Page 1

Bulletin F-DTFA

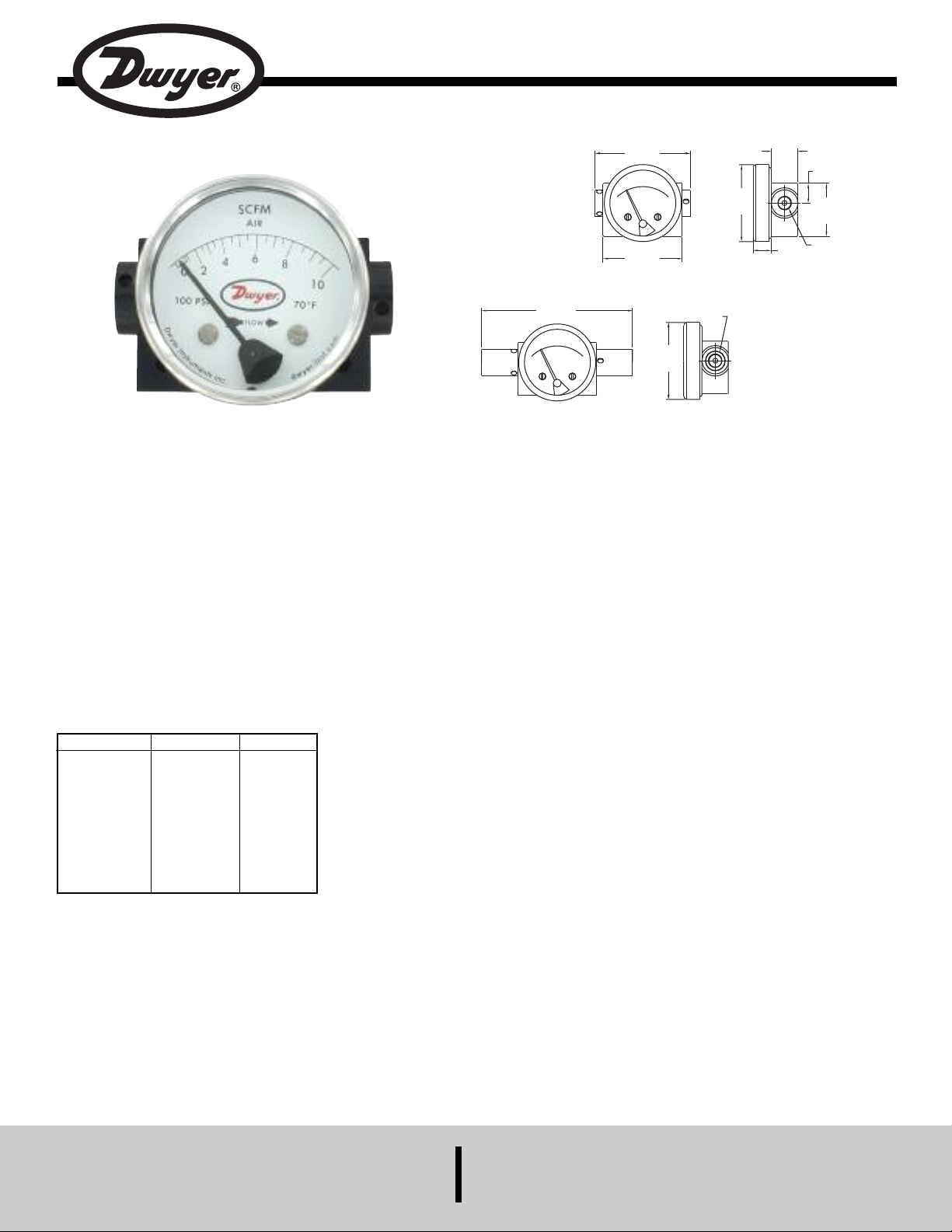

1/2˝ NPT PROCESS CONNECTION

5-47/64

[145.54]

Ø

2-59/64

[

74.17]

1

/2˝ NPT

I

NLET & OUTLET

1/4˝ NPT CONNECTION

3-19/32

[91.44]

1

[25.40]

3

[76.20]

11/16

[17.53]

1/4˝ NPT

INLET & OUTLET

3

/4

[

19.05]

2

[50.80]

Ø

2-59/64

[

74.17]

Series DTFA Variable-Area Flowmeter for Gases

Specifications - Installation and Operating Instructions

The Series DTFA Variable-Area Flowmeter for Gases measures gas

rates with ±5% of full-scale accuracy at an affordable price. Rugged

aluminum construction ensures great compatibility and the strength to

withstand system pressures of up to 3000 psig (200 bar). With a wide

variety of flow ranges available, the Series DTFA can be used with many

different applications all at an economical price.

