Page 1

Series MFS2

Magnetic Inductive Flow Sensor

.

Page 2

Series MFS2

Table of contents page

0 About this operating manual......................................................................................3

1 Device description.....................................................................................................4

1.1 Intended use ...........................................................................................................5

1.2 Exclusion of liability .................................................................................................5

2 Safety instructions.....................................................................................................6

3 Construction and function..........................................................................................7

4 Installation of MFS2...................................................................................................7

4.1 Installation instructions............................................................................................8

4.2 Assembly.................................................................................................................9

5 Electrical connection ...............................................................................................10

6 Commissioning and measuring operation ...............................................................11

6.1 Commissioning......................................................................................................11

6.2 Measuring operation .............................................................................................11

7 Maintenance and cleaning ......................................................................................11

8 Disassembly and disposal.......................................................................................12

9 Technical data.........................................................................................................13

9.1 Characteristics MFS2............................................................................................13

9.2 Materials table.......................................................................................................14

9.3 Pressure drop........................................................................................................14

9.4 Dimensions ...........................................................................................................15

Copyright notice:

The reproduction, distribution and utilization of this operating manual as well as the communication

of its contents to others without express authorization is prohibited. Offenders will be held liable for

the payment of damages. All rights reserved in the event of the grant of a patent, utility model or

design.

- 2 - Dwyer_MFS2 • 11/2013

Page 3

Series MFS2 About this operating manual

0 About this operating manual

The operating manual is aimed at specialists and semi-skilled personnel.

Before each step, read through the relevant advice carefully and keep to the specified

order.

Thoroughly read and understand the information in the section "Safety instructions".

If you have any problems or questions, please contact your supplier or contact us directly

at:

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City

INIDANA 46361, U.S.A.

Phone: (219) 879 - 8000

Fax: (219) 872 - 9057

Email: info@dwyer-inst.com

Hazard signs and other symbols used:

WARNING! / CAUTION! Risk of injury!

This sign indicates dangers that cause personal injuries that can lead to health defects or

cause considerable damage to property.

CAUTION! Electric current!

This sign indicates dangers which could arise from handling of electric current.

CAUTION! Material damage!

This sign indicates actions which could lead to possible damage to material or environmental

damage.

ADHERE TO OPERATING MANUAL!

NO DOMESTIC WASTE!

The device must not be disposed of

together with domestic waste.

Pay attention to and comply with

information that is marked with this symbol.

Follow the specified instructions and steps.

Adhere to the given order.

NOTICE!

This symbol indicates important notices,

tips or information.

Check the specified points or notices.

Reference to another section, document or

source.

• Item.

Technical changes reserved - 3 -

Page 4

Device description Series MFS2

1 Device description

The MFS2 series from Dwyer, is a non-contact flow sensor. The measurement is performed

using magnetic induction and works without any moving parts.

The MFS2 is used for measuring or metering water and aqueous solutions. The compact

design and independence from the intake and discharge sections allows the MFS2 to be

used under a variety of conditions.

Components:

Sensor housing:

The sensor housing consists of plastic and

has the IP65 degree of protection.

Electrical connection:

The electrical connection is made via 4-pin

plug M12x1.

Operation / flow indicator LED.

Type plate with flow direction (marking)

Process connection:

The process connections are available in

different sizes.

Versions:

The MFS2 is available in different nominal sizes from DN 8 to DN 25.

The versions can be configured differently (MFS2 Data sheet).

Scope of delivery and accessories:

Before installing the device, check the delivered items and ordered accessories:

Scope of delivery:

1x MFS2 as ordered.

1x Operating manual.

1x Packaging.

