Page 1

Series LFM In-Line and Panel Mount Flowmeter

Specifications - Installation and Operating Instructions

Bulletin V-31

The Series LFM In-Line Flowmeter measures the flow of

water and other compatible media. Models possess dual GPM

and LPM scales. Various size ranges and connections are

available to satisfy your application.

INSTALLATION

1. Select an indoor (only) location that is free from excess

vibration, within the specified temperature limits, and away

from direct sunlight.

2. Handle carefully. Hand-tighten flange nut connection rings.

O-Rings will seal if hand tightened only. Do not

overtighten the

adapters and fittings.

3. Install the flowmeter in an exact vertical plane, one that is in

proper alignment with the existing plumbing. Use wall or other

structural supports at the top and bottom of the unit. Do not

allow the instrument to support the weight of pipes or tubing.

4. Use plumbers tape thread sealant. Do not

use pipe dope

compounds, which can craze and crack housing. Hand tighten system pipe fitting to adapter fitting. If additional torque is

needed to seal pipe joint, use strap wrench on adapter fitting.

5. If using solvent-based glues like PVC cement, in the piping

system, do so with the meter’s body removed until glue has

cured, then purge the system before re-installing. Do not solder brass fittings with the body installed, because the heat

generated to solder the brass fittings will damage the flowmeter.

CAUTION: Ball valves and solenoid valves can have a “water

cannon” effect on opening, creating pressure that exceeds the

warrantied ratings and will damage the flowmeter.

