Page 1

Series DPML-4 LCD Digital Panel Meters

P Models

°

F

°C

PSI

%

V

A

KW

PF

1

-9/64

[

29]

2.390 REAR HOUSING

[60.6]

2

-13/32

[

61]

1

[25.4]

2

-35/64

[

64.5]

1

/8

[

3]

6

3/64

[

25.1]

1-5/8

[41.1]

P

ANEL CUTOUT FOR

W

INDOW MOUNTING

1

*

P Models

V

A

KW

PF

1

13

°F

°C

PSI

%

Specifications - Installation and Operating Instructions

Bulletin G-61

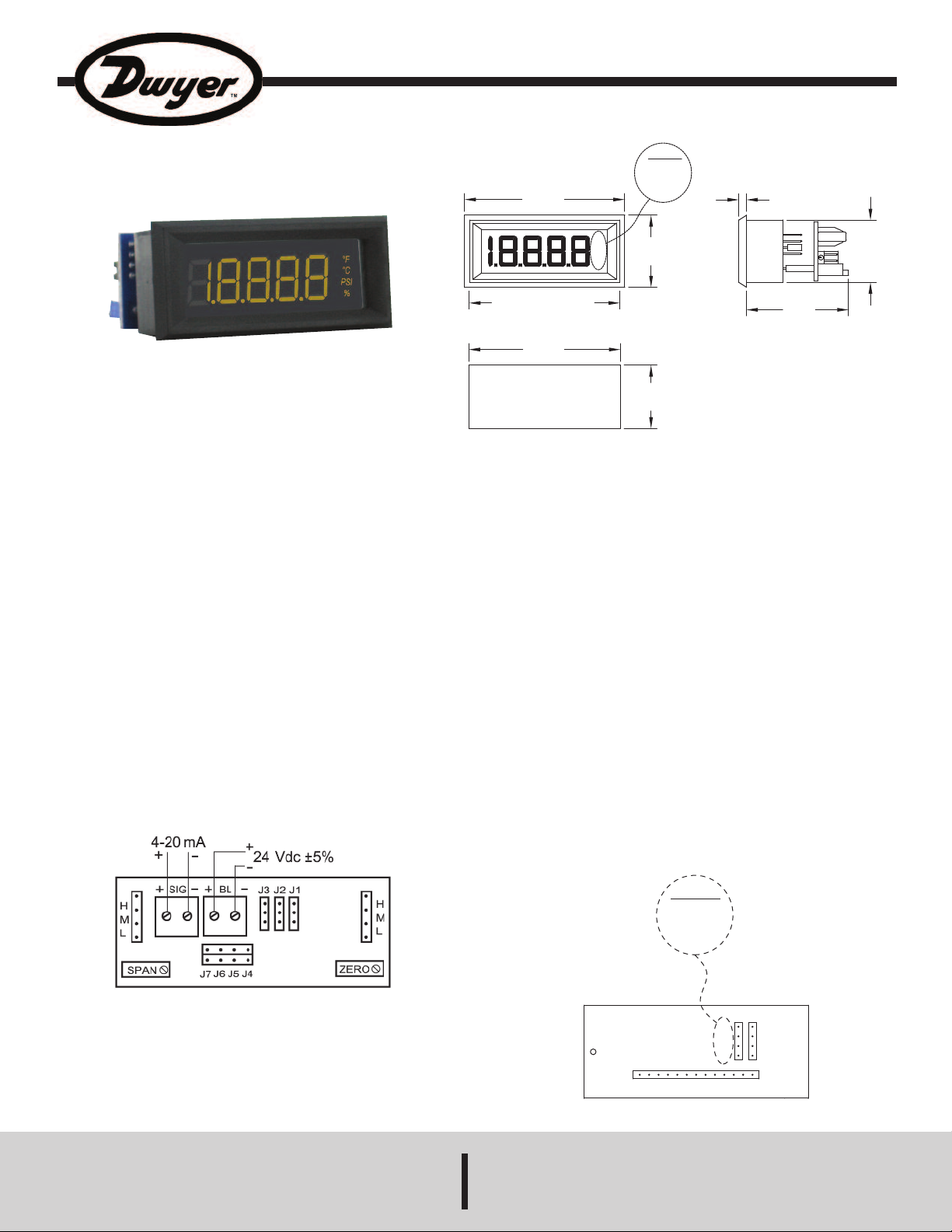

The Series DPML-4 LCD Digital Panel Meter offers a large 4-1/2 digit

LCD display with a choice of red, amber or green segments for easy

viewing at a distance. The meter accepts loop powered 4-20 mA DC

input. Standard features include field engineering units and decimal

point positions. A separate 24 VDC power supply is required for the

operation of the back light.

