Page 1

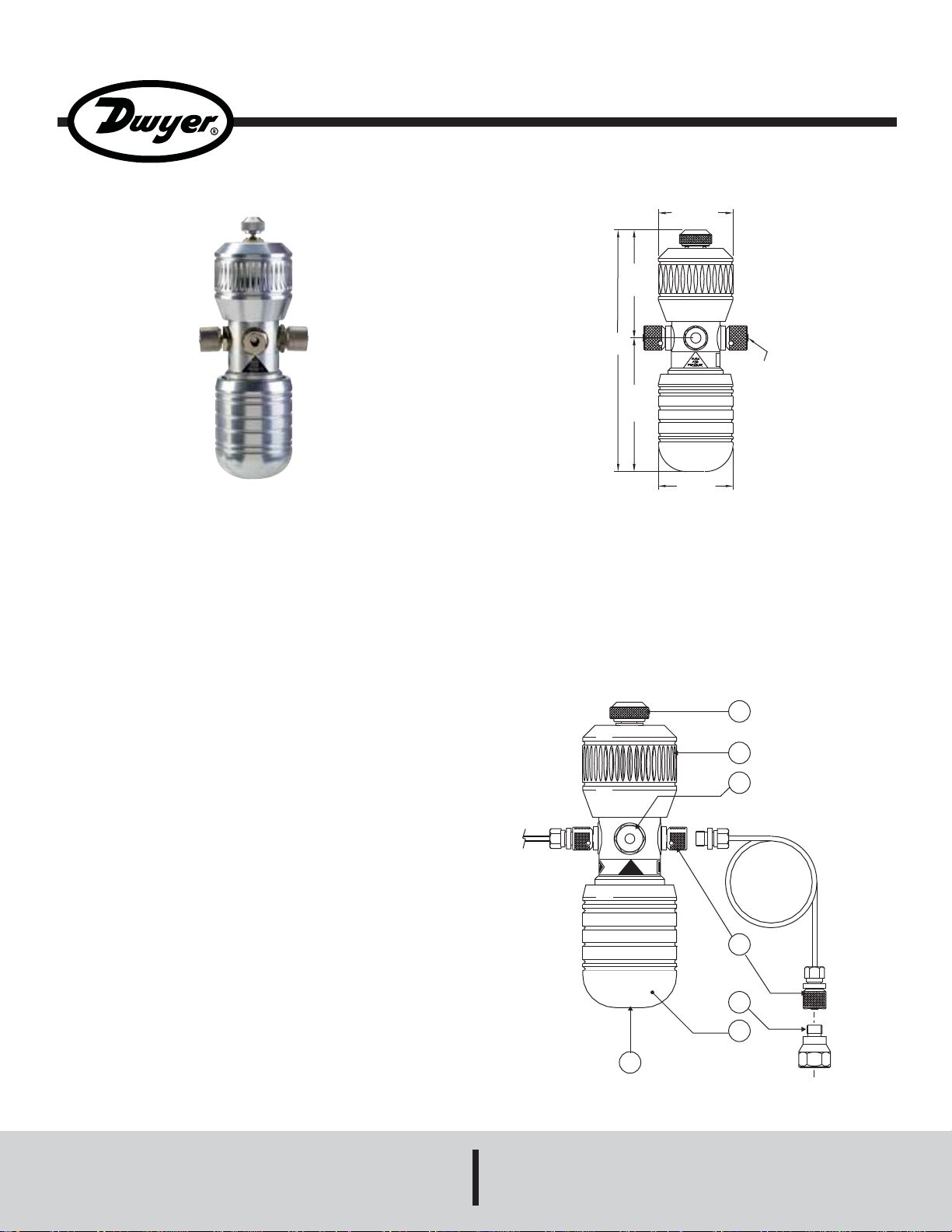

Model HP Hand Pump

Specifications - Operating Instructions

5-29/32

[150]

3-17/64

[83]

MAX

4-1/16

[103]

MAX

Ø1-13/16

[46]

Ø1-13/16

[46]

Bulletin TE-HP

QUICK CONNECT

FITTINGS

The Model HP Hand Pump provides a dual source of pneumatic

pressure and vacuum for verifying the calibration of pressure

instrumentation. Pump can generate pressures up to 45 psi (3 bar) and

vacuum to -27˝ Hg (-910 mbar). The compact pump is designed for

portability and single hand operation.

