Page 1

Bulletin J-25

Particu late Moni tori n g Sy s tems

DPM

Particulate Monitoring

Systems

DPM Control Units

PMS Sensors

INSTALLATION & OPERATING

MANUAL

Dwyer Instruments, Inc.

102 Indiana Highway 212

P.O. Box 373

Michigan City, IN 46361 USA

Telephone 800-872-9141

www.dwyer-inst.com

Page 2

Particu late Moni tori n g Sy s tems Installation & Operating Manual

I. Technical Support & Return Procedure

Dwyer Instruments, Inc. provides industry leading technical support for all product lines. The

technical support department is staffed with a team of engineering professionals.

Areas of assistance provided by the Technical Support department include:

• Pre-Installation Site Analysis

• Product Installation

• General Operation

• Application Specific

• Routine Calibration

• EPA Compliance

• Performance Upgrades and Add-On Features

To ensure the best and most efficient technical support please be prepared with the following

information prior to contacting Dwyer Instruments, Inc. If it is determined that the component must be

returned for evaluation/repair, a Return Material Authorization number will be issued. You must

include the RMA number on the packing slip and mark the outside of the shipping container.

• Company Name ________________________________________

• Product Model Number ________________________________________

• Product Serial Number ________________________________________

• Date of Installation ________________________________________

• Reason for Return ________________________________________

Dwyer Instruments Technical Support may be reached by:

Phone: (800) 872-9141

Fax: (219) 872-9057

E-Mail: tech@dwyer-inst.com

Hours of Operation: 8AM – 5PM Central Standard Time

• Any control unit or particulate sensor that was exposed to hazardous materials in a process

must be properly cleaned in accordance with OSHA standards and a Material Safety Data

Sheet (MSDS) completed before it is returned to the factory.

• All shipments returned to the factory must be sent by prepaid transportation.

• All shipments will be returned F.O.B. factory.

• Returns will not be accepted without a Return Material Authorization number.

Document No. 209-1025-D ii ©2007

Page 3

Particu late Moni tori n g Sy s tems Installation & Operating Manual

II. Notifications

This document contains important information necessary for proper operation of the product.

It is strongly urged that all users of the product read this manual in its entirety. All instructions

should be followed properly and any questions that arise should be discussed with Dwye r

Instruments, Inc .

Any use or distribution of this document without the express consent of Dwyer Instruments,

Inc. is strictly prohibited. Any reproduction is prohibited without written permission.

In no event will Dwyer Instruments, Inc. be liable for any mistake, including lost profits, lost

savings, environmental compliance costs or other incidental or consequential damages arising

out of the use or inability to use this manual, even if advised of the possibility of such damages,

or an y claim b y any oth er par ty.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

Warning statements help you to:

• Identify a hazard

• Avoid a hazard

• Recognize the consequences

Identifies information that is critical for successful application and

IMPORTANT

Identifies information, sections or statements in this manual that apply to

understanding of the product.

approved hazardous area systems, regulations or installation.

Document No. 209-1025-D iii ©2007

Page 4

Particu late Moni tori n g Sy s tems Installation & Operating Manual

III. Approvals and Certifications

CE Conformant

The Control Units and Particulate Sensors conform to the appropriate country standards and

governing regulations listed below:

• EN 61010/1993 “Safety requirements for electrical equipment for measurement, control

and laboratory use.”

• EN 55011/1991 “Limits and methods of measurement of radio interference

characteristics of industrial, scientific and medical equipment”. Class A: Industrial and

commercial.

• EN50082-1/1993 “Electromagnetic compatibility – Generic immunity standard”. Part 1:

Residential, commercial and light industry.

CSA Certified

This Particulate Monitoring system is certified by the Canadian Standards Association (to

US and Canadian Standards) for use in hazardous locations as specified below:

Particulat e Se nsor:

Intrinsically Safe for Hazardous Locations

PMS-AHZ1 Intrinsically Safe Particulate Sensor in the following areas:

Class I, Division 1, Groups A, B, C, and D

Class II, Division 1, Groups E, F, G

Class III

For use with the Control Units listed below, 70ºC maximum ambient.

Note: There is no temperature rise caused by electrical components. Temperature

code is based only on ambient temperature, (e.g. a 200°C process requires a T3

rating.)

Control Unit:

For use in Ordinary Locations Only

DPM-AHZ1 Control Unit rated 115 Vac/230 Vac, 0.1A or 24Vdc, 0.25A, -25ºC to

70°C, with intrinsically-safe output to Particulate Sensor.

DPM-AHZ1 Control Unit - Approved for use with PMS-AHZ1

sensors, where the PMS-AHZ1 sensor is the only component located in

the hazardous area.