- 4 - Dwyer_MFS2 • 11/2013

Page 5

Series MFS2 Device description

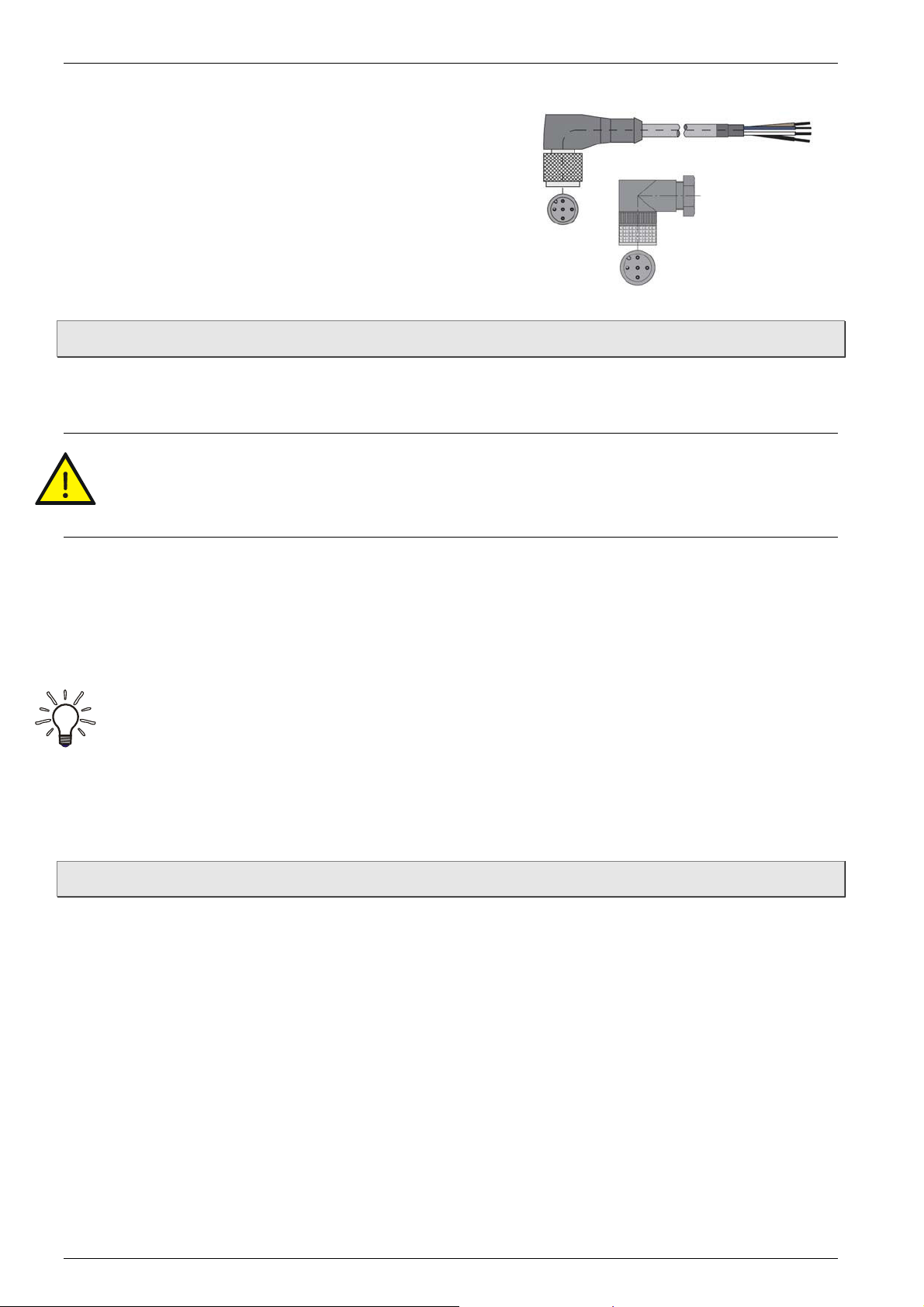

Accessories:

Connection cable with moulded M12x1 coupling

socket.

M12x1 coupling socket as component.

1.1 Intended use

The magnetic inductive flow sensor MFS2 must only be used for measuring and metering

liquids with a minimum conductivity of 20 μS/cm.

WARNING! No safety component!

The magnetic inductive flow sensor of the series MFS2 are not safety components in

accordance with Directive 2006-42-EC (Machine Directive).

Never use the MFS2 as a safety component.

The operational safety of the device supplied is only guaranteed by intended use. The

specified limits ( § 9 "Technical data") may under no circumstances be exceeded.

Before installing the device, check that the wetted materials of the device are compatible with

the media being used ( § 9.2 "Materials table").

Measuring tube empty (or partially filled). / Conductivity too low.

