Page 1

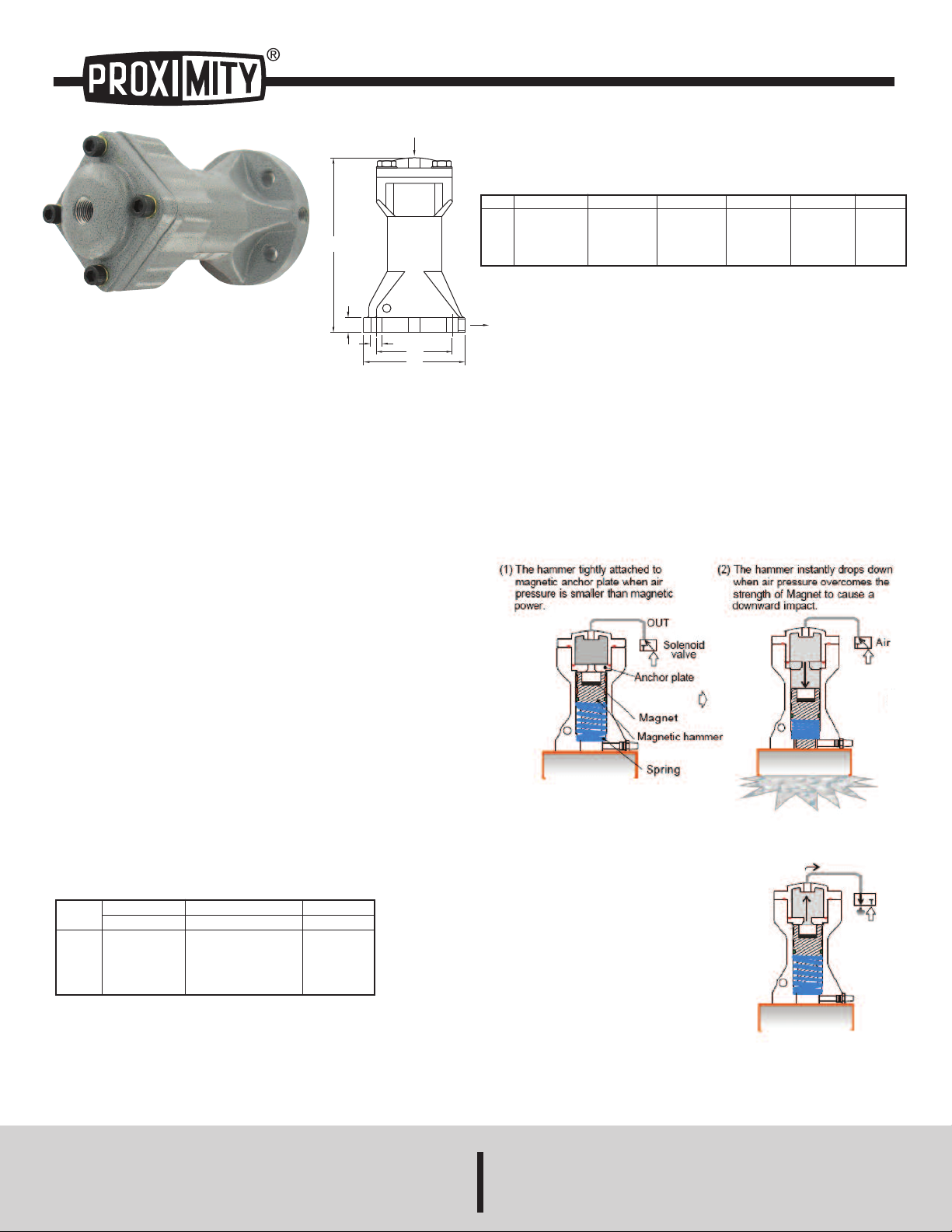

Series IPV Air Hammer

IN

O

UT

A

D

ØH

Ø

C

Ø

B

Specifications - Installation and Operating Instructions

odel

M

PV-1

I

PV-2

I

PV-3

I

PV-4

I

A

.43˝ (138 mm)

5

.54˝ (166 mm)

6

.19˝ (208 mm)

8

0.56˝ (269 mm)

1

B

ø

.15˝ (80 mm)

