Page 1

Table of contents page

1. Device description and intended use ...............................................................................................2

2. Safety instructions ............................................................................................................................2

2.1 Qualified personnel ...................................................................................................................3

2.2 Special safety instructions ........................................................................................................3

3. Unpacking and inspecting the delivery.............................................................................................4

4. Material specifications of components .............................................................................................4

5. Suitable liquids (medium) .................................................................................................................4

6. Installation of the flow sensor ...........................................................................................................4

6.1 Mechanical installation..............................................................................................................4

6.2 Electrical connection .................................................................................................................6

7. Maintenance and repairs ..................................................................................................................7

8. Decommissioning and disposal........................................................................................................7

9. Technical data ..................................................................................................................................7

10. Dimensions, pressure drop...............................................................................................................8

Page 2

Device description and intended use Series MFS

1 Device description and intended use

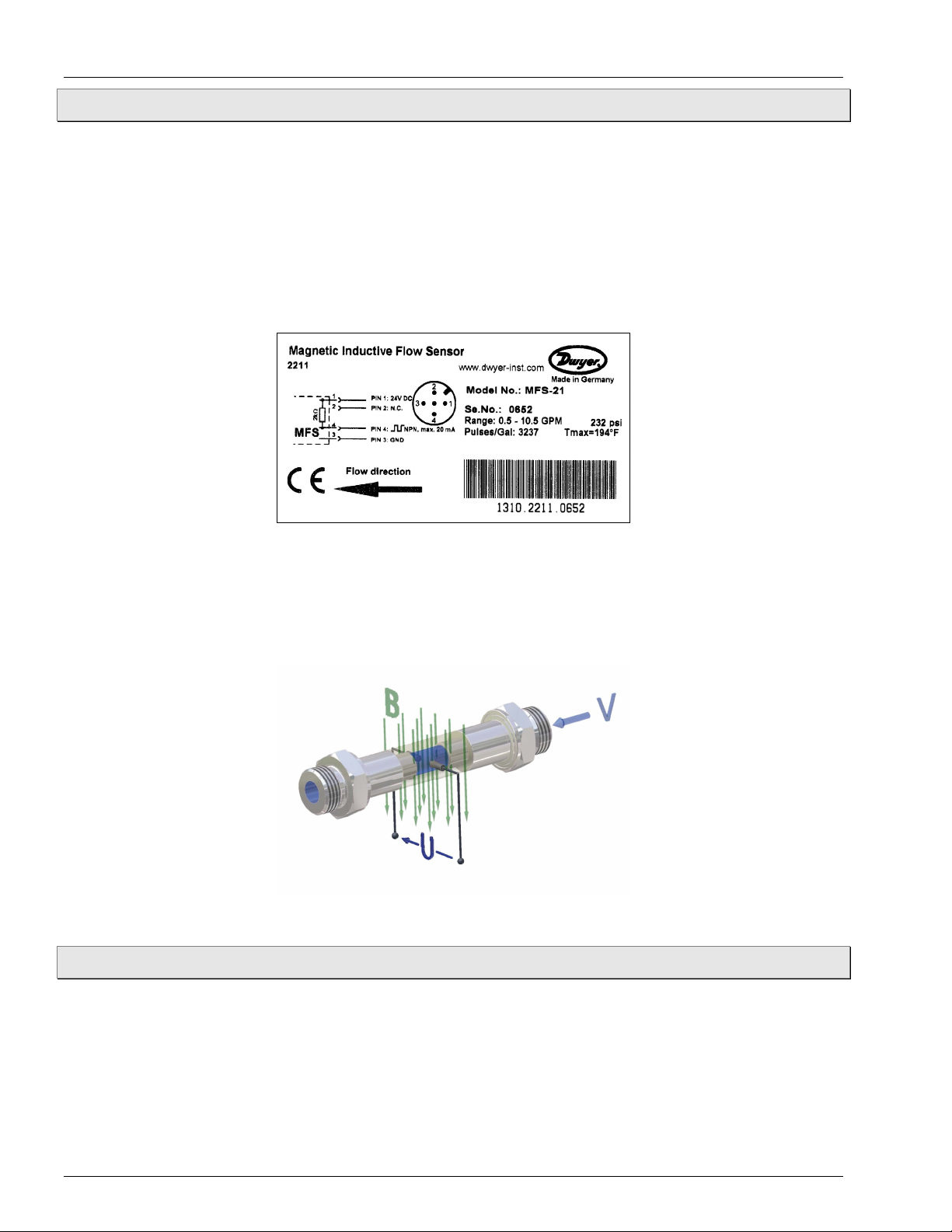

Series MFS sensors are used for continuously measuring flow rates or dosing electrically conductive liquids. The

