Page 1

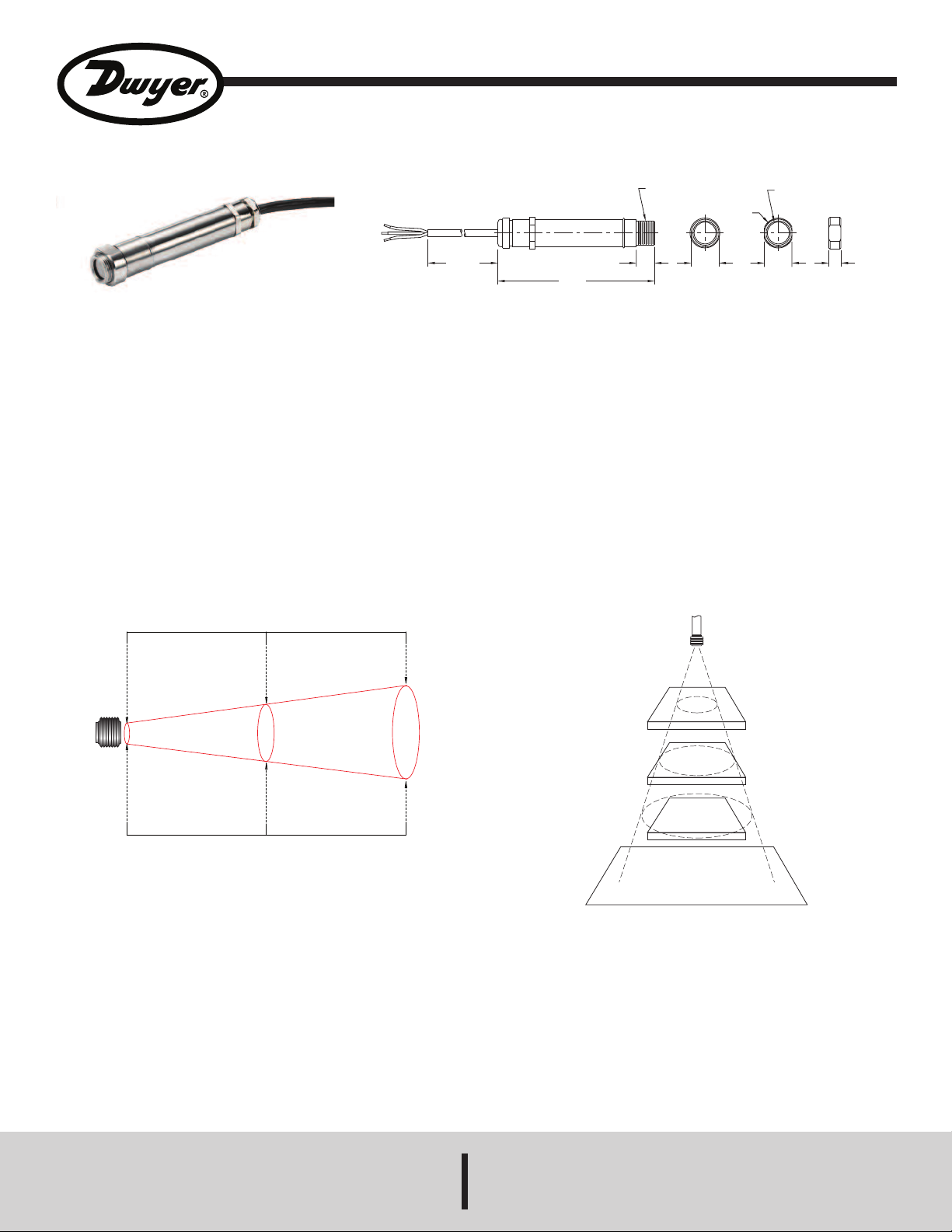

Series ILA In-Line IR Sensor

3 Ft CABLE

[1000]

4-1/16

[103]

15/32

[12]

M16 ULTRA FINE 1.0MM PITCH M16 ULTRA FINE 1.0MM PITCH

NUT

45/64

[18.0]

5/16

[8.0]

23/32

[18]

ø23/32

[18]

Sensor

BEST

GOOD

INCORRECT

Background

Target greater

than spot size

Target equal to

spot size

Target smaller

than spot size

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.9

45.2

78.6

0.5

1.8

3.1

0 19.7 39.4

0 500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 15:1

Specifications - Installation and Operating Instructions

Bulletin E-90-ILA

Dwyer Series ILA non-contact sensors, measure

temperatures from 32 to 932°F (0 to 500°C) and provide a linear

4 to 20 mA, 0 to 50 mVDC or thermocouple output. The 2-wire

signal is compatible with almost any indicator, controller,

recorder, data logger, etc., without the need for special

interfacing or signal conditioning. They are suitable for most

materials such as food, paper, textiles, plastics, leather, tobacco,

pharmaceuticals, chemicals, rubber, coal, and asphalt.

