Page 1

Mark Series Position

Indicator/Transmitter

Installation and Operating Manual

Bulletin V-30

Proximity Controls

A Division of Dwyer Instruments, Inc.

P.O. Box 373

Michigan City, Indiana 46361, U.S.A.

Phone: 219/879-8000 • Fax: 219/872-9057

www.dwyer-inst.com • Email: info@dwyer-inst.com

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 11/13 FR# 85-443266-00 Rev. 8

Page 2

ONTENTS

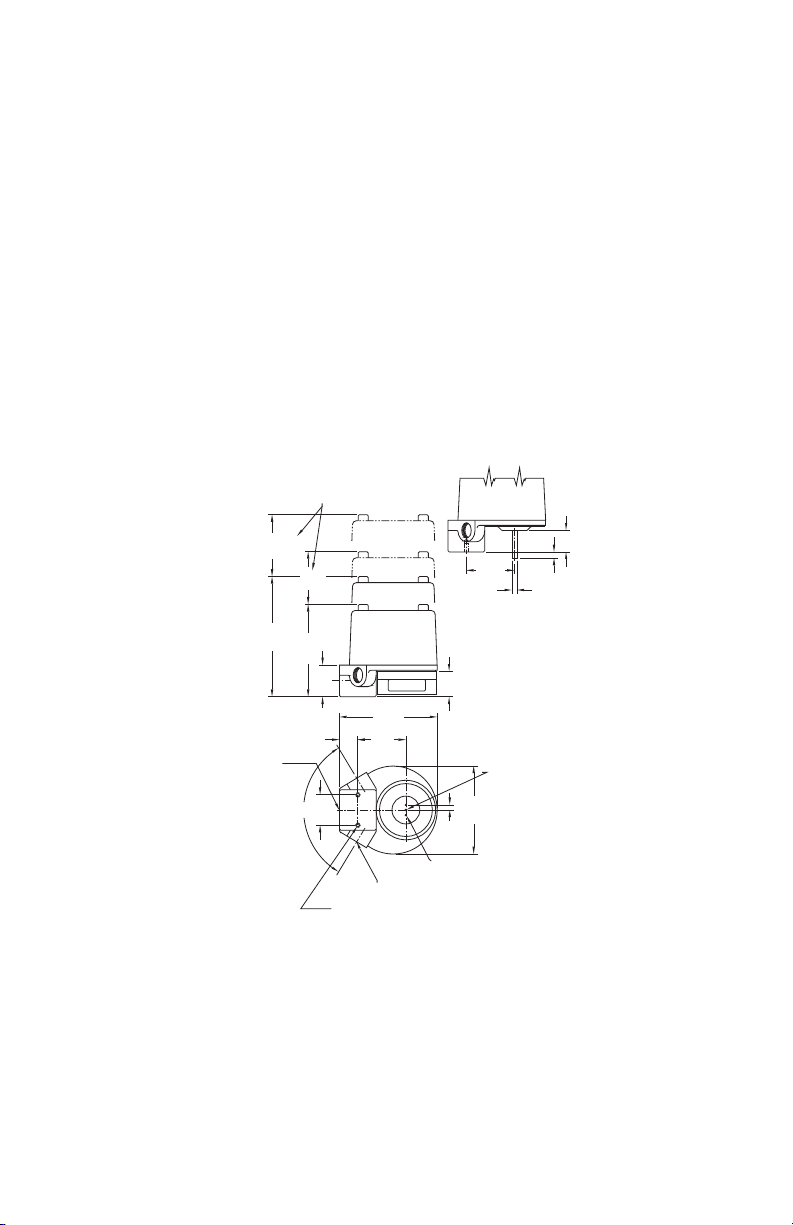

CLEARANCE REQUIRED

FOR COVER REMOVAL

LEVER DRIVE

1-1/16

(26.99)

5/16

[7.94]

.249 ± .001

[6.32 ± .03]

2-3/8

[60.33]

DIRECT DRIVE

4-1/4

[107.95]

3

[76.20]

5-15/16

[150.81]

*4-9/16

[115.89]

1-1/4

[31.75]

#6-32 UNC THREAD

X 1/4 [6.35] DEEP

1-9/16

[39.69]

4-7/8

[123.83]

3/4 NPT

CONDUIT

CONNECTION

OR OPTIONAL

M25

1

[25.40]

2-3/8

[60.33]

Ø4-7/16

[112.71]

1/4

[6.35]

TYP

Ø1/8 [3.18] PIN

TYP 2 PLACES

1/2 NPT CONDUIT CONNECTION (OPTIONAL)

OR OPTIONAL M20 2 PLACES

1/4-20 UNC THREAD X 7/16 [11.11] DP

TYP 2 PLACES

*FOR MODELS 11, 12, 41 & 42

118°

1-1/2

[38.10]

OPEN

C

imensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

D

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Model Number Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Junction Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

actory Sealed Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

F

ounting Kits for Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

M

ark 1 and 4 Direct Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

M

Mark 1 and 4 Lever Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Mark 3 Direct and Lever Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Mark 1, 3, and 4 with Potentiometer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mark 1, 3, and 4 with Transmitter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

ark 1, 3, and 4 Transmitter with

M

®

ART

H

ommunication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

C

iring, Intrinsic Safety and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-25

W

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DIMENSIONS

HART®is a registered trademark of HART Communication Foundation.

1

Page 3

NTRODUCTION

I

he Proximity Controls Mark Series is a line of position indicators with a selection of various output options. Three

T

odel styles make up the Mark Series to cover almost any application. A magnetic drive that completely seals the

m

switch compartment from the atmosphere for maximum leak protection is utilized in the Mark 1. The Mark 3 uses the

same magnetic drive of the Mark 1, but it can be used for multi-turn applications with 1 to 25 revolutions, such as gate

valves. A through shaft drive is incorporated in the Mark 4 making the unit a lower cost alternative to the Mark 1 for

applications that are not as demanding.

tandard models in the Mark Series have visual position indicators and are weatherproof, flameproof, and submersible.

S

large variety of outputs are available to fit specific applications. There is a choice of 1 to 6 switch outputs of 13

A

varieties including inductive sensors, high temperature switches, gold contact switches, hermetically sealed switches,

and high current switches. Besides the switch outputs the Series offers potentiometer outputs, 4 to 20 mA transmitters

and HART

T

inear valves. For the Mark 1, 3, and 4 this instruction manual starts with installation of the unit to the device being

l

®

communication.

he units are purchased for either direct drive applications, such as rotary valves, or lever drive applications, such as

monitored, and the set up of switch models. Separate instructions follow covering the potentiometer and transmitter set

up if your unit has those options.

2

Page 4

PECIFICATIONS

S

eneral

G

Product Ratings:

Weatherproof and flameproof. NEMA 1, 2, 3, 3R, 3S, 4, 4X, 6, 7, 9, 12, 13. (Housing styles M and N are NEMA 4,

4X only.)

L rated: Class I, Div. 1 & 2, Groups B, C, D (Some units available for Group A, consult factory); Class II, Div. 1 & 2,

U

roups E, F, and G.

G

CSA rated: Class I, Div. 1 & 2, Groups A, B, C, D; Class II, Div. 1 & 2, Groups E, F, and G; Submersible to 50 feet.

ATEX Compliant:

B suffix, directive 94/9/EC,

EMA 03 ATEX 2391X, 0344 II 2G Ex d IIC T6 Gb for -25°C/-40°C/-50°C ≤ Tamb ≤ 70°C and T5 for -

K

5°C/-40°C/-50°C ≤ Tamb ≤ 80°C optional wording depending on output and switch type selected. Compliant per EN

2

60079-0:2009 and EN 60079-1:2007.

–IS suffix directive 94/9/EC,

KEMA 03 ATEX 1392X, 0344 II 1G Ex ia IIC T4 Ga.

(Switch type C is not available with ATEX; Switch type B is not available with ATEX intrinsically safe, –IS suffix).

Compliant per EN 60079-0: 2009, EN 60079-11: 2007, and EN 60079-26: 2007.

IECEx Compliant:

–IE suffix IECEx DEK II.0056X Ex d IIC T6 Gb for -25°C/-40°C/-50°C ≤ Tamb ≤ 70°C and T5 for -25°C/-40°C/-50°C ≤

Tamb ≤ 80°C optional wording depending on output and switch type selected. Compliant per IEC 60079-0: 2007; IEC

60079-1: 2007.

–II suffix IECEx DEK II.0061X II Ex ia IIC T4 Ga. Compliant per EN 60079-0:2007 EN 60079-11:2006 and EN 6007926:2006. (Switch type C is not available with IECEx; Switch type B is not available with IECEx intrinsically safe, II

suffix).