The green LED may blink irregularly if the measuring tube of the MFS2 is empty or

partially filled, or if the conductivity of the fluid being used is too low. Random pulses will

be present at the output, but they do not represent an actual flow.

Ensure that the measuring tube of the MFS2 is always completely filled ( § 4.1

"Installation instructions").

Ensure that the conductivity of the fluid is at least 20 μS/cm.

1.2 Exclusion of liability

We accept no liability for any damage or malfunctions resulting from incorrect installation,

inappropriate use of the device or failure to follow the instructions in this operating manual.

Technical changes reserved - 5 -

Page 6

Safety instructions Series MFS2

2 Safety instructions

Before you install the MFS2, read through this operating manual carefully. If the

instructions contained within it are not followed, in particular the safety guidelines, this

could result in danger for people, the environment, as well as the device and the system

it is connected to.

The MFS2 correspond to the state-of-the-art technology. This concerns the accuracy, the

operating mode and the safe operation of the device.

In order to guarantee that the device operates safely, the operator must act competently and

be conscious of safety issues.

Dwyer provides support for the use of its products either personally or via relevant literature.

The customer verifies that our product is fit for purpose based on our technical information.

The customer performs customer- and application-specific tests to ensure that the product is

suitable for the intended use. With this verification all hazards and risks are transferred to our

customers; our warranty is not valid.

Qualified personnel:

The personnel who are charged for the installation, operation and maintenance of the

MFS2 must hold a relevant qualification. This can be based on training or relevant tuition.

The personnel must be aware of this operating manual and have access to it at all times.

The electrical connection should only be carried out by a fully qualified electrician.

General safety instructions:

In all work, the existing national regulations for accident prevention and safety in the

workplace must be complied with. Any internal regulations of the operator must also be

complied with, even if these are not mentioned in this manual.

Degree of protection according to EN 60529:

Please ensure that the ambient conditions at the site of use does not exceed the

requirements for the stated protection rating ( § 9 "Technical data").

Only use the MFS2 if it is in perfect condition. Damaged or faulty devices must be

checked without delay and, if necessary, replaced.

When fitting, connecting and removing the MFS2 use only suitable appropriate tools.

Do not remove or obliterate type plates or other markings on the device, as otherwise the

warranty is rendered null and void.

Special safety instructions:

(Further) Warnings that are specifically relevant to individual operating procedures or

activities can be found at the beginning of the relevant sections of this operating manual.

- 6 - Dwyer_MFS2 • 11/2013

Page 7

Series MFS2 Construction and function

3 Construction and function

Construction:

The measuring tube with its earthing sleeves and electrodes

passes through the sensor housing and forms the external

process connection of the MFS2.

A magnetic field for the measurement process is generated

inside the sensor housing, which also contains the sensor and

signal conditioning circuitry.

The two stainless steel electrodes are located in the middle of the

measuring tube between the earthing sleeves. The MFS2 does

not need any moving parts to make measurements. The inside of

the measuring tube is completely open, allowing the fluid to flow

unhindered through the measuring tube.

Function:

The magnetic inductive flow sensor functions according to the induction principle:

The measuring tube is located in a magnetic field (B).

If an electrically conductive medium (V) flows through

the measuring tube and, therefore, at right angles to

the magnetic field, a voltage (U) that is proportional to

the mean flow velocity, will be induced in the medium

and subsequently picked up by the two electrodes.

4 Installation of MFS2

Before installing, check that

the wetted materials of the device are suitable for the media being used ( § 9.2

"Materials table").

the equipment is switched off and is in a safe and de-energized state.

the equipment is depressurized and has cooled down.

SUITABLE TOOLS:

Use only suitable tools of the correct size.

Technical changes reserved - 7 -

Page 8

Installation of MFS2 Series MFS2

4.1 Installation instructions

CAUTION!

Risk of malfunction due to external magnetic fields!

Magnetic fields close to the device can cause malfunctions and

should be avoided.

Ensure that no external magnetic fields are present at the

installation site of the MFS2.

The MFS2 can always be installed anywhere along the pipeline. Straight sections of

piping are preferable, however.

Installation can occur in horizontal and vertical pipes. The flow sensor is only suitable for

application in completely filled pipe systems.

As a matter of principle, magnetic inductive flow sensors are widely independent from the

flow profile. An inlet section is not absolutely necessary.

