Page 1

Bulletin PC-LCT216

Series LCT216 Timer/Counter/Tachometer

Specifications - Installation and Operating Instructions

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Page 2

TABLE OF CONTENTS

Model Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation 3

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Front Panel Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Timer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Parameter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Timing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Counter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Counter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Counter Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Tachometer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tachometer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tachometer Output Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Mixed Timer / Counter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mixed Timer / Counter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 2

Page 3

MODEL NUMBER IDENTIFICATION

LCT216

Power Supply

1 = 100 to 240 VAC

Output Type

0 = Transistor

Communications

0 = None

1 = Relay

GETTING STARTED

1. Install the control as described on page 4.

2. Wire your control following the instructions on page 5. Please read the Precautions

section located at the end of this manual before wiring the control.

INSTALLATION

Mount the instrument in a location that will not be subject to excessive temperature, shock,

or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. Prepare the panel by cutting

and deburring the required opening per the panel cut out dimensions listed below. Follow

the mounting instructions listed on page 4. Lastly, wire the controller per the appropriate

wiring diagram listed on page 5.

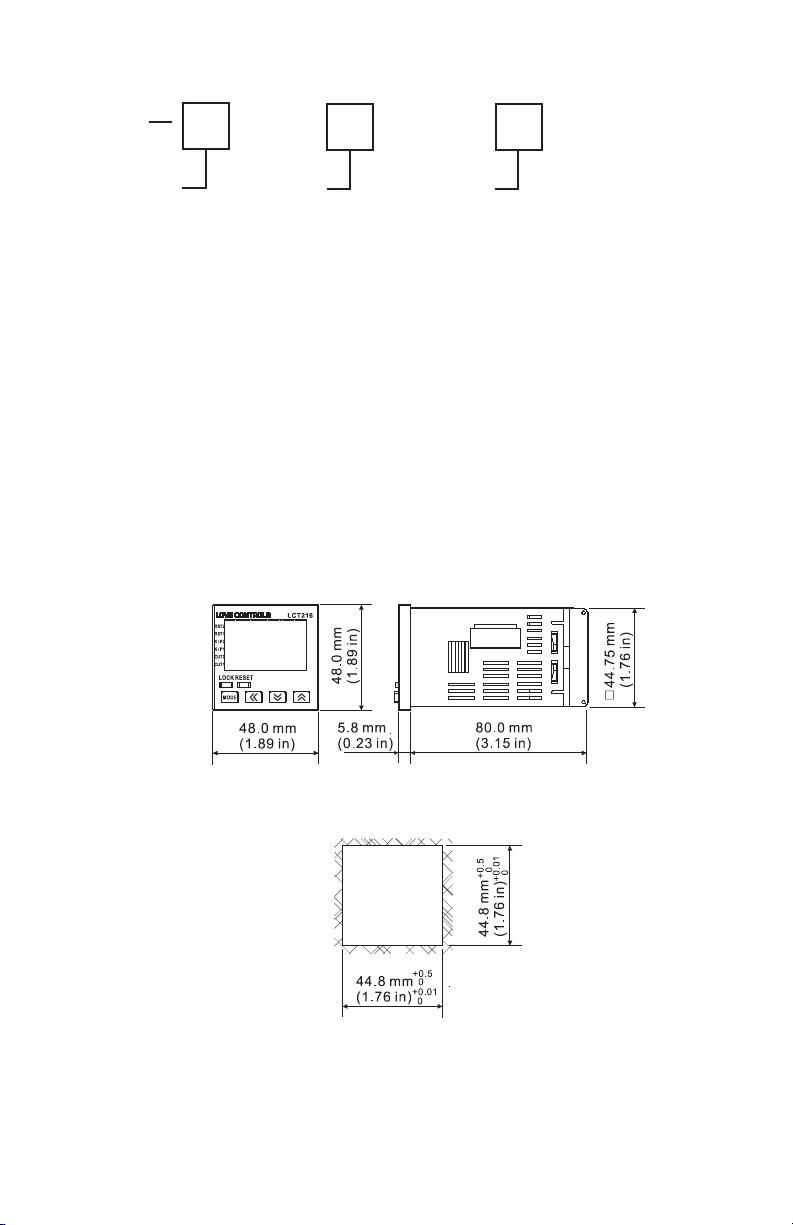

Physical Dimensions

Panel Cut Out

Page 3

Page 4

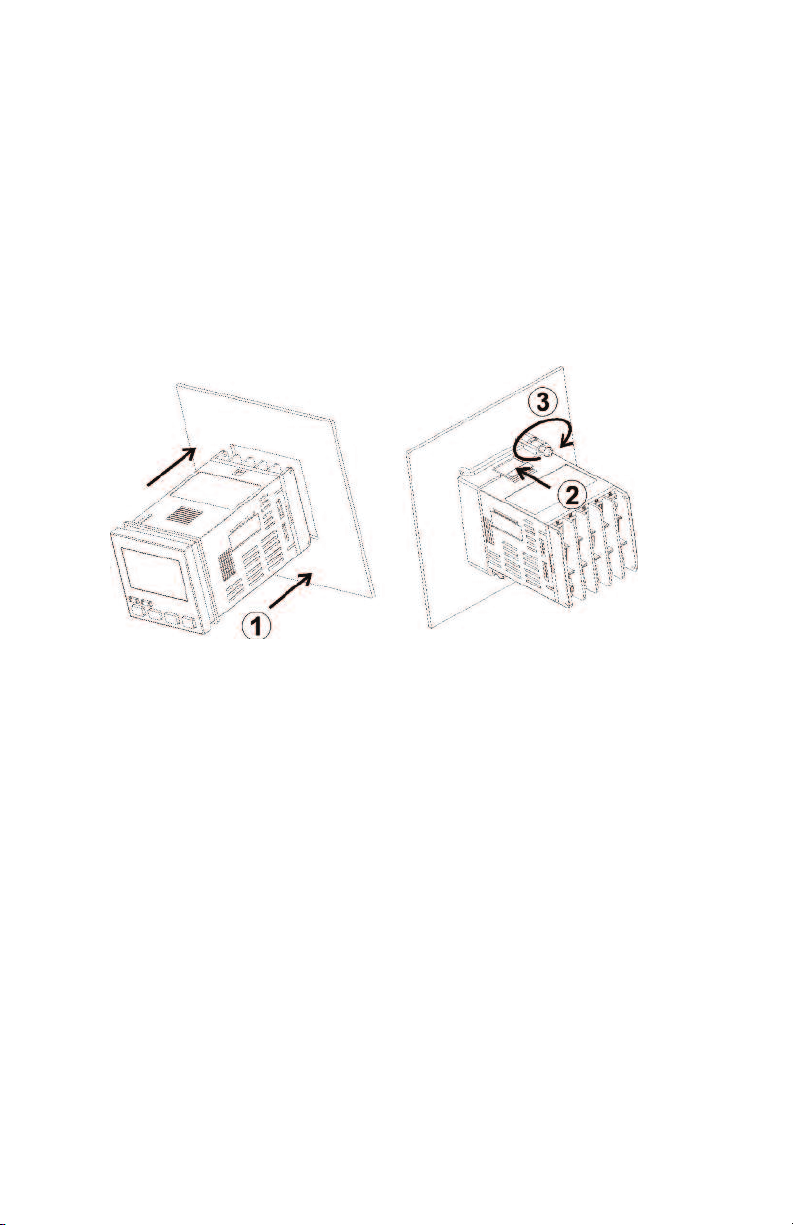

MOUNTING METHOD

Step 1: From the front of the panel, slide the controller housing through the cut out. The

housing gasket should be against the housing flange before installing.

Step 2: Slide the mounting collar over the housing from the rear of the panel.

Step 3: Push the mounting collar forward until the bracket stops at the panel wall.

Step 4: Insert and tighten the screws on the bracket to secure the controller in place.

(The screw torque should be 0.8 kgf-cm).