operational safety of the supplied equipment is only guaranteed if it is operated according to its intended use

(measuring and dosing of liquids). The specified limit values (see the chapter “Technical Data”) should never be

exceeded.

It is the user's responsibility to select the appropriate technology which is suitable for the specific application, to

install it correctly, to carry out tests, and to maintain all the components.

The magnetic inductive flow sensor features no moving parts and is, therefore, almost wear free and suitable for

a wide range of measuring applications. A flow-proportional frequency signal is provided as the output signal.

Product label

Functional principle

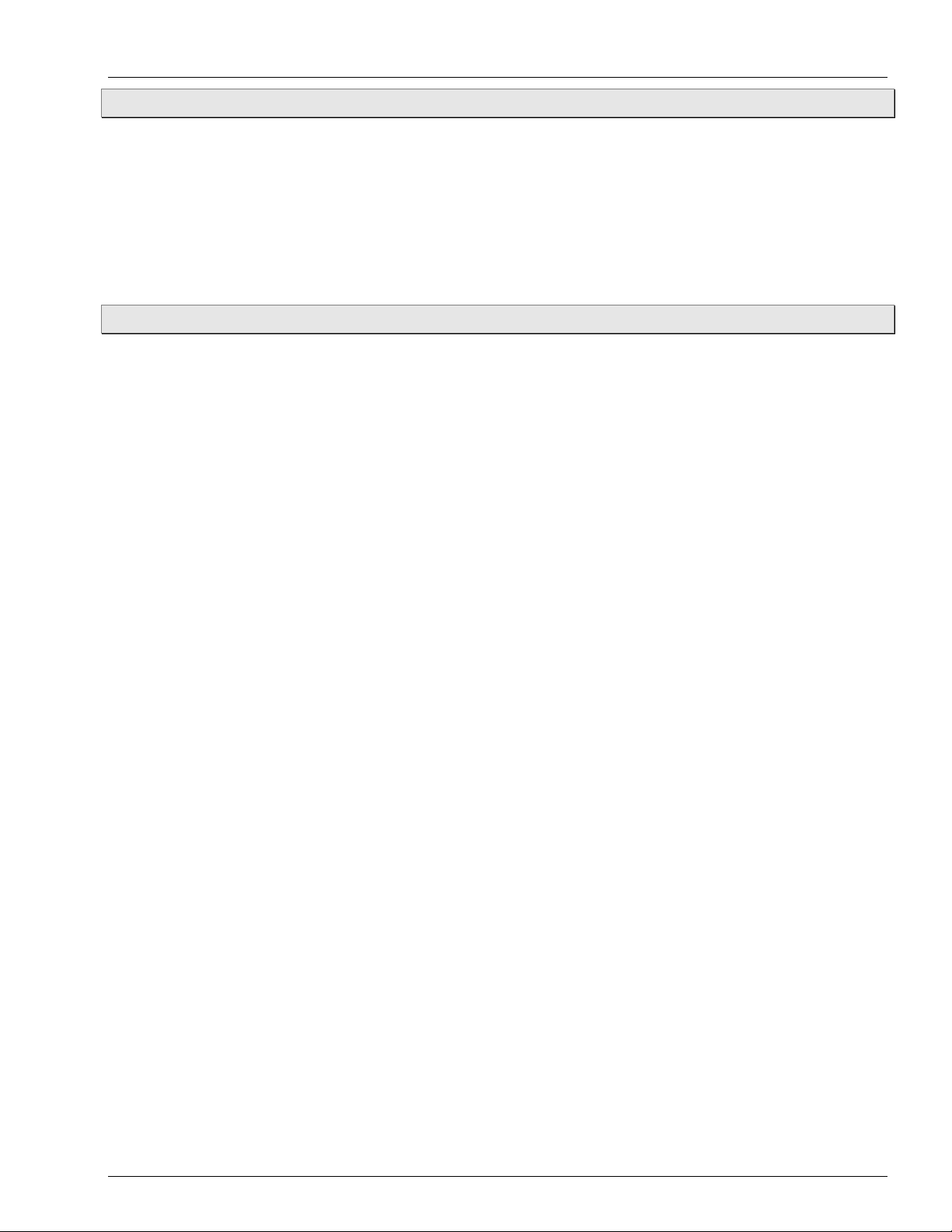

The magnetic inductive flow sensor functions according to the induction principle:

The measuring pipe is located in a magnetic field (B). If an electrically conductive medium (V) flows through the

measuring pipe and, therefore, at right angles to the magnetic field, a voltage (U) which is proportional to the

mean flow velocity will be induced in the medium and subsequently picked up by the two electrodes.

Fig. 1: Functional principle

2 Safety instructions

Always read the operating instructions carefully prior to installing the new product. Always adhere to the

instructions contained herein, especially the safety instructions, otherwise there is a potential risk of personal

injury and damage to instruments and systems.

Even though assistance is provided through personal consultation or this manual, it is the responsibility of the

customers to determine the suitability of the product for the specific application.

The magnetic inductive flow sensors are state-of-the-art devices, concerning the accuracy, functioning and safe

operation of the device.

However, professional and safety conscious conduct of the operator is required to ensure safe operation.

Technical changes reserved 2 08/2011

Page 3

Safety instructions Series MFS

2.1 Qualified personnel

The personnel entrusted with installing, operating and maintaining the MFS have to be suitably qualified;

the required knowledge can be gained via training courses or appropriate on-the-job instruction. The

personnel must be familiar with the contents of these instructions, which need to be available to them at all

times.

The electrical connection should only be carried out by a fully qualified electrician.