INMETRO Compliant:

IM suffix, Certificate: NCC 13.02338 X; Marking: Ex ia IIC T4 Ga

EM suffix, Certifcate: NCC 13.02339 X; Marking: Ex d IIC T6 Gb or Ex d IIC T5 Gb

Electrical Connections: Screw terminal. Optional factory sealed leads that are 36˝

(914.4 mm) of 16 AWG.

Conduit Connection: 3/4˝ female NPT standard. Optional one or two 1/2˝ female NPT. M25 and M20 optional

(Standard on SAA certified products).

Mounting Orientation: Not position sensitive.

Weight: 4 to 6 lb (1.5 to 3.0 kg).

Operational Life: Over 10,000,000 cycles.

Maximum Altitude: 2000 meters.

3

Page 5

Mark 1, 3 and 4 with Switch Outputs

Temperature Limits: -58 to 176°F (-50 to 80°C). Switch Type C rated to 350°F (176°C) for 600 hours, Switch Type T

rated to 250°F (121°C) continuous. (ATEX flameproof, -B suffix and IECEx flameproof, -IE suffix, rated -50°C

-58°F) to 80°C (176°F) for switch type A, G, H, T, or M, -40°C (-40°F) to 80°C (176°F) for switch type O, R, S, V, or

(

, -25°C (-13°F) to 80°C (176°F) for switch type B, D, I, or AS Interface; ATEX intrinsically safe, -IS suffix and IECEx

W

ntrinsically safe, II suffix, rated -25°C (-13°F) to 40°C (104°F) for switch type D or I, -40°C (-40°F) to 40°C (104°F)

i

for switch type R, V, or W, or -50°C (-58°F) to 40°C (104°F) for switch type A, G, or H.)

Switch Type: See model chart on pages 5 and 6.

Electrical Rating: See model chart on pages 5 and 6.

et Point Adjustment: Mark 1 and 4: 5 to 360°. Mark 3: 1 to 25 revolutions.

S

Mark 1, 3, and 4 with Potentiometer

Accuracy: ± 0.5% of full span. Optional ± 0.25% of full span.

Temperature Limits: -40 to 176°F (-40 to 80°C).(ATEX flameproof, -B suffix and IECEx flameproof, -IE suffix, rated -

0°C (-40°F) to 80°C (176°F) for switch types A, G, M, O, R, S, T, V, or W, -25°C (-13˚F) to 80°C (176°F) for switch

4

ypes B, D, or I.; ATEX intrinsically safe, -IS suffix and IECEx intrinsically safe, II suffix, rated -25°C (-13°F) to 40°C

t

(104°F) for switch type I, -40°C (-40°F) to 40°C (104°F) for switch types O, R, S, V, or W.)

Power Rating: 1.5 Watt maximum.

Output Signal: 1000 Ohm standard. Optional 2000, 5000, 10000, or 20000 Ohms.

Zero and Span Adjustments: Span trim pot with 2000 Ohm adjustment. No zero adjustment.

Rotational Travel: Mark 1 and 4: Minimum: 0°, Maximum: 340°. Mark 3: 0 to 10 revolutions.

Mark 1, 3, and 4 with Transmitter

Accuracy: ± 0.5% of full span. Optional ± 0.25% of full span.

Temperature Limits: -40 to 176°F (-40 to 80°C). (ATEX flameproof, -B suffix and IECEx flameproof, -IE suffix, rated

-40°C (-40°F) to 80°C (176°F) for switch types A, G, M, O, R, S, T, V, or W, -25°C (-13°F) to 80°C (176°F) for switch

types B, D, or I.; ATEX intrinsically safe, -IS suffix and IECEx intrinsically safe, II suffix, rated -25°C (-13°F) to 40°C

(104°F) for switch type I, -40°C (-40°F) to 40°C (104°F) for switch types O, R, S, V, or W.)

Power Requirements: 5 to 30 VDC.

Current Consumption: 50 mA.

Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Trim pots for adjusting both. Mark 1 and 4: Span is adjustable from 50 to 300°. Mark

3: Span is adjustable from 1.5 to 8.5 revolutions.

Conduit Connection: 3/4˝ female NPT standard. Optional one or two 1/2˝ female NPT. M25 and M20 optional

(Standard on SAA models).

Rotational Travel: Mark 1 and 4: Minimum: 50°, Maximum: 300°. Mark 3: Minimum: 1.5 revolutions, Maximum: 8.5

revolutions.

Mark 1, 3, and 4 Transmitter with HART

®

communication

Accuracy: ± 0.5% of full span. Optional ± 0.25% of full span.

Temperature Limits: -40 to 176°F (-40 to 80°C). [ATEX flameproof, -B suffix and IECEx flameproof, -IE suffix, rated

-40°C (-4°F) to 80°C (176°F) for switch types A, G, M, O, R, S, V or W, -25°C (-13°F) to 80°C (176°F) for switch

types B, D or I; ATEX intrinsically safe, -IS suffix and IECEx intrinsically safe, II suffix, rated -40°C (-40°F) to 40°C

(104°F) for switch types O, R, S, V or W; -25°C (-13°F) to 40°C (104°F) for switch type I].

Power Requirements: 8 to 30 VDC.

Current Consumption: 21 mA.

Output Signal: 4 to 20 mA.

®

HART

Receive Impedance: Rx = 500 kΩ; Cx = 2500 pF.

Zero and Span Adjustments: Pushbuttons or HART

®

communication master for setting both. Mark 1 and 4: Span is

adjustable from 0 to 330°. Mark 3: Span is adjustable from 1.5 to 8.5 revolutions.

Conduit Connection: 3/4˝ female NPT standard. Optional one or two 1/2˝ female NPT. M25 and M20 optional

(Standard on SAA models).

Rotational Travel: Mark 1 and 4: Maximum: 330°. Mark 3: Minimum: 1.5 revolutions, Maximum: 8.5 revolutions.

4

Page 6

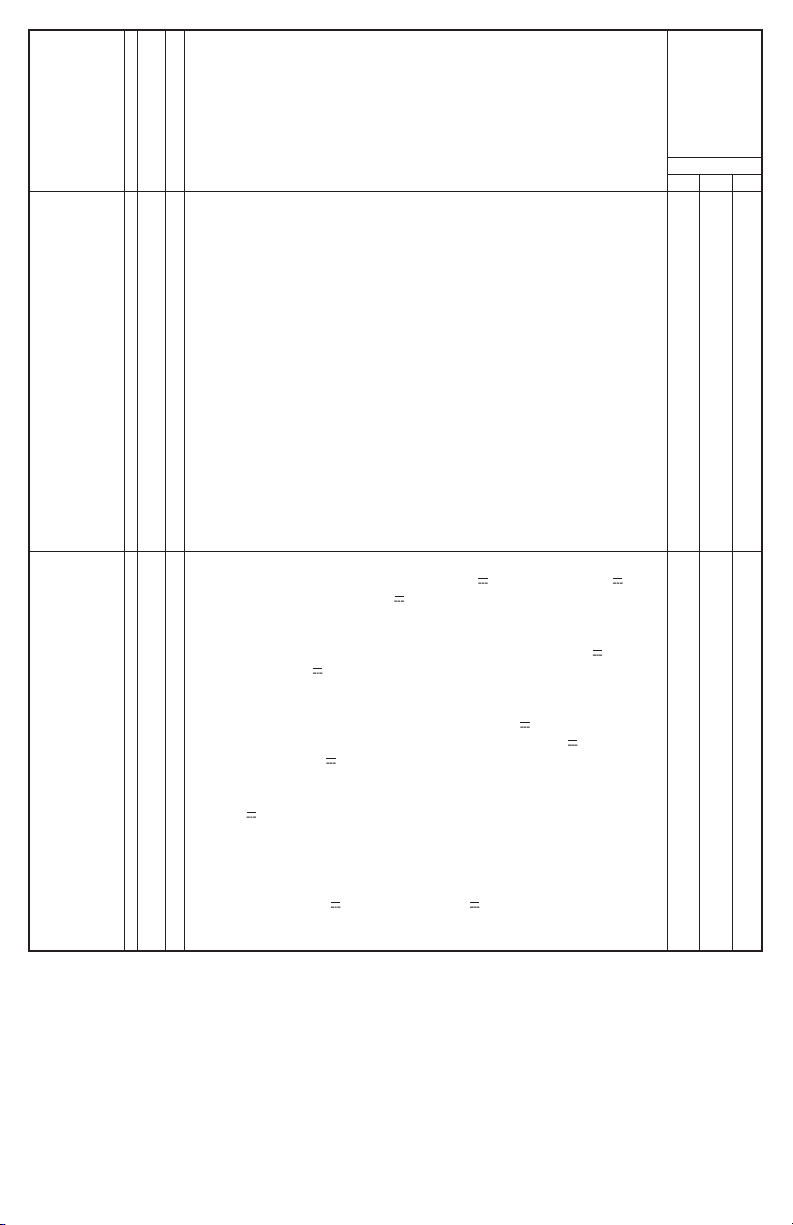

vailable

Construction

Mark 1, Magnetic Coupling

1

Mark 3, Multi-Turn

3

Mark 4, Thru-Shaft

4

A

ptions “A”