Mounting Bracket Installation

Page 4

Page 5

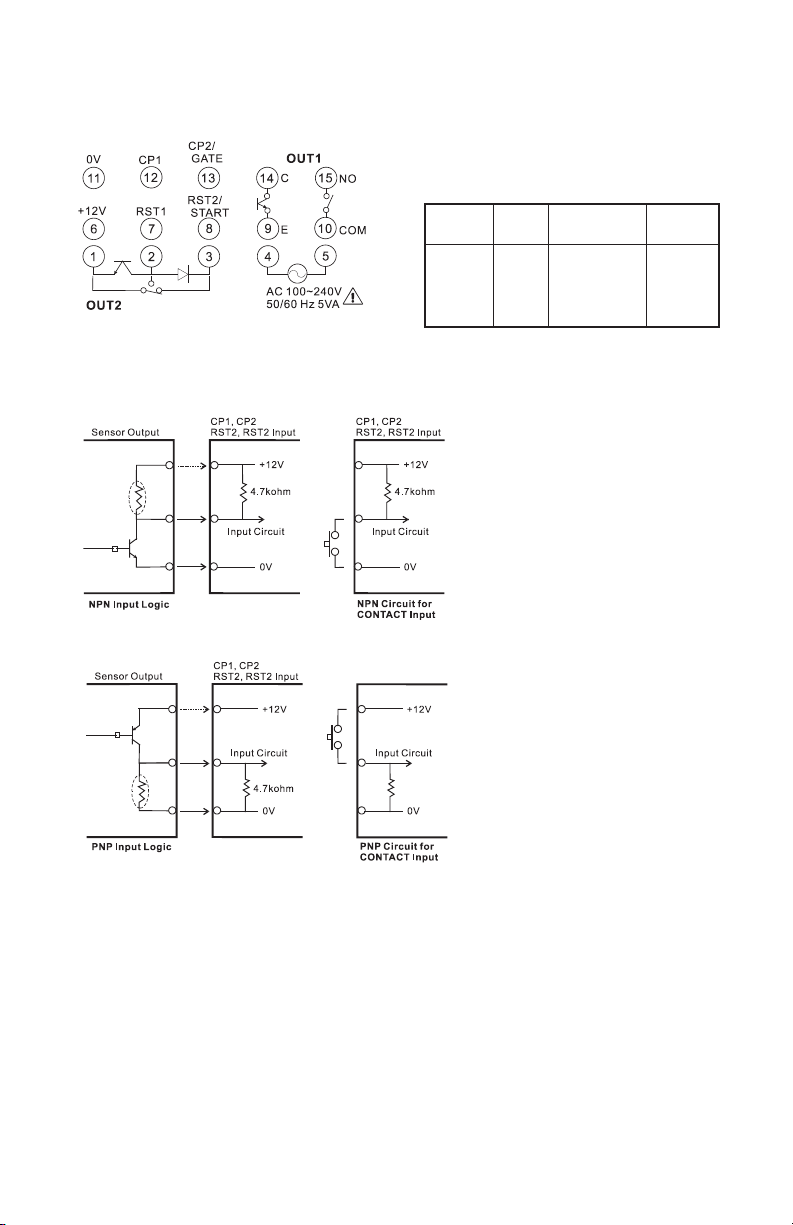

WIRING

Terminal Identification

Input Connections

NPN

PNP

Multi-Function Input PIN

Counter

CP1

CP2

Reset1

Reset2

Timer

Gate

Reset1

Start

Tachometer

CP1

Reset1

Timer &

Counter

CP1

Gate

Reset1

Start

Page 5

Page 6

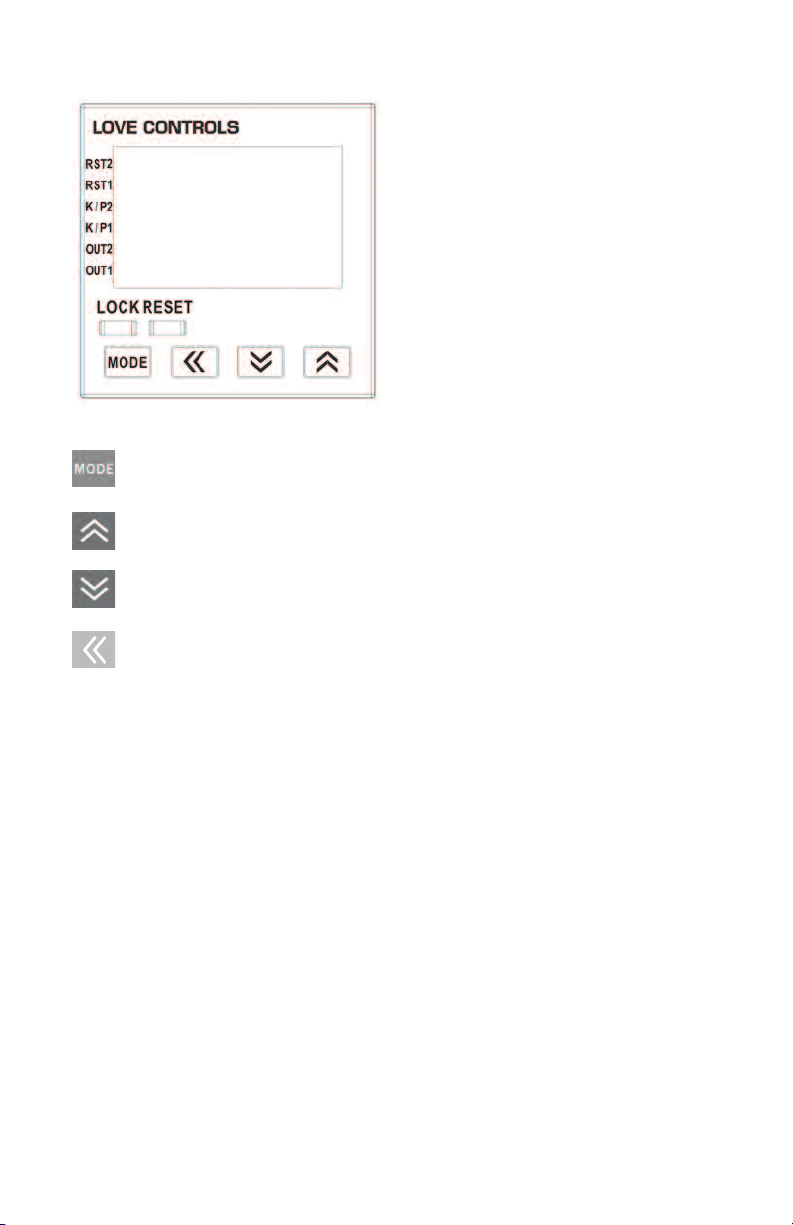

FRONT KEY FUNCTIONS

Key functions are as follows:

MODE: Pressing the Mode key advances the display to the next menu

item and saves any changed parameter values.

UP ARROW: Increments a value or changes a menu item. If pressed while

in the home display, the set point value will be increased.

DOWN ARROW: Decrements a value or changes a menu item. If

pressed while in the home display, the set point value will be decreased.

LEFT ARROW: Changes the selected digit to the left. This is used to

quickly change set point values for large values.

RESET: Clear and reset the PV display.

LOCK: Press to enter secure mode. See Security Feature section for

more information.

Page 6

Page 7

SECURITY FEATURES

The Series LCT216 has two built-in security lock settings to prevent unauthorized personnel

from changing parameter settings.

The LoC1 setting affects all parameters in the controller. If LoC1 setting is enabled, the

operator will have to unlock the controller to make any changes to the controller’s

parameters

The LoC2 setting affects all parameters except the set point and the reset function. If LoC2

setting is enabled, the only parameters that the operator will be able to change are the set

point and resetting the process value. In order to change any other parameters, the operator

will have to unlock the control before making a change.

In order to unlock the control, the operator must depress the MODE and LEFT ARROW key

simultaneously.

CONTROL OPERATION DESCRIPTION

Home Display

The HOME display is the normal display while the control is operating. If no errors or

functions are active, the HOME display will indicate the process value on the top display and

the set value on the bottom display. Below the set value, the current mode of operation will

be shown as TAC (tachometer), CNT (counter), or TMR (timer). There will also be a

descriptor for the time units and type of counter operation.

While in the HOME display, the user can use the UP ARROW, DOWN ARROW, and LEFT

ARROW keys to change the set point value. The RESET key will clear the process value.

The LOCK key will enable the security feature.