To reach the highest accuracy of the measurement, you should use straight inlet and

outlet sections according to the nominal width (DN). The inlet section has to be at least

10 x DN; the outlet section 5 x DN in order to achieve the specified accuracy.

The inlet and outlet sections and the gaskets must have the same or a slightly larger

inside diameter than the measuring tube in order to achieve the specified accuracy.

- 8 - Dwyer_MFS2 • 11/2013

Page 9

Series MFS2 Installation of MFS2

If two or more MFS2 devices are used side by side, maintain

a separation of at least 1" between adjacent devices.

If adjacent devices are too close together, operation of both

devices may be impaired due to mutual interference.

4.2 Assembly

The MFS2 is installed directly into the pipeline. The compact design and light weight of the

unit make wall-mounting unnecessary.

IMPORTANT NOTICES:

• Observe the flow direction indicated on the type plate.

• Observe the mounting dimensions ( § 9.4 "Dimensions").

Select an appropriate location for installation ( § 4.1

"Installation instructions").

To ensure the best possible measuring accuracy, a vertical

installation position with increasing flow is preferable (no

collecting of dirt deposits).

Wrap the MFS2 connections with 1 to 2 wraps of thread tape

(e.g. Teflon® tape). Wrap tape in a clockwise direction,

viewed form the end, leaving the first two threads uncovered.

Make sure the tape does not intrude into the flow path.

Attach the MFS2 with arrow pointed in the direction of flow.

The fittings should be screwed into MFS2 hand tight.

CAUTION! Material damage!

Do not use excessive force. The MFS2 can be

damaged.

While tightening, counter the MFS2 only by hand!

If you use an open-end or a pipe wrench, the MFS2 can

be damaged.

To tighten the MFS2, use an open-end or a pipe wrench

for the fittings and only the hand for the MFS2.

Tighten the MFS2 an additional ¾ to 1 turn.

Technical changes reserved - 9 -

Page 10

Electrical connection Series MFS2

5 Electrical connection

The electrical connection of the MFS2 is via the 4-pin plug M12x1 at the top.

The corresponding connection cables with moulded coupling socket are available in various

lengths included in the range of Dwyer accessories.

CAUTION! Electric current!

The electrical connection should only be carried out by a fully qualified electrician.

De-energize the electrical system before connecting the MFS2.

Connection and wiring:

Screw the coupling socket of the connection cable to the plug of the MFS2.

Tighten the knurled nut of the coupling socket with a maximum torque of 1 Nm.

Connect the connection cables according to the following wiring diagrams.

Pin assignment:

Pin configuration with

NPN frequency output:

Pin 1: +U

Pin 3: GND

Pin 2 / 4: Frequency output NPN/PNP

B

PNP frequency output:

Pull-up- / pull-down-resistors R.

We recommend using resistors of ~2,2 kΩ (24V) and 0.25 W for the pull-up / pull-down

wiring.

Please note that the maximum signal current of 25 mA will not be exceeded.

- 10 - Dwyer_MFS2 • 11/2013

Page 11

Series MFS2 Commissioning and measuring operation

6 Commissioning and measuring operation

Before switching on the MFS2 for the first time, please follow the instructions in the following

section.

6.1 Commissioning

Check that

the MFS2 has been installed correctly and that all screw connections are sealed.

the electrical wiring has been connected properly.

the measuring system is vented by flushing.

Switch on the supply voltage.

The red LED is lit permanently. The MFS2 is ready for use and goes into measuring

operation.

6.2 Measuring operation

The red LED is constantly lit to indicate that the MFS2 is

operational.

The green LED blinks according to the frequency of the output

signal.

This blinking is not perceptible to the human eye at frequencies

above 30 to 40 Hz,

so the green LED appears to be constantly lit.

Frequency output:

The frequency output provides a flowproportional PNP/NPN square wave signal.

7 Maintenance and cleaning

Maintenance:

The MFS2 is maintenance-free and cannot be repaired by the user. In case of a defect, the

device must be replaced or sent back the manufacturer for repair.

CAUTION! Material damage!

When opening the device, critical parts or components can be damaged.

Never open the device and perform any repair yourself.

Cleaning:

Clean the MFS2 with a dry or slightly damp lint-free cloth. Do not use sharp objects or

aggressive agents for cleaning.