3

.94˝ (100 mm)

3

.51˝ (140 mm)

5

.77˝ (172 mm)

6

C

ø

.36˝ (60 mm)

2

.95˝ (75 mm)

2

.13˝ (105 mm)

4

.51˝ (140 mm)

5

D

.47˝ (12 mm)

0

.63˝ (16 mm)

0

.63˝ (16 mm)

0

.94˝ (24 mm)

0

Bulletin P-14

onnection

øH

0.35˝ (9 mm)

0.43˝ (11 mm)

0.59˝ (15 mm)

0.75˝ (19 mm)

C

/4˝

1

/4˝

1

/4˝

1

/8˝

3

IPV Series Air Hammers

• One impact wave caused by one shot

• High strength aluminum structure

• Impact force and interval timing can be set based on requirement

• Magnetic hammer stores magnetic strength to increase the piston’s

impact power

Series IPV Air Hammer (single impact model) focuses on a limited

target. Other equipment of the target is minimally affected by it. The air

hammer’s impact won’t separate water out of humid mixtures. It is often

applied onto a pipe or clean elbow in a tank filled with humidity or low

specific gravity material.

HOW IT OPERATES

The IPV series air hammer contains a powerful magnet inside the

hammer. The hammer and magnet are tightly closed before activation.

However, as the inlet air pressure gets higher than the force, this

tightens the hammer and magnet. The hammer and magnet will

separate and cause more strength for impact power. The spring will

bring the hammer back to the initial position automatically after the

impact. By doing this, the air pressure will be released and the strength

of the air pressure will be delivered to the target impact container. It will

help to smooth the flow and prevent accumulation inside the container.

SPECIFICATIONS

Temperature Limit: 212°F (100°C).

Noise Level Range: 60-75 dBA.

Supply Pressure: 43.5 to 87 psi (3 to 6 bar).

Air Consumption: See model chart.

Air Connection: 1/4˝ BSPT female with 1/4˝ OD push to connect

adapter on IPV-1, IPV-2 and IPV-3; 3/8˝ BSPT female with 3/8˝ OD push

to connect adapter on IPV-4. Also includes muffler for exhaust port.

Model

IPV-1

IPV-2

IPV-3

IPV-4

lbf•s (N•S)

.225 (1.0)

.630 (2.8)

1.66 (7.4)

2.81 (12.5)

Impulse

Air Consumption

3

(l) per stroke

in

1.71 (0.028)

5.0 (0.082)

14.0 (0.228)

27.8 (0.455)

Weight

lb (kg)

2.43 (1.1)

3.97 (1.8)

8.82 (4.0)

18.52 (8.4)