INSTALLATION

The Series DPML-4 is designed to snap into a 2.4˝ (61 mm) W x 1˝ (25.4

mm) H panel cutout. No additional hardware is required.

WIRING

The unit is powered by a 4-20 mA loop and the screw terminal for wiring

is located on the back of the adder board marked with + SIG -. The

backlighting requires a 24 VDC power supply and should be connected

to terminals identified with + B/L -.

Backlight setting min/max display values

SPECIFICATIONS

Inputs: 4 to 20 mA.

Input Impedance: 300Ω nominal.

Accuracy: ±(0.1% FS + 2 count).

Power Supply: Powered by control loop.

Backlight Power Supply: 24 VDC @ 35 mA typical.

Span and Zero: Adjustable (±19999 counts).

Display: 4-1/2 digits, 7 segments, 0.45˝ (11.4 mm) H.

Decimal Points: 4-position, user selectable.

Engineering Units: DPML-XXX: °F, °C, %, PSI; DPML-XXXP: V, A,

KW, PF.

Polarity: Automatic, “-” displayed.

Operating Temperature: 32 to 122°F (0 to 50°C).

Storage Temperature: -4 to 158°F (-20 to 70°C)

Mounting: Snap-in bezel mount.

Connection: Screw terminals.

Conversion Rate: 3 per second.

Warm-Up: 10 minutes typical.

Weight: 2 oz (56.7 g).

Agency Approvals: RoHS.

OPERATION

Selecting Engineering Units

Four sets of jumper pins are located in the back of the meter, between

the meter and the adder board. Move the jumper to fit over the

appropriate pins which correspond to the desired engineering unit. See

Figure 2.

