align the mating port flanges, NPT’s or connections of the tank with

those of the ViewRite. DO NOT A TTEMPT T O FORCE ALIGNMENT. To do so may damage the welds or

compromise the integrity of the ViewRite. While following standard practices and procedures, tighten the flange

bolts, NPT’s or connections. Recommended torque values are supplied in Figure A, page 4.

9. Before Filling the T ank . . . . Be sure that the inst allation is free of foreign particles, especially any that are

magnetic. Check that all connections are secure. A hydrostatic pressure test of the complete assembly

is recommended.

NOTE

Dwyers recommends that you include at least one support bracket in your installation for ViewRite units greater than

10 feet (120 inches, 3048 mm) in length. Depending on the specific installation, a load-bearing support at the base

of the ViewRite may be beneficial.

______________________________________

1

Gaskets or seals for the port flanges are not supplied with the ViewRite.

- 3 -

Page 4

Figure A

(Recommended Torque Values are for Lubricated Threads, Only)

Indicator Type

Fastener

Description

Nominal

Size

Torque Value

70 - 80 Lb.-Inches NTE

(Not to Exceed) 120 Lb.-Inches

30 Lb-Feet

60 Lb-Feet

100 Lb-Feet

150 Lb-Feet

250 Lb-Feet

350 Lb-Feet

70 - 80 Lb-Inches

Standard Alloy,

Top-Mount Alloy

Mini

Bolt, Nut

Bolt, Nut

3/8 Inch

1/2 Inch

5/8 Inch

3/4 Inch

7/8 Inch

1 Inch

1-1/8 Inch

5/16 Inch

Flag Installation

General Notes

Under normal circumstances, it should not be necessary to reposition the flag assembly on your ViewRite. However , if

you find it desirable or necessary to reposition the flag assembly , we strongly recommend that you first mark the distance from the top of the weldment to the top of the flag assembly. Before securing the flag assembly in a new radial

position, ensure that the distance from the top of the flag assembly to the top of the weldment is the same as the previously noted dimension. Making a temporary or permanent mark on the weldment can ease the process.

Maintenance

The only maintenance typically required is to ensure that the internal walls of the weldment and the float are free of

foreign matter. This may be accomplished by removing the float assembly from the unit and wiping both the float and

the inside wall of the float chamber or weldment. Any maintenance interval is to be est ablished by the user of the

ViewRite and would depend upon the characteristics of the application. Maintenance could coincide with tank cleaning

or flushing.

Float Installation

Mini ViewRite Float:

T o accomplish the removal and subsequent reinst allation of the float assembly , follow the appropriate instructions provided on page 5 for the ViewRite type and mounting configuration you have selected.

To set magnet position hold the float vertical. A paper clip will attach to the magnet to show its position. Adjust the

magnet position by gently tapping the end of the float.

Basic Float Part No. 807100

(Liquid Specific Gravity Range: 0.8 to 1.2)

Float

Part Number

85206

83453

85208

85209

84158

Dimension

“X”

Liquid

Specific

Gravity

0.8

0.9

1

1.2

0.85

“X”

Dimension

5”

4.5”

4”

3.312”

4.75”

TOP

807100

(Liquid Specific Gravity Range: 1.5 to 3.8)

- 4 -

Basic Float Part No. 807200

Float

Part Number

88111

801708

“X”

Dimension

Liquid

Specific

Gravity

1.9

1.5

“X”

Dimension

2”

2.6875”

TOP

807200

Caution

Make sure that the tank is depressurized

and that liquid has been emptied prior to

removal of the float assembly.

Page 5

ViewRite with Side Connections (Alloy and Mini)

The float assembly can be removed without disturbing the mounting of the ViewRite unit to the tank.

1. Carefully remove the end cap (access to the float assembly) which may be retained by bolts or NPT threads.

The float assembly should be resting on the end cap as it is being lowered.

Support the float assembly while setting the end cap aside.

Note: For units supplied with top float access, the float assembly must be

extracted from the top of the weldment by engaging the hooking ring

provided on the top of the float.

2. Withdraw the float assembly from the unit, exercising caution not to damage the float. Note the “TOP”

indication marking on the float assembly.

3. Wipe down the weldment and the float assembly with a clean, lint-free cloth.

4. Carefully reinsert the float assembly into the weldment, ensuring that the “TOP” indication marking on the

float assembly is positioned in the same manner as when it was removed.

5. Remove the old gasket or O-ring from the end cap assembly and replace it with a new gasket or O-ring.

6. With the new gasket or O-ring properly positioned, reassemble the end cap assembly to the weldment.

Tighten the end cap or secure flange fasteners, using the proper recommended torque value, as supplied

in Figure A -page 4.

ViewRite with Top and Bottom Connections (Alloy and Mini)

The ViewRite unit should be adequately supported when removing it from the tank.