Model HP features a pressure relief valve and fine adjustment for control

better than 0.0015 psi (0.1 mbar). Pump includes two 39˝ (1 m) hoses

terminating in 1/4˝ female NPT connections and instruction manual.

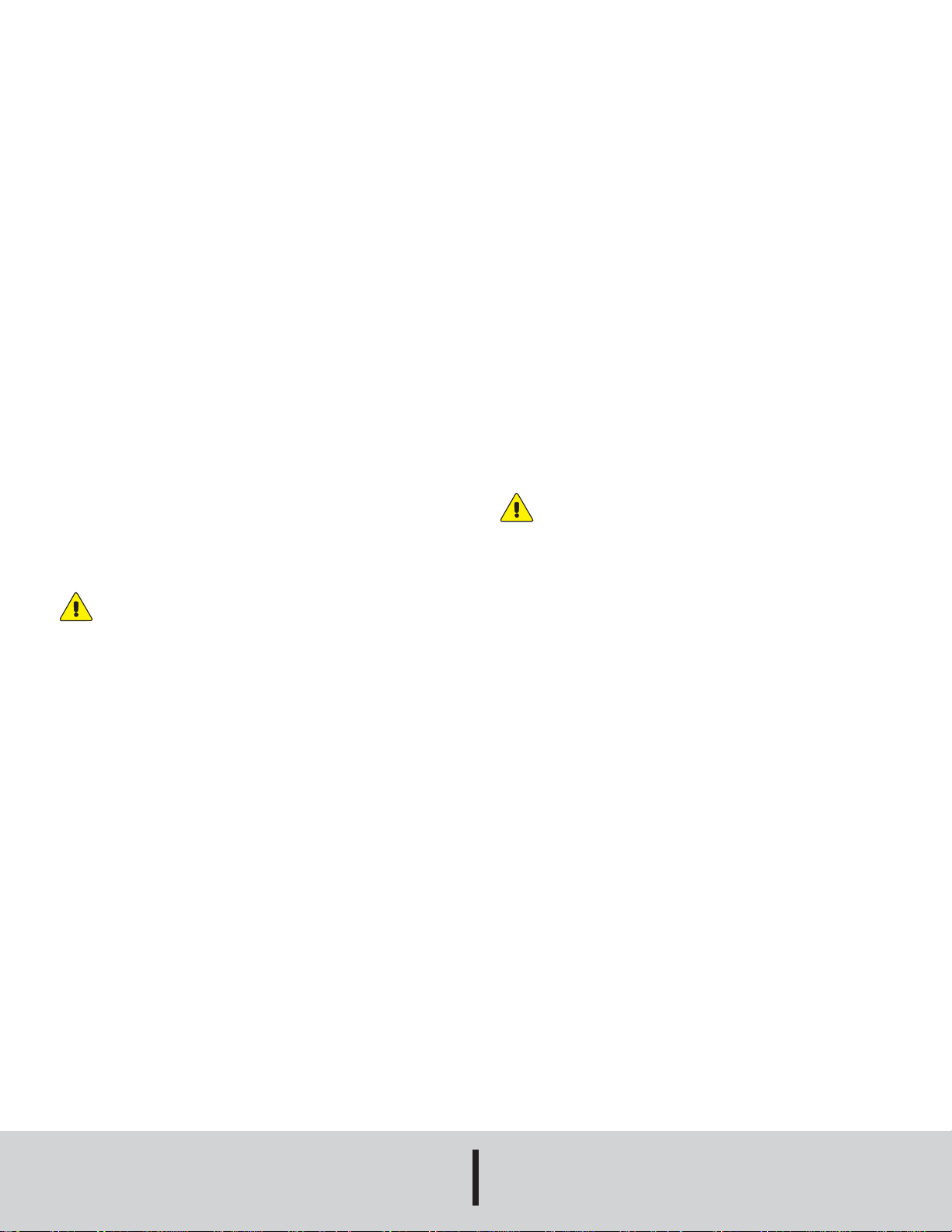

FIGURE 1 KEY:

1. Pressure release valve

2. Fine adjustment control

3. Pressure/vacuum selector

4. Knurled “quick fit” connectors

5. Two flexible hoses to item under test and master instrument

6. NPT adaptor set

7. Pump handle

8. Pressure relief valve

SPECIFICATIONS

Output Ranges: -27˝ Hg to 45 psi (-910 mbar to 3 bar).