FIGURE 1

Note: If backlight supply is not loop supply, ground should be referenced

together.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

FIGURE 2

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

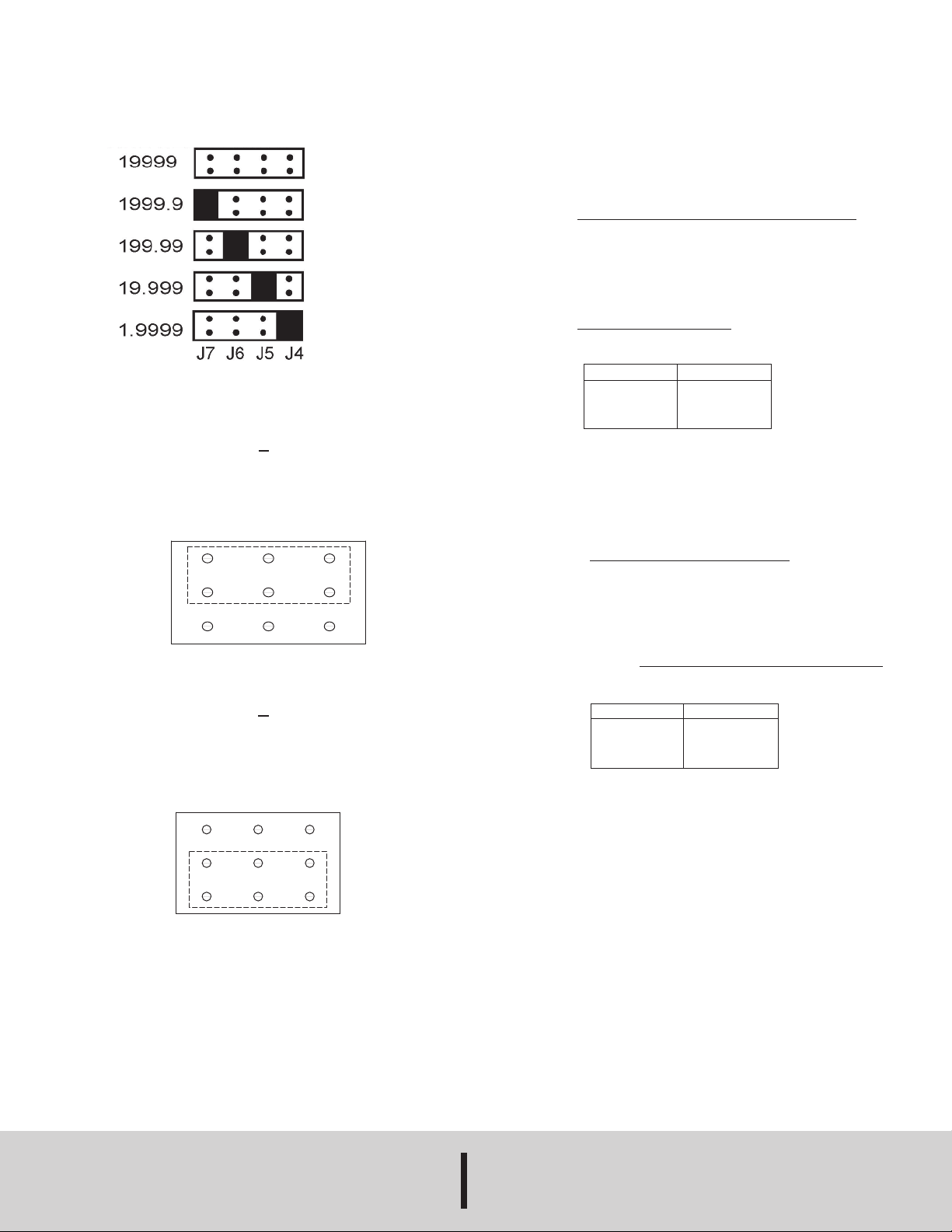

Selecting Decimal Point Position

A

J3 J2

J1

B

A

J3 J2

J1

B

Five decimal point positions are available on the digital process meter,

J4-J7. Move the jumper to correspond to the desired decimal point

location. See Figure 3.

Span & Zero Adjustment

The unit is equipped with a span adjustment and a zero to L,M,H. Use

the potentiometer for the zero adjustment.

Span Adjustment:

If:

Min Display is ≤ 0 or

Min Display is > 0 and Max Display ÷ Min Display > 5

Then:

Span Factor = 2.5 (Max Display - Min Display)

4000 + 0.02 (Min Display) - 0.004 (Max Display)

If:

Min Display is > 0 and Max Display ÷ Min Display ≤ 5

Then:

Span factor = Max Display - Min Display

1600

FIGURE 3

Setting Min/Max Display Value J1, J2, J3 (See Figures 4 & 5):

If:

Min Display is ≤ 0 or

Min Display is > 0 and Max Display Min Display > 5

Then:

J1, J2 & J3 should be all set to the top jumper (see Figure 4).

If:

Min Display is > 0 and Max Display Min Display ≤ 5

Then:

J1, J2 & J3 should be all set to the bottom jumper (see Figure 5).

•

•

FIGURE 4

•

•

Span Factor

0-12

10-22

22-32

Zero Adjustment:

If:

Min Display is ≤ 0 or

Min Display is > 0 and Max Display ÷ Min Display > 5

Then:

Zero Factor = (250,000 + Min Display) x 83,834

If:

Min Display is > 0 and Max Display ÷ Min Display ≤ 5

Then:

Zero Factor =

MAINTENANCE/REPAIR

Upon final installation of the Series DPML-4, no routine maintenance is

required. The Series DPML-4 is not field serviceable and should be

returned if repair is needed. Field repair should not be attempted and

may void warranty.

[]

(250,000 + 400 (Span Factor))

10,634 -

(Min Display - 400 (Span Factor)) x 83,834

[]

Zero Factor

0-3994

3320-7314

6640-10634

Set Jumpers

L

M

H

- 73,200

250,000

Set Jumpers

H

M

L

WARRANTY/RETURN

FIGURE 5

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR # R2-443466-00 Rev. 4

DWYER INSTRUMENTS, INC.

Refer to “Terms and Conditions of Sale” in our catalog and on our

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...