Page 1

Bulletin E-37

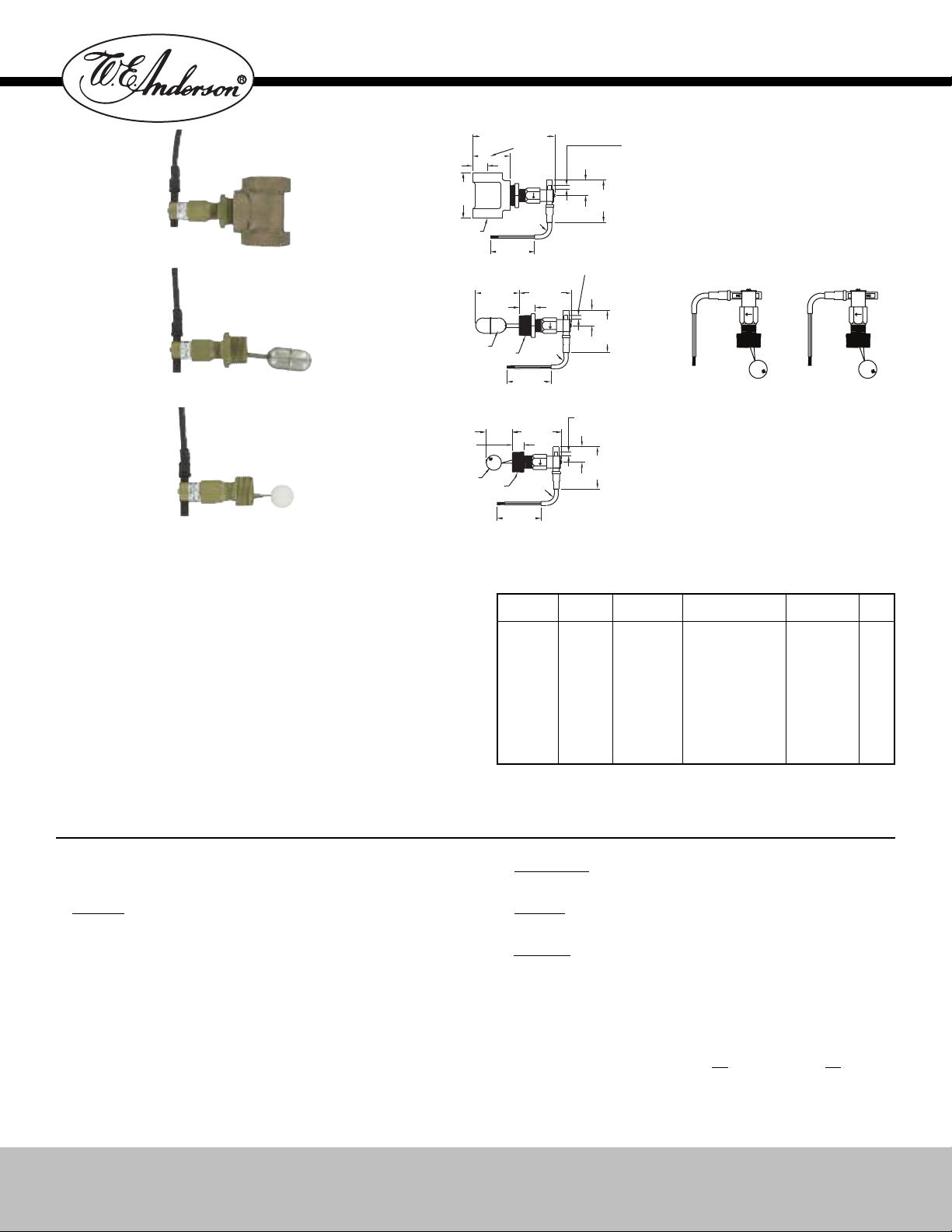

1

/4 [6.35]

T

RAVEL TO

N

ORMALLY

C

LOSED

P

OSITION

2-7/8

[73.07]

5-7/16 [138.13]

4 [101.6]

18 AWG

LEAD WIRE

1 NPT

3

[

76.20]

1

[

25.40]