Document No. 209-1025-D iv ©2007

Page 5

Particu late Moni tori n g Sy s tems Installation & Operating Manual

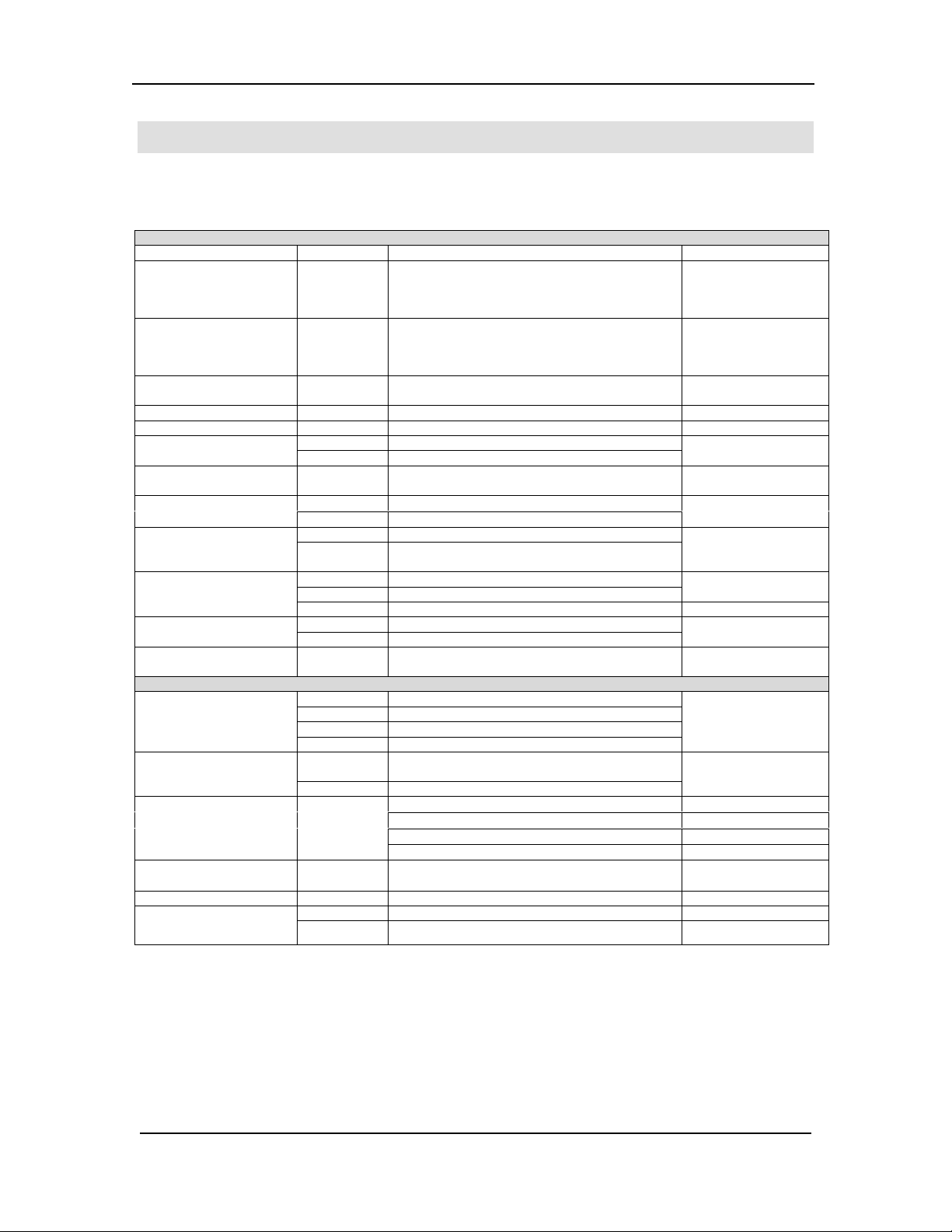

IV. Specifications

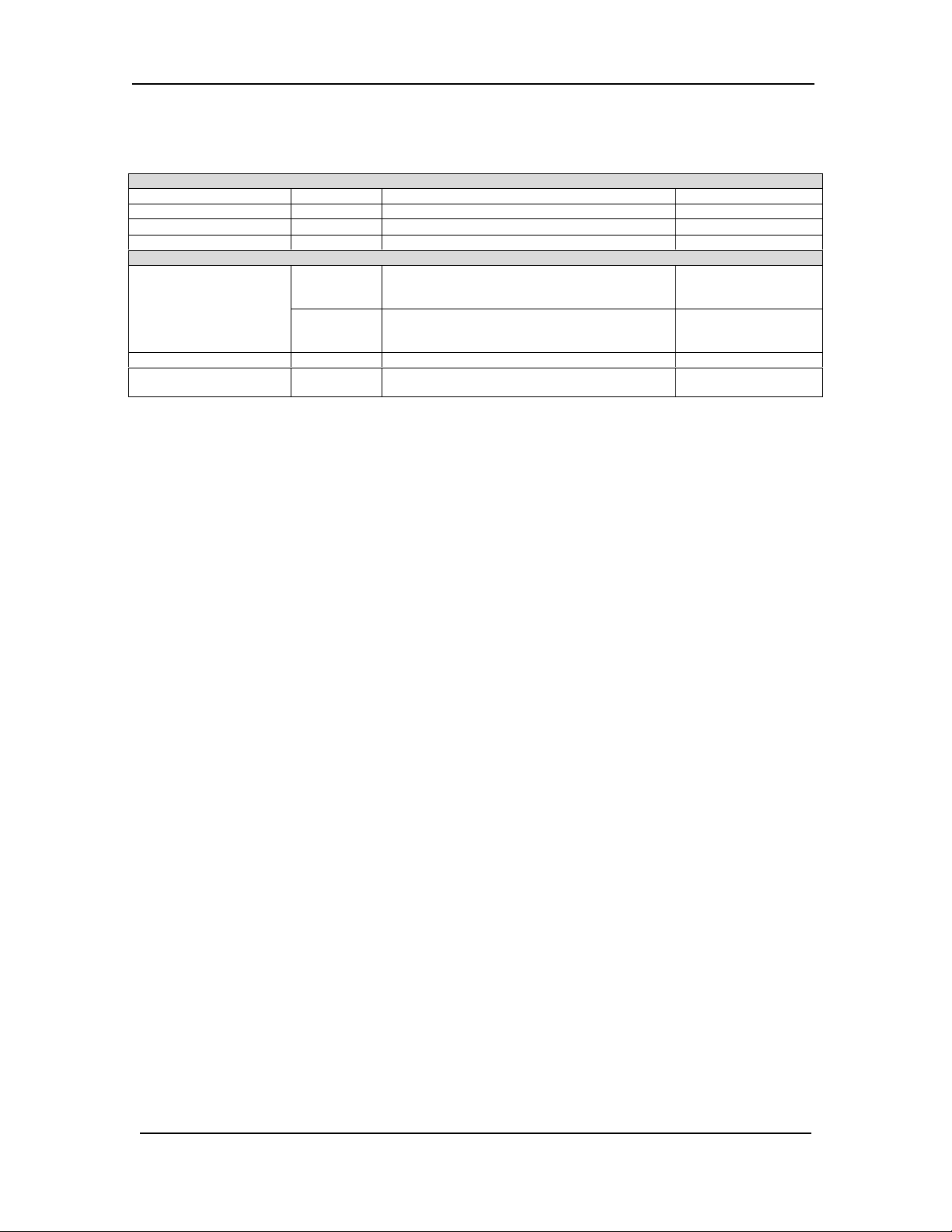

PARAMETER DETAIL SPECIFICATION NOTE

Input Voltage 115V~

230V~

24VDC

Input P ower 6 Watts Max.

Measurement Units picoamperes (pA) 1 x 10 ⎯ ¹² Amp

Detection Level/Range

Electronic Accuracy

Temperature Range

Relay Outputs

4-20mA Output (Optional)

RS-485 Network (Optional)

Enclosure Type

Mounting

Materials

Process Temperature Range Operating

Ambient Temperature Range Operating

Pressure Range Operating Full Vacuum to 10PSI (2.11kg/cm²) Higher Optional

Enclosure

Standard 5.0pA – 5000pA

Optional 0.5pA – 5000pA

Operating

Storage

Type Form A (SPST)

Rating

Type Isolated

Rating 470Ω Max. Loop Impedance

Span Adjustable Via Keypad Default: 1000pA LOG

Type Isolated, Multi-drop, ½ Duplex

Settings 19,200 BPS, 8 Data Bits, 1 Stop Bit, No Parity

NPT ½” NPT Thread

QC 1.5” Quick-Clamp (Mounting ferrule is 1” NPT)

FL ANSI Flange (2”, 150# is typical)

Other Others Available

Probe

Nipple/Mount Stainless Steel

Type Painted Cast Aluminum Other - Consult Factory

Rating NEMA 4X (IP 66) Other - Consult Factory

CONTROL UNIT

97–132V~, 47–63Hz

Fuse: 0.032A, Slo-Blo 250V, Type ‘T’

Fuse: 0.050A, Slo-Blo 250V, Type ‘T’ when Self

Check Option is installed

195–264V~, 47–63Hz

Fuse: 0.032A, Slo-Blo 250V, Type ‘T’

Fuse: 0.050A, Slo-Blo 250V, Type ‘T’ when Self

Check Option is installed

22–26VDC

Fuse: 0.250A, 250V, Type ‘T’

± 5% of Range, std

± 1% of Range, optional

-13°F to +160°F (-25°C to +70°C)

-40°F to +185°F (-40°C to +85°C)

5A @ 240V~ Resistive **Customer must provide a

8A (maximum) fuse in series with relay load.

Painted Cast Aluminum NEMA 4X or optional CSA

Approved Enclosure

PARTICULATE SENSOR

Stainless Steel

With Protective Teflon Layer

-40°F to +250°F (-40°C to +120°C)

-40°F to +450°F (-40°C to +232°C)

-40°F to +800°F (-40°C to +426°C)

> 800°F

-40°F to +160°F Maximu m (-40 °C to +70°C)

Maximum Must be Calculated for each application

Selector Switch to 115V

Selector Switch to 230V

No Select or Swit ch

Optional Model

Over Fu ll Temp Range

Modbus/RTU Protocol

Other optional

Other optional

Higher Optional

T-Code Ratings for

AHZ1 option only

Document No. 209-1025-D

Page v ©2007

Page 6

Particu late Moni tori n g Sy s tems Installation & Operating Manual

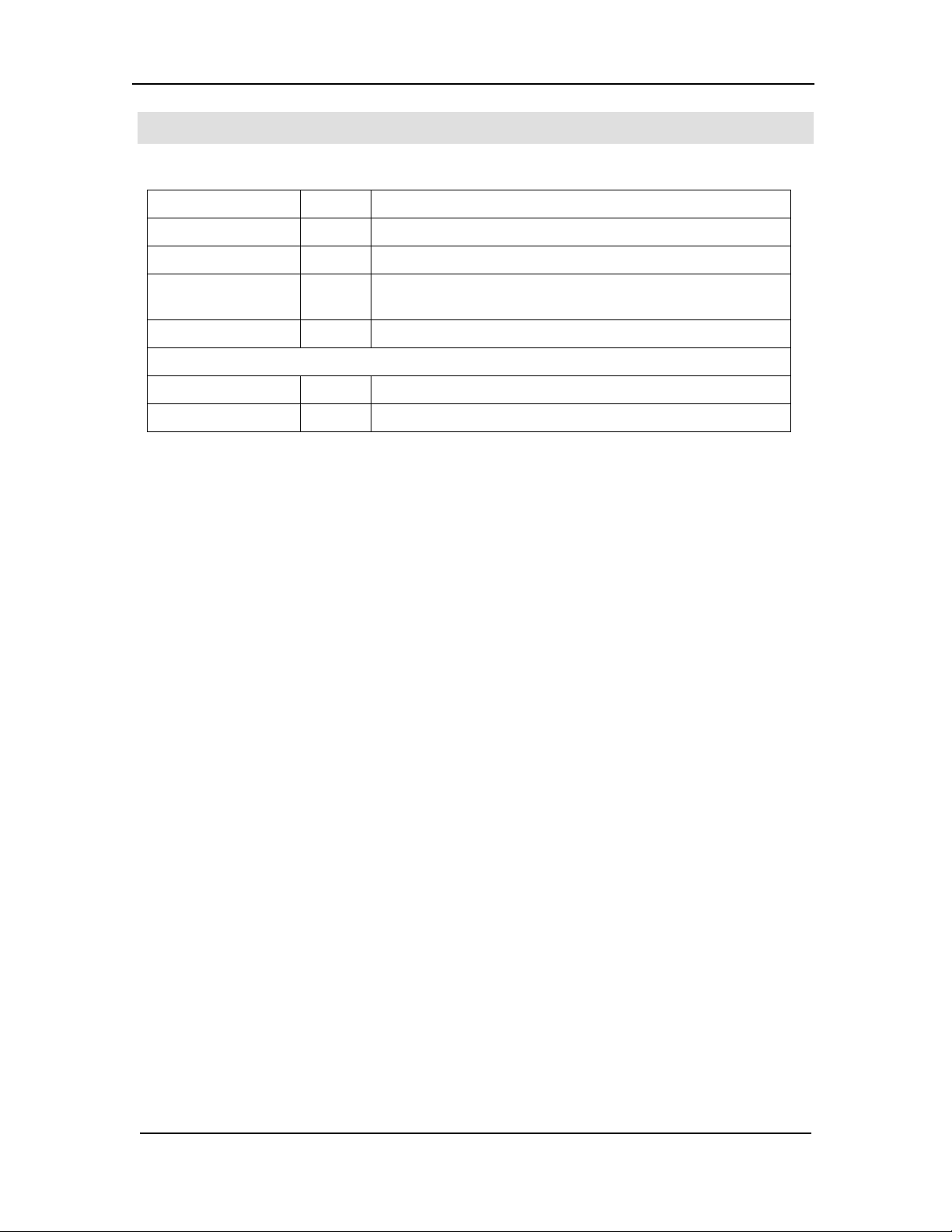

PARAMETER DETAIL SPECIFICATION NOTE

Type High Quality Coaxial

Temperature Range

Maximum Len gth 300 ft.

