Page 1

Series LDT Leak/Over-Temperature Detection Relay

Specifications - Installation and Operating Instructions

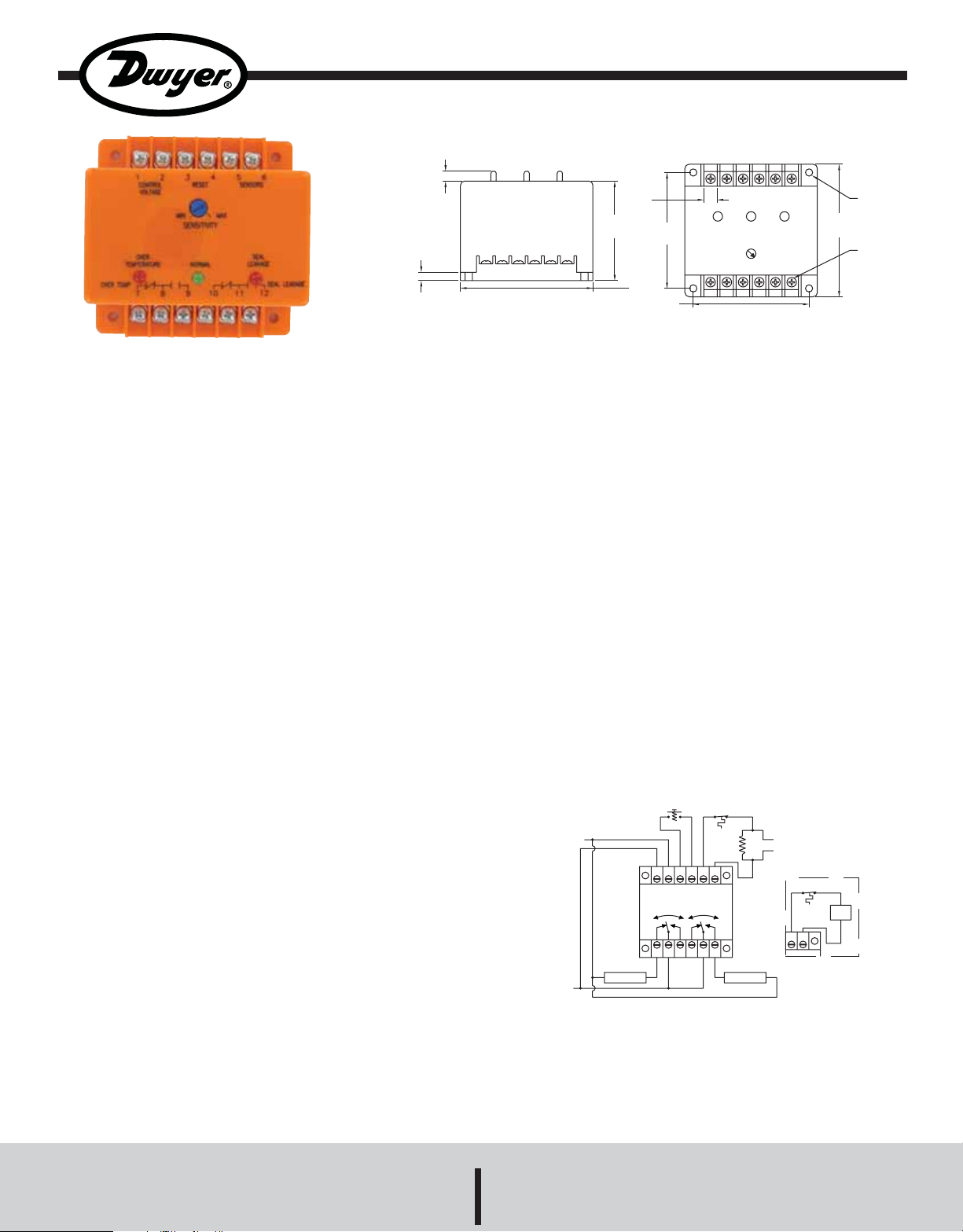

Bulletin L-42

19/64

(7.54)

1/4

(6.35)

The Series LDT0 is used to monitor the shaft seal and the stator

temperature of a submersible pump to detect a leak or over-temperature

before pump failure. A leak is detected by sensing the status of a float or

conductivity switch installed in the seal cavity. When this resistance drops

below the set sensitivity, the output relay energizes and the LED indicator

illuminates. When the seal failure condition clears, the relay automatically

resets. A normally closed temperature switch mounted on the stator

detects over-temperature. The temperature safety feature incorporates a

bistable relay that retains its position during power loss and latches on until

the remote reset button is pressed. The LDT has adjustable leak sensitivity

from 1 k to 35 k ohm. Installation is made simple with a surface mount

configuration.

Important: Read the following carefully and completely before installing or

connecting LDT units.

Note: DO NOT exceed specified electrical rating. Doing so may result in

damage to control unit and load device.

INSTALLATION

1. Lock out all electrical current to relevant control panel during

installation.

2. Fasten the surface mount LDT unit in a control panel.

3. Make the appropriate connections as shown in the wiring

diagram (Figure A) to the corresponding numbered contacts on

the LDT unit.

4. A 100 k ohm resistor must be connected as shown if

conductive probes are used.

5. Set the potentiometer on face of unit to desired resistance (set

to 1 k for float switch configuration).

6. Resume power to control panel and monitor system for proper

functionality.

MAINTENANCE

Upon final installation of the Series LDT Leak/Over-Temperature Detection

Relay, no routine maintenance is required. A periodic check of the system

calibration is recommended. The Series LDT is not field serviceable and

should be returned if repair is needed (field repair should not be attempted

and may void warranty). Be sure to include a brief description of the

problem plus any relevant application notes. Contact customer service to

receive a return goods authorization number before shipping.

3

(76.20)

(101.6)

3/8

(9.53)

4

3-1/4

(82.55)

3-1/4

(82.55)

4

(101.6)

Ø7/32

(5.56)

#8-32

SPECIFICATIONS

Power Requirement: 120 VAC, 50/60 Hz.

Power Consumption: 4 VA (approximate).

Sensitivity: 1 k to 35 k ohm adjustable.

Temperature Limits:

Operating: -4 to 131°F (-20 to 55°C);

Storage: -40 to 185°F (-40 to 85°C).

Sensor Voltage: 12 VDC.

Switch Type: (2) SPDT.

Electrical Rating: 10 A @ 120 VAC resistive.

Response Times:

Leakage Trip: 1 s.

Leakage Reset: 1 s.

Temperature Trip: 0.1 s.

Indicators: Green LED illuminates under normal operation. Red LED’s

illuminate when leak or over-temperature is detected.

Enclosure: Polycarbonate dust cover.

Mounting: Surface mount.

Weight: 17 oz. (482 g).

Agency Approval: UL 508.

THERMAL

NEUTRAL

HOT

RESET

1 2 3 4 5 6

7 8 9 10 11 12

LOAD

SWITCH

100KΩ

ALARM

COND.

PROBE

THERMAL SWITCH

COND.

FLOAT

5 6

ALTERNATE

CONDUCTIVE FLOAT

SWITCH CONNECTION

Figure A

©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A. 10/07 FR# R3-443592-02

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...