Page 1

Bulletin A-37

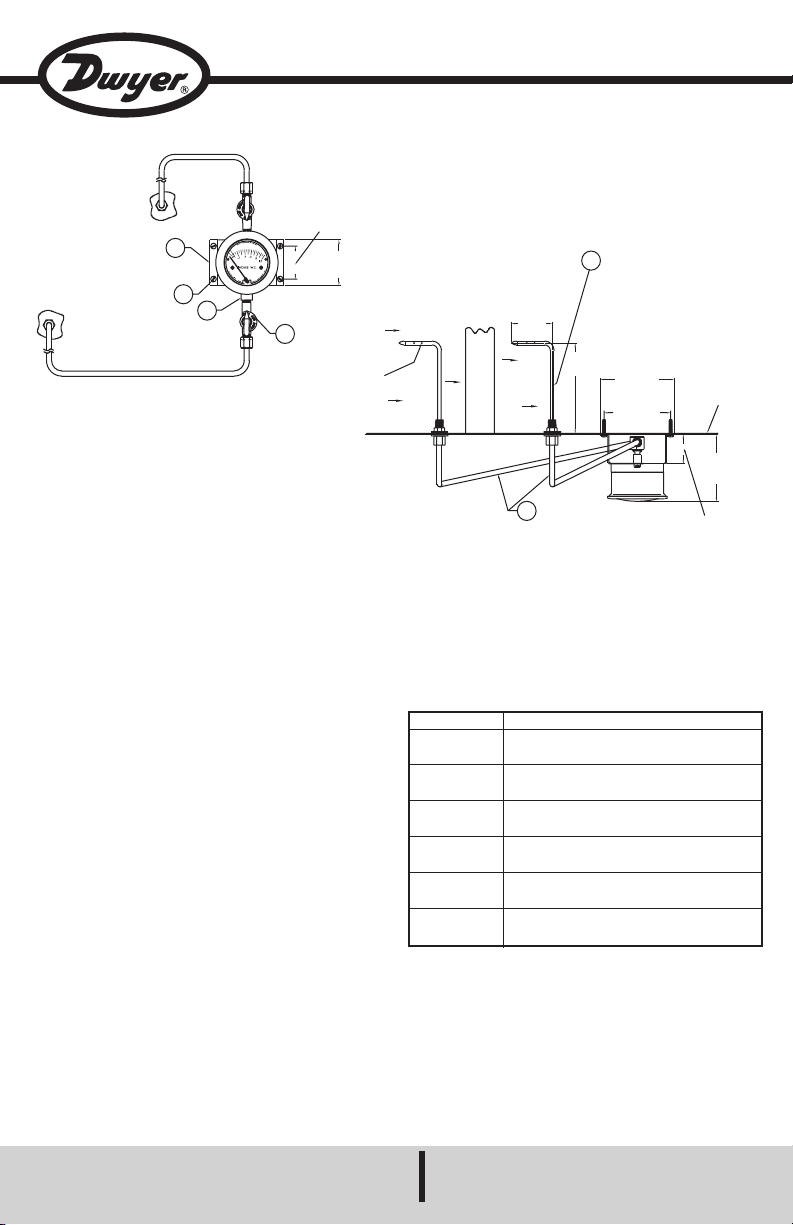

L

OW PRESSURE LINE

HIGH PRESSURE LINE

1-9/16

[39.69]

2-1/4

[57.15]

2X #60 HOLES

Ø3/64 [Ø.047]

A

IR

FLOW

2

[

50.8]

4

[101.6]

FILTER

WALL

3-5/8

[92.08]

3-1/4

[82.55]

3-7/32

[81.76]

1-7/16

[36.51]

2

FILTER ELEMENT

1

6

5

4

3

AIR

FLOW

Minihelic®II Air Filter Gages

Specifications - Installation and Operating Instructions

INSTALLATION PROCEDURE

1. Drill two 7/16˝ diameter holes in duct, one on either

side of filter and at least 12˝ upstream and downstream.*

Install static pressure fittings as shown above with tips

pointing into the air stream.