Approximate Particulate

Concentration

Velocity Range 150 ft/min. (45.7 m/min.) and Higher

Particle Size Range

Operating

DETECTION LEVEL/RESO LUTI ON AND APPLICATION RANGE

5.0pA

Standard

0.5pA

Upgrade

PARTICULATE SENSOR CABLE

-40°F to +392°F (-40°C to +200°C)

At least 5.0 – 5000 mg/m³

At least 0.002 to 2.0 gr/ft³

At least 0.5 to 5000 mg/m³

At least 0.0002 to 0.2 gr/ft³

0.3 Micron and higher

If <10.0 Micron, 0.5pA Detection Required

Barely Visible to Visible

>5% Opacity

Moderate Dilute Flow

Invisible to Barely

Visible, < 5% Opacity

Light Dilute Flow

Document No. 209-1025-D

Page vi ©2007

Page 7

Particu late Moni tori n g Sy s tems Installation & Operating Manual

V. Installation Drawings

Drawing Number Sheets Description

225-1016-01 2 Particulate Monitor Installation Drawings

225-1014-06 1 Particulate Flow Sensor Installation Drawing, All Mounts

225-1036 1 High Temperature / High Pressure Particulate Flow Sensor

Installation Drawing

Hazardous Area Control Drawing

225-1005 1 Hazardous Area Control Drawing

Document No. 209-1025-D

Page vii ©2007

Page 8

Particu late Moni tori n g Sy s tems Installation & Operating Manual

TABLE OF CONTENTS

1.

Safety...............................................................................................................................................2

1.1 Applicable Use.......................................................................................................................... 2

1.2 General.....................................................................................................................................2

1.3 Hazardous Area Systems........................................................................................................... 3

2. Introduction.................................................................................................................................... 4

3. Control Unit Installation.................................................................................................................5

3.1 Location.................................................................................................................................... 5

3.2 Wiring.......................................................................................................................................5

3.3 Grounding................................................................................................................................. 6

4. Particulate Sensor Installation........................................................................................................7

4.1 Location.................................................................................................................................... 7

4.2 Mounting....................................................................................................................... ........... 8

4.3 Senso r Te mperatu re Considerations...........................................................................................9

5. Particulate Sensor Coaxial Cable Installation.............................................................................. 10

6. Control Unit Operation.................................................................................................................12

6.1 User Interface Overview.......................................................................................................... 12

6.2 Menu 1 Setup..........................................................................................................................13

6.3 Menu 2 Setup..........................................................................................................................14

6.4 Menu 3 Setup..........................................................................................................................16

6.5 Long Term Averaging.............................................................................................................17

6.6 4-20mA Analog Output Scaling............................................................................................... 18

6.7 Interpreting Particulate Readings for Fabric Filter Applications................................................ 20

6.8 Alarm Levels for Fabric Filter Applications ............................................................................. 22

7. Manual System Zero Check.......................................................................................................... 23

8. Automatic Self Checks.................................................................................................................. 26

8.1 Control Unit Hardware Check..................................................................................................26

8.2 Control Unit Zero Check.........................................................................................................27

8.3 Control Unit Span Check.........................................................................................................28

8.4 Sensor Cable Ch eck................................................................................................................. 28

8.5 Particulate Sen sor Check ......................................................................................................... 28

8.6 Process Running Signal........................................................................................................... 29

8.7 Monitoring Self Check Status.................................................................................................. 29

8.8 Particulate Alarming During Self Checks................................................................................. 30

8.9 Self check Recording............................................................................................................... 30

9. Troubleshooting ............................................................................................................................ 31

10. Routine Maintenance....................................................................................................................31

11. Spare Parts.................................................................................................................................... 32

12. Appendix ....................................................................................................................................... 33

12.1 Modbus®/RTU RS-485 Networking Protocol .......................................................................... 34

12.2 Ethernet/IP® Networking........................................................................................................ 37

Documen t No. 210-1003- M Page 1 ©2007

Page 9

Particu late Monitoring Sy s tems Installation & Operating Manual

1. Safety

1.1 Applicable Use

These particulate monitor systems ar e not designed for use as a functional safety device and do not

carry a SIL rating. The device must not be used as part of a safety system or as an input signal to a

safet y system. Th es e m on itors are designed for general process and environ mental moni toring.

1.2 General

This apparatus is available with various agency approvals as noted in the approvals section. All

versions of this device have been designed to comply with EN 61010, safety requirements for

elec tric al equipment for measurement, control and laboratory u s e, and are s u pp lied in a safe condition.

Before beginning an installation the following safety precautions and all precautions noted listed

throughout this manual and in the installation drawin gs must be followed.

AREA CLASSIFICATION

• Before installing any device confirm area classification requirements. Do

not install any device that is not tagged as suitable for the required area

classificati on .

PROCESS AND AMBIENT CONDITIONS

• Before installing any device, confirm ambient temperature, process

temperature and process pressure requirements. Do not install any device

that is not tagged as suitable for the required temperatures and pressures.

Confirm compatibility of the wetted and non-wetted materials.

INSTALLATION PERSONNEL AND SERVICE

• Only appropriately licensed and trained professionals should perform the

mechan ical and el ectrical ins tallation.

• This device does not contain field serviceable components other than the

line fuse. Only factory personnel can perform service on this equipment.

• For operator safety and to prevent ignition of flammable or combustible

atmospher es always disconnect power before servicing.

GROUNDING AND FUSING

• Before turning on the instrument, you must connect the protective earth

terminal of the instrument to a proper earth ground. Grounding to the

neutral conductor of a single-phase circuit is not sufficient protection.

• Only fuses with the required current, vol tage and specified type should be

used. D o n ot u s e r ep aired fuses or short-cir cu ited fuse hol d er s .

REGULATORY CODES

• Installation and operation must adhere to all national an d local codes.

Documen t No. 210-1003- M Page 2 ©2007

Page 10

Particu late Monitoring Sy s tems Installation & Operating Manual

1.3 Hazardous Area Syste ms

Systems approved for use in hazardous areas include nameplates indicating that they a re suitable for

inst allation in hazard ou s areas. The nameplate list s allowable hazardous areas and T code ratings as

well as approval agency markings. Do not install any device that is not tagged as suitable for the

area classifica tion.

Section s or st at emen ts in thi s man ua l tha t a pply to a pproved ha zar dous ar ea syst ems or in s tall at ion s

are designated with the following symbol. Designation for use in hazardous areas does not make the

system su itable for use as a functi onal safety device.

EXPLOSION HAZARD

• Hazardous area control drawing 225-1005 must be followed for proper

installation.

• Installation mu st be in accord ance with ANS I /ISA RP12.6 an d National

Electric Code ANSI/NFPA 70, Article 504

• Substitution of components may impair intrinsic safety.

• Do not connect or disconnect components unless power has been

disconnected.

• Designation for use in hazardous areas does not make the system

suit able for use as a fun ctional safety device.

Documen t No. 210-1003- M Page 3 ©2007

Page 11

Particu late Monitoring Sy s tems Installation & Operating Manual

2. Introduction

A Parti culate Mon itorin g System con sist s of a contr ol unit, a par ticul ate sensor and a sen sor coaxia l

cable. Applications include continuous emissions monitoring, baghouse filter leak detection and

process particulate flow monitoring. Types of particulate include both solid particulates (dusts,

powders, granulars and pellets) and liquid particulates (mists). Various control unit models and

sensors are pr ovided to match the application and process monitoring needs.

Principle of Operation

Particulate Monitoring Systems employ a highly reliable technology based on induction. A sensor

probe is mounted in an air flow stream such as a pipe, duct or stack (for small tubing an inline nonintr usive ring sen sor is employed). As particul ate flows near and over the sen sing element, minut e

electr ical cur rents ar e induced in th e sensor an d transfer red to th e control unit by a coa xial cable. A

microprocessor filter s and processes the signal into a normalized, absolute output that is lin ear to the

mass concentrat ion of particu late.

_ MASS CORRELATION

IMPORTANT

It is important to note that the above relation between instrument units (pA) and

actual mass (mg/m

appropriate model and range and for providi ng a general indic ation of the typic al

particulate levels monitored. For a true correlation between (pA) and actual

mass (mg/m

must be performed for each application and a recommended model and

detection level must be ordered. It is also important to note that th e accuracy of

such correlations is application dependent and produces the best results with

consistent particulate and process conditions. The user must follow proper

procedures and must understand the typical accuracy of such correlation

techn iques. Consult factor y for detail s.

3

or gr/cf) is just an approximate guide for selecting the

3

or gr/cf), a gravimetric correlation such as an isokinetic sample

Control Unit

The con trol un it (i .e. el ectroni cs) is h oused in a ru gged cast alumin um encl osure. An LCD di splays

particulate levels in bar-graph and digital forms. A lockable membrane keypad is provided for setup

and adjustment. An optional self ch eck sub system is available to automatically verify calibration and

operation of the con trol unit, sen sor and cable. Various r elay, analog inputs and outputs, as well as

seri al communications are ava ilable in the control unit.

Particulate Sensor

The particulate sensor is very rugged and vir tually maintenance-free. The sensor is passive with no

active circuits for high reliability and durability. It does not require special alignment and is not

affected b y normal vibration.

Coaxial Cable for Particulate Sensor

The cable that connects the particulate sensor to the control unit is a high-quality coaxial cable

specifically desi g ned for the system. Maximum length i s 30 0 ft ( 9 1m ). Do not use substitute cable.

