Page 1

Series DSS Direct-Contact Speed Switch

ø4-3/4

(120.65)

4-7/8

(123.83)

FRONT VIEW

SIDE VIEW

2

(50.8)

1-17/64

(32.03)

8

-63/64

(228.09)

3/4” NPT PIPE TAP

BOTH SIDES

REAR VIEW

7/8

(22.23)

2

-1/2

(63.50)

1-1/4

(31.75)

MOUNTING HOLE PLAN

2-1/4

(57.15)

Specifications - Installation and Operating Instructions

Bulletin E-17

The Series DSS Direct-Contact Speed Switch is a compact switch

designed to include all mechanical and electronic components in one

housing. It will produce an output signal at a predetermined speed which

may be either over-speed, under-speed or zero-speed. Rugged, heavyduty construction combined with solid state electronics and photo-electric technology makes this one of the most advanced motion detectors

available. Series DSS protects all valuable rotating equipment including

belt conveyors, bucket elevators, rotary feeders or screw conveyors. It

operates in a clockwise or counter-clockwise direction and mounts in

any position.

SPECIFICATIONS

Temperature Limits: -50° to 150°F (-45° to 65°C).

Enclosure: Aluminum with screw cover

Enclosure Rating: DSS-W: NEMA 3S, 4 & 4X. DSS-E: NEMA 3S, 4 &

4X, NEMA 7: Class I groups C & D, NEMA 9: Class II groups F & G.

Switch Type: DPDT.

Electrical Rating: 3A @ 120/240 VAC, 1/10 Hp @120/240 VAC.

Electrical Connections: Screw terminal.

Conduit Connections: (2) 3/4” female NPT.

Mounting Orientation: Any.

Set Point Adjustment: Adjustment screw.

Power Requirements: 105-135 VAC, 50/60 Hz, 210-250 VAC, 50/60

Hz; or 24 VAC/DC depending on model.

Power Consumption: 3 watts.

Repeatability: 2% maximum at constant voltage and temperature.

Pick-up Point: 3 speed ranges at which relay will energize:

Low: 0.1 to 10 RPM;

Medium: 1 to 100 RPM;

High: 10 to 1000 RPM.

Signal Point: Speed at which relay will de-energize. Recommended to

be 15-20% lower than pick-up point.

Start-up Delay: Adjustable up to 45 seconds.

Radial Load on Input Shaft: 125 lbs maximum.

End Thrust on Input Shaft: 100 lbs maximum.

Rotation: Either clockwise or counter-clockwise.

Driving Torque: 1”/lb maximum.

Shaft: 5/8” diameter with 3/16” x 7/8” key.

Weight: 5 lbs (2.3 kg).

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

OPERATING PRINCIPLE

Note: Switch should be concentric with

t

The model CMS motion switch can be driven by one of the following

If

a stub shaft is required, we suggest the use of a 5/8” stub shaft. Use with a

s

The Series DSS Motion Switch senses motion by means of a precision

metal disc mounted on the input shaft. This disc generates measurable

light pulses by a series of slots on its periphery, which rotate past an

infrared light source. A photo-electric sensor monitors the series of light

pulses and converts them to digital electronic signals. Solid state circuitry then analyzes the digital signals and activates or de-activates the output relay at the pre-set speed.

Field adjustment of the signal set point is easily accomplished by means

of an adjustment screw on the electronics. For under-speed sensing, the

signal point is set below the normal operating speed of the unit. The output relay will then de-energize if the speed drops below the signal point.

For over-speed sensing, the pick-up point is set above the normal operating speed. The output relay will energize if the speed exceeds the pickup point. Zero-speed sensing can be accomplished by turning the adjustment screw to its minimum setting. The output relay will then de-energize

when the shaft speed of the unit approaches zero.