Parameter Configuration Display

Holding the MODE KEY for 3 seconds will enter the parameter configuration display. Once

in the parameter configuration display, the parameter will be listed in the top display and the

value of that parameter will be listed in the bottom display. Pressing the MODE key will cycle

through the parameters for the respective operation modes. The UP and DOWN arrows

change the values of the parameters. The MODE key must be pressed to save any changes.

Return to the HOME display by holding the MODE key for 3 seconds.

Page 7

Page 8

TIMER SETTINGS

The timer function of the series LCT216 takes a signal input to start a timing sequence. The

sequence can be paused using the GATE input or reset using RST1 input. Use the below

parameters and timing functions to configure the timer.

Parameter Configuration

PV SV

FUnC timE Sets the controller to function as a timer.

t mode UP Sets the display to count up or down.

down

t otmd Sets the output timing functions. See the timing functions

section or page 9 for detail description of each timing

function.

t Unit Sets the display units of measure. See below table for a

list of the available units.

Display

S 001

S 01

S 1

mS 001

mS 01

m 01

M 1

HmS

Hm 1

H 1

T oUt 1 Sets the pulse width (t) for output 1. The default output timeis

rtSr Sets the minimum pulse width at either 1 msec or 20 msec.

inPtLC Sets the transistor input type to NPN or PNP. For contact input,

Units

sec.

sec.

sec.

min., sec.

min., sec.

Min.

Min.

Hr., min., sec.

Hr., min.

Hr.

Range

0.01 to 9,999.99

0.1 to 99,999.9

1 to 999,999

0.01 to 9,959.99

0.1 to 99,959.99

0.1 to 99,999.9

1 to 999,999

1 to 995,959

1 to 999,959

1 to 999,999

Table A: List of Timing Units

0.02 seconds. If you wish the system to keep the operation of

the output, please set the output time to 0.00 seconds.

the selection can be either PNP or NPN, but the selection will

determine whether the connection is to terminal 11 or terminal 6.

See the input connection diagrams on page 5.

Resolution

10 msec.

0.1 sec.

1 sec.

10 msec.

0.1 sec.

0.1 min.

1 min.

1 sec.

1 min.

1 hr.

Maximum Time

9,999.99 sec.

99,999.9 sec

999,999 sec.

5,999.99 sec.

59,999.9 sec.

99,999.9 min.

999,999 min

359,999 sec. (100 hr.)

599,999 min. (10,000 hr.)

699,999 hr.

Page 8

Page 9

Timer Functions

Page 9

Page 10

COUNTER SETTINGS

Parameter configuration

PV SV

FUnC Cont Sets the controller to function as a counter

CntFUn Select the counter to perform single stage counting, two

stage counting, batch counting, total counting or dual

counting.

STAGE1 Controller has a single process value and set point value.

Output 2 will be the same as output 1.

STAGE2 Controller has up to two set point and process values. The

operation is based on the input modes and output types.

bAtCH Controller can be set to count batch processes. In this mode,

the counter will count up until it reaches the set value and then will

increment the batch present value by one. The process will

continue until the batch set point value is reached.

totAL Controller has a single set point. The display can show the

present value since last reset or total counts.

dUAL Controller will either add or subtract the counts from the two

counter inputs.

C inPt Counter input mode can be selected to count up or down when a

counter input signal is received.

UP The present value will increase with each counter input signal.

doun The present value will decrease with each counter input signal.

Page 10

Page 11

Ud A Command up / down setting will increase or decrease the

Co unti ng up

Cou nt ing d own

Prohibit

A A

0

1

2

3

4

H

L

H

L

0

CP1

CP2

Present

Val ue

CP1: Counter input CP2: Counter input prohibit ed

Note: has to be larger than width of min. Input signal

A

Prohibit

A A

0

1

2

3

4

5

H

L

H

L

0

CP1

CP2

Present

Val ue

CP1: Counter input prohibited CP2: Counter input

Note: has to be larger than width of min. Input signal

A

Prohibit

AA

n

n-2

n-1

n-4

n-3

H

L

CP1

CP2

Present

Val ue

0

H

L

CP1 : C ou nte r in put C P2 : Co un ter inp ut pro hib it ed

Note: has to be larger than width of min. Input signal

A

A

Prohib it

A

n

n-1

n-2

n-3

n-4

n-5

H

L

H

L

CP1

CP2

0

Present

Value

CP1 : C ou nte r in put pr oh ibi ted C P2: Cou nt er i np ut

No te: h as t o be la rge r t han wid th o f m in. In put sig na l

A

Co mm and co un tin g u p/ dow n

U

D_A

Indivi dual coun ting up/do wn

UD_B

Quadr ature inp ut

UD_C

B B B B

0

11

2

2

3

H

L

CP1

CP2

Present

Val ue

0

Note : has to be lar ger tha n width of 1/ 2 min. in put sign al.