All work has to be carried out in accordance with existing national regulations on accident prevention and

safety at work and with any internal regulations of the operator, even if they are not specified in these

instructions.

2.2 Special safety instructions

To avoid damage to the flow sensors and the monitored system, only use our flow sensors to measure

liquid flows.

Prior to installation, ensure whether the material of the flow sensor is suitable for the medium to be

measured.

In order to achieve accurate measurements, only use liquids with a minimum conductivity of 50 S/cm.

Ensure that the maximum specified operating pressure is not exceeded.

Never remove a flow sensor from a pipe system under pressure.

Ensure that the maximum specified operating temperatures are not exceeded.

Select suitable measures to prevent the medium from freezing in the flow sensor.

Protect the flow sensor against external magnetic fields in the immediate vicinity, since these can impair

device functioning.

Caution: Voltage Hazard!

Always de-energize the system before connecting the connector cable.

It is prohibited to remove or make product labels or any other information attached to the equipment

indecipherable, otherwise all warranties and the responsibility of the manufacturer no longer apply.

Caution: Ensure that the maximum electrical load specified on the product label is never exceeded,

otherwise the electronic unit will be damaged.

Attention: Do not use MFS in processes in which a disturbance may possibly cause a risk of the health

and lives of others.

The customer is to verify the applicability of the product on the basis of our technical details and customer-

and applicationspecific test to proof the products fitness for ist purpose. By this checking, hazards and risks

are subrogated to the customer and our warranty expires.

For problems or questions contact:

DWYER INSTRUMENTS, INC.

P.O. Box 373

Michigan City, INDIANA 46361, U.S.A.

Phone: (219) 879 - 8000

Fax: (219) 872 - 9057

Email: info@dwyer-inst.com

Technical changes reserved 3 08/2011

Page 4

Unpacking and inspecting the delivery Series MFS

3 Unpacking and inspecting the delivery

ª Unpack your flow sensor MFS.

The MFS is delivered in special protective packaging. Keep this protective packaging for sending the instrument

for repairs to the manufacturer, or dispose the packaging under the official rules of the public waste disposal

system of your area.