Process Connection: 1/4˝ female NPT (quick fit).

Fine Adjustment: Better than 0.0015 psi (0.1 mbar).

Materials: Nickel plated brass and anodized aluminum.

Weight: 20 oz (587 g).

1

2

3

PUSH

FOR

PRESSURE

4

7

5

6

FIGURE 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

DESCRIPTION OF KEY ITEMS

Release Valve (1)

This can be used to reduce or release the pressure in the system. The

rate of pressure reduction is dependent upon the degree of rotation

when opening the valve. Minimal force is required to seal the system.

Fine Adjustment Control (2)

The pressure generated can be finely adjusted by turning the fine

adjustment control (2) in or out to increase or decrease pressure

accordingly.

Important: Do not wind the fine adjustment control (2) any further

when the top of the pump body is visible.

GUIDELINES FOR USE

1. Calibration/comparison against analog gage

1.1 Connect a test gage using appropriate adaptor and sealing to one of

the flexible hoses (5) or directly to body using adaptor (6).

1.2 Connect item under test using appropriate adaptor and sealing to the

second flexible hose (5) or directly to body using adaptor (6).

Note: Adaptors tightened to a maximum torque or 15 Nm.

1.3 Screw fine adjustment control (2) in fully and then out 4-6 full turns.

1.4 Screw pressure valve (1) in fully, tightening to ensure good seal.

Pressure/Vacuum Selection (3)

Press the selector (3) as indicated on the label to engage the desired

mode. Ensure that the Release Valve (1) is open before changing mode.

Pressure Ports (4)

The hoses (5) and adaptors (6) are fitted by simply screwing them into

the connectors (4) by turning the knurled nut on the connector fully anticlockwise.

Adjustable Pressure Release Valve (8)

(For protection of sensitive instruments)

The maximum output pressure can be set using the pressure relief valve

located inside the main Piston, accessed via the handle retaining screw

(adjustment range between 50 mbar and 3 bar).

Note: The pump should only be used for pressurizing small

volumes due to its small displacement. If the pump has not been

used for a period of time, it could be difficult to operate on the first

stroke.

WARNING: Do not connect to external pressure source.

1.5 Using a flat blade screwdriver (2.5 mm wide max), adjust the

pressure relief valve (8) to se the desired maximum output pressure.

Turn the grub screw located in the main piston clockwise to increase or

anti-clockwise to decrease the pressure setting.

1.6 Operate handle (7) until the pressure is close to that finally required.

1.7 Wind the fine adjustment control (2) in to increase pressure or out to

decrease pressure until required pressure is reached.

Note: The pressure may take up to 30 seconds to settle after

increasing pressure due to thermodynamic effects, settling of seals

and expansion of the flexible hose.

CAUTION: STOP unscrewing the fine adjustment control (2)

when the top of the pump body becomes visible.

1.8 Reductions in pressure can also be achieved by careful use of the

pressure release valve (1).

1.9 Vacuum is achieved using the above procedure and having the

pressure/vacuum selector (3) pushed completely towards the vacuum

position.

Note: Release pressure before changing mode.

2. Fault Investigation

In the event that the pump appears to lose pressure then the procedure

above should be repeated ensuring new seals are used, adaptors are

tightened sufficiently and the pressure release valve (1) is tightened

firmly.

Note: The connections to the hand held test system are sealed with

“o” ring or bonded seals and should not leak.

DO NOT attempt to tighten the other fittings to the pump as this could

lead to damage of sealed joints. When testing for leaks it may be noticed

that air is drawn in or expelled from around the pressure/vacuum

selector. This is normal and should cause no concern.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

FR# R6-443775-00

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...