B

H

L

0

present value with each counter 1 input signal depending on if

counter 2 input is engaged. When counter 2 input is engaged, each

counter 1 input signal will decrease the count.

Ud b Individual up / down setting will increase the present value with

each counter 1 input signal and decrease with each counter 2 input

signal.

Ud C Quadrature up / down uses the order of the inputs to determine

whether to count up or down. If counter input 1 leads counter input

2, the unit will count up. If counter input 2 leads counter input 1, the

unit will count down.

Page 11

Page 12

C otmd Counter Output Mode determines the output operation of the

control. It also determines how the counter will function after

reaching the set point. See the output mode charts on page 13 for

more information.

C SPEd Counting Speed can be set from one count per second up to

10,000 counts per second. This setting determines the minimum

input signal width.

t oUt1 Sets the pulse width (t) for output 1.

t oUt2 Sets the pulse width (t) for output 2.

Point Sets the number of digits to the right of the decimal point on the

display.

PSCALE Pre-Scale is used when converting the process value’s units of

measure. The pre-scale value would be set as the conversion factor.

(Pv = Pv * PSCALE)

PwErS Power Save feature allows the control to save the current process

value upon loss of power.

SAvE Save process value upon power loss

CLEAr Clear process value upon power loss

rtSr Minimum width of reset signal determines how long the reset

terminals must be engaged to reset the device.

inPtLC Input signal can be set for PNP or NPN. This parameter

determines which wiring diagram should be used.

Page 12

Page 13

Counter Output Mode Charts

RESET

999999

S

V1

SV2

0

OUT2

O

UT1

R

ESET

999999

SV2

SV1

0

OUT2

OUT1

RESET

999999

SV2

SV1

0

OUT2

OUT1

RESET

999999

S

V1

SV2

0

OUT2

O

UT1

Output

mode

setting

Inpu t mode

Up

Do wn Up/ Do wn A, B, C

K

P

Q

A

TT

TT

TTTTTT

TT TT

TT TT TTT TTT

TTTTTT

TT

T

T

TTT

TTT

999999

RESET

S

V2

SV1

OUT2

O

UT1

0

TT

T

T

TTT T

TT

R

ESET

9

99999

SV2

SV1

0

O

UT2

OUT1

TT

RESET

999999

S

V2

0

OUT2

OUT1

SV1

R

ESET

999999

SV2

SV1

0

OUT2

OUT1

TT TTT TTT

TT TT T

T

TTTT TT

TT T T TTT TTT

I

npu t mod e

U

p Do w n Up / Do w n A , B , C

F

N

C

R

Output

m

ode

s

etting

RESET

999999

SV2

SV1

0

OUT2

OUT1

RESET

99999 9

SV2

SV1

0

OUT2

OUT1

RESET

9

99999

SV1

SV2

0

OUT2

OUT1

O

utput

m

ode

setting

Inp ut mod e

Up/D own A , B, C

S

T

D

Output Modes S, T, and D can only be used with up/down counting inputs.

Page 13

Page 14

TACHOMETER SETTINGS

OUT 2 set val ue

Me asur eme nt va lue

OUT1 set value

OUT1

OUT2

OUT 1 set v alue : O UT1 ON

Meas ure ment va lue

OUT 2 set v alue : O UT2 ON

(LO-LO)

OUT2 set value

Mea sur eme nt va lue

OUT 1 se t valu e

OUT1

OUT2

Mea surem ent v alue

OUT 1 set va lue : O UT1 ON

Meas urem ent va lue OUT2 se t valu e : OUT2 ON

(LO-HI)

OUT2 set val ue

Measure ment value

OUT1 set va lue

OUT1

OUT2

(HI-LO)

Mea sur emen t valu e OU T1 set value : OUT1 ON

Mea sur emen t valu e

OUT2 set value : OUT2 ON

OUT 2 set val ue

Measurem ent value

OUT 1 set val ue

OUT1

OUT2

(HI-HI)

Measure ment value OU T1 se t valu e : OUT 1 ON

Measur ement value

OUT2 set value : OUT2 ON

Parameter Configuration

PV SV

FUnC tACH Sets the controller to function as a tachometer.

tAotmd Tachometer Output Mode determines the output condition when the

process value exceeds the set point value. See output mode charts

below for more information.