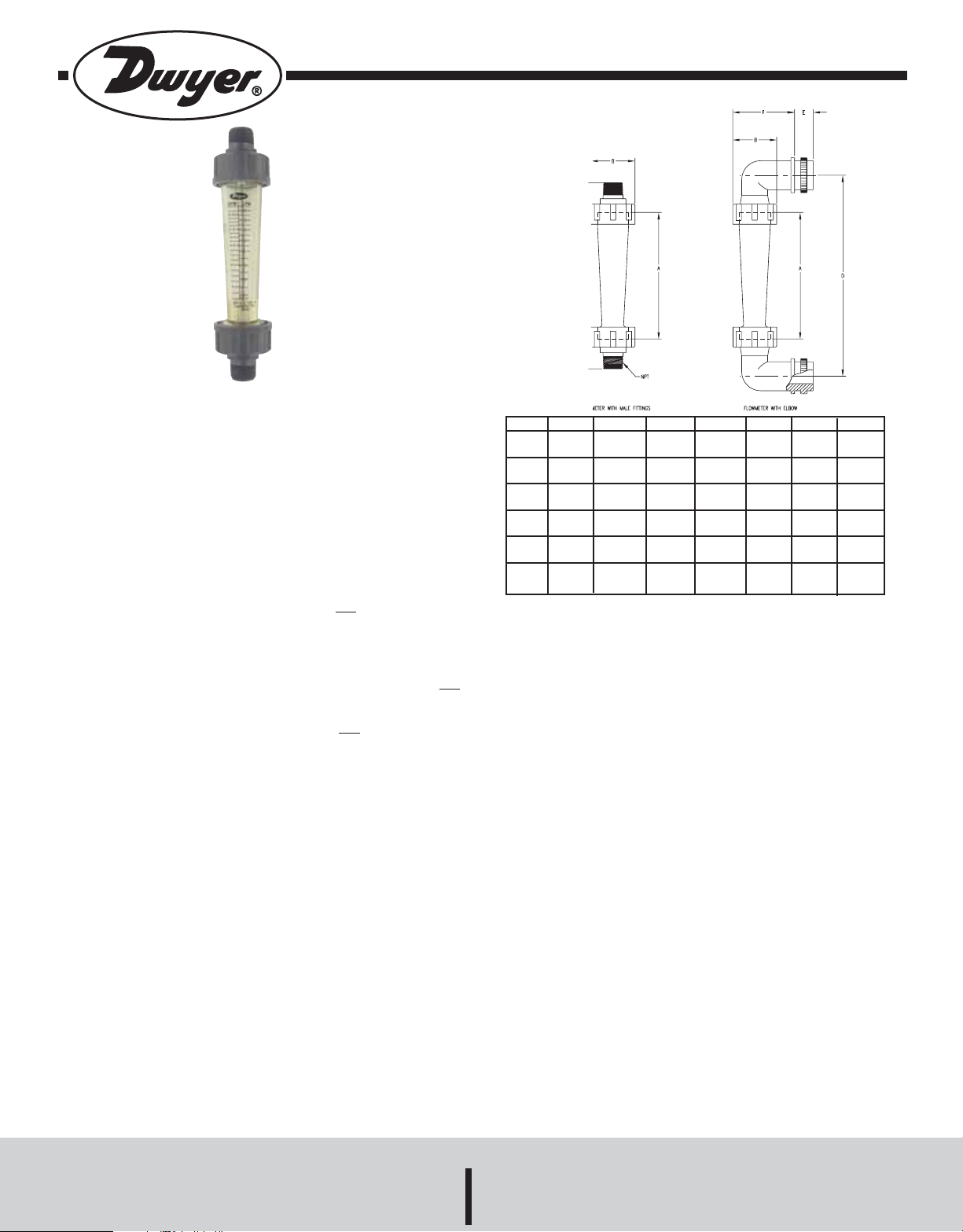

(25)

NPT

F

1/2 NPT

1/2 NPT

1/2 NPT

3/4 NPT

1 NPT

2 NPT

Model

LFMA

LFMB

LFMC

LFMD

LFME

LFMF

A

3-15/16

(100.01)

6-5/16

(160.34)

5-9/32

(134.14)

6-45/64

(170.26)

8-55/64

(225.03)

11-27/64

(290.12)

B

ø1-21/32

(ø42.07)

ø1-63/64

(ø50.40)

ø1-63/64

(ø50.40)

ø2-21/64

(ø59.13)

ø2-27/32

(ø72.23)

ø3-15/16

(ø100.01)

C

6-45/64

(170.26)

8-55/64

(225.03)

8-9/32

(210.34)

9-27/32

(250.03)

12-19/64

(312.34)

15-3/4

(400.05)

D

8-55/64

(225.03)

7-11/16

(195.26)

10-41/64

(270.27)

12-51/64

(325.04)

E

63/64

(25)

63/64

(25)

63/64

(25)

1-15/64

(31.35)

2-15/64

(56.75)

2-15/64

(56.75)

51/64

(20.24)

63/64

SPECIFICATIONS

Service: Compatible liquids.

Wetted Materials: See chart.

Temperature Limits: See chart. Varies with pressure.

Pressure Limit: See chart. Varies with temperature.

Accuracy: ±5% full scale.

Process Connections: Various male and female NPT, metric

union connectors, and 90° male NPT elbow fittings available

depending on model series.

OPERATION AND MAINTENANCE

Once installed, the Series LFM In-Line and Panel Mount

Flowmeter is self-operating and requires no maintenance other

than an occasional cleaning with mild soap and a bottle brush.

For this purpose, the unit has been designed so that its body

can be removed quickly and easily while leaving all fittings

intact.

When removing float for cleaning, note the floats “up” position.

The float is a precision part and must be reassembled without

adverse treatment, i.e. dropping, denting, and surface abrasion.

The standard technique for reading a Variable Area Flowmeter

is to locate the of greatest or widest diameter on the float, and

then align that with the theoretical center of the scale graduation. In the event that the float is not aligned with a grad, an

extrapolation of the float location must be made by the operator as to its location between the two closest grads.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

