Page 1

Series HFO Flow Alarm

Specifications – Operating Instructions

Bulletin F-HFO

Series HFO Flow Alarms are typically used to

make or break a set of electrical contacts to

signal a limit setting. They may be used to turn

on a warning light, sound a bell or horn, or even

to shut down a process. The switches on the

flow alarm can be configured to open or close a

contact for an increasing or decreasing set

point. Decreasing flow set points may be

located anywhere in the lower 2/3 of the scale

while increasing set points may be located

anywhere in the upper 2/3 of the scale.

Note: Refer to Series HF In-Line Flow Monitor,

Bulletin F-55, “Installation and Operating

Instructions” for installation, operation, and

cleaning instructions for the basic flow monitor

cartridge (included). The following instructions

are specifically for the Series HFO Flow Alarm

switches.

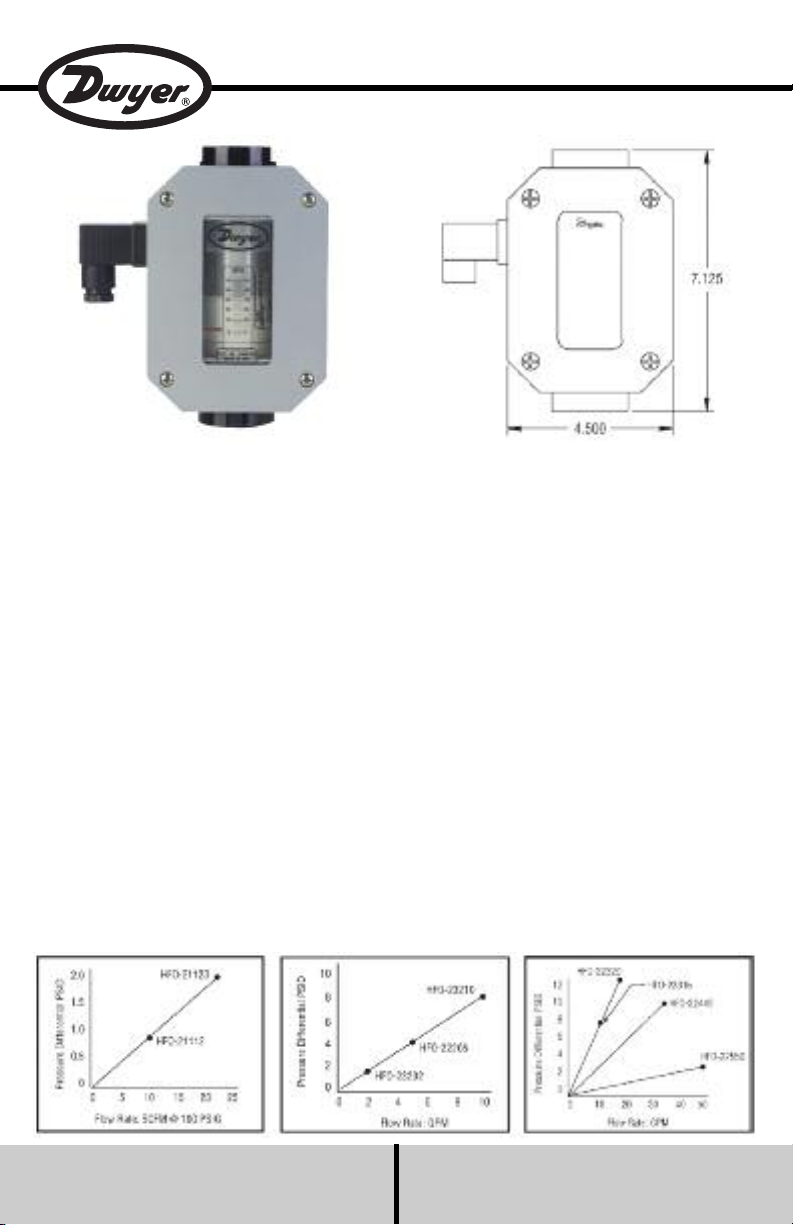

PRESSURE DIFFERENTIAL VS. FLOW RATE

1/4˝ FEMALE NPT 1/2˝ FEMALE NPT 3/4˝, 1˝ & 1-1/2˝ FEMALE NPT

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Materials: Body: Aluminum, brass or

304 SS; Seals: Buna-N or Fluoroelastomer;

Magnet: PTFE coated Alnico; Other internal

parts: 304 SS.