O

signifies

available with

corresponding

construction

tyle.

s

Mark

Output

ype

T

Switch

1

1

2

Switches

2

3

K OHM Potentiometer 1/2%. Available with switches, see note below.*

1

31

K OHM Potentiometer 1/4%. Available with switches, see note below.*

1

32

2K OHM Potentiometer. Available with switches, see note below.*

5

3

5K OHM Potentiometer. Available with switches, see note below.*

10

3

10K OHM Potentiometer. Available with switches, see note below.*

320

20K OHM Potentiometer. Available with switches, see note below.*

4

4 Switches

5

Transmitter 1K OHM Potentiometer 1/2%. 4 to 20mA. Available with

3 4

1

A

A

A

A

A

A

A

A

A

A

-A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

switches, see note below.*

51

Transmitter 1K OHM Potentiometer 1/4%. Available with switches, see note

A

A

A

below.*

52

Transmitter 2K OHM Potentiometer. Available with switches, see note

6

below.*

7

6 Switches. Available with Switch Types B, C, I, R, V, W.

8

AS-interface and 1 Switch. Available with Switch Types B, I, R, W.

9

AS-interface and 2 Switches. Available with Switch Types B, I, R, W.

Transmitter with HART

®

communication. Available with switches, see note

A

A

A

A

A

A

A

A

A

A

-A

-A

A

below.*

Switch Type

& Rating

A

SPDT Snap, Rated: 15A @ 125/250/480 VAC (~) ; 1/8 hp @ 125 VAC

(~), 1/4 hp @ 250 VAC (~), 1/2A @ 125 VDC (), 1/4A @ 250 VDC().

B

Inductive Sensor. 10 to 30 VDC (). Load: 0.1A.

C

SPDT High Temperature Snap, 350°F (176°C) for 600 hours, Rated:

A

A

A

A

--

A

A

A

A

15.1A @ 125/250/277 VAC (~).

D

DPDT Snap, Rated: 10A @ 125/250 VAC (~), 0.3A @ 125 VDC (),

A

A

A

0.15A @ 250 VDC ().

G

SPDT Gold Contact Snap, Rated: 1A @ 125 VAC (~).

H

SPDT Hermetically Sealed Snap, Rated: 1A @ 125 VAC (~).

I

NAMUR Inductive Sensor. 15 mA max @ 5-25 VDC ().

M

SPDT Magnetic Blow-Out, Rated: 10A @ 125 VAC (~)/VDC (), 1/4 hp

A

A

A

A

A

A

A

-A

-A

A

@ 125 VAC (~)/VDC ().

0

No Switches

R

SPDT Hermetically Sealed Reed, Rated: 2A @ 125 VAC (~), 2A @

A

A

A

A

A

--

24 VDC ().

S

SPDT Snap, Rated: 4A @ 125/250 VAC (~).

T

SPDT High Temperature Snap, 250°F (121°C) Continuous, Rated: 5A

A

A

A

-A

A

@ 125/250/480 VAC (~).

V

SPDT Snap, Rated: 10A @ 125/250 VAC (~), 1/3 hp @ 125/250 VAC

A

A

A

(~), 1/2A @ 125 VDC (), 1/4A @ 250 VDC (), 4A @ 125 VAC

(tungsten).

W

SPDT Gold Contact Snap, Rated 0.1A @ 125 VAC (~).

A

A

A

*Note: Mark 1 and 4 potentiometer and transmitter outputs will have no switches when ordered with switch type 0; 2

switches if ordered with switch types B, C, I, R, V, or W; and 4 switches if ordered with switch type S. Mark 3

potentiometer and transmitter outputs will have no switches when ordered with switch type 0, and 2 switches if ordered

with switch types A, D, G, M or T.

Available on Mark 1, 3, 4

5

Page 7

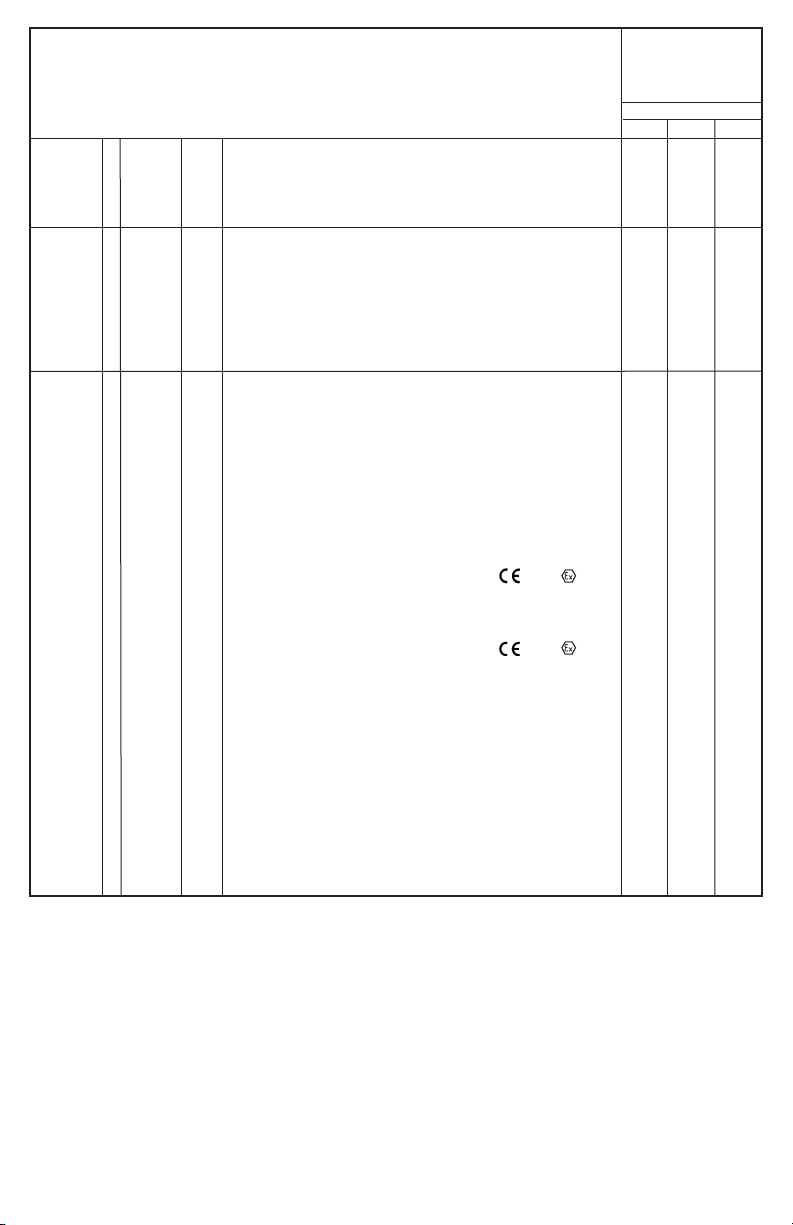

Available Options “A”

signifies available

with corresponding

construction style.

M

3 4

1

Driving

Method

Enclosure

Options

EXAMPLE MODEL NUMBERS

12VD0-J1

Mark 1, 2 Switches both Type V – SPDT, Direct Drive, Painted Aluminum Enclosure with Junction Package.

A

D

E

L

M

0

1

2

5

6

7 thru 20

A Direct or Yoke Drive without Visual Indicator.

Direct Drive (or Yoke) with Visual Indicator.

irect or Yoke Drive with Visual Indicator, Single Window.

D

ever Drive (Shaft Projection) without Visual Indicator.

L

ever (Shaft Projection) with Visual Indicator.

L

Aluminum, Painted Black

Aluminum, Painted White Epoxy with SS trim

Aluminum, Painted Red

Aluminum, Painted (color not yet specified)

ast 316 Stainless Steel

C

Aluminum, Painted (color not yet specified)

C1

Long Dwell Cam (not on Mark 3)

C2

Double Cam (not on Mark 3)

FKM

FKM Seals

J1

Junction Package with One 1/2˝ NPT Female Conduit

Connection and Terminal Strip.

J2

Junction Package with Two 1/2˝ NPT Female Conduit

Connection and Terminal Strip.

SV1

1 Attached Solenoid Valve (Must be ordered with J1 option).

SV2

2 Attached Solenoid Valves (Must be ordered with J2 option).

MT

Metric Threaded Conduit Connection, M25 (M20 for optional

J1 and J2 connections).