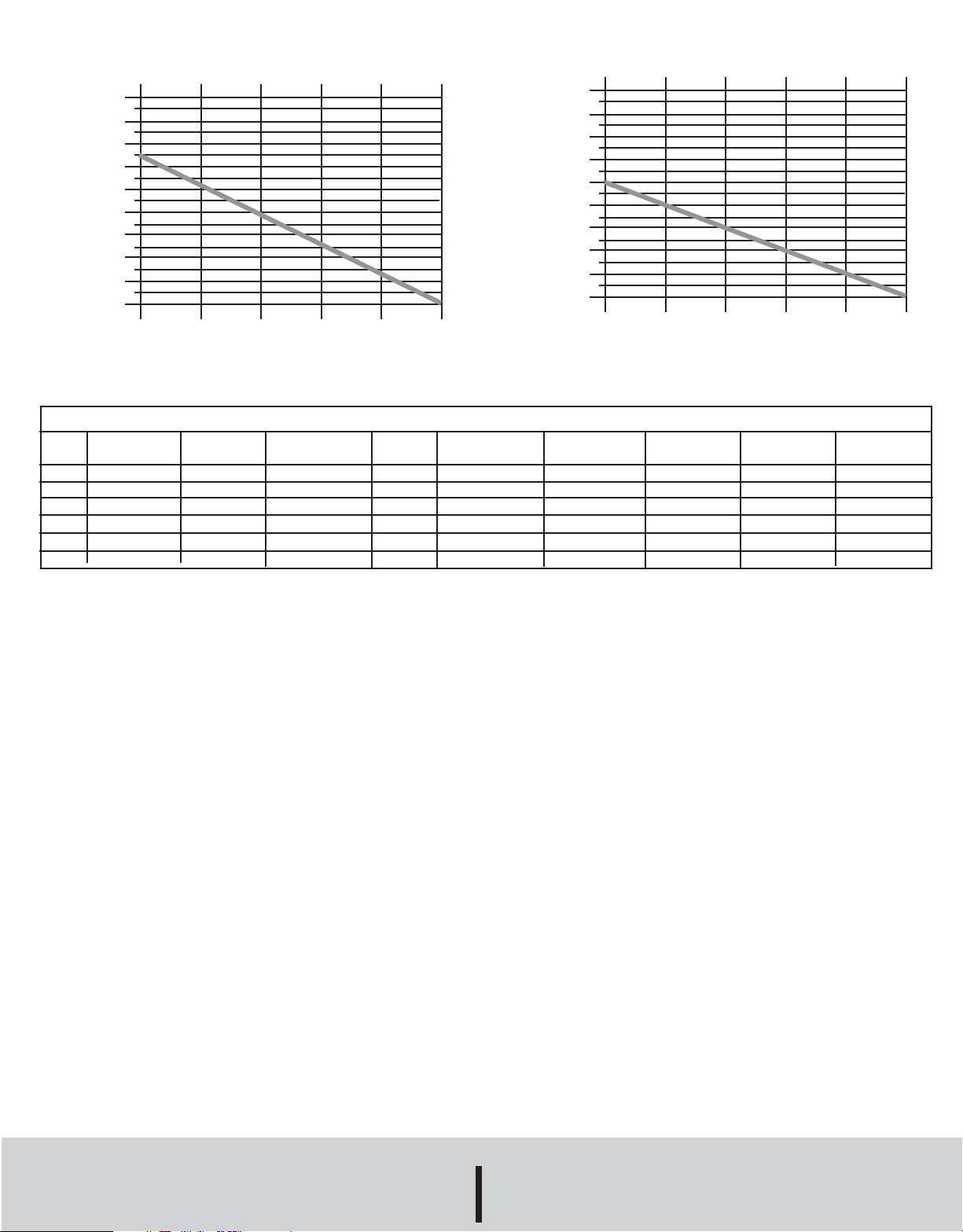

Temperature

212°F (100°C)

194°F (90°C)

176°F (80°C)

158°F (70°C)

140°F (60°C)

122°F (50°C)

104°F (40°C)

86°F (30°C)

68°F (20°C)

50°F (10°C)

Model

Polycarbonate

LFMA

Polycarbonate

LFMB

Polycarbonate

LFMC

Polycarbonate

LFMD

Polycarbonate

LFME

Polycarbonate

LFMF

Flowmeter Temp. vs. Pressure Chart

0

0

Body

29

(2)

Flange

Nut

ABS

ABS

ABS

ABS

ABS

ABS

58

(4)

Pressure

PSI (Bar)

Float

Stop

ABS

ABS

ABS

Polypropylene

Polypropylene

Polypropylene

87

(6)

Temperature

212°F (100°C)

194°F (90°C)

176°F (80°C)

158°F (70°C)

140°F (60°C)

122°F (50°C)

104°F (40°C)

86°F (30°C)

68°F (20°C)

50°F (10°C)

116

(8)

145

(10)

Wetted Materials vs. Series

Float

S.S.316

S.S.316

S.S.316

S.S.316

S.S.316

S.S.316

O’ring

Fluoroelastomer

Fluoroelastomer

Fluoroelastomer

Fluoroelastomer

Fluoroelastomer

Fluoroelastomer

Female

Thread

PA66 (nylon)

PA66 (nylon)

PA66 (nylon)

Temperature vs. Pressure

Chart when using PVC elbow fittings

0

0

29

(2)

Thread

/

/

/

PA66 (nylon)

PA66 (nylon)

PA66 (nylon)

Male

ABS

ABS

ABS

58

(4)

Pressure

PSI (Bar)

NPT Elbow

87

(6)

90 Male

PVC

PVC

PVC

PVC

PVC

/

116

(8)

145

(10)

Metric

Union

ABS

ABS

ABS

PVC

PVC

ABS

©Copyright 2006 Dwyer Instruments, Inc. Printed in U.S.A. 12/06 FR# R1-443531-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...