Technical changes reserved - 11 -

Page 12

Disassembly and disposal Series MFS2

8 Disassembly and disposal

CAUTION! Risk of injury!

Never remove the device from a plant in operation.

Make sure that the plant is shut down professionally.

Before disassembly:

Prior to disassembly, ensure that

the equipment is switched off and is in a safe and de-energized state.

the equipment is depressurized and has cooled down.

Disassembly:

Remove the electrical connectors.

Remove the MFS2 using suitable tools.

Disposal:

NO HOUSEHOLD WASTE!

The MFS2 consists of various different materials. It must not be disposed of with

household waste.

Take the MFS2 to your local recycling plant

or

send the MFS2 to Dwyer.

- 12 - Dwyer_MFS2 • 11/2013

Page 13

Series MFS2 Technical data

9 Technical data

The technical data of customized versions may differ from the data in these instructions.

Please observe the information specified on the type plate.

9.1 Characteristics MFS2

Type MFS2-1 MFS2-2 MFS2-3 MFS2-4 MFS2-5 MFS2-6

Measurement device characteristics

Flow range [gpm] 0.066…1.3 0.26…5.3 0.66…13.2 1.3…26.4 2.6…53 3.3…66

Accuracy* ±1% of reading

Repeatability 1%

Output signal starting

from [gpm]

(Accuracy 5%)

Max. flow rate [gpm] 1.6 6.6 15.8 31.7 63.4 79.3

Response time < 100 ms

Indications red LED = Supply voltage • green LED = Flow

0.02 0.07 0.27 0.52 1.05 1.3

Output signal characteristics

Frequency output:

- Pulse rate / K-Factor**

[pulses/gal]

- Resolution** [ml/pulse]

- Signal shape

- Signal current

15000 3000 1500 750 380 300

0.25 1.3 2.5 5.0 10.0 12.6

Square wave signal • duty cycle 50:50

can be connected as PNP or NPN open collector

≤ 25 mA

Electrical characteristics

Supply voltage 24 VDC ±15%

Power consumption 0.6 W

Electrical protection

measures

Electrical connection 4-pin plug M12x1

Degree of protection IP 65 (only with a connected coupling)

short-circuit proof • protected against polarity reversal

Process variables

Medium to measure Water and other conductive liquids

Min. conductivity of the

medium

Medium temperature 14…140 °F (not freezing)

Ambient temperature 41…140 °F

Nominal diameter DN 8 DN 15 DN 20 DN 25

Inner diameter 0.31 in 0.55 in 0.71 in 0.98 in

Max. working pressure

(at … °F)

Process connection ½ - 14 NPT ¾ - 14 NPT 1 - 11.5 NPT 1¼ - 11.5

* test conditions: Water 73.4 °F

** other pulse rate / resolution on request.

optional: Output signal with lower frequency, designed specifically for connection to digital PLC

inputs.

145 psi (68 °F) • 116 psi (104 °F) • 87 psi (140 °F)

higher pressure ratings on demand

20 μS/cm

NPT

Technical changes reserved - 13 -

Page 14

Technical data Series MFS2

9.2 Materials table

Component Material

Sensor housing ABS

Component-

wetted

Measuring tube PVDF

Process connections PVDF

O-ring EPDM

Electrodes Stainless steel 316L

Grounding rings Stainless steel 316L

9.3 Pressure drop

X

X

X

X

X

- 14 - Dwyer_MFS2 • 11/2013

Page 15

Series MFS2 Technical data

9.4 Dimensions

MFS2-1 … MFS2-5:

Type

MFS2-1

MFS2-2

MFS2-3

MFS2-4

MFS2-5

L1 L2 D1 D2

[inches] [inches] [inches]

4 0.86 ½ - 14 NPT Ø 0.31

4 0.86 ½ - 14 NPT Ø 0.31

4.02 0.86 ¾ - 14 NPT Ø 0.55

4.41 1.04 1 - 11.5 NPT Ø 0.71

4.41 1.04 1 - 11.5 NPT Ø 0.71

MFS2-6:

Technical changes reserved - 15 -

Page 16

Series MFS2

- 16 - Dwyer_MFS2 • 11/2013

Loading...

Loading...