Documen t No. 210-1003- M Page 4 ©2007

Page 12

Particu late Monitoring Sy s tems Installation & Operating Manual

3. Control Unit Installation

3.1 Location

The foll o wi ng factors should be cons idered when d etermining the contr ol un it locati on:

Locate at a position that is convenien t for setup and operation

Mount at eye level

Mount to a flat surface in a vertical orientation

Do not mount to surfaces with excessive heat or vibration

INSTALLATION PERSONNEL

• Only appropriately licensed professionals sh ould install this product.

• For operator safety and to prevent ignition of flammable or combustible

atmospher es always disconnect power before servicing.

CONTROL UNIT LOCATION

• The con trol unit may only be located in ordinary locations (non-hazardous

safe areas).

• Do not locate the control unit in a hazardous area unless it is inside an

appropriately rated explosion-proof or purged enclosure and

par t of an appr oved h aza rdou s ar ea syst em wi th a ppr oved c ontr ol un it an d

approved sensor assembly.

• Do not l ocate the con trol unit in or n ear sources of very high elect rical n oi s e

such as a Variable Frequency Drive (VFD) or Motor Control Center. Locate

the con trol unit at least 10 feet fr om thes e sources an d, if possibl e, power

the control unit from a separate power source. If power is supplied from the

same br anch cir cuit or a cir cui t con tainin g el ectri cal n oise, in st all a quali ty

line filter such as an Islatrol IC+102.

Mounting: Mounting holes are in tegrated into the enclosure base. Mounting hardware should be

capable of supporting five times the control unit weight. Refer installa tion drawings for dimensions.

supplied as

3.2 Wiring

An appr opriatel y li censed electrician mu s t p er form all electrical connection s.

CONTROL UNIT WIRING

• All wiring must be rated 250V minimum.

• The con trol un it mu st be moun ted wit hin si ght of an appropr iate elect ri cal

disconnect (on/off switch) to ensure safety during installation and

maintenance.

• The coaxial cable must be in conduit that is separate from all other circuits.

Documen t No. 210-1003- M Page 5 ©2007

Page 13

Particu late Monitoring Sy s tems Installation & Operating Manual

There are connections inside the control unit for the sensor coaxial cable, the power supply, relay

contacts and optional 4-20mA or RS-485 outputs. Refer to the installation drawings.

Conduit openings are provided in the bottom of the enclosure to route wiring into the enclosure.

Never drill new c onduit openings in the side or top of th e enclosure as a bad conduit seal may allow

water to enter the enclosure.

3.3 Grounding

Proper grounding of the control unit is essential to ensure reliable operation and operator safety.

When used as part of an approved hazardous area system two separate ground connections are

required, protective ground and intrin sic safet y ground. It is not suffi cient to use a single ground

connection and jumper the protective and intrinsic safety grounds inside the control unit enclosure.

CONTROL UNIT GROUNDING

• Protective earth ground must be connected to t erminal #1.

• The enclosure co ver must be bonded to the enclosure base with the s u pplied

gr ound bonding wire – do n ot remove .

• When used a s par t of an approved haz ardous area system: Intr insic safet y

ground must be connected to terminal #2 and must be less than 1 ohm with

respect to earth ground. Refer to control drawing 225-1005.

• When used a s par t of an approved haz ardous area system: Intr insic safet y

ground must utilize a grounding electrode independent of the protective

eart h ground.

Documen t No. 210-1003- M Page 6 ©2007

Page 14

Particu late Monitoring Sy s tems Installation & Operating Manual

4. Parti culate Sensor I nst allation

4.1 Location

The foll o wi ng factors should be cons idered when d etermining the sensor location:

Area Classifica tion

Flow conditions

Electrical (Faraday) shi elding

Atmospheric shielding (in the case of ducts and stacks open to atmosphere)

Access for install at i on and service

SENSOR LOCATION

• Before installing the sensor, confirm ar ea classification r equirements. Do

not install any device that is not tagged suitable for the required area

classificati on .

• Before installing the particulate sensor, confirm ambient temperature,

process t emperat ure and process pressur e requirem ents. Do not install an y

device that is not tagged as suitable for the required temperatures or

pressures. Confirm compatibility of wetted and non-wetted materials.

• For hazardous areas, a maximum ambient temperature of the particulate

sensor enclosure must not be exceeded. Refer to the Temperature

Considerations section for full details.

It is essent ial for th e pip e/duct to pr ovide a n el ectri cal (Far aday) sh iel d for t he sen sor. It is ther efore

required that the pipe, duct or stack is metal and earth grounded (small inline tubing sensors pr ovide

their own section of metal pipe which also must be grounded). Consult the factory when insertion

probe style sensors are to be installed in non-conductive pipes, ducts such as plastic or fiberglass.

The particulate sensor must be installed in a position where the flow is reasonably laminar and th e

particulate is evenly distributed. The ideal position is where the pipe/duct is straight and free of items

such as valves, damp ers or ot her fl ow obst ructions for a l e ngth of 4 diameters or longer . Horiz ontal or

vertical sections are acceptable. For basic flow/no flow detection it is not necessary to select a

location with a long straight section if access has to be sacrificed dramatically. For trending and

measur em ent the n eed for a s tra igh t sect i on and lamin ar flow in creases. Th e par ti cul ate s en sor sh oul d

be position ed with appr oximately two thirds of the straight section upstr eam of the sensor and one

third downstream. The particulate sensor should be located in the center of the pipe/duct. If the

pipe/ducting is square it should be located in the center of one of the sides. In either case, be sure the

position is such that the tip of the sensor reaches the midpoint or beyond. Always use good

engineering sense and be sure th e s ensor will interact with a r easonable rep resentat ion of the flow.

For emissions detection applications such as baghouses or cartridge collectors, good locations are

generally found upstream of the blower. Th e particulate sensor can be located downstrea m of the

blower but not too close to th e stack outlet. There must be sufficient duct downstream of the sensor to

provid e adeq uat e electr ical and atmosp her ic shi eldin g. Th e sensor shoul d be locat ed up strea m of an y

sampling ports by at least two feet. It is not necessary that the sensor be in the same section of the

duct/stack as the sampling ports. Particulate sampling ports require fully-developed laminar flow and

longer straight sections.

Documen t No. 210-1003- M Page 7 ©2007

Page 15

Particu late Monitoring Sy s tems Installation & Operating Manual

Extreme vibration should be avoided.

_ ATMOSPHERIC AND ELECTRICAL SHIELDING OF SENSOR

IMPORTANT

• It is essential for the pipe/duct to provide an electrical (Faraday) shield for

the sensor. The pipe/duct or stack should be metal with a high quality earth

ground. Consult the factory for non-conductive pipes/ducts such as plastic

or fiberglass. (Small in-line sensors for small tubing provide their own

section of metal pipe, which also must be grounded).

• When the sensor is placed in a stack/duct choose a location away from

atmosph ere so wind driven atmospheric particulate or rain does not flow

over the sensor and so ex ternal electrical n oi se cannot affect operati on .

• Do not p lace the sen sor where th e pipe/duct i s corroded or cr acked whi ch

may allow water droplets to create signals as they flow by.

4.2 Mounting

The foll o wing types of process moun ts are availa bl e for the stan dard probe style sensors:

NPT, Quick-Clamp an d AN S I fl ange.

Inline sensors for small tubing are supplied with swage lock or other tube connections to mount inline

with metal or plastic tubing.

Installation drawings of each mounting type ca n be found in the appendix.

HAZARDOUS AREA SENSOR GROUNDING

• For hazardous area applications an external sensor earth ground cable is

require d to main tain sensor ground ing duri ng in stallat ion an d m ainte nance.

• The ground cable must remain attached when the sensor is temporarily

removed fr om the process – do not disconnect the ground cable.

• Leave sufficient ground cable service loop for easy removal of the sensor

from the process.

Documen t No. 210-1003- M Page 8 ©2007

Page 16

Particu late Monitoring Sy s tems Installation & Operating Manual

4.3 Sensor Temperature Considerations

The sensor may be ordered with on e of three process temperature ranges:

1. -40ºF to 250ºF (-40ºC to 121ºC)

2. -40ºF to 450ºF (-40ºC to 232ºC)

3. -40ºF to 800ºF (-40ºC to 426ºC)

4. Consult Factory for Temperatures >800°F

Note: For the process temperatures in the ran ge of 233ºC - 426ºC, a high temp probe must be used.

The max imum allowab le ambie nt temp erature at sensor housing is 70ºC.

Table: T Code Rating for Sensor

Process Temperature Does Not Exceed

Maximum Ambi en t

75ºC (167ºF) 125ºC (257ºF) 225º C (437ºF) 325ºC (617ºF) 426ºC (800ºF)

70ºC (160ºF) T6 T4 T2C T1* T1*

Documen t No. 210-1003- M Page 9 ©2007

Page 17

Particu late Monitoring Sy s tems Installation & Operating Manual

5. Particulate Sensor Coaxial Cable Installation

Connection: Prior to making coaxial cable connections review the following routing in structions.

IMPORTANT

_ PARTICULATE SENSOR COAXIAL CABLE ROUTING

• The sensor cable must be installed in con duit that is separate from all other

wiring.

• The cabl e sh oul d be r ou ted from th e part i cula te s en sor t o the c ontrol unit in

a pa th t hat avoid s hi gh vi brat ion, hea t over 394 °F (200°C) and an y stron g

magn etic or electrical field s.

• The cabl e should be locat ed at least 18 in (46 cm) away from an y p ower

lines (conduit), motors, frequency drives and other sources of electrical

inter ference throughout its entire path.

• The cabl e shou ld be i nsta lled in metal lic con duit . At th e process en d, use a

section of shielded flex conduit that is 1 to 2 times the probe length to serve

as a ser vice loop.