ª Inspect the delivery first.

Standard delivery MFS:

• flow sensor

• operating instructions

4 Material specifications of components

Prior to installation, ensure whether the wetted components are suitable for the medium to be measured!

Components Materials Mediums contacting

Electrodes Stainless steel 316 SS Yes

Process connections Stainless steel 316 SS Yes

Pipe PEEK Victrex 450GL30 Yes

Gasket EPDM Yes

Housing Aluminium pressure diecasted No

5 Suitable liquids (medium)

Liquids with a minimum conductivity of 50 S/cm are suitable as the medium. Always ensure whether the

material of the flow sensor is suitable for the medium to be measured.

6 Installation of the flow sensor

6.1 Mechanical installation

• Protect the flow sensor against external magnetic fields in the immediate vicinity, as these can impair device

functioning (see Fig. 2).

Fig. 2:

No external magnetic fields in the

immediate vicinity of the MFS

• The sensor can be installed at any position in the pipe system. Straight pipe sections are recommended

because the flow velocity may vary in bends (see Fig. 3).

Technical changes reserved 4 08/2011

Page 5

Installation of the flow sensor Series MFS

• Installation can occur in horizontal and vertical pipes. In horizontal pipes the sensor should be installed in a

horizontal position to ensure that the measuring electrodes are always wetted by the medium. The flow

sensor is only suitable for application in completely filled pipe systems.

• As a matter of principle magnetic inductive flow sensors are widely independent from the flow profile. An inlet

section is not absolutely necessary.

To reach the desired accuracy of the measurement, straight inlet and outlet sections according to the

nominal pipe size (NPS) should be used. The inlet section has to be at least 10 x NPS and the outlet section

5 x NPS in order to achieve the specified accuracy.

Fig. 3: Installation of the MFS

• The inlet and outlet sections and the gaskets must have the same or a slightly larger inside diameter than the

measuring tube in order to achieve the specified accuracy.

• When tightening screw connections always grip the hexagon nut (see Fig. 4).

Fig. 4: Counterhold the screw connection

Technical changes reserved 5 08/2011

Page 6

Installation of the flow sensor Series MFS

6.2 Electrical connection

• Caution: Voltage Hazard!

Always de-energize the system before connecting the wires.

Warning:

We recommend the use of shielded connecting cables

only. The shield should not be connected to ground. We

recommend to ground the pipes directly before and behind

the MFS (see Fig. 5).

We offer appropriate connecting cables with 4-pin cable

socket as accessories. The shield is connected with the

knurled nut. They are available in various lengths.

Electrical connection with 4(5)-pin connector M12x1:

ª Screw the 4-pin contact box M12x1 onto the

connector.

ª Tighten it with a tightening torque of max. 0.74 ft lb.

ª Connect the connecting cables of the MFS (see

Fig. 6).

Fig. 5: Ground the pipes

Important!

Do not connect Pin 5 (center pin)!

Fig. 6: Electrical connection

The output signal Pin 4 is a flow-proportional frequency signal (see Fig. 7). It represents a square-wave output

signal whose amplitude roughly corresponds to the supply voltage. The supply voltage and the output signal are

not galvanically isolated.

After switched on, the operating status is shown by a

multiple flashing of the LED. Throughout the operation, the

LED flash corresponds to the flow rate:

• No flow rate Ö no flashing.

• Low flow rate Ö slow flashing.

• High flow rate Ö fast flashing.

Fig. 7: Frequency output signal

The optional analog output Pin 2 provides a flow proportional signal current of 4 to 20 mA. Please note the

maximum load of 250 to GND.

Connection to an Programmable Logic Controller (PLC):

Most digital PLC inputs are designed for connection to PNP signals. The MFS has an NPN frequency signal with

an integrated 2k pull-up resistor. Its signal current of ~12 mA is recognized as a signal by the current PLC.

Thus, operating a MFS with a PLC should not present any problems.

The frequency output of the MFS should be attached to a

digital input of the PLC.

Important! Please ensure that your PLC is able to process

the high frequencies of the MFS output signal.

ª Attach the connecting cable of the MFS to the PLC as

illustrated in diagram 8.