C SPEd Maximum Input Frequency can be set from one count per second up

to 10,000 counts per second.

Point Sets the number of digits to the right of the decimal point on the

display.

PSCALE Pre-Scale is used when converting the process value’s units of

measure. This value is commonly used to convert the input

frequency (counts per second) to a rotational speed (rpm) using the

below equation.

Frequency (Hz) * Pre-Scale = Rotation Speed (rpm)

Pre-Scale = 60 / n (where n = number of pulses per

revolution).

St tAC Initial Power Up Interrupt delays the output from triggering for up to

99.9 seconds.

St AvG Input Filter allows the tachometer to average 2, 4, or 8 readings to

give a more stable reading. (1= 2 data points, 2 = 4 data points, and

3 = 8 data points).

rtSr Minimum Width of Reset Signal determines how long the

inPtLC Input signal can be set for PNP or NPN. This parameter

Tachometer Output Mode Charts

reset terminals must be engaged to reset the device.

determines which wiring diagram should be used.

Page 14

Page 15

TIMER + COUNTER MIXED MODE SETTINGS

Parameter Configuration

PV SV

FUnC miX Sets the controller to function as a timer and counter.

T mode Timer Mode sets the timer to count up or Down.

T otmd Timer Output Mode sets the output timing functions. See the

timing functions section on page 9 for detail description of each

timing function.

t Unit Sets the display units of measure. See table A on page 8 for a list

of the available units.

C inPt Counter input mode can be selected to count up or down when a

counter input signal is received.

UP The present value will increase with each counter input

signal.

doun The present value will decrease with each counter input

signal.

C otmd Counter Output Mode determines the output operation of the

control. It also determines how the counter will function after

reaching the set point. See the output function tables on page 13

for more information.

C SPEd Counting Speed can be set from one count per second up to

10,000 counts per second. This setting determines the minimum

input signal width.

t oUt1 Sets the pulse width (t) for output 1.

t oUt2 Sets the pulse width (t) for output 2.

Point Sets the number of digits to the right of the decimal point on the

display.

PSCALE Pre-Scale is used when converting the process value’s units of

measure. The pre-scale value would be set as the conversion factor.

(Pv = Pv * PSCALE).

Page 15

Page 16

PuErS Power Save feature allows the control to save the current process

value upon loss of power.

SAvE Save process value upon power loss

CLEAr Clear process value upon power loss

rtSr Minimum width of reset signal determines how long the reset

terminals must be engaged to reset the device.

inPtLC Input signal can be set for PNP or NPN. This parameter

determines which wiring diagram should be used.

DIP SWITCH SETTINGS

The Series LCT216 can be configured either using the configuration parameters discussed

in the previous section or by using DIP switches located on the side of the housing. When

the DIP switch setting is turned on, the parameters can be viewed, but not changed using

the front panel.