The coa xi a l ca ble i s c on n ected t o th e con t r ol un it by a coa x con n ector a nd is connected t o th e sen s or

by two ring terminal s . The connect ors are norma ll y sup p lied pre- assembled t o th e cable.

Once t he cable h as been r outed, in sert th e coax conn ector int o the contr ol unit enclosur e leavin g a

very small service loop as specified in the installation drawing shown in the appendix. A larger

service loop should be used at the sensor end, typically 1 to 2 times the sensor length. Any small

amount of extra cable length should be pulled into the nearest junction box and NOT left in the sensor

housing or in th e control unit enclosure. If there is a significant amount of extra cable ( many feet), the

cable sh ould be sh orten ed at th e sensor end and the sen sor end connector s should be re-assem bled

using factory-supplied connectors and instructions.

IMPORTANT

_ COAXIAL CABLE INSIDE THE CONTROL UNIT

• A ferrite suppressor is located on the sen sor coaxial cable near the coax

connector and must remain inside the control unit enclosure.

• The bla ck ca ble i n sula ti on must ext en d a min imum of 6 i n (15 cm ) in t o th e

coax cabl e conduit .

• Do not l eave any excess ca bl e in the control unit or sensor housin g .

Insid e the particulate sensor encl osure, att ach the coax cable as in di cated in th e s ensor dra win g. When

connecting the braided shield, ensure it does not touch the surge voltage protection assembly. Do not

leave exc es s cable in side the sensor housing.

Documen t No. 210-1003- M Page 10 ©2007

Page 18

Particu late Monitoring Sy s tems Installation & Operating Manual

Sensor Test Port (Non-Hazardous Areas Only)

Location: A test por t should be installed in a negative pressure location. It must be located upstream

of the sens or s o pa rt i cu la t e ca n fl o w very nea r an d around t he s en s or . It sh ou l d be l oca t ed a t le a st 3 ft

(1 m) upstream of th e sensor and it should be located on the same side of the duct as the sen sor so

particles can pass very near and around the sensor. If possible locate the test port at ground level.

Mounting: The test port is either screwed into a 1/8 inch NPT threaded h ole, or welded in position.

(Note: A foot or so of tubi n g can be con n ect ed t o th e nip pl e to ma ke it eas y to dr aw par ti cl es out of a

conta iner. Only a pinch of particu late at a time is n eeded for a response check.)

_ TEST PORT INSTALLATION

IMPORTANT

• Installation of a sensor test port enables checking the response to an actual

increase in particulate.

Documen t No. 210-1003- M Page 11 ©2007

Page 19

Particu late Monitoring Sy s tems Installation & Operating Manual

6. Control Unit Operation

6.1 User Interface Overview

The following drawing shows the user interface consisting of a four-button keypad and an LCD

display. The LCD display has a scalable analog bar graph combined with a digital readout for ease in

interpreting the dyn amic readings, which are typical with particulate flow.

Control Unit

The con trol unit has two alarm relays which are individually activated when the reading continuously

exceeds the alarm setpoint for the amoun t of time delay specified. Each is an SPST (FORM A) r elay

contact output.

Alarm logic may be set to Normal or Fail-safe mode. In Normal mode, the alarm relay contact is open

under normal conditions and closes when the associated alarm is active. In Fail-safe mode, the alarm

relay contact is closed under normal conditions and opens when th e associated alarm is active, or

when power to the control unit is removed.

When th e r ea din g ex ceeds t h e a lar m s etp oint , the a l arm del ay timer is started. As long as th e reading

remains above the alarm setpoint, the alarm delay timer will continue timing. If the reading drops

below the alarm setpoint before the alarm delay timer expires, the alarm delay timer is reset. If the

reading r emains above the alarm setpoint and th e alarm delay timer expires, an alarm is activated and

the as sociated alarm relay cont act will close ( N ormal logi c) or open (Fail- safe logic).

If an a larm is act ivated an d the rea ding drops bel ow th e alarm setp oint, th e alarm i s cleared and the

alarm delay timer is reset. As described above, alarms will clear automatically and no operator

acknowledgment is required.

Control units designed for powder flow applications include the ability to define a LOW alarm level

that wi ll activat e when the parti cu late reading falls BELOW the setpoint. See Menu 1 Setu p d etails.

Documen t No. 210-1003- M Page 12 ©2007

Page 20

Particu late Monitoring Sy s tems Installation & Operating Manual

6.2 Menu 1 Setup

Alarm setpoints are accessed through Menu 1 setup. To enter Menu 1, press the SETUP key.

Setpoints may be modified by pressing the UP and DOWN arrow keys. Values are saved by pressing

the ENTER key. To discard any changes made and return to the main screen, press the

SETUP/ESCAPE key. Refer to the Menu 1 setup diagram below for menu navigation and allowable

setpoin t ranges. Features designated with an asterisk (*) ar e optional. Operation of optional features is

dependant upon model and options selected at the time of order. The following setup menus ar e based

on firmware vers ion 2.2 7 or higher.

From the main screen, press the SETUP key to enter the Menu 1 setup screen.

Use the UP/DOWN arrow keys to adjust settings to the desired values. Press the

ENTER key when finished to save a value and proceed to next menu item.

Press the SETUP/ESCAPE key to return t o the main sc reen without saving the

current parameter’ s v alue.

Menu Item Range D e finitio n

Alarm #1

Relay #1

Setpoint

Alarm #1

Relay #1

Delay

0-5000

pA

1-600

Sec

The alarm setpoint is compared to the proc ess

reading to determine al arm status. Relay #1 will

close when alarm #1 is active and open when

alarm #1 is cleared.

Number of seconds the reading must exc eed the

alarm setpoint before alarm relay #1 contac t will

close.

* Alarm #1

Relay #1

Logic

Alarm #2

Relay #2

Setpoint

HI/LO Select the logic for the alarm. HI activates when

the reading is above the setpoint. LO activates

when the reading is below the setpoint .

0-5000

The alarm setpoint is compared to the proc ess

pA

reading to determine al arm status. Relay #2 will

close when alarm #2 is active and open when

alarm #2 is cleared.

Alarm #2

Relay #2

Delay

1-600

Sec

Number of seconds the reading must exc eed the

alarm setpoint before alarm relay #2 contac t will

close.

* Alarm #2

Relay #2

Logic

HI/LO Select the logic for the alarm. HI activates when

the reading is above the setpoint. LO activates

when the reading is below the setpoint .

Documen t No. 210-1003- M Page 13 ©2007

Page 21

Particu late Monitoring Sy s tems Installation & Operating Manual

6.3 Menu 2 Setup

Navigation within Menu 2 is similar to that described in Menu 1. Featur es designated with an asterisk

(*) are optional. Operation of option al features is dependant upon model an d options selected at the

time of order. The following setup menus are based on firmware version 2.27 or higher.

Press the SETUP and ENTER keys at the same time from any main screen to enter

the Menu 2 setup screen. Use the UP/DOWN arrow keys to adj ust the sett ing to the

desired value. Press the ENTER k ey to save the value and proceed t o the next set up

screen. Press the SETUP/ESCAPE k ey to return to the mai n screen without saving the

current parameter’ s v alue.

Menu

Item

Range Definition

Bar

Graph

Span

Automatic Linear

Automatic Log

100,000 Log

10,000 Log

1,000 Log

100.0 Log

10,000 Linear

1,000 Linear

100.0 Linear

10.0 Linear

1.0 Linear

Allows the user to configure the f ul l-scale

span of the bar graph readout. The user

may select a fixed scale, or a auto-ranging

scale where the unit will s el ect it’s own sc ale

automatically. The user can select between

a LINEAR or LOGARITHMIC scale. (Log

scaling is recommended f or process e s with

dynamic, spiking readings suc h as a

baghouse or cartridge ty pe dust coll ect or.)

Lock

Keypad

No/Yes Locks the keypad to prevent unauthorized

modifications. Once locked, alarm lev els

cannot be viewed or modified until the

keypad is unlocked. To ulock, enter Menu 2

and set the lock keypad parameter to NO.

Reset

Defaults

No/Yes Resets all alarm set poi nts and user-

adjustable parameters to their factory default

values by selecting YES

* 4-20mA

Minimum

Scale

* 4-20mA

Output

Span

0.0 Linear

0.1 – 10.0 Log

0 – 5,000 Linear

1 – 900,000 Log

Sets the 4mA value of the 4-20mA output.

Entering “0.0” defines Linear scale. A value

other than “0.0” defines logarithmic scale.

Sets the 20mA value of the 4-20mA output.

Linear span can be set to any value.

Logarithmic span wi ll also determine the

number of decades. Example:

Linear output: Min Scale=0.0, Output

Span=1,000.

3-decade logarithmic output: Min Scale=1.0,

Output Span=1,000.

* Network

Address

1 - 32 Modbus®RTU slave address for the RS-485

serial network. Each devic e must have a

unique address.

Documen t No. 210-1003- M Page 14 ©2007

Page 22

Particu late Monitoring Sy s tems Installation & Operating Manual

Fail-safe

Relay 1

Fail-safe

Relay 2

Process

Run

Relay

Enable

* Perform

Zero

Check

* Perform

Span

Check

No/Yes When set to “Yes”, inverts the alarm relay

logic. Relay is ON when NO alarm conditi on

exists and is OFF when there IS an alarm

condition. Relay is OFF when power is

removed from the control unit.

No/Yes When set to “Yes”, inverts the alarm relay

logic. Relay is ON when NO alarm conditi on

exists and is OFF when there IS an alarm

condition. Relay is OFF when power is

removed from the control unit.