B

Directive 94/9/EC, KEMA 03 ATEX 2391 x, 0344 II 2G

Ex d IIC T6 Gb (-25/-40/-50°C ≤ Tamb ≤ 70°C) (T5 (-25/-40/50°C ≤ Tamb ≤ 80°C) optional wording). Depending Output

and Switch Type Selected.

IS

Directive 94/9/EC, KEMA 03 ATEX 1392 x, 0344 II 1G

Ex ia IIC T4 Ga.

IE

IECEx DEK II.0056X Ex d IIC T6 Gb (-25/-40/-50°C ≤ Tamb ≤

70°C) (T5 (-25/-40/-50°C ≤ Tamb ≤ 80°C) optional wording >.

Depending on output switch type selected.

II

IECEx DEK II.0061X II Ex ia IIC T4 Ga.

IM

Certificate: NCC 13.02338 X; Marking: Ex ia IIC T4 Ga

EM

Certificate: NCC 13.02339 X; Marking: Ex d IIC T6 Gb or Ex d

IIC T5 Gb

PP

Plug J1, J2 Ports

PT

Paper Tag

SS

Stainless Steel Conduit Plug(s)

STR

Stainless Steel Tag Riveted

STW

Stainless Steel Tag Wired

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

--

A

--

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

ark

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

15VD0

Mark 1, 2 Switches both Type V – SPDT, 4 to 20 mA transmitter, Direct Drive, Painted Aluminum Enclosure.

6

Page 8

JUNCTION PACKAGE

Complete factory assembled packages combine visual indication, solenoids, switches and transmitter in a single

convenient UL, CSA, IECEx certified or ATEX compliant assembly which saves labor and reduces cost. The simple

package is shipped ready for installation, complete with optional custom designed mounting kit for your specific

pplication. Many options are available such as painted aluminum, epoxy coated aluminum or stainless steel housings

a

ncluding a standard 3/4” NPT conduit entrance and choice of 1 or 2 additional 1/2˝ NPT conduit entrances. The optional

i

onduit entrances are drilled and tapped in the base of the position indicator housing and solenoid valves are screwed

c

into the entrances. 22 to 16 AWG wire leads from solenoids, switches and optional transmitter are terminated in

prelabeled, easy-access terminal strips protected inside the housing. Note: UL, CSA and SAA approval and ATEX

ompliance requires complete package assembly by Proximity. Consult the factory for recommended UL, CSA, SAA

c

pproved or ATEX or IECEx compliant solenoid valve options. Please consult page 3 and 4 for ATEX Safety Code.

a

unction

J

Package

Note: Junction package is not available on six switch

models, switch type A, D, G, H, and T models.

FACTORY SEALED LEADS

Eliminate the possibility of conduit contamination and the need for seal fittings with Proximity’s factory sealed (potted)

leads. This seal has been UL tested to 6000 psi (413 bar) and is UL and CSA listed for Class I, Groups A, B, C, D;

Class II, Groups E, F & G; Div. 1 & 2 locations. Groups may vary depending on the switch model. Standard leads are

16 AWG and 36˝ (91.44cm) long.

Factory Seal

Cutaway of

Model 12ADO

7

Page 9

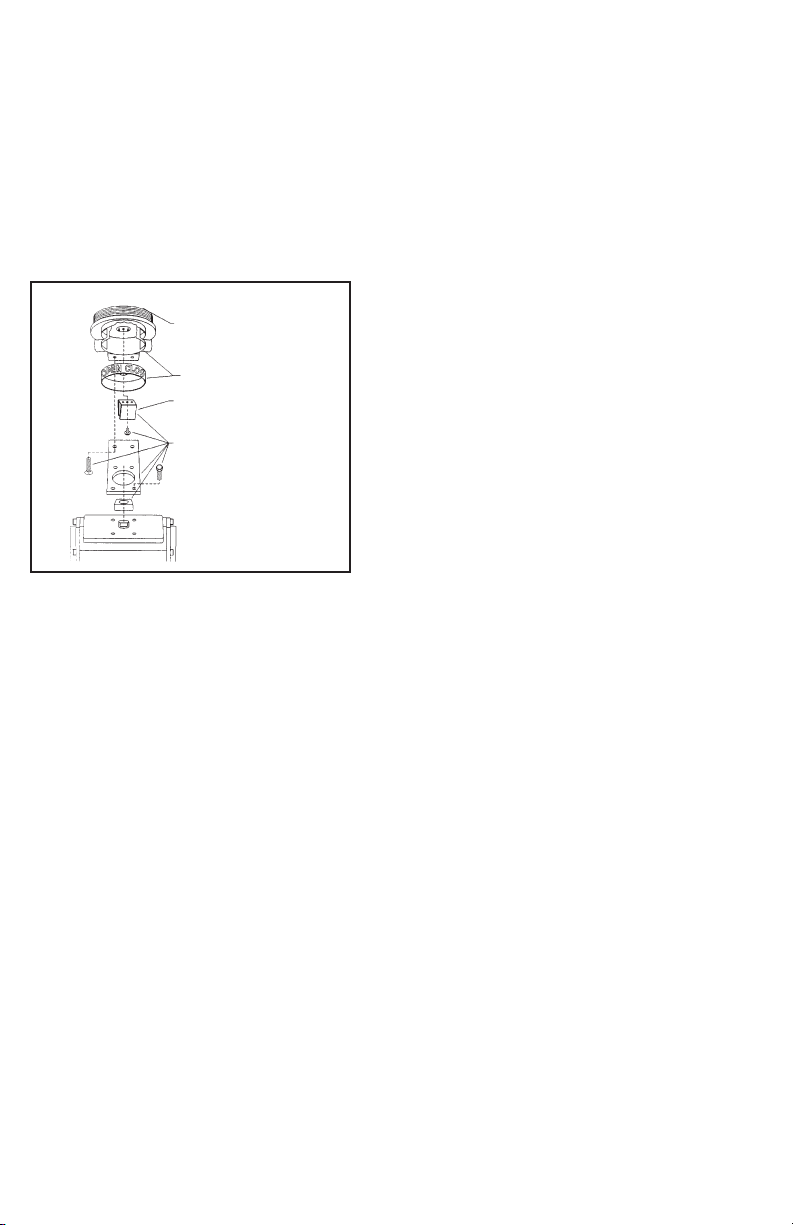

MOUNTING KITS

ounting kits are available for direct installation of the Proximity Controls Mark Series onto most valve and actuator

M

rands. Proximity Controls has over 2000 kits available and can custom make kits for any application. Each kit is

b

pecially designed for a particular actuator or valve, making field mounting simple with standard tools. Mounting kits

s

can be used with any model in the Mark Series, since external features are identical. Rotary valve kits utilize direct drive

couplings, while linear valve kits use a lever drive.

Kits include a drive yoke or slotted lever arm, bracket, and fasteners made in either zinc plated steel or stainless steel.

he high strength, spring tempered, stainless steel drive yoke/coupling is tailored to fit securely to a specific valve or

T

ctuator stem ensuring that there is no slippage or binding. No special alignment fixtures are required due to switch-

a

ffset design and yoke to stem engagement that makes installation a snap.

o

If you have purchased this unit without a mounting kit, please contact us to get the proper kit for your application.

SWITCH

VISUAL INDICATOR

DRIVE YOKE

MOUNTING KIT

VISUAL INDICATOR

A stainless steel mechanical visual indicator is standard on direct drive units. The indicator provides visual open and

closed indication and a degree scale, which can easily be seen from 75 feet away. The scale is adjustable in 15°

increments and the windows are adjustable in a 56° range with 90° fixed increments. Factory options include 180°

indication, flow path indication, special colors, and LED’s.

8

Page 10

MARK 1 AND 4 DIRECT DRIVE INSTALLATION

1.

2.

3.

4.

5.

1

2

3

4

INSTALLATION PROCEDURE

1. Unscrew cover. Keep threads clean and free from damage.

2. Switches are set at factory when in counterclockwise

osition. Index marks should appear as shown (Mark 1

p

nly). Set screws, or holes in manual cams, (#2, 4 and 6) on

o

losed switches will be directly above index marks.

C

2 Switch Unit #1 Open #2 Closed

4 Switch Unit #1, 3 Open #2, 4 Closed

6 Switch Unit #1,3,5 Open #2,4,6 Closed

. Attach appropriate Drive Yoke onto two pins using a #6-32

3

crew provided. (Note: Coupling is a special spring temper

s

yoke or solid metal block. Do not attempt to fabricate your

own yokes.)

4. Attach mounting bracket (127-003 is shown) to switch

housing using 1/4˝ screws provided.