Viscosity Limit: 500 SSU.

Temperature Limits: 170°F (76°C).

Pressure Limits: See Chart.

Enclosure Rating: NEMA 4X (IP65).

Accuracy: Measuring ±4% FS over entire

range; ±2.5% over center third of the

measuring range.

Repeatability: ±1% of full scale.

Switch Type: SPDT, 10A @ 250 VAC; 0.5A @

125 VDC (resistive), 1/4 hp @ 250 VAC

(inductive); 3A @ 125 VAC “L” lamp load.

Shipping Weight: 1/4 to 1/2˝ female NPT

Models: 3 lb (1.4 kg); 3/4 to 1˝ female NPT

Models: 4.5 lb (2.0 kg); 1-1/2˝ female NPT

Models: 12 lb (5.4 kg).

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

Operation:

44 44

2

222

6666

88

1

100

88

1

100

GGPPMM

P

OINTER

S

S WWIITTCC HH GG LL II DDEE

SS CC RR EE WW

FF LL OO WW RR AA TT EE

SS CC AA LL EE

AA LL AARRMM

S

S WWIITTCC HH

FF LL OO WW IINNDDIICC AA TT OORR

L

L IINN EE

F

F OO LL LLOO WWEERR

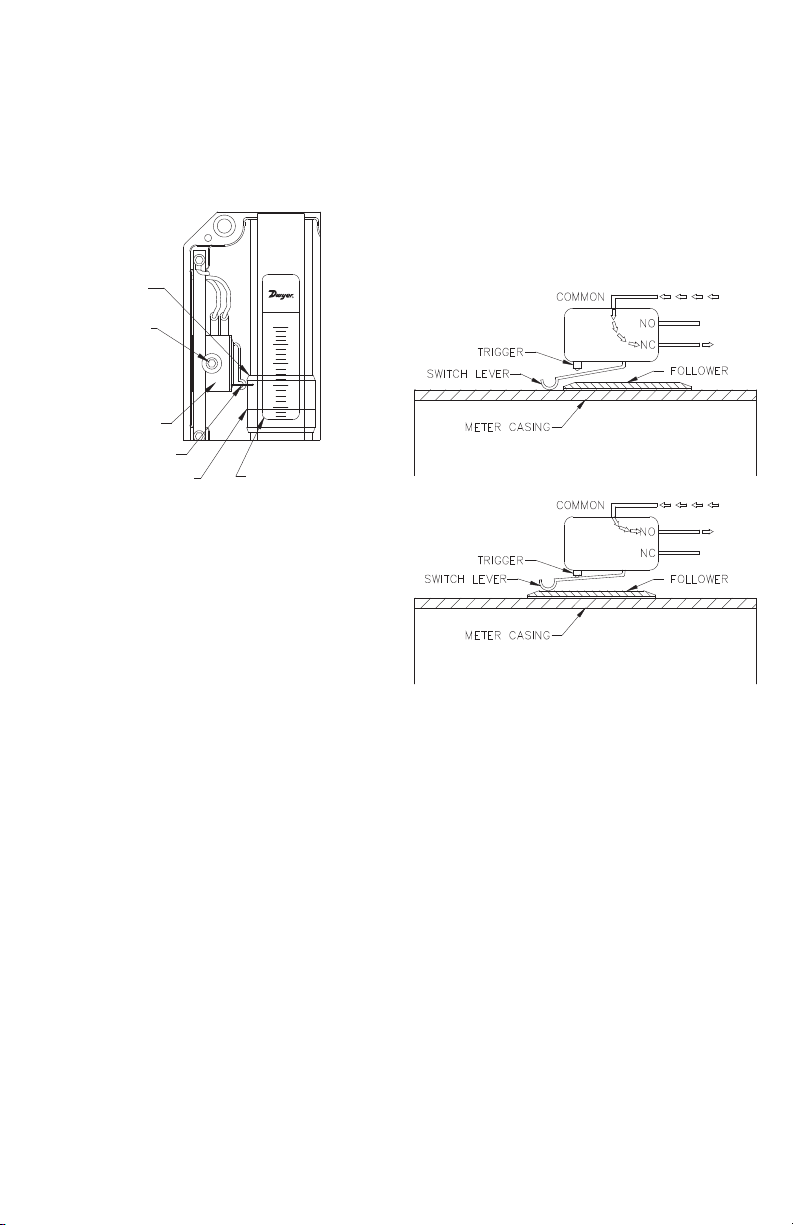

Illustration 1 shows the primary mechanism for

a single flow alarm. The HFO dual-switch flow

alarms contain two sets of these same

components (wiring to the DIN connector is

described on page 3). The configuration is such

that the high alarm is for increasing flow, and the

low alarm is for decreasing flow.

Illustration 1

The follower moves in unison with an orifice

plate inside of the unit’s pressure vessel via a

magnetic coupling in order to indicate flow rate.

As the follower moves with changes in flow rate,

the flow rate is determined by relating the

position of the flow indicator line to the

increments on the flow rate scale.

The pointer indicates the set point for the alarm

switch. In Illustration 1, the switch will be

actuated at all flow rates below 4 GPM. To

change the set point, simply loosen the switch

glide screw one (1) turn and slide the switch to

the desired position along the flow rate scale.

When the pointer is pointing to the desired flow

rate, re-tighten the switch glide screw.

Switches:

The switch is a simulated roller, lever operated

low force microswitch. The specifications for this

switch are listed on the first page. The switch is

actuated when movement of the follower

causes the switch lever to be lifted. In Illustration

2, the switch has not yet been actuated, and the

