Page 1

Model HHP Hydraulic Hand Pump

Specifications – Operating Instructions

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

BULLETIN TE-HHP

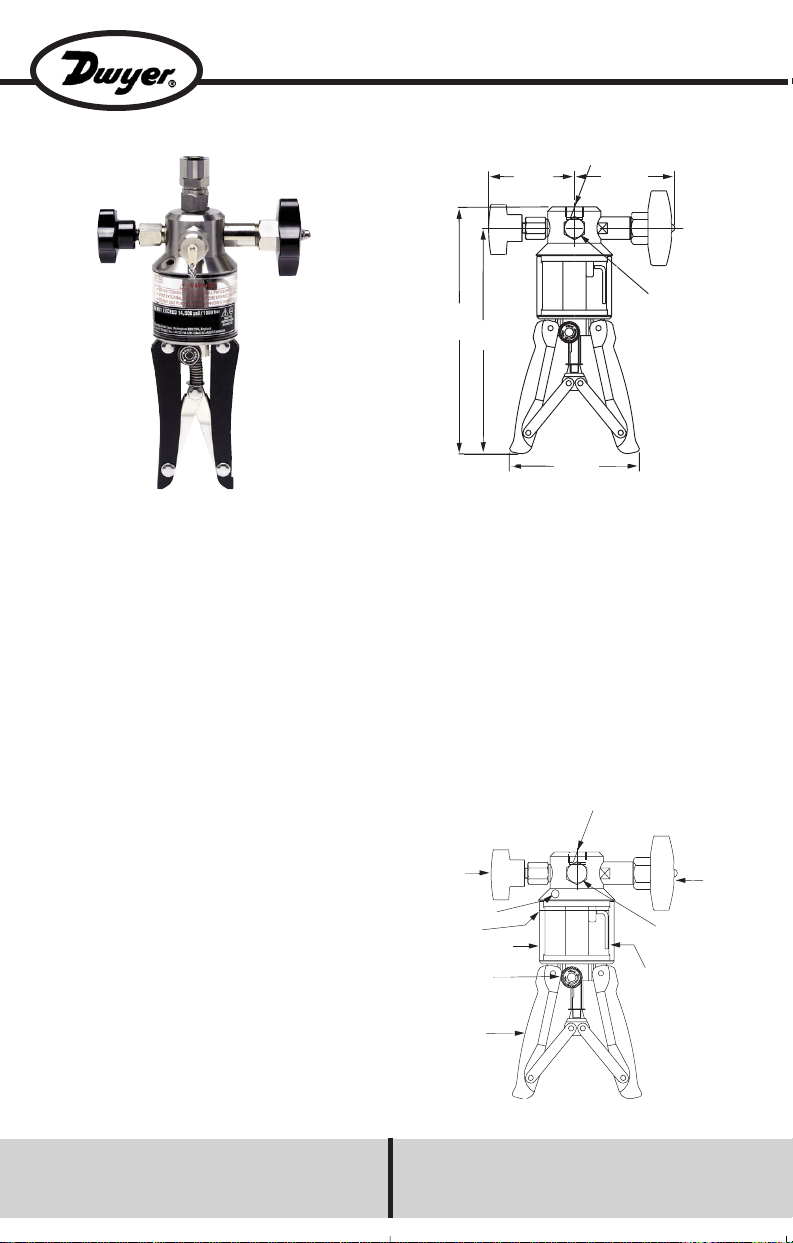

1/4 Female

NPT

8-11/32

[212]

9-1/8

[232]

3-3/16

[81]

4-7/32

[107] MAX

1/4 Female NPT

Pressure Port

4-13/16

[202]

4

3

2

5

6

7

8

10

Recommended

fluid level

(9*)

Fig. 1

SPECIFICATIONS

Output Ranges: 0 to 10,000 psi

(0 to 700 bar).

Process Connection: 1/4˝ female

NPT (quick fit).