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

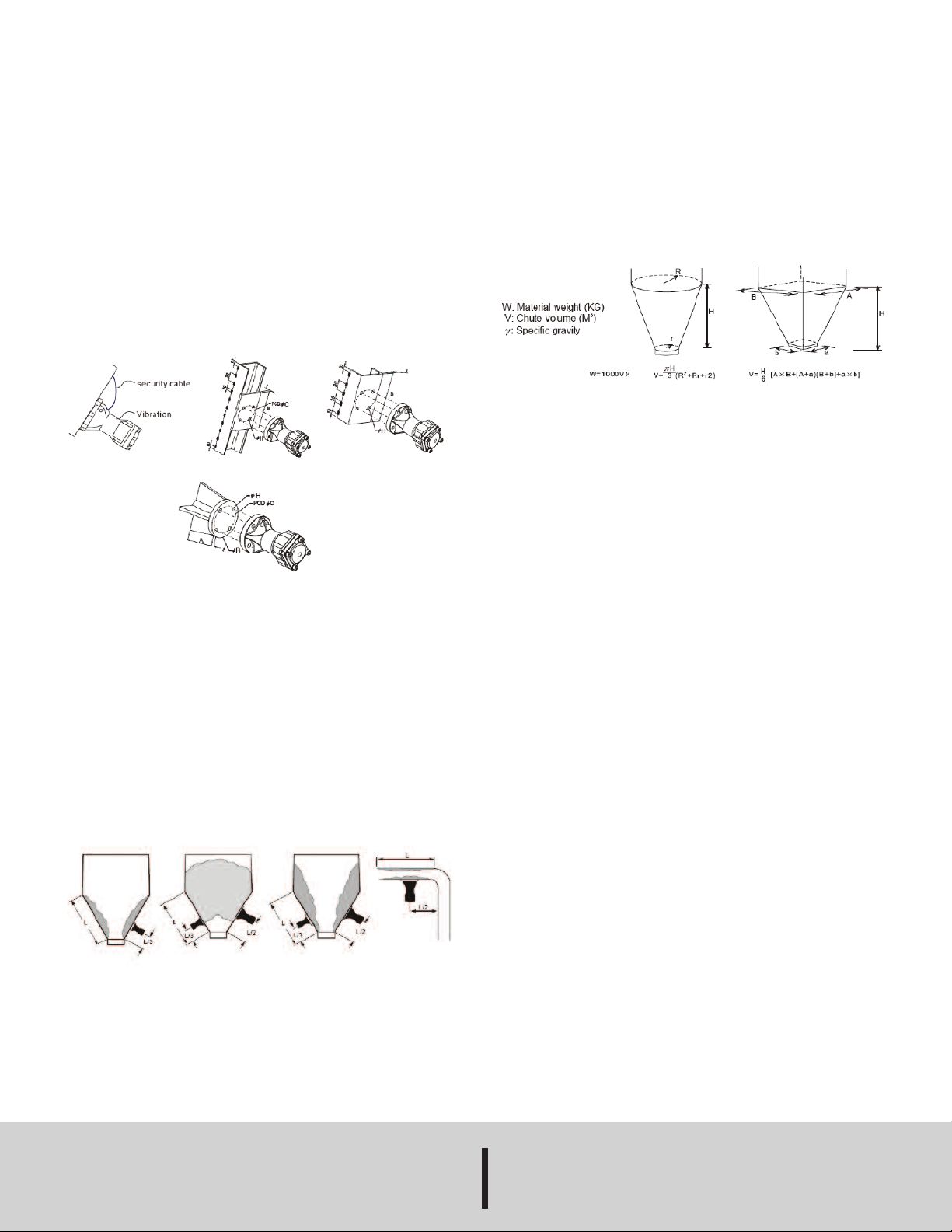

INSTALLATION

Vibration force transmits more efficiently in a conical hopper tank as

opposed to a rectangular hopper. It is recommended that you install two

vibrators in rectangular hoppers.

1. Vibrator force can be transmitted more efficiently by using “U” shape

steel supports. It can help materials run smoother in the tank or pipe. It

also reduces tank damage accidents.

2. To avoid tank wall amplitude caused by the vibrator moving in a left or

right direction, use “U” shape steel.

3. Reinforced board is required between “U” shape steel and a thin tank

wall.

4. To increase vibration fields in a big hopper tank, criss-cross “U” shape

steel.

Attention: Vibration has to be fixed by a high tension bolt, washer, and

spring washer. Connect with a security cable if the vibrator is installed

onto a hopper.

Vibration Force Calculation

Taking the accumulated situation into consideration, the appropriate

vibrator will give 0.2~0.5 G accelerated vibration onto the target object.

F= 0.2-0.4 GW F: Vibration force (N)

G: Acceleration of gravity

W: Material weight (KG)

Material Weight Calculation

Generally speaking, the hopper portion of the tank should be taken into

consideration.

MAINTENANCE

Upon final installation of the Series IPV Air Hammer, no routine

maintenance is required. A periodic check of the system calibration is

recommended. The Series IPV is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and may

void warranty). Be sure to include a brief description of the problem plus

any relevant application notes. Contact customer service to receive a

return good authorization number before shipping.

NOTES:

Various tanks are based on application requirement. Customers choose

appropriate vibrator types to meet with various applicant demand (tank

shape, material, applied material, etc). Suitable vibrators will not only

prevent obstruction problems but won’t damage the tank walls.

Large amplitude and low frequency piston types fit in granule with low

specific gravity applied material. It is recommended to use multiple

vibrators in serious clog situations or large tank surroundings. According

to various clog situations, required vibrations and suitable install

positions (usually 1/2 L or 1/3 L) are shown below.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# R6-443512-00 Rev.2

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...