SW

Counter

8

Reset Pulse Width

On = 1 ms, Off = 20 ms

7

Input Type

On = PNP, Off = NPN

6

N/A

5

Counting Speed

On = 10K CPS, Off = 30 CPS

4

Output Mode of Counter

See Table D

3

Output Mode of Counter

See Table D

2

Input Mode of Counter

On = Down, Off = Up

1

On = Enable DIP Switch

Off = Disable DIP Switch

Timer

Reset Pulse Width

On = 1 ms, Off = 20 ms

Units of Timer

See Table C

Units of Timer

See Table C

Units of Timer

See Table C

Output Mode of Timer

See Table D

Output Mode of Timer

See Table D

Time Counting Up/Down

On = Down, Off = Up

On = Enable DIP Switch

Off = Disable DIP Switch

Table B: DIP Switch Parameter List

Page 16

Tachometer

Reset Pulse Width

On = 1 ms, Off = 20 ms

Input Type

On = PNP, Off = NPN

N / A

Counting Speed

On = 10KHz, Off = 30 Hz

Output Mode of Tachometer

See Table D

Output Mode of Tachometer

See Table D

N / A

On = Enable DIP Switch

Off = Disable DIP Switch

Page 17

SW

SW5

OFF

ON

OFF

ON

OFF

ON

OFF

ON

SW3

OFF

ON

OFF

ON

SPECIFICATIONS

Operating Temperature Range: 32 to 122°F (0 to 50°C).

Humidity Conditions: 35 to 85% RH (non-condensing).

Control Output Ratings: (Out 1) Relay: SPST 5A at 250 VAC, Transistor: NPN Open

collector 100 mA / 30 VDC residual voltage = 1.5 VDC max; (Out 2) Relay: SPST 5A at

250 VAC, Transistor: NPN Open collector 100 mA / 30 VDC residual voltage = 1.5 VDC

max.

Weight: 4 oz (114 g).

Reset Time: 0.001 seconds minimum.

Inputs: Dry contact, PNP, or NPN.

Timing Functions: 14 pre-programmed timing functions.

Supply Voltage: 100 to 240 VAC 50 / 60 Hz.

Power Consumption: Less than 10 VA.

Internal Power Supply: 12 VDC ±10%, 100 mA..

Display: Two-line 6 digit negative transmissive LCD display.

Agency Approvals: CE, UL.

6

SW7

O

F

F

O

F

F

O

N

O

N

O

F

F

OF

F

ON

ON

Table C: Timer Units of Measure

SW4

OFF

OFF

ON

ON

Table D: Output Mode Configurations

Displayed Unit

OFF

0.01 s

OFF

0.1 s

OFF

1 s

OFF

min, 0.01 s

ON

min, 0.1 s

ON

0.1 min

ON

min

ON

hr, min, s

Output Mode Configuration

Counter

F

N

C

R

Timer

Signal ON Delay 1

Signal ON Delay 2

Signal OFF Delay

Signal ON

Tachometer

Lo-Lo

Lo-Hi

Hi-Lo

Hi-Hi

Page 17

Page 18

DANGER

. Make sure the power is disconnected when you check the unit inside.

2

1. When the power is on, DO NOT touch the AC terminals in case an electric shock

may occur.

WARNING

injury to workers or damages on other equipment when used in a dangerous environment, please make

sure it is installed in an automatic safety protection device.

LCT216 is an OPEN-TYPE device. They are intended for installation completely within

an overall panel and for use in counting or timing applications. If it will cause series

1. Always use recommended solder-less terminals: Fork terminals with isolation

(M3 screw, width 7.0 mm), hole (diameter 3.2 mm). Screw size: M3x6.5 (with

6.8x6.8 square washer). Recommended tightening torque: 0.4 N.m (4kgf.com).

Applicable wire: solid/twisted wire of 2 mm2, 12 AWG to 24 AWG. Please be

sure to tighten them properly.

2. Prevent dust or metallic debris from falling into the device and cause

malfunctions.

3. DO NOT modify or uninstall the device.

4. DO NOT use empty terminals.

5. Make sure the wires are correctly connected to proper terminals.

6. Keep away from high-voltage and high-frequency environment during

installation in case of interference.

7. Prevent using the device in premises which contain: dust or corrosive gas, high

humidity, high radiation, vibration and shock.

8. LCT216 is an open-type device. Make sure to install it in an enclosure to

prevent dust, humidity in case of an electric shock.

9. Please make sure the power cables and signal device are installed correctly

before switching on the power; otherwise serious damage may occur.

10. DO NOT touch the terminals or repair the device when the power is on;

otherwise an electric shock may occur.

11. Please wait for one minute after the power is switched off to allow the capacitor

to discharge and DO NOT touch the internal wiring within this period.

12. Use dry cloth to clean the device. DO NOT use acid or alkaline liquid to clean

the device.

©Copyright 2011 Dwyer Instruments, Inc Printed in U.S.A. 5/11 FR# R5-443702-00

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Loading...

Loading...