Gage Connection: 1/4˝ female NPT.

Materials: Stainless Steel and

tempered glass.

Weight: 3.5 lbs (1.6 kg).

Model HHP Hydraulic Hand Pump generates

pressures up to 10,000 psi (700 bar). Scissor

action pump allows quick priming and pressure

generation. Use in conjunction with an analog or

digital pressure gage for a complete

calibration system.

The pump is designed with a large, see through

reservoir with a capacity of over 4 oz. A variety of

fill liquids can be used including mineral oil,

distilled water, and alcohol. The sealed stainless

steel and tempered glass construction provide

leak free operation.

Model HHP offers adjustable over pressure

protection, fine control, and a unique selector

switch to move from priming to high

pressure generation.

Figure 1 Key:

1. 1/4” NPT female connection to take master

instruments. E.g. Digital/Analog indicators.

2. Pressure release valve.

3. Fine control.

4. Front port: 1/4” NPT female.

5. 100cc’s Reservoir.

6. Reservoir filling plug.

7. Priming/High pressure selector.

8. Fluid inlet tube.

9. Rear port: 1/4˝ NPT female reserved for

valve pressure relief.

10. Pump Handles.

Page 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

©Copyright 2003 Dwyer Instruments, Inc Printed in U.S.A. 5/03

WARNING: HIGH PRESSURE:

Uncontrolled release of high pressure is

hazardous to personnel and may cause

damage to equipment. Before

connection of any pressure component

to the HHP ensure that the

component(s) is/are isolated from the

pressure supply and any internal

pressure is released slowly. Do not

connect HHP to external pressure

source. Pressure built up internally

during use can be extremely high,

ensure that all connections are

made correctly.

GUIDELINES FOR USE:

1. Remove filling plug (6) and fill reservoir

(5) to the recommended level with the

appropriate fluid and replace plug.

2. Connect master instrument to pump via

connection (1) using the appropriate seals

and adaptors.

3. Connect instrument under test to

flexible hose/gage adaptor and attach to

pump via the quick-fit connection (4).

4. Adjust the Fine control (3) to

‘mid-travel’.

5. Ensure the pressure release valve (2) is

open (turn fully clockwise then one turn

anti-clockwise). Fully squeeze handles ‘in’

and turn the selector (7) to the

‘prime’ position.

6. Operate handles several times to expel

air from the pump. (Ensure that the fluid

inlet tube (8) remains immersed in fluid at

all times).

7. Close the release valve (2) fully

clockwise.

8. Prime system by squeezing handles

together and then releasing, allowing the

oil to enter the pump cylinder. Repeat as

necessary until system is fully primed and

low pressure is indicated on either the

master or test instrument.

9. With handles fully squeezed ‘in’ select

the ‘high’ pressure position on selector (7)

and operate handles to generate

approximate pressure.

Note: Smaller handle strokes enable

easier pressure generation at

high pressures.

10. Adjust pressure to required value

using the fine control (3).

Note: Pressure will fall slightly,

immediately after pressure generation due

to thermodynamic effects, but will stabilize

after a short time.

Warning: Do not exceed maximum

operating pressure indicated on pump

label!

11. To totally release pressure from the

system turn release valve (2) one turn anticlockwise and select the ‘prime’ position

on selector (7) after first squeezing

handles fully in.

Note: Careful use of the release valve (2)

and fine control (3) enable a controlled

release of pressure, essential for

calibration purposes.

12. RESERVOIR FLUID LEVEL: If the fluid

level in the reservoir falls considerably

during use, a partial vacuum can be

created in the reservoir which may affect

the pump performance. To avoid this,

simply allow air to enter the reservoir by

partly unscrewing the filling plug (6).

13. SEAL REPLACEMENT: Dependent on

the frequency of use, the Main Piston Seal

(and others) will need replacing. Call

factory for replacement seal.

Loading...

Loading...