No/Yes When set to “Yes”, enables use of the

process run relay input channel. When set

to “No”, disables use of this input. Refer t o

Automated Self Checks section of the

manual for details on use of this relay input.

No/Yes When set to “Yes”, triggers an automatic

zero check. Refer to Automatic Self Checks

section of manual for full det ails.

No/Yes When set to “Yes”, triggers an automatic

span check. Refer to Automatic Self Checks

section of manual for full det ails.

Documen t No. 210-1003- M Page 15 ©2007

Page 23

Particu late Monitoring Sy s tems Installation & Operating Manual

6.4 Menu 3 Setup

Navigation within Menu 3 is similar to that described in Menu’s 1 and 2. Features designa ted with an

asterisk (*) are option al. Operation of optional featur es is dependant upon model and option s selected

at the time of order. The following set up menu s are bas e d on firmware version 2.27 or high er.

Press the UP and DOWN keys at the same time from the main screen to enter the Menu 3 setup

screen. Use the UP/DOWN arrow keys t o adjust a setting to the desired value. Press the ENTER

key to save the value and proceed to the next screen. Press the SETUP/ESCA PE key to return t o

the main screen without savi ng the current param eter’s value.

Menu Item Range Definition

Signal

Filter

Frequency

* Units of

Measure

Auto-

Range

Delay

0.033 – 2.0

Hz

1111 pA

2222 mg

1 – 30

Sec

This parameter controls the low-pass filtering of the input

signal. Setting the f requency lower gives a more stable

output reading. Setting the f requency higher gives a more

dynamic output reading. Signal filtering is applied to the

numeric readout only unl ess bar graph/4-20mA filtering is

ON (see setting below).

This parameter sets the displ ayed and out put uni ts of

measure to be either pA or mg/m

first requires correl ation testing and instrument scaling.

This parameter controls how long the bar graph readout

must be at either extreme before it automat ical ly switc hes

ranges. If the bar graph is switching ranges t oo oft en, t he

auto-range delay shoul d be inc reased.

* Peak Hold

Time

0 – 60

Sec

This parameter sets the amount of time a rapidly

occurring peak reading is displ ayed. Peak Hold is used

for processes that are very dynamic wit h spiki ng

readings.

* Bar Graph

&

4-20mA

Output

Filtering

*

Correlation

Values

MINIMUM

and

MAXIMUM

(EM 70)

Yes/No This parameter enables or disables filtering of the bar

graph and the optional 4-20mA output. The fil tering

applied is the Signal Filt er Frequency parameter listed

above. Filtering is enabled by selecting YES and disabled

by selecting NO.

0 – 5000

pA1=0

pA2=5000

pA3=0

pA4=5000

These parameters are used to re-sc al e the output from

pA to mg/m

entered and equivalent Scaled min/max values (pA3 and

pA4) are entered. The control unit will convert the Raw

values to Scaled values automatic al ly . To rem ove all

scaling, set Raw min=Scaled min and Raw max=Scaled

max. Example: 0-5000pA = 0-4000mg/m

pA1=0, pa2=5000, mg3=0, mg4=4000

3

. Raw min/max values (pA1 and pA2) are

3

. Conversion to mg/m

3

3

Documen t No. 210-1003- M Page 16 ©2007

Page 24

Particu late Monitoring Sy s tems Installation & Operating Manual

6.5 Long Term Averaging

The lon g ter m averagin g function provi d es a rolling average of the real-time r eadings over time.

Averaging setpoints are accessed through averaging setup screen. To enter the averaging setup screen,

press the SETUP key while viewing the MAIN AVERAGE screen. Navigation within the setup

menu is similar to that described in the previous setup screens.

Press the ENTER key to toggle between the Real-Time displ ay and the Average displ ay.

Main

Screen

Real-Time

Display

Average

Display

Units

Shown

pA Displays the real-t i me reading. Before display, the real-time

reading is process ed through a low-pass input signal filter

which smoothes the reading. See t he low-pass “S ignal Filter

Frequency” setup in the Menu 3 setup section.

ApA Displays a selectable rolling time average of the real-time

reading. The average period (in mi nutes) is adjustable

through the average setup screen. The word “AV G” is quickly

shown in place of the readout once every five sec onds,

indicating that the dis pl ayed and out put reading is an

average.

Description

Press the SETUP key from the MAIN AVERAGE screen to enter the

AVERAGE setup s creen. Use the UP/DOWN arrow keys to adjust

settings to the desired val ues. P ress the ENTER key t o save a value and

proceed to next setup screen. Press the SETUP/ES CAPE key to return

to the main average screen without s avi ng the current parameter’s value.

Menu Item Range Definition

Average

Period

Clear

Average

0-360

Min

YES/NO When YES is select ed and the ent er

Number of minutes the real-tim e

reading is averaged to comput e the

average reading.

key is pressed the averaging is cleared

and the average reading is initi al iz ed

to 0.

Documen t No. 210-1003- M Page 17 ©2007

Page 25

Particu late Monitoring Sy s tems Installation & Operating Manual

6.6 4-20mA Analog Output Scaling

Particulate levels may be transmitted to external devices with the 4-20mA analog output. Typical

applications include remote monitoring of particulate levels with a PLC, chart recorder or panel

meter. The 4-20mA output is tran smitted as linear or multi-decade logarithmic output.

Two parameters determine the type of output signal. The “4-20mA Minimum Scale” parameter

determin es the pA equivalent of the 4mA output. Setting this parameter to “0.0” enables the Linear

scale. A value oth er than “0.0” ini tiates Loga rithmic scale. Th e “4-20mA Output Span ” paramet er

determines the pA equivalent of th e 20 mA output.

The 4-20mA analog output represents the linear or logarithmic equivalent of the “pA” particulate

levels. Once the ana log output has be en transm itted to the PLC o r cha rt recorder, it is recommended to

convert the 4-20mA signal back into pA to assist in data interpretation, alarm level determination and

historical data comparison. This can be of particular importance for EPA regulatory applications. The

follo wing two examp les show the formulas used to convert the 4-20mA sign al into pA.

4-20mA Linear Output

Linear out put is sel ected when the “4 -20m A Out put Min imum Scale” is s et to “0.0 ” pA. To con vert

the 4-20mA output signal back to pA, use the following formula:

pA = ((4-20mA Output Span) * (mA - 4)) / 16

Example:

Where: 4-20mA Minimum Scale = 0.0 and

4-20mA Output Span = 1000pA (from Menu #2)

4-20mA Output pA

4 0.0

5 62.5

6 125.0

7 187.5

8 250.0

9 312.5

10 375.0

11 437.5

12 500.0

13 562.5

14 625.0

15 687.5

16 750.0

17 812.5

18 875.0

19 937.5

20 1000.0

Documen t No. 210-1003- M Page 18 ©2007

Page 26

Particu late Monitoring Sy s tems Installation & Operating Manual

4-20mA Logarithmic Output

To convert the 4-20mA logarithmic output back to pA, use the following formula:

1. Compute the number of output decades:

Number_Of_Decades =Log [(4-20mA Output Span)/(4-20mA Minimum_Scale)]

2. Scale mA input to prop er log(1 0 ) argument:

Y = Number_Of_Decades * (mA – 4.00) / 16

3. Convert log(10) argument to pA:

pA = 10^(Y) * (4-20mA Minimu m_Scale)

Example #1: See Menu #2 for d etails.

Where: 4-20mA Minimum Scal e = 0.1pA

4-20mA Output Span = 1000pA

Number_Of_Decades = Log (1000 / 0.1) = 4

4-20mA Output Y pA

4 0 0.1

5 0.25 0.2

6 0.5 0.3

7 0.75 0.6

8 1 1.0

9 1.25 1.8

10 1.5 3.2

11 1.75 5.6

12 2 10.0

13 2.25 17.8

14 2.5 31.6

15 2.75 56.2

16 3 100.0

17 3.25 177.8

18 3.5 316.2

19 3.75 562.3

20 4 1000.0

Documen t No. 210-1003- M Page 19 ©2007

Page 27

Particu late Monitoring Sy s tems Installation & Operating Manual

Example #2: See Menu #2 for d etails.

Where: 4-20mA Output M inimum Scale = 0.5pA

4-20mA Output Span = 500pA

Number_Of_Decades = Log (500 / 0.5) = 3

4-20mA Output Y pA

4 0.00 0.5

5 0.19 0.8

6 0.38 1.2

7 0.56 1.8

8 0.75 2.8

9 0.94 4.3

10 1.13 6.7

11 1.31 10.3

12 1.50 15.8

13 1.69 24.3

14 1.88 37.5

15 2.06 57.7

16 2.25 88.9

17 2.44 136.9

18 2.63 210.8

19 2.81 324.7

20 3.00 500.0

6.7 Interpreting Particulate Readings for Fabric Filter Applications

Particulate flow is very dynamic in natur e, thus the output signal is also usually very dynamic. This is

more often the case with fabr ic filter and dust collection exhaust monitoring applications where filter

emissions and filter cleaning systems can cause wide ranging variations in the particulate levels.

When monitoring downstream of fabric filter, it is often possible for the difference between baseline

readings and peak readings following cleaning cycles, to vary by a factor of 10 or even 100. This is

the reason for the log arithmic ou tput (lin ear ou tput is also ea sily selected using the k eypa d ).

The logarithmic scale provides the ability to simultaneously monitor and resolve the baseline and

peak readings. It is not uncommon to have baseline readings of less than 10pA wh ile at the same time

peak readings may be over a hundred or more.