1

9

[

482.6]

C

ABLE

1/4 [6.35] TRAVEL

TO NORMALLY

CLOSED POSITION

2

-7/8

[

73.07]

19

[482.6]

CABLE

1

NPT

4 [101.6]

18 AWG

LEAD WIRE

NORMALLY CLOSED NORMALLY OPEN

Ø1 [25.40] X

2 [50.80] LONG

2-7/8

[

73.03]

3-1/2

[88.90]

1

[25.40]

2

-3/8

[

60.33]

1

[25.40]

1-1/16

[26.99]

2-7/8

[73.07]

1

[

25.40]

1

/4 [6.35] TRAVEL

T

O NORMALLY

CLOSED POSITION

1-3/4

[44.45]

Ø

1

[

25.40]

1

NPT

4 [101.6]

18 AWG

LEAD WIRE

3

-1/4

[

82.55]

1

9

[

482.6]

C

ABLE

3

/4

[

19.05]

Series L10 Flotect™Mini-Size Level Switch

Specifications – Installation and Operating Instructions

SPECIFICATIONS

Service: Compatible liquids.

Wetted Materials:

Float: Solid polypropylene or 304 SS;

Body: Brass or 303 SS;

Magnet: Ceramic;

External float chamber (tee): None,

brass, or 304 SS; Other: Lever arm,

pin, spring, etc.: 301 SS, 302 SS,

316 SS.

Temperature Limit: 200°F (93°C).

Pressure Limit: See model chart.

Enclosure Rating: Weatherproof,

meets NEMA 4X (IP66).

Switch Type: SPST hermetically

sealed reed switch. Field adjustable

for normally open or normally closed.

Electrical Rating: 1.5 A @ 24 VDC

res., 0.001 A @ 200 VDC res., 0.5A @

125 VAC.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S.A.

INSTALLATION

1. Unpack switch and remove any packing material found inside lower housing or

float chamber (tee).

2. WARNING

switch. Care should be taken to avoid dropping the switch on hard surfaces or

impacting the switch assembly.

3. Switch must be installed with body in a horizontal plane with arrow on side of

body pointing down.

4. If switch has an external float chamber (tee), connect it to vertical sections of 1˝

NPT pipe installed outside vessel walls at appropriate levels. If unit has no external

float chamber, it must be mounted in a 1˝ NPT half coupling welded to the vessel

wall. The coupling must extend through the wall. Use Teflon

joint compound to assure a good seal.

5. Connect the wiring in accordance with local electrical codes.

6. Inductive, capacitive and lamp loads can all create conditions harmful to the reed

switch.

Mechanical shock and vibration can cause damage to the reed

Electrical Connections: 18 AWG, 19˝

(483 mm) long, PVC jacket. Rated

221°F (105°C).

Process Connection: 1˝ male NPT

standard on models without external

float chamber. Change 3 in model

number to 4 for 1-1/4˝, to 5 for 1-1/2˝, or

6 for 2˝. 1˝ female NPT on models with

external float chamber.

Mounting Orientation: Horizontal with

index arrow pointing down.

Weight: Approximately 10 oz (0.283 kg)

without external float chamber, 2.32 lb

(1.05 kg) with external float chamber.

Specific Gravity: See model chart.

Agency Approvals: UL and CSA.

Switch Enclosure: Nylon.

®

thread tape or pipe

Model

Number

L10-B-3-O

L10-B-3-A

L10-B-3-C

L10-B-3-B

L10-B-3-H

L10-S-3-O

L10-S-3-A

L10-S-3-C

L10-S-3-S

L10-S-3-L

A) Inductive loads can be caused by electromagnetic relays, electromagnetic

solenoids and electromagnetic counters, all with inductive compenents as the

circuit load.

B) Capacitive

parallel to the reed switch. IN a closed circuit, the calbe length (150 ft or more) to

the switch can introduce a capacitance.

C) Lamp loads

resistance.

In addition to these causes, exceeding any of the maximum electrical ratings can

lead to premature or immediate failure. This includes inrush and surge currents

greater than the maximum switching current. To accomodate these conditions,

see diagrams on the reverse for possible solutions.