5. With actuator shaft rotated to its counterclockwise position,

spread the Drive Yoke and slip it down onto the square (or

rectangular) part of the actuator shaft. Attach bracket with

two hex cap screws. Before tightening screws, operate

control slowly with a wrench or power, and observe that

drive shaft and drive yoke are concentric and perpendicular

in complete stroke. Adjust position as required, and tighten

all the mounting screws. Check concentricity and

perpendicularity. Readjust per above steps as necessary.

ADJUSTMENT PROCEDURE

A. Using a wrench or power, rotate the actuator shaft to extreme clockwise position. All switches should change to their

opposite function.

B. The cam can be relocated and repositioned by loosening the set screw. To adjust manual cams, grasp cam on

knurled segment of cam surface. Simply rotate the cam on spline attached to the shaft. Feeling or sound of clicks

indicates 6º incremental adjustments. Stop rotating and release pressure on cam when it is at proper actuation

point. This allows cam to engage spline. Check the circuit to verify contact at proper point. Rotate shaft. Repeat

steps above as necessary. Lock manual cam on spline by tightening set screw provided for additional security.

C. Screw on cover and tighten against o-ring seal until cover does not turn.

See Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

9

Page 11

MARK 1 AND 4 LEVER DRIVE INSTALLATION

1

2

3

4

3

4

CLOCKWISE

INSTALLATION PROCEDURE

1. Attach proper mounting bracket to switch housing using screws provided. Tubular spacers are provided for some

installations.

2. Attach appropriate driving lever onto shaft. Do not tighten.

3. Attach switch and bracket to actuator, making sure that lever is free to rotate over entire range of actuator stroke.

4. Attach driving pin or bolt through lever arm if slotted, or on driving side of solid lever. (It may be necessary to loosen

or remove mounting bracket to accomplish connection on some actuators.)

5. Operate actuator very slowly and observe movement of all pins and levers to be sure there are no interferences.

Slide lever up or down on switch shaft to most desirable position. When all motions are made and clearances are

adequate, tighten clamp screw on lever that was left loose in step 2. Tighten all mounting screws. Recheck the

travel of all levers and pins for proper clearance through the entire stroke of the actuator.

6. Unscrew cover. Keep threads clean and free from damage. Index marks are imprinted into driven magnet collar as

shown (Mark 1 only). Set screws or holes in manual cams (#2, 4 and 6) will be directly above index marks on those

switches that are Closed. Marks must be in line when making switch cam adjustments. Cams are set at factory

when in the counterclockwise position, as shown, and listed as follows:

2 Switch Unit #1 Open #2 Closed

4 Switch Unit #1, 3 Open #2, 4 Closed

6 Switch Unit #1, 3, 5 Open #2, 4, 6 Closed

90º travel in clockwise direction will reverse all of above switch positions.

10

Page 12

ADJUSTMENT PROCEDURE

A. Operate actuator to full closed position. Set screws hold cams in place on the shaft. For manual cams, grasp cam

n knurled segment of cam surface and simply rotate cam to get correct actuation point. Clicks indicate incremental

o

djustments. Applying pressure on cam in direction of protruding actuation segment of cam surface, and rotating,

a

liminates incremental adjustments. Stop rotating and release pressure on cam when at proper actuation point. This

e

allows engagement of cam to spline. Check circuit to verify contact at proper point. Repeat the cam adjustment

steps as necessary. Lock manual cam on spline with set screw provided for additional security.

B. Operate actuator to opposite extreme (full Open), and adjust cams to suit.

C. Screw on cover and tighten against o-ring seal until cover does not turn.

ee Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

S

11

Page 13

MARK 3 DIRECT AND LEVER DRIVE INSTALLATION

SHAFT DRIVE

YOKE DRIVE

CLOCKWISE

C

AM SCREWS

1

2

A

B

C

D

E

INSTALLATION PROCEDURE

Mount the switch as necessary, concentric and perpendicular over the rotating shaft that is to be monitored. Direct drive

yokes are available in many widths and lengths to fit your needs (Yokes are fabricated from spring temper stainless

steel. Do not attempt to fabricate your own yokes.) Shaft drive units require an appropriate coupling (flexible type

recommended) to the shaft being monitored.

ADJUSTING PROCEDURE

1. Remove cover by unscrewing. Take care to keep threads clean and free from damage.

2. Clockwise rotation of the yoke or shaft will move the bar up, counterclockwise moves it down.Switches are set at

the factory for approximately one revolution of the yoke or shaft to actuate switch #1. Notice, that the cam screw for

switch #1 is in location E. By changing that cam screw to location D, three additional revolutions of the yoke or shaft

will be required to actuate #1 switch. Moving the cam screw to holes C, B or A will add three revolutions for each

location moved, until 13 revolutions are required between switch #1 and 2 actuation.

3. The cam screw for switch #2 in location A. By moving it to location B, C, D, or E, three revolutions are added for

each location change.

4. Rotate the switch slowly through the full cycle several times before tightening the bolts securely. Observe the

rotation for signs of yoke or shaft misalignment or binding with the actuator shaft. Correct as necessary, then

tighten the mounting bolts and recheck alignment.

12

Page 14

. The following chart shows the various combinations of screw positions and resulting revolutions between switch

5

ctuation.

a

Cam Screw Locations Number of Revolutions

Switch #1 Switch #2 Between Switch Actuation

EA1

D

C

B

AA13

AB16

AC19

AD22

A

6. Switch actuation at all intermediate number of revolutions or partial revolutions can be selected by turning the cam

screws in or out when located at the nearest location shown above. Any partial number of turns may be selected,

such as 4-1/2 or 12-3/4.

See Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

D4

A7

A 10

E 25

13

Page 15

MARK 1, 3 AND 4 WITH POTENTIOMETER INSTALLATION

TERMINAL3

TERMINAL 2

TERMINAL 1

1 2 3

Potentiometer

Resistance

Ohms

1000

2000

5000

10000

20000

Ohms Per Degree

of Rotation

2.9

5.8

14.7

29.4

58.8

Resistance Between Pins

No. 2 to No. 1

CCW-SET

500

1000

2500

5000

10000

CW-90°

235

471

1178

2354

4708

No. 2 to No. 3

CCW-SET

500

1000

2500

5000

10000

CW-90°

765

1529

3823

7646

15294

INSTALLATION AND ADJUSTMENT

1. Attach the switch to the actuator or valve. Refer to Installation and Adjustment Instructions:

p. 9 for Direct Drive Mark 1 and 4 Models

p. 10-11 for Lever Drive Mark 1 and 4 Models

p. 12-13 for Mark 3 Models

2. Remove cover by unscrewing. Take care to keep threads clean and free from damage.

3. On models 13XXX and 43XXX, the switches are set at the factory when in the counterclockwise position as shown.

Switch #1 is open, and #2 is closed. When cams are rotated 90º clockwise, #1 becomes closed and #2 is open.

The cams may be adjusted to increase or decrease the 90º rotation. For model 33XXX refer to pages 12 and 13

for Switch Adjustment Procedure.

4. The potentiometer is positioned at the factory with the resistance element approximately centered. The resistance

readings in the chart are typical of each different potentiometer.

5. To adjust the potentiometer to a different range, loosen the two lower set screws on the coupling. While holding the

cams in the desired position, rotate the coupling and potentiometer shaft to the preferred location. Rotating

clockwise reduces resistance between pins 2 and 1, and increases resistance between 2 and 3. Rotating

counterclockwise increases resistance between pins 2 and 1, and reduces resistance between 2 and 3. If the

resistance “jumps” rapidly, the pot is improperly rotated and functioning in the 20º dead area. Retighten the 2 set

screws. A 2K span adjustment pot is provided, to activate move bypass shunt to the other pin.

See Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

14

Page 16

ARK 1, 3 AND 4 WITH TRANSMITTER INSTALLATION

1

2

3

1

2

CLOCKWISE

ROTATION

M

Potentiometer

Resistance Ohms

1000

2000

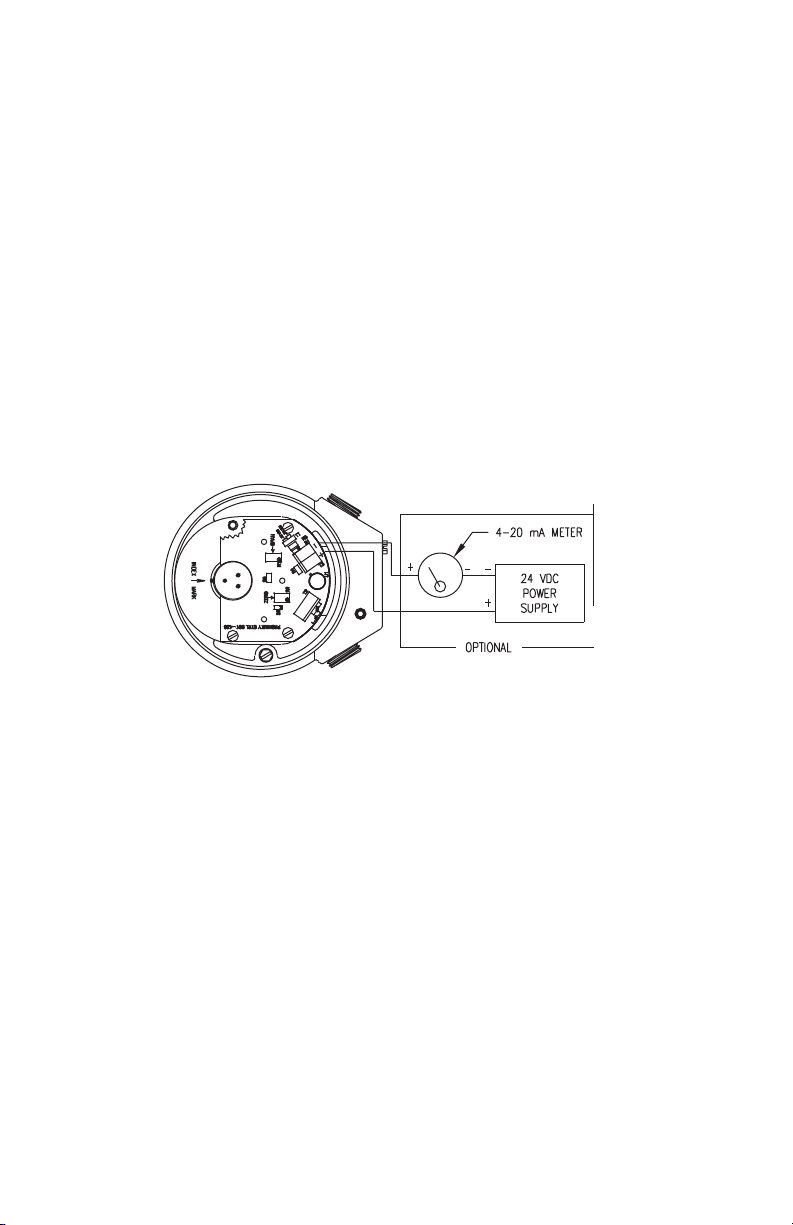

Models 15XXX, 35XXX and 45XXX Rotary Position Indicating Switches contain a 4-20 mA Transmitter and two Single

Pole Double Throw (SPDT) Micro switches. Models 150XX, 350XX and 450XX contain a 4-20 mA transmitter only, no

switches.

• 4-20 mA output is fully adjustable for various rotations (zero and span). See chart above for rotation ranges using

various potentiometers.

• 4-20 mA circuit is supply reversal protected and thermal protected.

• Clockwise or counterclockwise rotation corresponding to increased current output can conveniently field selected

with plug connector.

INSTALLATION AND ADJUSTMENT

1. Attach the switch to the actuator or valve. Refer to Installation and Adjustment instructions:

2. Remove cover by unscrewing. Take care to keep threads clean and free from damage.

3. On models 15XXX and 45XXX, the switches are set at the factory when in the counterclockwise position as shown.

4. The potentiometer is positioned at the factory with the resistance element approximately centered.

p. 9 for Direct Drive Mark 1 and 4 Models

p. 10-11 for Lever Drive Mark 1 and 4 Models

p. 12-13 for Mark 3 Models

Switch #1 is open, and #2 is closed. When cams are rotated 90º clockwise, #1 becomes closed and #2 is open.

The cams may be adjusted to increase or decrease the 90º rotation. For model 35XXX refer to pages 12 and 13

for Switch Adjustment Procedure.

Ohms Per

Degree of

Rotation

2.9

5.8

Rotation Range

Mark 1 & 4

Min

Max

50°

300°

25°

150°

Mark 3

Min

1.5 turns

.75 turns

Max

8.5 turns

4.3 turns

15

Page 17

ALIBRATION

C

A. Set the valve at the position where you want the meter to read 0% (that is 4 mA). It may be necessary to move the

plug connector to change the direction of current output to increasing for clockwise rotation or vice versa.

B. On models 15XXX, loosen the two bottom set screws on the coupling. Rotate the coupling and potentiometer shaft

to the position where the meter reads 0% (4 mA). Tighten two set screws.

. Turn valve to opposite position where meter should read 100% (20 mA). Use small screwdriver to adjust the blue

C

ectangular potentiometer "span" until 100% (20 mA) is on the meter. If it is not possible to reach 100%, refer to

r

roubleshooting instructions.

T

D. Return valve to original position at 0% (4mA). Use small screwdriver to adjust "zero" turning until 0% (4 mA) is read

on meter. Repeat steps C & D until 4 and 20 mA read consistently on each end of stroke.

TROUBLESHOOTING

. If no current flows, check polarity of current loop (plus and minus screws on terminal strip). Also check loop

I

esistance for open line.

r

I. If full output current cannot be achieved by adjustment, voltage at transmitter may be too low. If so, increase power

I

supply voltage until a minimum of 15 volts is registered or move voltage shunt to 12 VDC.

III. If current increases and decreases in the wrong direction, move the plug Connector from CW to CCW or vice versa.

IV. Check specs to make sure you are in range of adjustment, (See chart on previous page).

V. If the zero adjustment does not have enough range, the zero must be mechanically realigned as follows: Set the

“zero” (fine 4 mA) adjustment to the middle of its range. (Full multi-turn range is 25 revolutions; set at 12-1/2

revolutions.) Repeat calibration steps B, C and D.

Two Wire Connections

See Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

16

Page 18

MARK 1, 3 AND 4 TRANSMITTER WITH HART®COMMUNICATION INSTALLATION

1

2

Models 19XXX, 39XXX and 49XXX Rotary Position Indicating Switches contain a 4-20 mA Transmitter with HART

communication and two Single Pole Double Throw (SPDT) Micro switches. Models 190XX, 390XX and 490XX contain

a 4-20 mA transmitter with HART

• 4-20 mA output is fully adjustable for various rotations (zero and span) using pushbuttons or a HART

®

communication only, no switches.

®

communication master.

• 4-20 mA circuit is polarity insensitive and thermal protected. Though the output terminals are labeled (+) and (-) the

transmitter will function if the terminals are reversed.

• Clockwise or counterclockwise rotation corresponding to increased current output can be selected by use of zero

and span pushbuttons or a HART

®

communication master.

INSTALLATION AND ADJUSTMENT

1. Attach the switch to the actuator or valve. Refer to Installation and Adjustment instructions:

p. 9 for Direct Drive Mark 1 and 4 Models

p. 10-11 for Lever Drive Mark 1 and 4 Models

p. 12-13 for Mark 3 Models

2. Remove cover by unscrewing. Take care to keep threads clean and free from damage.

3. On models 19XXX and 49XXX, the switches are set at the factory when in the counterclockwise position as shown.

Switch #1 is open, and #2 is closed. When cams are rotated 90º clockwise, #1 becomes closed and #2 is open.

The cams may be adjusted to increase or decrease the 90º rotation. For model 39XXX refer to pages 12 and 13

for Switch Adjustment Procedure.

4. The potentiometer is positioned at the factory with the resistance element approximately centered.

®

17

Page 19

CIRCUIT BOARD FEATURES

* OPTIONAL, MAYBE CONNECTED TO TEST POINT AS SHOWN OR TO SCREW TERMINALS

** REQUIRED FOR HART® COMMUNICATIONS, OPTIONAL OTHERWISE

FIND SHUNT

FAULT SHUNT

WP SHUNT

SQUAWK LED

TEST POINT

4-20mA

METER

+

-

-

+

**250Q

HART

® *

COMMUNICATION MASTER

24VDC

POWER

SUPPLY

• Two test points are provided as a convenience for attaching a HART

®

communication master.

• The WP (write project) shunt enables and disables the ability to change configuration settings. It can prevent

nintended configuration changes from an accidental press of the ZERO or SPAN button and from communications

u

ith a HART

w

o allow configuration changes.

t

®

ommunication master. Set this shunt to ON to prevent configuration changes. Set this shunt to OFF

c

• The FAULT shunt determines whether the transmitter fails high or low in a fault condition. When set to high the

transmitter will output 21.0 mA in a fault condition. When set to low the transmitter will output 3.6 mA in a fault

condition. The transmitter will output 3.8 mA and 20.5 mA when operating normally.

• The FIND shunt determines if the transmitter will respond to a FIND command. When set to ON the transmitter

ill respond to a HART

w

ommands. This is useful for allowing a HART

c

The LED will flash in response to a HART

•

a transmitter attached to a HART

®

ommunication master’s Find Command. When set to OFF the transmitter will ignore FIND

c

®

communication master.