Particulate levels listed below are typical for new or well maintained bag or cartridge filter dust

collection system. Man y factors, other than generic bag wear may contribute to high particulate levels

including but not limited to: Improper filter installation, bad tube sheet seals, improper filter media

for process condition s, high differ ential pressure or a lack of a filter cake buildup.

Documen t No. 210-1003- M Page 20 ©2007

Page 28

Particu late Monitoring Sy s tems Installation & Operating Manual

PARTICULATE READING GUIDE FO R FABRIC FILTERS

IMPORTANT

• The guide below is only an approximate guide for modern, highly-efficien t baghouses

• With large r or old er bagh ouses, readings can be significantly higher than t he ran ges shown below

• Shaker and reverse air baghouses will have higher peak readings as compared to pulse jet

• Readings tend to be higher when new filter s are installed and a filter cake h as yet to form

• With sm all cartrid ge filters, th e r eadings tend to be a t the lower en d of the ranges

• Readings tend to also be lower with highly-efficien t filter media such as Gor e-Tex® fabric (Gore-

Tex is a reg istered tr ademark of W.L. G ore & Associat es .)

•

Typical Readings and Guide for New Efficient Fabric Filters

AVERAGE

BASELINE READINGS

PEAK READINGS

(after cleaning cycle)

FILTER CONDITION

1 – 10 pA Less than 50pA No significant emissions

10 – 100 pA Less than 500pA On set of emissions

100 – 1000pA Gr eater than 500pA Significant emissions present

_ ALARM LEVELS FOR EPA COMPLIANT LEAK DETECTION

IMPORTANT

• Alarm levels for EPA compliant leak detection such as MACT regulations should initially be set as

low as possible unt il sufficien t trend data has been logged and all considerations have been made.

• Do not in crease th e alarm levels without pr oper justification.

• Documentation of properly determined alarm levels is recommended as well as locking out alarm

set point adjustment except to authorized personnel.

• Consu lt factor y for alarm set point as sistance an d or FilterWare Visualization and EPA Compliance

Software for advanced alarming and alarm record keeping.

Documen t No. 210-1003- M Page 21 ©2007

Page 29

Particu late Monitoring Sy s tems Installation & Operating Manual

6.8 Alarm Levels for Fabric Filter Applications

For fabric filter applications it is recommended to set two alarm levels either using the internal alarms

and or using the optional 4-20mA output signal that is sent back to a PLC or other recording system.

One al ar m should be set based on the average base line reading and another alarm should set ba s ed on

the pea k r eadings foll o wi ng cleanin g cycl es .

Normal ly, Al arm # 1 is used for det ectin g su stain ed incr eases in th e base lin e rea ding . For ex ampl e a

baghouse that has new, highly-efficient filters may h ave an average baseline reading of 10-20pA. It

would then be recommend to set the baselin e alarm at 30-50pA with an alarm delay time that was

long en ough so th at cl ean ing cycle pea ks di d n ot act i vat e the basel i n e alar m . Ea ch a p pli cati on ca n be

different (for exampl e much hi gher readings are possible with larger, older bagh ous es) and each plant

may have different operating demands in terms of how sensitive the alarms should be set. It is,

therefore, recommended to initially set the alarm as low as possible and to tr end and data log the

readings over time before finalizing the settings. Correlations to stack test data can also be

incor p orated to correlate the ou tput to actu al mass concentration to set more quantitative al arms.

Normally, Alarm #2 is set to detect changes in the peak readings caused by the filter cleaning cycles.

Recall that as filters just begin to tear or become por ous, the momentary puffs of particulate emissions

that normally occur just after a cleaning cycle will increase in peak heigh t and duration (peak width).

Essentially the cleaning cycle amplifies the existen ce of small tears. Thus, setting an alarm to detect

changes in the peak emissions is often referred to as a Pr e-Visible Alarm as it is the best, and most

reliable, approach to detecting emissions before become visible. When a sustained increase in the

baseline level occurs, particulate emissions will likely be visible and th e filters should be changed

immediately. Wh ere as, when only the peak emissions have increased, emission will likely not be

visible and there likely would be time to schedule ch anging the filters (i.e. early warning).

Telephone or on-site assistance is available to provide suggestions in setting alarm levels.

Documen t No. 210-1003- M Page 22 ©2007

Page 30

Particu late Monitoring Sy s tems Installation & Operating Manual

7. Manual System Zero Check

The S ystem Zer o Check is us ed at in stall ati on to confi rm prop er in stal lati on and for tr oublesh ootin g.

This check is mostly for control units that are not equipped with the optional self check subs ystem.

SAFETY

• Always disconnect power to the control unit before making any wiring

changes at eith er the control unit or sensor as well as when making any

mount ing changes or replacing any component.

• Do not remove the sensor (even when power is disconnected) from a

running process if it will in any wa y compromise personnel or plant safety.

• All regulatory and plant safety procedures must be followed at all times

whil e p er forming any equipment ch eck or maintenance.

• For hazardous area sensors, do not disconnect the external earth ground

strap.

• Do not perform any pr ocedure if it will in any way compromise hazardous

area procedures .

SYSTEM ZERO CHECK

1. Shut the process off, stop p ing flow complete ly, including all ai rf low not just

particulate flow. The slightest amount of flowing particles can create a

signal. If process flow cannot be stopped, the particulate sensor can be

removed from the process and installed in a grounded test pipe to create a

shielded, no flow condition.

2. Let the system stabilize for 2-3 minutes.

3. Read the display. It should be below the con trol units specified minimum

detection level. If the system passes this ch eck th en it is assured that there

are no false signals entering the system.

If th e system z er o ch eck is not s uccess ful , each comp on ent of th e system sh oul d

be checked individ u ally, in the fol lowing or d er :

1. Control Unit Zero Ch eck

2. Coaxi al Cable Zero Check

3. Sensor Zero Check

Documen t No. 210-1003- M Page 23 ©2007

Page 31

Particu late Monitoring Sy s tems Installation & Operating Manual

CONTROL UNIT ZERO CHECK

1. Disconnect power to the control unit.

2. Open th e en cl osure co ver an d uns cr ew the coa xi al cabl e con n ector from th e

contr ol unit. Leave the connector inside the control unit en closure. Make

sure th e con nector d oes n ot s lip down into the conduit.

3. Close the control un it enclosur e cov er.

4. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

5. Read the display. It should be below the con trol units specified minimum

detection level. If the control unit passes this check, there are no false

signals entering th e control unit.

PASS:

1. Discon nect power from the control unit.

2. Open th e enclosu re cover and re-a ttach th e coaxial ca ble conn ector to th e

control unit.

3. Close the enclosure cover and proceed to th e Coaxial Cable Zer o C heck.

FAIL:

1. If a zer o r eadin g cann ot be obt ain ed, cl ose th e encl osur e cover an d con tact

the factory for fur ther assistance.

COAXIAL CABLE ZERO CHECK

1. Disconnect power to the control unit.

2. Open the sensor enclosure cover and disconnect the coaxial cable center

conduct or from th e sensor pr obe end. Do n ot disconn ect the coaxia l cable

shi eld. Do not r emove the probe fr om the pr ocess. Lea ve the coaxi al cabl e

center conductor ring terminal hanging in free space within the sensor

enclosure (do not isolate it with tape) and close the cover.

3. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

4. Read the display. It should be below the con trol units specified minimum

detecti on l evel. If t h e coax ial ca ble pa sses th is ch eck th en ther e ar e no fal se

signals entering the coaxial cable.

PASS:

1. Disconnect power to the control unit.

2. Open the sensor enclosure cover and re-attach the coaxial cable center

conductor to the s e nsor probe en d.

3. Close the sensor enclosure cover and proceed t o the sensor zero check.

FAIL:

1. Check cable insta llation and routing in struction s in the Instal lation s ection

of this manual for proper cable installation. Make any changes necessary.

2. Cont act the factor y for fu rther ass istance.

Documen t No. 210-1003- M Page 24 ©2007

Page 32

Particu late Monitoring Sy s tems Installation & Operating Manual

Once th e contr ol unit an d coaxial cable zer o have been checked, p roceed to t he Sen sor Zero Ch eck.

To per form the sen sor zer o check the proc ess flo w must be stoppe d or a sensor test pip e (avai labl e

from Factory) or length of metal pipe will be needed (4”-6” diameter pipe or larger). The pipe should

be at least 3 in (8 cm) longer than the probe itself and must be grounded. The length of pipe will serve

as an el ectrical sh ield for the pr obe wh ile it is out of th e process.

SENSOR ZERO CHECK

1. Do not remove the sensor from a running process if it will in any way

compr om ise personn el, plant sa fety or hazard ou s area safety procedures .

2. Disconnect power to the control unit.

3. Remove t he sensor from th e process and insert it into the gr ounded m etal

test p ipe. For hazardous area sen sors do n ot disconn ect the ext ernal sensor

eart h ground strap.

4. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

5. Read the display. It should be below the con trol units specified minimum

detection level. If the sensor passes this check there are no false signals

from the sensor.

PASS:

1. Disconnect power to the control unit.

2. Remove the sensor from the grounded test pipe and re-insert into the

process. For hazardou s area sensor s do not d isconnect th e external sen sor

gr ound strap.

FAIL:

1. Cont act the factor y for fu rther ass istance.

When p erforming a zero check, keep in min d th at it may be acceptable t o c onsider a small fal s e signal

negligible. For example if the baseline readings are 100pA and a system zero offset of 1pA was

found, this is only a 1% affect on the normal readings. If using the device for basic flow/no flow

detection or basic emissions detection, this would not be significant.