2. Attach Minihelic

studs and nuts supplied with gage.

3. Thread two-way vent valves into adapter elbows.

Handle of valve must align with remaining opening in

elbow when tight. Press completed assemblies onto

barbed connections at rear of gage as shown above.

4. Select a vertical plumb mounting surface for the gage

within 5 ft of the static tips. Location should be

reasonably free of vibration which can cause gage

pointer to oscillate. Attach bracket to surface with 4 sheet

metal screws supplied.

5. Cut aluminum tubing to length and connect between

static pressure tips and gage. The tip on the upstream

side of the filter is connected to the high pressure gage

connection.

6. Turn handles of both valves to “vent” position and

check gage for zero reading. Adjust if necessary

following instructions in bulletin A-36. Turn valves to

“line” or on position and read pressure drop. Periodically

re-check zero point to assure accuracy.

®

II gage to mounting bracket using

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Operating Instructions for Minihelic®II Differential

Pressure Gages are included in Bulletin A-36 packed

with each gage. This kit is designed for gages with

standard barbed connections. If your gage has

optional male pipe threads, purchase (2) 1/8˝ x 1/8˝

NPT elbows to replace fittings included.

PARTS LIST/A-609 KIT

Part Number

1

2

3

4

5

6

Phone: 219/879-8000 www.dwyer-inst.com

Description

Static Pressure Tip with integral 1/4˝

compression fitting. 2 included.

5´length 1/4˝ diameter aluminum

tubing. 2 included.

Surface Mounting Bracket. 20 ga. steel

with flat black finish.

#6 x 3/4˝ Pan Head sheet metal screw.

4 included.

1/8˝ NPT female adapter elbow. 2

included.

2 Way Vent Valve 1/8˝ NPT male x 1/4˝

compression fitting. 2 included

Page 2

INSTALLATION CHECK AND TROUBLESHOOTING

Before putting your air filter gage into service or in the

event of initial pressure drop readings that don’t agree

ith the filter manufacturer’s specified pressure drop,

w

ake the following checks:

m

. Check zero adjustment of the gage as described

1

above.

2. Check all tubing connections for tightness from gage to

the static tip or fitting connection.

3. Check plastic cover of gage to be sure it is securely in

lace and and air tight.

p

. Check static pressure tips or fittings to be sure they are

4

ot plugged.

n

5. Check installation of static tips or fittings.* Be sure

static pressure tips point directly into the air stream. A

velocity pressure error can be created if the air blows

directly into the openings.

OPERATION

With vent valves in “LINE” position the gage will

indicate pressure drop across the filter. If the reading

varies substantially from the filter manufacturer’s rating

for a clean filter, check the system for proper setting of

controls, air balancing of system, leakage in system and

whether or not the correct filter has been installed.

When pressure drop across the filter reaches the

maximum recommended by the manufacturer, the filter

should be serviced or replaced.

MAINTENANCE/REPAIR

Upon final installation of the Minihelic

maintenance is required. The Minihelic

erviceable and should be returned if repair is needed.

s

ield repair should not be attempted and may void

F

arranty.

w

®

II, no routine

®

II is not field

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog

and on our website. Contact customer service to receive

Return Goods Authorization number before shipping

a

he product back for repair. Be sure to include a brief

t

escription of the problem plus any additional application

d

notes.

*NOTE ON LOCATION OF STATIC PRESSURE TIPS.

The location of static pressure tips is of primary

importance in securing reliable readings. For maximum

accuracy, it is essential that the influence of the velocity

of the air be eliminated to permit sensing the true static

pressure. Note that some installations do not provide a

straight duct approach to the filter bank which may cause

air to swirl and eddy.

Tips should be located as recommended by the

specifying engineer or by the filter manufacturer. In the

absense of such recommendations, locate the tips at

least 12˝ upstream and downstream from the filters in a

zone of minimum turbulance.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 9/12 FR# 14-440488-00 Rev.1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...