INSTALLATION

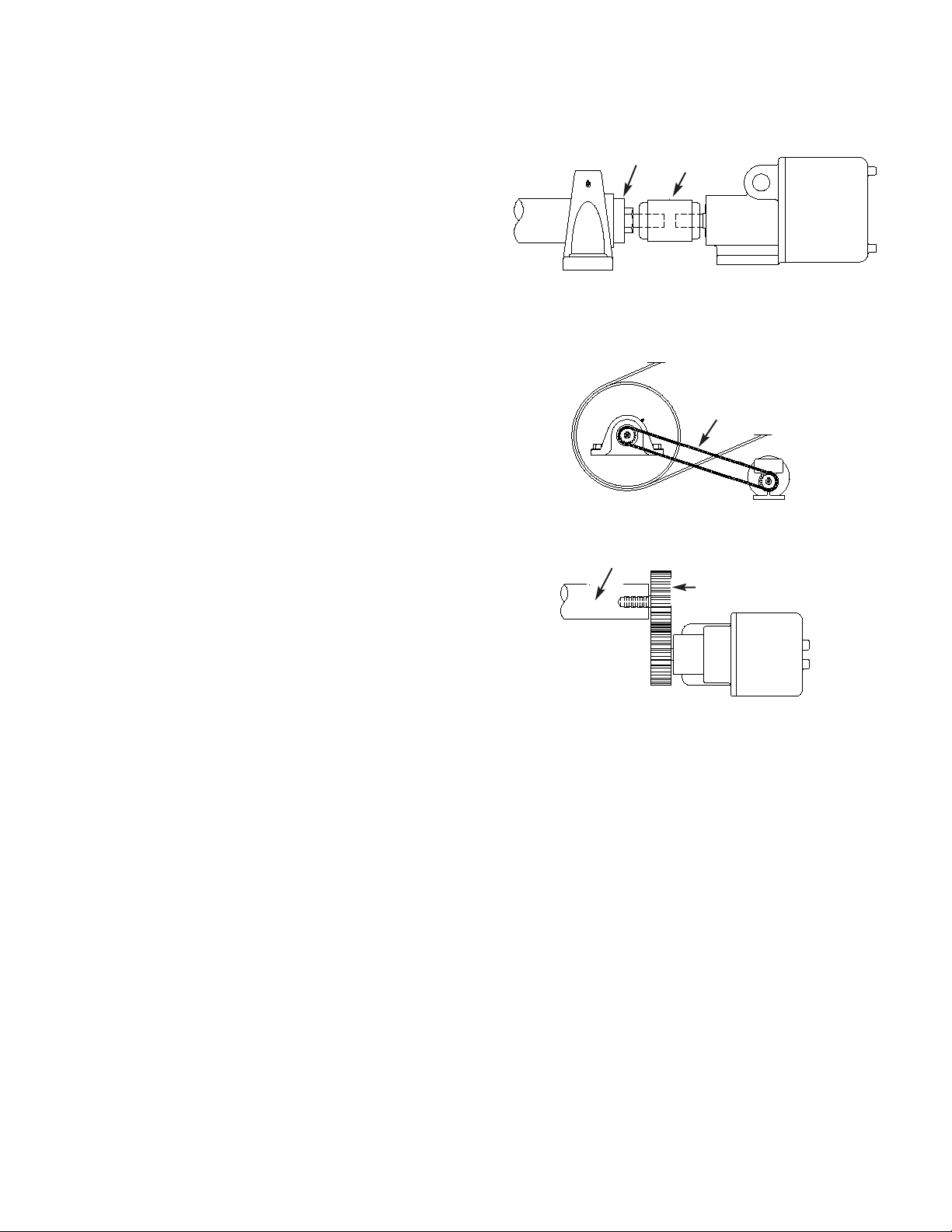

1. FIGURE 1: Suggested Coupling Arrangement, side view. Direct connection through a coupling (preferred means). Note: Switch should be

concentric with the mating shaft. If stub is used, it must be concentric

with the main shaft. If a stub shaft is required, we suggest the use of a

5/8” stub shaft. Use with a split or flexible type coupling.

ustomer’s shaft with

C

concentric stub shaft

Flexible coupling

2. FIGURE 2: Cog Belt Drive (timing) or Roller Chain Drive: A V-Belt drive

is not as desirable because of possible slippage.

LOCATION & MOUNTING

The Series DSS motion switch can be mounted for operation in any position. The surface to which the switch is affixed should be as flat and as

smooth as possible. Bearing brackets and shim plate sets can be used

to mount the unit directly to the pillow block supporting a shaft. On installations where vibration conditions are not extreme, use 1/4” diameter

machine bolts with lock washers through the four mounting holes in the

base of the switch. (Mounting bolts and lock washers are not furnished

with the switch.) If vibration conditions are extreme, use of a doweling is

recommended through two mounting holes in the switch base. The

switch should be mounted as axially in line, and/or parallel as possible to

the existing shaft, which is to drive the switch. The Series DSS motion

switch can be driven by one of the following means:

Cog belt (timing) or

roller chain drive

3. FIGURE 3: Suggested Spur Gear Arrangement (top view)

ustomer’s shaft with

C

oncentric stub shaft

c

Spur gears

Page 3

WIRING

FIGURE 4: Electronics View

ormally closed 2

N

Common 1

2

L

L

1

Time Delay

peed Range

S

L

H

M

Use only solid conductors

f 14 AWG of smaller

o

peed set point

S

ndicates relay energized

I

Green LED

Yellow LED

Indicates pulses

Normally open 2

ormally open 1

N

Normally closed 1

Common 1

Remove end cap to expose terminals and pick-up speed adjustment

screw. Wire input power from source to terminals L1 & L2. Be certain to

use the provided ground screw. The output of the Series DSS is a DPDT

relay. There are two sets of output contacts. Each set includes normally

open, normally closed and common. As a result, the unit can be used to

control two separate circuits such as a motor starter and a signal light.