Fig. 8: Control with PNP Input signal

Technical changes reserved 6 08/2011

Page 7

Maintenance and repairs Series MFS

7 Maintenance and repairs

The flow sensor is maintenance-free and cannot be repaired by the user. In the unlikely event of a defect, the

device has to be returned to the manufacturer for repair work.

8 Decommissioning and disposal

ª Never remove a flow sensor from a system under pressure.

ª Remove all the electrical connectors and disassemble the flow sensor.

ª The flow sensor consists of various materials. Never dispose of the flow sensor in domestic waste.

ª Return the flow sensor to the manufacturer for correct disposal.

9 Technical data

The technical data of customized versions may differ from the data in these instructions. Please observe the

information specified on the product label.

Type MFS-1X MFS-2X MFS-3X

Characteristics measurement device

Measurement range 0.25 to 5.3 GPM (1 to 20 l/min) 0.5 to 10.5 GPM (2 to 40 l/min) 2.5 to 52.8 GPM (10 to 200 l/min)

Accuracy ±2% of reading

Repeatability 1%

Start of output signal ~ 0.13 GPM (~ 0.5 l/min) ~ 0.25 GPM (~ 1 l/min) ~ 1.3 GPM (~ 5 l/min)

Response time < 500 ms

Flow indication LED green, flow proportional flashing

Characteristics output signal

Frequency output:

- Pulse rate / K-factor 3,237 pulses/gal (855 pulses/l)

factory-set

- Resolution 0.0003 gal/pulse (1.2 ml/pulse)

factory-set

- Signal shape Square-wave signal y duty cycle 50:50 y NPN, 2 k pull-up resistor (built-in)

- Signal current max. 20 mA, current limited

Analog output (optional):

- Signal current 4 to 20 mA

corresp. 0 to 5 GPM* (0 to 20 l/min*)

- max signal current ~ 26 mA

- max working resistance 250 to GND

Electrical characteristics

Supply voltage 24 VDC ±10%

Current consumption max 80 mA

Electrical connection 4(5)-pin-plug M12x1

Electrical protection measures short-circuit proof (up to 30 V) / polarity protection (up to -30 V)

Degree of protection NEMA 4 (IP 65)

Process variables

Medium to measure Water and other conductive liquids

Min conductivity of the medium 50 µS/cm (lower conductivity affects the accuracy)

Max medium temperature 194 °F (90 °C)

Min medium temperature 32 °F (0 °C) (not freezing)

Ambient temperature 41 to 158 °F (5 to 70 °C)

Nominal pipe size (NPS) ¼'' '' ¾''

Nominal pressure 232 psi (PN 16)

Process connection ½” NPT male thread 1” NPT male thread

* other range on request

3,237 pulses/gal (855 pulses/l)

factory-set

0.0003 gal/pulse (1.2 ml/pulse)

factory-set

4 to 20 mA

corresp. 0 to 10 GPM* (0 to 40 l/min*)

757 pulses/gal (200 pulses/l)

factory-set

0.0013 gal/pulse (1.2 ml/pulse)

factory-set

4 to 20 mA

corresp. 0 to 52 GPM* (0 to 200 l/min*)

Technical changes reserved 7 08/2011

Page 8

Dimensions, pressure drop Series MFS

10 Dimensions, pressure drop

MFS-1X and MFS-2X

5.06 [124.5]

½’’ NPT

0.55 [12]

~ 3.2 [~82]

M12x1

0.47 [12]

1.02 [26]

Ø0.

/

Ø0.

~ 3 [~77]

1.26 [32]

2

7

[

3

9

[

~ 2.2 [~57]

1.22 [31]

7]

10]

Nut size

1.063 [27]

plug M12x1

MFS-3X

light emitting diode

0.98 [12]

5.59 [116]

~3.2 [~82]

M12x1

0.47 [12]

~ 3.0 [~77]

Ø

0

1.36 [34.5]

.

79

~ 2.2 [~57]

1.22 [31]

[

20

]

1.15 [29]

1’’ NPT

Nut size

1.338 [34]

plug M12x1

light emitting diode

Technical changes reserved 8 08/2011

Loading...

Loading...