Documen t No. 210-1003- M Page 25 ©2007

Page 33

Particu late Monitoring Sy s tems Installation & Operating Manual

8. Automatic Self Checks

An optional self check subsystem is available to automatically verify calibration and proper operation

of the electroni cs, sensor and cable. Self checks can be performed while the system is online and

monitoring particulate. No external test equipment or operator intervention is requir ed to activate or

complete the self check routines. Any errors detected by t he self checks are r eported through the

display, 4-20mA, relay and Modbus® outputs. The following automatic self checks are per formed:

• Contr o l Uni t Hard ware C heck

• Control Unit Calibration (Zero and Span )

• Sensor Cable Check

• Particulate Sensor/Probe Check

The control unit zero and span self checks that are performed meet all requirements of the EPA

MACT Qua lity Assurance specifications . Self checks are automatically run every hour . A manual Self

Check may be activated anytime through the control unit keypad.

8.1 Control Unit Hardware Check

The Contr ol Unit Hard ware Ch eck is an automat ic check of all major electrica l compon ents in the

control unit. This check is automatically performed each time power is applied to the control unit.

Check Description

Watchdo g Timer

SRAM Checks the integrity of the SRAM memory.

Non-Volatile

Memory

Option Board

Analog Converter

Calibration

Monitors all program tasks running in the microprocessor and

automatically resets the processor in the event of lock-up.

Checks the integrity of the Non-Volatile memory. The results of this

check produce a check su m value whi ch is an alyzed each time a nonvolatile memor y write occurs.

Checks for proper installation of Power Supply, RS-485 and Self

Ch e ck option boards.

Check s calibrat ion of the 22 bit hi gh resoluti on an alog converter.

Documen t No. 210-1003- M Page 26 ©2007

Page 34

Particu late Monitoring Sy s tems Installation & Operating Manual

8.2 Control Unit Zero Check

The Zero Check will verify instrument zero calibration. The internal self check subsystem will

automatically perform the following procedure:

1. Electronic discon nect of th e par ticulat e sen s or cable

2. Allow th e reading to stabilize

3. Measure the reading and compare to the allowabl e zero toler ance

4. Electronic re- con nect of the par ticulat e sensor cable and resume normal operati on .

There are four independent methods to acti va te the zero ch eck :

Method Description

Power-Up

Keypad

Automatic

Remote

A zero check is automatically performed each time power is applied to

the con trol unit

The operator may activate a zero check manua ll y th rough the control

unit keypad. Reference Menu #2 setup tree for complete details.

The con trol unit may be configured to automatically per form a zero

check on a period basis. A re-settable delay timer controls the time

period between self checks. The delay timer is set to 1 hour by default.

The delay timer is reset each time self checks are performed regardless

of the activation meth od.

Automatic self ch eck s may be activated at preset hourly, daily and

monthly dates/times when connected to a computer running the

FilterWare Visualization application.

The operator may activate a zero check manually when connected to a

remote computer running th e FilterWare Visualization application .

Alternately, self checks may be independently activated from any

remote PC or PLC with Modbus® communication capability.

Documen t No. 210-1003- M Page 27 ©2007

Page 35

Particu late Monitoring Sy s tems Installation & Operating Manual

8.3 Control Unit Span Check

The Span Check will verify the in strument span calibration. The internal self check subsystem will

automatically perform the following procedure:

1. Electronic discon nect of th e par ticulat e sen s or cable

2. Electronic inp ut of a calibrated p A reference signal

3. Allow th e reading to stabilize

4. Measure the reading and compare to the allowabl e s p an toleran ce

5. Electronic discon nect of th e r eference si gnal

6. Electronic re- con nect of the par ticulat e sensor cable and resume normal operati on .

There are four independent methods to acti va te the span check :

Method Description

Power-Up

Keypad

Automatic

Remote

A span check is automatically performed each time power is applied

to the control unit

The operator may activate a span check manually through th e control

unit keypad. Reference Menu #2 setup tree for complete details.

The con trol unit may be configured to automatically per form a span

check on a period basis. A re-settable delay timer controls the time

period between self checks. The delay timer is set to 1 hour by default.

The delay timer is reset each time self checks are performed regardless

of the activation meth od.

Automatic self ch eck s may be activated at preset hourly, daily and

monthly dates/times when connected to a computer running the

FilterWare Visualization application.

The operator may activate a span check manual ly when connect ed to a

remote computer running th e FilterWare Visualization application .

Alternately, self checks may be independently activated from any

remote PC or PLC with Modbus® communication capability.

8.4 Sensor Cable Check

Integrity of th e s ensor cable i s ch eck ed using ad vanced dig ital signal processin g algorithm s. Th e cable

check oper at es con tinuou sly an d does n ot int erfere wi th nor mal m onitor ing of th e pr ocess par ticu late

signal. The sensor cable check i s disabled whi le zero or span ch eck s are being per formed.

For proper operation of the sensor cable check a process running signal must be provided to the

control unit. Reference section 8.6 for full details.

8.5 Particulate Sensor Check

Operation of the particulate sensor/probe is checked using advanced digital signal processing

algorithms. The particulate sensor ch eck operates continuously an d does not interfere with normal

monit oring of the pr ocess parti culate si gnal. The par ticulate sen sor check is d isabled whi le zero or

span ch ecks are being performed.

Documen t No. 210-1003- M Page 28 ©2007

Page 36

Particu late Monitoring Sy s tems Installation & Operating Manual

8.6 Process Running Signal

A process running signal in dicates to th e control un it wheth er the main pr ocess fan i s ON or OFF.

Connection of a process running signal adds the following capabilities to the automatic self check

subsystem:

1. Sensor cable check – reference section 8.4 for fu r ther details.

2. Automatic system zero – veri fi es zero of the tot al system el ectronics, cable and s ensor while fu l ly

inst alled in the process.

For proper operation the following conditions must be met:

1. A process runnin g signal must be conn ected t o the contr ol unit process ru n relay in put chan nel.

This signal must be pr ovided from an isolated, non-powere d relay con tact that cl oses when th e

main process fan is on, and opens wh en the main pr ocess fan is off. A motor starter auxiliary

contact an d/or separate con trol relay ar e typically used to provide this signal to the control unit.

Refer to the installation drawings for details on making connections to the relay input channel.

2. The pr ocess r un relay in put chann el mu st be en abled for u se. Ref eren ce men u # 2 setu p tree f or

complete details.

8.7 Monitoring Self Check Status

There are four independent methods to monit or the status of the self check s u bsystem.

LCD Display

The con trol unit’s LCD display will indicate the current status of the self check subsystem as listed

below:

PV Units Display Indication

‘pA’ or ‘m g’ No self checks currently runn ing. The most r ecent self check s were

successful, no failures

‘SC1’ Zero ch eck in process

‘SC2’ Span ch eck in process

‘ER1’ Zero error

‘ER2’ Span error

‘ER3’ Sensor error

‘ER4’ Cable error

‘ER5’ SRAM error

‘ER6’ Non-Volatile memory error

‘ER7’ Option board error

‘ER8’ Analog converter error

‘ER9’ System zero error

Documen t No. 210-1003- M Page 29 ©2007

Page 37

Particu late Monitoring Sy s tems Installation & Operating Manual

Alarm Relay

An alarm output relay can be activated if any self checks are unsuccessful. The alarm relay will

remain activated until a subsequent self ch eck is perfor med success fully, or power to the con trol unit

is disconnected. Alarm relay #1 will be activated in the event of a self check failure by default. Alarm

output relays may be configur ed to operate in normal or fail-sa fe m od es.

4-20mA Output

The 4-20mA output will be driven to non-standard levels to indicate self check status as listed below:

mA Output Indication

3.8mA Zero or sp an ch eck in process, s ensor is disconnect ed

3.6mA A self check er ror has occurred

Serial or Ethernet Communication Network

All information regarding status, control and setup of the self check subsystem is accessible as

regi s ter data through the contr ol unit’s communication networ k. See the Modbus® register map at the

end of this documen t for a complete detailed listing of registers data available.

8.8 Particulate Alarming During Self Checks

All particulate alarms are put in a suspend mode while a self check is being perfor med. When a self

check i s com p leted, all particulat e alarms will r es u me normal operation.

8.9 Self check Recording

EPA MACT regulations require that plants maintain a recor d of all self checks performed. To reduce

the number of plant personnel required to generate these records, the control unit provides two

methods suitable for automated record generation.

4-20mA Output

The 4-20mA output will be driven to specific, non-standard levels to indicate that self checks are

being performed and if any self check has failed. A PLC may be easily configured to monitor for

these sp ecifi c, n on-stan dard , mA levels a nd tr ansmi t stat us infor mation to a cen tral plant in format ion

network for record storage.

Serial or Ethernet Communication Network

The over all stat us of each self ch eck, a s well a s the r esult s of th e most r ecent sel f check s per formed ,

are acces sible t hrough the Modbus® network p ort. Thi s informa tion may be monit ored and log ged

with a remote PC running SCADA application software. Optional FilterWare Visualization and

Reporting software is available to monitor all of the control units self check information and

automatically generate MACT compliant self check reports.

Documen t No. 210-1003- M Page 30 ©2007

Page 38

Particu late Monitoring Sy s tems Installation & Operating Manual

9. Troubleshooting

The following is pr imarily used when troubleshooting a system without the option al automatic self

checks. When tr oublesh ootin g, consi der each componen t of th e system: T he contr ol unit , th e sensor

coax cabl e and the sensor assembl y.

False High Signals (False Alarms)

1. When an appar ent false h igh sign al is pr esent, fir st check t he process t o be sur e the par ticulat e