CONDUIT INSTALLATION:

Use only hubs of suitable sizes that are UL/CSA approved for WATERTIGHT use. Install per the hub manufacturer’s instructions. Be sure the

location selected will provide adequate wire bending space.

SIGNAL SET POINT

FOR USE AS AN UNDER-SPEED SWITCH:

Select the speed range required by changing the switch to LOW for 0.1

to 10 RPM, MEDIUM for 1 to 100 RPM and HIGH for 10 to 1000 RPM.

Turn the set point potentiometer to the counter-clockwise stop. With

motion present on the input shaft and at normal operating RPM, the yellow LED should blink. The green LED should turn on indicating that the

output relay is energized. Slowly turn the set point adjustment screw

clockwise until the output relay de-energizes. (A “click” will occur at this

point.) Back up until the output relay energizes. Thus, when speed drops

below the set point, the green LED should turn off indicating that the output relay is de-energized. If the normal operating speed of the input shaft

exceeds 10 RPM for the LOW, 100 RPM for the MEDIUM or 1000 RPM

for the HIGH, the unit should be adjusted as follows. Turn the set point

adjustment screw clockwise until it reaches the stop. When the speed

drops below 10 RPM for the HIGH, the relay will energize.

NOTE: Typically, the motor contact is wired in series with one of the NO

output contacts and an alarm is wired with one of the NC output contacts.

FOR USE AS AN OVER-SPEED SWITCH:

Select the speed range required by changing the switch to LOW for 0.1

to 10 RPM, MEDIUM for 1 to 100 RPM and HIGH for 10 to 1000 RPM.

Turn the set point potentiometer to the counter-clockwise stop. With

motion present on the input shaft and at normal operating RPM, the yellow LED should turn on indicating that the output relay is energized.

Slowly turn the set point adjustment screw clockwise until the output

relay de-energizes and the green LED turns off. (A “click will occur at this

point.) with the potentiometer on that setting, if the speed increases the

output relay will energize.

NOTE: Typically, the motor contact is wired in series with one of the NO

output contacts and an alarm is wired with one of the NC output contacts.

FOR USE AS A ZERO-SPEED SWITCH:

Select the LOW speed range by changing the switch to LOW for 0.1 to

10 RPM. Turn the set point potentiometer to the counter-clockwise stop.

This will give a set point of 0.1 RPM. Thus, when the speed drops below

0.1 RPM, the output relay will de-energize.

NOTE: Wiring should be the same as for under-speed applications.

Page 4

TIME DELAY SETTING

The Series DSS motion switch has a start-up delay that is adjustable up

to 45 seconds. This setting should be set, depending on the application

and the length of time it takes for the conveyor to reach its normal operating RPM. This time delay takes effect upon power-up of the Series

DSS after shutdown. AC power to the Series DSS must be interrupted for

timer to be reset. This delay only effects start-up, avoiding nuisance

start-up alarms.

TROUBLESHOOTING PROBLEMS & SOLUTIONS

PROBLEM: SOLUTION:

No pulses from yellow LED: Check power supply.

Make sure input shaft is turning.

PROBLEM: SOLUTION:

Relay is not energized or de-energized: Check power supply. When

expected. (I.e. green LED not on: Make sure input shaft is turning. Or off

when expected.) Check for proper set point.

Check for proper speed setting.

(LOW, MEDIUM or HIGH)

PROBLEM: SOLUTION:

Alarm sounds when equipment is started: Check start-up delay setting.

Check for proper connections between alarm and relay. AC power must

be interrupted for alarm to reset.

PROBLEM: SOLUTION:

Alarm does not go off when expected: Check power supply. Check for

proper connections between alarm and relay.

MAINTENANCE

Upon final installation of the Series DSS Direct-Contact Speed Switch,

no routine maintenance is required. A periodic check of the system calibration is recommended. The Series DSS is not field serviceable and

should be returned if repair is needed (field repair should not be attempted and may void warranty). Be sure to include a brief description of the

problem plus any relevant application notes. Contact customer service to

receive a return goods authorization number before shipping.

PROBLEM: SOLUTION:

Equipment is not shut off when expected: Check power supply. Check for

proper connections between control circuit and relay.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# R6-443493-00 Rev. 1

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...