®

ommunication master to discover the transmitter.

c

®

ommunication master’s Squawk Command. This is useful for identifying

c

CALIBRATION

A. Place the WP shunt in the OFF position if necessary to allow calibration to be performed.

B. Set the valve at the position where you want the meter to read 0% (that is 4 mA). Press and hold the ZERO

pushbutton for two seconds or use a HART

C. Turn valve to opposite position where meter should read 100% (20 mA). Press and hold the SPAN push button

for two seconds or use a HART

®

communication master to set the SPAN point.

®

communication master to set the ZERO point.

D. Reposition the WP shunt if desired.

See Pages 19-25 for wiring procedure, intrinsic safety parameters, relevant warnings and schematics.

18

Page 20

WIRING PROCEDURE: GENERAL

CONDUCTOR

SCREW

LOCKWASHER

CLAMP

• Complete all electrical wiring in accordance with Local and National Electrical Codes by qualified personnel

• It may be necessary to segregate power and signal circuits in separate conduit entries.

For units supplied with both internal ground and external bonding terminals, the ground screw inside the housing

•

ust be used to ground the control. The external bonding screw is for supplementary bonding when allowed or

m

equired by local code. When external bonding conductor is required, conductor must be wrapped a minimum of

r

180° about the external bonding screw. See below.

• Products with flying leads shall be terminated in approved junction box.

WIRING PROCEDURE: HAZARDOUS LOCATIONS, FLAMEPROOF CABLE CONNECTION:

• The cable entry device shall be certified in type of explosion protection flameproof enclosure “d” suitable for the

conditions of use and correctly installed.

• For ambient temperatures above 60°C, cables and cable glands suitable for at least 95°C shall be used.

CONDUIT CONNECTION:

• An Ex d, EEx d or UL and/or CSA (with appropriate classes and groups) certified sealing device such as a conduit

seal with setting compound shall be provided immediately following the conduit entrance to the enclosure. UL &

CSA listed factory sealed leads are provided from the factory on request.

• For ambient temperatures above 60°C, the wiring and setting compound in the conduit seal shall be suitable for

at least 95°C.

• Degree of protection IP66/68W is maintained when suitable glands/plugs are used.

WIRING PROCEDURE: HAZARDOUS LOCATIONS, INTRINSIC SAFETY

• Potentiometer, Transmitter and each Switch and/or NAMUR Sensor must be treated as separate intrinsically safe

circuits.

ELECTRICAL RATINGS:

• Potentiometer, see page number 4.

• Transmitter, see page number 4

• Switches, see model chart on page number 5.

INTRINSIC SAFETY INPUT PARAMETERS: (SUFFIX “IS” & II)

• Potentiometer, Ui = 30V; Ii = 50mA; Pi = 0.65W.; Li = 0µH; Ci = 0nF.

• Transmitter, Ui = 30V; Ii = 100mA; Pi = 1.3W; Li = 0µH; Ci = 0nF.

• Switches, Ui = 30V; Ii = 100mA; Pi = 1.3W; Li = 0µH; Ci = 0nF.

• Namur Sensor, Ui = 16V; Ii = 76mA; Pi = 242mW; Li = 50µH; Ci = 40nF.

• Transmitter with HART

®

communication, Ui = 30V; Ii = 100mA; Pi = 1.3W; Li = 0µH; Ci = 4nF.

19

Page 21

AUTION: GENERAL

C

• Protection provided by the equipment may be impaired if the equipment is used in a manner not

specified by the manufacturer.

• Risk of electric shock - disconnect supply circuit before opening. Keep unit tightly closed while

circuits are alive.

Suitable insulation between signal wiring and hazardous voltage wiring must be provided.

•

AZARDOUS LOCATIONS, FLAMEPROOF

AUTION

C

• De-energize supply circuit before opening.

• To prevent ignition of hazardous locations, replace cover before energizing the electrical circuits.

• After de-energizing delay 3 minutes before opening.

Do not open AS-interface equipped units when an explosive atmosphere may be present.

•

H

• Keep cover tightly closed when in operation.

WARNING

• Inspect thru shaft/bushing joint, of Mark 4, periodically for wear, if gap exceeds .0033˝ (.0 84 mm) for a length of 1˝

(25.4 mm) return to Proximity Controls, A Division of Dwyer Instruments, Inc. for repair or replace unit. The thread of the

cover with 4.000-16UN 2A/B must have a minimum of 7 threads engaged.

CAUTION

capable sparks.

NOTICE

for other Directives of the EU.

MARK 4 FLAME PROOF ENCLOSURE OPTION B & IE

Repairs only to be conducted by Proximity Controls, A Division of Dwyer Instruments, Inc.

•

HAZARDOUS LOCATIONS, INTRINSIC SAFETY

• Enclosure must be protected from mechanical friction and impact with iron/steel to prevent ignition

Units without suffix B or IS are not Directive 94/9/EC (ATEX) Compliant. These units are not

intended or use in potentially hazardous atmospheres in the EU. These units may be CE marked

20

Page 22

C

NO

NC

C

N

O

N

C

C

NO

NC

C

NO

NC

SW 4

TOP

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

SWITCH

INTRINSICALLY

SAFE BARRIERS

SW 4

TOP

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

SWITCH

C

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

SW 4

ABOVE 3RD

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

SWITCH

GREEN WIRE

- GROUND

SW 4

ABOVE 3RD

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

SWITCH

INTRINSICALLY SAFE

BARRIERS

GREEN WIRE

- GROUND

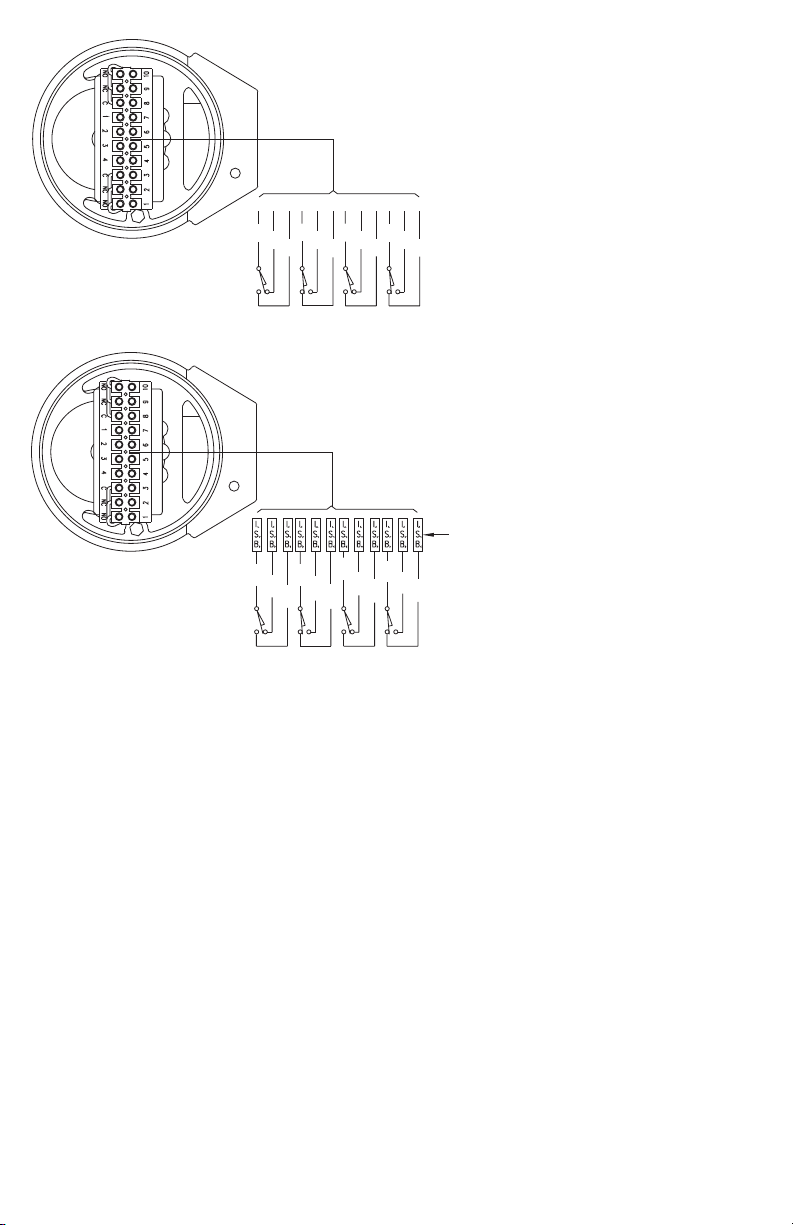

SCHEMATICS: GENERAL AND INTRINSIC SAFETY

1. Units supplied with switch option A, G, H, M or T have screw terminals on the back side of the switch for terminating

wires.