7. After installation, set the switch action to NO

closed). Normally open contacts close and normally closed contacts open when

liquid level in the vessel lifts the float past the actuation point. To change, loosen,

but do not remove, the two screws on the switch cap. Slide the reed switch

assembly to expose the switch action needed. Tighten screws when adjustment

is complete.

Body

Material

Brass

Brass

Brass

Brass

Brass

St. Steel

St. Steel

St. Steel

St. Steel

St. Steel

loads can be caused by capacitors connected in series with or

Installation/

Mounting

Side Wall

Side Wall

Side Wall

Ext. Tee

Ext. Tee

Side Wall

Side Wall

Side Wall

Ext. Tee

Ext. Tee

can be caused by switching lamp filaments which have low cold

Float

Material

Solid Polypropylene

Cylindrical St. Steel

Round St. Steel

Solid Polypropylene

Round St. Steel

Solid Polypropylene

Cylindrical St. Steel

Round St. Steel

Solid Polypropylene

Round St. Steel

(normally open) or NC (normally

Max. Press.

psig (bar)

1000 (68.9)

200 (13.8)

350 (24.1)

250 (17.2)

250 (17.2)

2000 (137.8)

200 (13.8)

350 (24.1)

2000 (137.8)

350 (24.1)

Min.

S.G.