1. Disconnect the top and bottom flange/socket or NPT connections.

2. Remove any other fasteners that retain the unit and/or support bracket(s) to the tank.

3. Remove the ViewRite unit from the tank, while avoiding any motion that will cause damage to the float assembly.

4. With the ViewRite placed in a horizontal position on a level surface, remove the end cap or flange and withdraw

the float assembly from the unit; noting the relative position of the portion of the float assembly marked “TOP”.

5. Wipe down the weldment and the float assembly with a clean, lint-free cloth.

6. Carefully reinsert the float assembly into the bottom of the float chamber or weldment, ensuring that the “TOP”

indication marking on the float assembly is positioned the same as when it was removed.

7. Remove the old gasket or O-ring from the end cap assembly and replace it with a new gasket or O-ring.

8. With the new gasket or O-ring properly positioned, reassemble the end cap assembly to the bottom of the

weldment. Tighten the end cap or flange bolts securely, using the proper recommended torque value, as

supplied in Figure A, page 4.

9. Complete installation of the unit by following the Installation Instructions for Standard ViewRites (Page 3,

Steps 7, 8 and 9).

- 5 -

Page 6

Indicating Scale

This Indicating Scale provides a numerical readout of

the liquid level in the tank, in addition to the visual level

displayed by the flag assembly. The indicating scale

is mounted alongside the flag assembly with special

clamps. The scale is normally graduated in inches

and feet, but may be graduated in other dimensional

or volumetric units. Scales that have an overall length

of more than 24 inches will be provided in two or more

sectional lengths.

Installation

Scales ordered with the ViewRite Magnetic Level Indicator are factory-installed. If ordered

separately, please follow the instructions below.

Mounting

The scale is simply installed on your ViewRite Magnetic Level Indicator using the bracketed

clamps supplied.

1. Att ach the scale onto the ViewRite Magnetic Level Indicator, wrapping the clamps around the flag

assembly and the weldment.

2. Tighten the clamps securely, with a torque not to exceed 5 lb.-inches.

- 6 -

Page 7

Troubleshooting

Condition Possible Cause

No Float

Float sticking, due to contamina-

No change in Media

Level Indication

Incorrect Fluid Level

Indication

tion in the fluid level

Float attracted, due to external

ferrous materials within close

proximity.

The float is damaged

Port is blocked

Float attracted, due to contami-

nation in the media

Float sticking, due to external

ferrous materials within close

proximity

Solution

Install float

Clean the float and weldment

Remove the ferrous materials

from close proximity

Replace the float

Remove blockage

Clean the float and weldment

Remove the ferrous materials

from close proximity

The float is damaged

The float is upside down

Flag assembly is upside-down.

Incorrect Color

Indicating Fluid Level

Note: Increased viscosity increases the response time of the ViewRite indicator

Warnings/Cautions

1. The ViewRite Magnetic Level Indicator must be maintained and installed in strict accordance with

this Instruction Bulletin. Failure to observe this warning could result in serious injuries or damages.

2. The liquids to be monitored must be compatible with the materials of construction. Specifications

of these materials will be provided upon request.

(The wrong color is indicating the

liquid level)

Replace the float

Invert the float

Rotate the flag assembly 180

degrees (with the end marked

“TOP” uppermost)

- 7 -

Page 8

MAINTENANCE/REPAIR

Regular maintenance of the total system is recommended to assure sustained optimum performance. These devices are

not field repairable and should be returned to the factory if recalibration or other service is required. After first obtaining a

Returned Goods Authorization (RGA) number , send the unit freight prep aid to the following. Please include a clear

description of the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City , IN 46360

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and Dwyer product catalog

and instruction bulletin. Failure to observe this warning could

result in serious injuries or damages.

For hazardous area applications involving such things as (but

not limited to) ignitable mixtures, combustible dust and

flammable materials, use an appropriate explosion-proof

enclosure or intrinsically safe interface device.

The pressure and temperature limitations shown on the

individual catalog pages and drawings for the specified flow

switches must not be exceeded. These pressures and

temperatures take into consideration possible system surge

pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical

to the life and operation of Dwyer products. Take care in the

proper selection of materials of construction, particularly wetted

materials.

DWYER INSTRUMENTS,INC.

P.O.BOX 373 MICHIGAN CITY , INDIANA 46361, U.S.A.

Life expectancy of switch contacts varies with applications.

Contact Dwyer if life cycle testing is required.

Ambient temperature changes do affect switch set points,

since the specific gravity of a liquid can vary with temperature.

Dwyer Products have been designed to resist shock and

vibration; however, shock and vibration should be minimized.

Filter liquid media containing particulate and/or debris to

ensure the proper operation of our products.

Electrical entries and mounting points in an enclosed tank

may require liquid/vapor sealing.

Dwyer Products must not be field-repaired.

Physical damage sustained by the product may render it

unserviceable.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

- 8 -

Loading...

Loading...