2. Units supplied with switch option D are supplied with 36” minimum (0.91 meters) flying leads.

. Units supplied with switch option B, C, I, R, S, V or W are supplied with terminal strips or 36˝ minimum (.091 meters)

3

lying leads.

f

. Units with J1 or J2 suffix are supplied with additional 2 or 4 termination points.

4

Figure 1: Wiring for switch types A, G, H, M, and T. 1,

2, or 4 switches.

Figure 3: Wiring for factory sealed leads option. 1, 2, or

4 switches. Switch 1 wires are red, switch 2 wires are

black, switch 3 wires are white, and switch 4 wires are

brown. Wires are labeled C, NO, NC.

Figure 2: Intrinsically safe wiring for switch types A, G,

H, M and T. 1, 2, or 4 switches

Figure 4: Intrinsically safe wiring for factory sealed

leads option. 1, 2, or 4 switches. Switch 1 wires are red,

switch 2 wires are black, switch 3 wires are white, and

switch 4 wires are brown. Wires are labeled C, NO, NC.

21

Page 23

Figure 5: Wiring for switch type D. 1, 2, or 4 switches.

C

N

O

N

C

C

NO

NC

SWITCH 4

TOP SWITCH

C

NO

NC

C

NO

N

C

S

WITCH 3

A

BOVE 2ND SWITCH

C

N

O

NC

C

N

O

NC

SWITCH 2

ABOVE 1ST SWITCH

C

NO

NC

C

NO

N

C

SWITCH 1

BOTTOM SWITCH

SWITCH 3

S

WITCH 1

S

WITCH 4

SWITCH 2

C

NO

N

C

C

NO

N

C

S

WITCH 4

TOP SWITCH

C

N

O

NC

C

N

O

N

C

S

WITCH 3

A

BOVE 2ND SWITCH

C

N

O

N

C

C

N

O

N

C

S

WITCH 2

ABOVE 1ST SWITCH

C

N

O

N

C

C

N

O

N

C

S

WITCH 1

BOTTOM SWITCH

I

NTRINSICALLY

SAFE BARRIERS

Figure 6: Intrinsically Safe wiring for switch type D. 1,

2, or 4 switches.

22

Page 24

Figure 7: Wiring for switch types C, R, V and

C

BRN

N

O

B

RN

NC

BRN

C

W

HT

NO

WHT

N

C

W

HT

C

BLK

N

O

B

LK

NC

BLK

C

RED

NO

RED

NC

RED

SW 4

TOP

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

S

WITCH

C

BRN

N

O

BRN

NC

BRN

C

WHT

NO

W

HT

N

C

WHT

C

B

LK

NO

BLK

NC

B

LK

C

RED

N

O

RED

N

C

RED

SW 4

TOP

SWITCH

SW 3

ABOVE 2ND

SWITCH

SW 2

ABOVE 1ST

SWITCH

SW 1

BOTTOM

SWITCH

I

NTRINSICALLY

SAFE BARRIERS

W. 1, 2, or 4 switches.

Figure 8: Intrinsically Safe wiring for switch

types C, R, V, and W. 1, 2, or 4 switches

23

Page 25

T

ERMINAL 3

S

EE WIRING SCHEMATIC

TERMINAL 2

SEE WIRING SCHEMATIC

T

ERMINAL 1

S

EE WIRING

S

CHEMATIC

WIRING SCHEMATIC

SPAN ADJUSTMENT

POTENTIOMETER

BYPASS

BY OTHERS

I

.S. BARRIER

I.S. BARRIER

J

2

3

2

1

5

VDC

Figure 9: Wiring for switch types B, C, I, R, V, and W.

S

W 6

A

BOVE 5TH

S

WITCH

S

W 5

A

BOVE 4TH

S

WITCH

S

W 4

A

BOVE 3RD

S

WITCH

S

W 3

A

BOVE 2ND

SWITCH

S

W 2

A

BOVE 1ST

SWITCH

SW 1

B

OTTOM

S

WITCH

USE CONNECTOR SUPPLIED WITH SWITCH ONLY.

MAKE SURE CONNECTOR IS PUSHED ON ALL

T

HE WAY TO ASSURE A TIGHT CONNECTION.

POTENTIOMETER

TRANSMITTER

C

B

R

N

O

BRN

N

C

B

RN

C

W

HT

N

O

W

HT

N

C

W

HT

C

B

LK

NO

B

LK

N

C

B

LK

C

R

ED

N

O

R

ED

N

C

R

ED

S

W 1

BOTTOM

S

WITCH

S

W 2

A

BOVE 1ST

S

WITCH

S

W 3

A

BOVE 2ND

S

WITCH

SW 4

T

OP

S

WITCH

123

1, 2, 4, or 6 switches. Switch types B and I have “+”

and “-” terminals.

Figure 10: Wiring for potentiometer and transmitter

outputs with switches. Refer to note at bottom of page 5

for switch details.

Figure 11: Intrinsically Safe wiring for potentiometer output. Refer to proper switch figure if unit has switches as well.

24

Page 26

SEE WIRING

SCHEMATI C

SEE WIRING

SCHEMATI C

WIRING SCHEMATIC

BY OTHERS

I.S. BARRIER

I.S. BARRIER

12 VDC

OR

2

4 VDC

S

W 4

TOP

SWITCH

S

W 3

ABOVE 2nd

SWITCH

S

W 2

ABOVE 1st

SWITCH

S

W 1

BOTTOM

SWITCH

C

BRN

C

WHTCBLKCRED

NO

BRN NOWHTNOBLKNORED

NC

BRNNCWHTNCBLKNCRED

7 8 9 10 11 12

1 2 3 4 5 6

igure 12: Intrinsically Safe wiring for transmitter output. Refer to proper switch figure if unit has switches as well.

WIRING SCHEMATIC

I.S. BARRIER

I.S. BARRIER

BY OTHERS

12 VDC

O

R

24 VDC

TERMINAL 2

SEE WIRING

SCHEMATIC

TERMINAL 1

SEE WIRING

SCHEMATIC

F

Figure 13: Intrinsically Safe Wiring for transmitter with HART® communication output. Refer to proper switch figure if

unit has switches as well.

25

Page 27

MAINTENANCE AND REPAIR

The moving parts of these units need no maintenance or lubrication. Some parts are replaceable by qualified

ersonnel, contact the factory for details.

p

ARNING

W

need of repair should be returned to the following address, freight prepaid. Be sure to include a brief explanation of the

roblem and any relevant application information.

p

roximity Controls

P

ttn: Repair Department

A

1431 State Highway 210E

Fergus Falls, MN 56537

LIMITED WARRANTY

Limited Warranty: The Seller warrants all Dwyer instruments and equipment to be free from defects in workmanship

or material under normal use and service for a period of one year from date of shipment. Liability under this warranty is

limited to repair or replacement EXW Ex Works Dwyer Instruments, Inc of any parts which prove to be defective within

that time or repayment of the purchase price at the Seller’s option provided the instruments have been returned, transportation prepaid, within one year from date of purchase. All technical advice, recommendations and services are based

on technical data and information which the Seller believes to be reliable and are intended for use by persons having

skill and knowledge of the business, at their own discretion. In no case is Seller liable beyond replacement of equipment

EXW Ex Works Dwyer Instruments, Inc or the full purchase price. This warranty does not apply if the maximum ratings

label is removed or if the instrument or equipment is abused, altered, used at ratings above the maximum specified, or

otherwise misused in any way.

THIS EXPRESS LIMITED WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER REPRESENTATIONS MADE BY

ADVERTISEMENTS OR BY AGENTS AND ALL OTHER WARRANTIES, BOTH EXPRESS AND IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE FOR

GOODS COVERED HEREUNDER.

BUYER’S REMEDIES

The buyer ’s exclusive and sole remedy on account of or in respect to the furnishing of non-conforming or defective

material shall be to secure replacement thereof as aforesaid. The Seller shall not in any event be liable for the cost of

any labor expended on any such material or from any special, direct, indirect, consequential or incidental damages to

anyone by reason of the fact that it shall have been non-conforming or defective.

Substitution of components may impair intrinsic safety of models with IS suffix. Use a damp cloth

with soap and water for cleaning and decontamination. Solvents may damage O-ring seals. Units in

26

Page 28

Proximity Controls

A Division of Dwyer Instruments, Inc.

P.O. Box 373

Michigan City, Indiana 46361, U.S.A.

Phone: 219/879-8000 • Fax: 219/872-9057

www.dwyer-inst.com • Email: info@dwyer-inst.com

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 11/13 FR# 85-443266-00 Rev. 8

Loading...

Loading...