The Optical Chart

The optical chart indicates the nominal target spot diameter at

any given distance from the sensing head and assumes 90%

energy. (See Figure 1).

SPECIFICATIONS

Temperature Range: 32 to 932°F (0 to 500°C).

Accuracy: 1% of reading or 1°C whichever is greater.

Emissivity: 0.95 (Fixed).

Distance to Target Size Ratio: 15:1.

Response Time: 240 ms.

Ambient Operating Temperature: 32 to 158°F (0 to 70°C).

Power Requirement: 24 VDC.

Repeatability: 0.5% of reading or 0.5°C whichever is greater.

Outputs: 4 to 20 mA, 0 to 50 mVDC, J type thermocouples.

Cable Length: 3.3 ft (1 m).

Spectral Response: 8 to 14 microns.

Housing: Stainless steel.

Weight: 3.35 oz (95 g).

Agency Approval: CE.

FIGURE 1

PREPARATION STAGE

Ensure that the sensor is focused on the target only.

Distance and Spot Size

The size of the area (spot size) to be measured determines the

distance between the sensor and the target. The spot size must

not be larger than the target. The sensor should be mounted so

that the measured spot size is smaller than the target. (See

Figure 2).

Atmospheric Quality

Smoke fumes or dust can contaminate the lens and cause errors

in temperature measurement.

Electrical Interference

To minimize electromagnetic interference or “noise” the sensor

should be mounted away from motors and generators.