electrical circuit is through the normally closed

(NC) contact. Illustration 3 shows the switch

after it has been actuated. In this scenario, the

electrical circuit is through the normally open

(NO) contact.

Illustration 2

Illustration 3

Page 3

Precautions:

• Be certain to properly ground the unit via the

ground (G) pin located on the unit’s DIN

connector.

• In order to avoid accidentally removing the

switch glide screw, never loosen it by more than

one or two turns. This screw can be difficult to

replace if accidentally removed.

• Avoid over tightening the switch glide screw.

• When the switch adjustments are complete,

make certain that the wires that are attached to

the switch have not been moved into a location

that will interfere with the follower or the switch

lever.

• Do not make any modifications to the unit’s

internal wiring.

Electrical Connections:

Standard Flow Alarms are pre-wired with 4-pin

DIN connectors which consist of a male section

as shown in Illustration 4 and the female section

shown in Illustration 5. To open the female

section, first remove the screw, then lift the

connector portion out of the casing by inserting

the head of a screwdriver into the

slot marked for that purpose. Illustration 6

shows the disassembled female section.

Illustration 4

Illustration 5

Illustration 7 shows the connections for the low

alarm switch as the unit is shipped from the

factory. The wiring code below identifies how

the DIN connector is configured for dual alarms.

If the NC contacts are needed for either switch,

a simple adjustment must be performed. On the

switch itself, disconnect the NO lead from the

quick connect terminal, and place it onto the NC

contact. This will change the operating condition

of that particular alarm switch.

Illustration 7, Low Alarm

Wiring Code: Dual Switch Alarm

White Both Common Terminal #1 of DIN

Black Decreasing N.O. Terminal #2 of DIN

Contact

Red Increasing N.O. Terminal #3 of DIN

Contact

Green Enclosure Ground Terminal “G” of DIN

Illustration 6

Page 4

STANDARD CONTROL CIRCUITS

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 5/12 FR# R1-443344-00 Rev. 4

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...