Calibration

All Series DTFA Variable-Area Flowmeters for Gases are calibrated at

the factory for mounting in the horizontal position and should be installed

that way for maximum accuracy.

The unit will normally retain its accuracy tolerance for the useful life of

the device. If you want to check the accuracy, do so only with

instruments of certified accuracy. Do not attempt to check accuracy with

other flowmeters piped in series. Even minor variations in piping and

back pressure can cause significant differences in indication. If in doubt,

return the flowmeter to the factory for a calibration check.

Model

DTFA-1A-10A

DTFA-1A-15A

DTFA-1A-20A

DTFA-1A-25A

DTFA-2A-30A

DTFA-2A-40A

DTFA-2A-50A

DTFA-2A-75A

DTFA-2A-100A

Range, SCFM

1.5 to 10

2.0 to 15

3.0 to 20

3.0 to 25

3.0 to 30

4.0 to 40

4.0 to 50

5.0 to 75

10.0 to 100

Connection

1/4˝ NPT

1/4˝ NPT

1/4˝ NPT

1/4˝ NPT

1/2˝ NPT

1/2˝ NPT

1/2˝ NPT

1/2˝ NPT

1/2˝ NPT

SPECIFICATIONS

Service: Compatible gases.

Wetted Materials:

Body: Aluminum;

Spring: 302 SS;

Range spring: 302 SS;

Magnet: PTFE-coated;

Metering cone: Acetal;

Seals: Buna.

Temperature Limits: -40 to 200°F (-40 to 93°C).

Pressure Limit: 3000 psig (200 bar).

Accuracy: ±5% FS.

Repeatability: ±1% FS.

Size: Diameter dial face 2.5˝ (63.5 mm).

Process Connections: See model chart.

Weight: DTFA-1A: 3 lb (1.36 kg); DTFA-2A: 5 lb (2.27 kg).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Location

Select a location where the flowmeter can be easily read and where the

temperature will not exceed 200°F (93°C). The mounting surface and

piping to the flowmeter should be free from excessive vibration. If pulsing

flow or vibration causes excessive pointer oscillation, contact factory for

ways to provide additional dampening.

Operation

If the media is likely to be dirty, it is recommended that a 50–micron filter is

placed upstream of the inlet port to assure a clean fluid flows medium

through the flowmeter. After all connections are complete, introduce flow as

slowly as possible to avoid damage. No lubrication or periodic servicing is

required. Keep case exterior, including front cover, clean for best visibility.

Because the device operates through a magnetic coupling system,

magnetic material near the flow block can affect accuracy. To minimize the

effect of outside interference, keep magnetic materials at least 3 inches

(7.6 cm) away from the unit.

Inlet Piping

It is a good practice to have the inlet port of the flowmeter be as free of

elbows, restrictions and size changes as possible. Inlet piping should be as

close to the flowmeter connection size as possible to avoid possible

turbulence which can occur with drastic size changes. The length of the

inlet piping has very little effect on normal pressure fed flowmeters.

For vacuum service the inlet piping should be as short and open as

possible to allow operation at or near atmospheric pressure, thus

maintaining the accuracy of the device. Note that for vacuum service, any

flow control valve must be installed on the discharge side of the flowmeter.

Outlet Piping

Piping on the outlet port should be at least as large as the flowmeter

connection. For gas and air service flowmeters such as the DTFA, the

piping should be as large and short as possible. This is so pressure within

the device will be at or near atmospheric for maximum accuracy.

MAINTENANCE/REPAIR

Upon final installation of the Series DTFA, no routine maintenance is

required. The Series DTFA is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number

before shipping the product back for repair. Be sure to include a brief

description of the problem plus any additional application notes.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 3/12 FR# R4-443968-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...