FIGURE 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

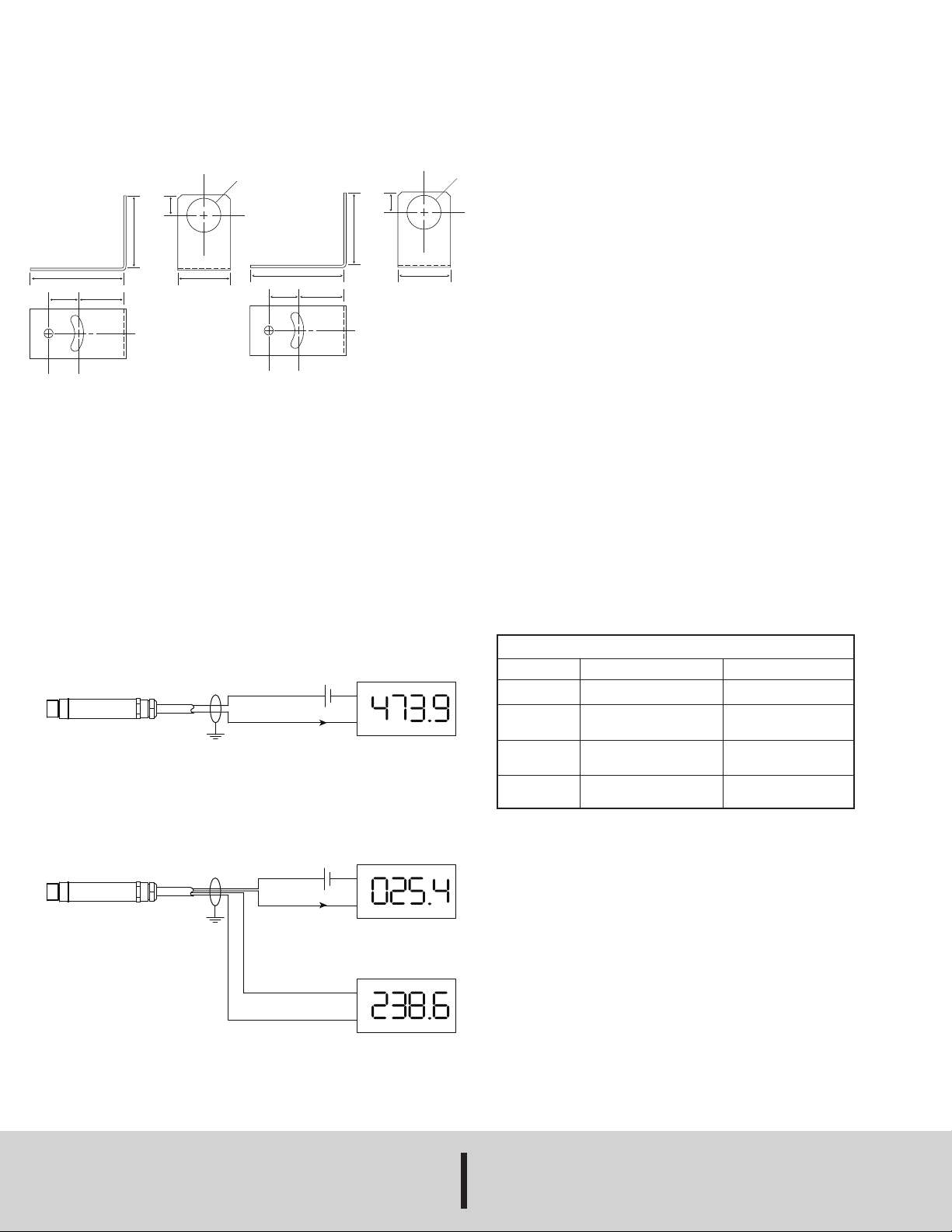

MECHANICAL STAGE

2x Mounting holes M4 clearance

Fixed Bracket

25

10

40

50

15 26

16 DIA

2

2

x Mounting holes M4 clearance

Fixed Bracket

25

10

40

50

15 26

16 DIA

2

+-

-

+

Display/Controller

4-20mA = Target

4-20mA

Temperature

Power Supply

+-

-

+

4-20mA = Sensor

Temperature

Power Supply

-

+

mV/TC = Target

Temperature

Two-wire units (4 to 20 mA models)

Four-wire units (J Type or 0 to 50 mV Outputs)

OP-

OP+

P

WR+

PWR-

PWR+

PWR-

Display/Controller

Display/Controller

4-20mA

All sensors come with a 3.3 ft (1 m) cable and a mounting nut.

The sensor can be mounted on brackets or cut outs of your own

design, or you can use the fixed and adjustable mounting

bracket accessories, which are shown below. (See Figure 3).

FIGURE 3

ELECTRICAL STAGE - WIRING:

Series ILA sensors are available as either two-wire or four-wire

units. J-type and 0 to 50 mV output models transmit the target

temperature as a 0-50 mV or J-Type thermocouple outputs plus

the internal sensor temperature as a 4-20 mA output. This

second 4 to 20 mA output can be used to ensure that the sensor

is being operated within the correct ambient temperature limits

and prevent damage caused by overheating or overcooling. It

can also be used to give an approximate indication of the air

temperature surrounding the sensor.

Note: The cable shield must be grounded at only one point,

which is usually at the controller/indicator. However, it can be

done at a junction box or other suitable location in the field area.

Operation

Once the sensor is in position and the appropriate power, air,

water and cable connections are secure the system is ready for

continuous operation by completing the following simple steps:

. Turn on the power supply.

1

2. Turn on the meter, chart recorder or controller.

3. Read/monitor the temperature.

Important

Be aware of the following when using the sensor:

• If the sensor is exposed to significant changes in ambient

temperature (hot to cold or cold to hot) allow 20 minutes for

the temperature to stabilize before taking or recording

measurements.

• Do not operate the sensor near large electromagnetic fields

(e.g.

around arc welders or induction heaters).

• Wire must be connected only to the appropriate terminals.

MAINTENANCE

Our customer service representatives are available for

application assistance, calibration repair, and solutions to

specific problems. Contact our customer service representatives

before returning any equipment, in many cases, problems can

be solved over the telephone. If the sensor is not performing, as

it should, try to match the symptom to the problem below. If the

table does not help, call Dwyer for further advice.

TROUBLE SHOOTING

Symptom

No Output

Erroneous

Temperature

Erroneous

Temperature

Erroneous

Temperature

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# R0-443516-00 Rev.3

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Probable Cause

No power to sensor

Incorrect wire connection

Faulty sensor

Field of view obstruction

Solution

Check power supply

Check wire color codes

Verify cable continuity

Remove obstruction

Loading...

Loading...