Page 1

Bulletin F-46

Mini-Master®Flowmeter

Instructions

Mini-Master®flowmeter mounts

easily from front of panel. Drill two 9⁄32"

or 5⁄16" dia. holes in panel on 21⁄16"

centers. Insert mounting connector

spuds. From rear, slide on the two

spring retainers (furnished) and push

on rubber or plastic tubing.

Connector at top, installed in panel,

has retainer and flexible tubing in place.

Connector at bottom shows alternative

connection with metal or rigid plastic

tubing, using a double compression

nylon tube union (as Dwyer Instruments, Inc. Part No. A-328).

Inlet Piping Run

It is good practice to approach the flowmeter inlet with as few elbows

and restrictions as possible. In every case the inlet piping should be at

least as large as the connection to the flowmeter. Length of inlet piping makes little difference for normal pressure fed flowmeters.

For flowmeters on vacuum air service the inlet piping should be as

short and open as possible. This will allow operation near atmospheric pressure and thereby insure the accuracy of the device. (Note that

for vacuum air service the flow control valve if any, should be on the

discharge side of the flowmeter. Either the TMV unit or a separate in

line valve may be applied.)

Discharge Piping

As on the inlet, discharge piping should be at least as large as the

flowmeter connection. In addition, for pressure fed flowmeters on air

or gas service the discharge piping should be as short and open as

possible. This will allow operation of the flow tube at near atmospheric pressure and insure the accuracy of the device.

Cleaning

The flow tube and flowmeter body can best be cleaned with a little

pure soap and water. Avoid liquid soaps which may have chlorinated

solvents in them and avoid prolonged immersion. Flush thoroughly

with clear water to remove all soap. When the instrument can no

longer be cleaned by this method it should be replaced.

DWYER INSTRUMENTS INC.

P.O. Box 373 • Michigan City, IN 46361 U.S.A.

Phone: 219/879-8000 • Fax: 219/872-9057

e-mail: info@dwyer-inst.com • www.dwyer-inst.com

Page 2

The performance of low range units used in air or gas applications may

be affected by static electicity. Excessive static charge may cause the

ball float to behave erratically or provide a false reading. To ensure the

proper function of the unit, the application should be designed to minimize or dispel static electricity.

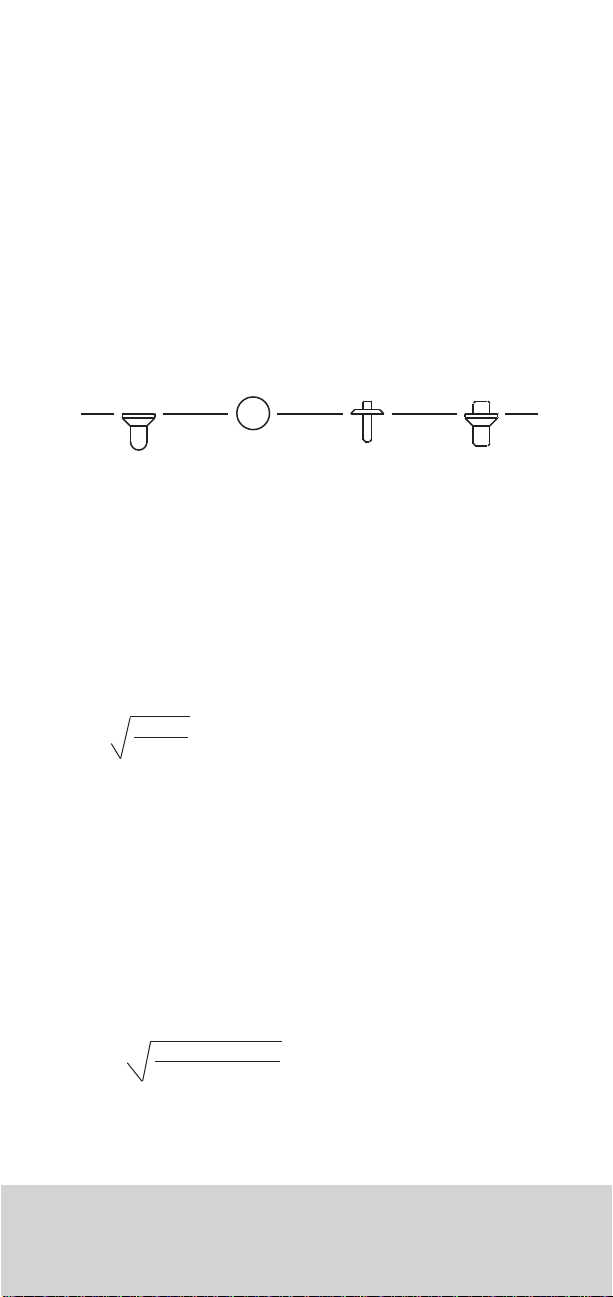

The standard technique for reading a Variable Area Flowmeter is to

locate the highest point of greatest diameter on the float, and then

align that with the theoretical center of the scale graduation. In the

event that the float is not aligned with a grad, an extrapolation of the

float location must be made by the operator as to its location between

the two closest grads. The following are some sample floats shown

with reference to the proper location to read the float.

Variable Area Flowmeters used for gases are typically labeled with the

prefix “S” or “N”, which represents “Standard” for English units or

“Normal” for metric units. Use of this prefix designates that the

flowmeter is calibrated to operate at a specific set of conditions, and

deviation from those standard conditions will require correction for the

calibration to be valid. In practice, the reading taken from the flowmeter scale must be corrected back to standard conditions to be used

with the scale units. The correct location to measure the actual pressure and temperature is at the exit of the flowmeter, except under vacuum applications where they should be measured at the flowmeter

inlet. The equation to correct for nonstandard operating conditions is

as follows:

2

= Q1x P1x T

Q

P2x T

2

1

Where: Q1= Actual or Observed Flowmeter Reading

2

Q

= Standard Flow Corrected for Pressure and

Temperature

1

P

= Actual Pressure (14.7 psia + Gage Pressure)

2

P

= Standard Pressure (14.7 psia, which is 0 psig)

1

T

= Actual Temperature (460 R + Temp °F)

T2= Standard Temperature (530 R, which is 70°F)

Example: A flowmeter with a scale of 10-100 SCFH Air. The float is sitting at the 60 grad on the flowmeter scale. Actual Pressure is measured at the exit of the meter as 5 psig. Actual Temperature is measured at the exit of the meter as 85°F.

2

Q

= 60.0 x (14.7 + 5) x 530

14.7 x (460 + 85)

2

Q

= 68.5 SCFH Air

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 59-440210-00 Rev. 9

DWYER INSTRUMENTS INC.

P.O. Box 373 • Michigan City, IN 46361 U.S.A.

Phone: 219/879-8000 • Fax: 219/872-9057

e-mail: info@dwyer-inst.com • www.dwyer-inst.com

Loading...

Loading...