0.9

0.5

0.7

0.9

0.7

0.9

0.5

0.7

0.9

0.7

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

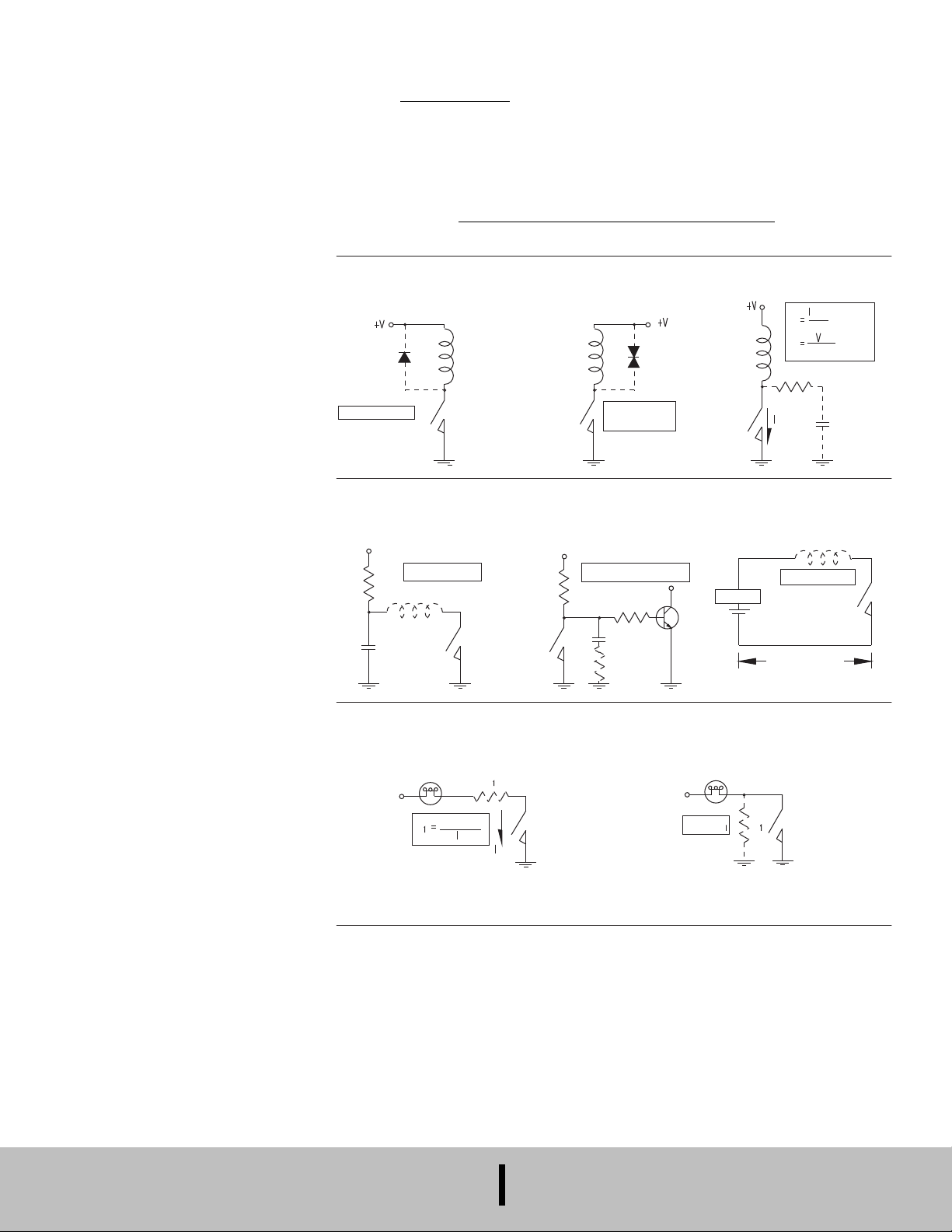

CIRCUIT INFORMATION FOR REED SWITCH PROTECTION

D

IODE SUPPRESSION

D

IODE

INDUCTIVE

LOAD

P

IV DIODE > V

R

EED

S

WITCH

R

EED

S

WITCH

U

SED IN

A

C CIRCUITS

V

ARISTER

VARISTER PROTECTION

I

NDUCTIVE

L

OAD

R

C SUPPRESSION

R

C

INDUCTIVE PROTECTION FOR

CABLE LENGTH CAPACITANCE

LOAD

REED

SWITCH

Cable Length

over 50 meters

[162.5 ft.]

REED

SWITCH

RESISTOR PROTECTION

FOR CAPACITIVE LOAD

S

URGE LIMITER FOR

C

APACITANCE IN SERIES

REED

SWITCH

CURRENT LIMITING RESISTOR

IN SERIES

CURRENT LIMITING RESISTOR

IN PARALLEL

REED

SWITCH

REED

SWITCH

INDUCTIVE

L

OAD

REED

S

WITCH

S

WITCH

[uf]

1

0

C

R

10*I

(1+50/E)

S

WITCH

2

C

LOAD

S

WITCH

SWITCH

L

OAD

C

R

L =0.5~5 mH

P

+V

R

A

P

L

R

A

+V

R = 50~500 Ohms

R

B

P

L

L = 0.5~5 mH

P

+V

R

L

R

R

V-0.12 R

L

2

+V R

L

5R > R

L

R

EAD INFORMATION BELOW BEFORE INSTALLING YOUR NEW REED SWITCH CONTROL!

xceeding the current capacity of this Reed Switch control may cause FAULTY OPERATION!

E

ou Reed Switch Control. The circuits below outline possible solutions to preventing overloads due to inrush or surge currents exceeding maximum or when the switch current

y

nd product of the lamps (low “cold” resistance) is outlined below. Failure to follow these measures to protect Reed Switch Contacts may cause the contacts to weld together

a

or result in premature wear.

nductive Loads

I

Possible causes –

An electromagnetic relay, electromagnetic solenoid,

electromagnetic counter with inductive component as

ircuit load.

c

Capacitive Loads

Possible causes –

capacitor connected in series or parallel with Reed

A

Switch control. In a closed circuit, a cable length (usually

greater than 50m [162.5 ft.]) used to connect reed switch

may also introduce static capacitance.

R

e aware of the inductive and capacitive or lamp loads you may be placing on

B

Possible Circuit Solutions Indicated by Dashed Lines

Lamp Loads

Possible causes –

A tungsten filament lamp load.

MAINTENANCE/REPAIR

Upon final installation of the Series L10, no routine maintenance is required. The

Series L10 is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number before

shipping the product back for repair. Be sure to include a brief description of the

problem plus any additional application notes.

©Copyright 2011 Dwyer Instruments, Inc.

Printed in U.S.A. 11/11

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S.A.

FR# 82-440851-00 Rev. 2

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...