Page 1

Bulletin P-DM-1200

4-31/64

[113.89]

3

X1/8

[

3.30]

1-59/64

[48.89]

17/64

[6.91]

Ø5

[127.00]

PRESSURE

CONNECTIONS

21/64 [8.59] LONG

3-5/64

[78.27]

1

[25.44]

3-15/32

[88.12]

Ø13/64

[

5.18]

Ø

25/64

[

10.03]

Series DM-1200 DigiMag®Digital Differential Pressure and Air Flow Gage

Specifications - Installation and Operating Instructions

he Series DM-1200 DigiMag

T

s the ideal digital instrument to take the place of analog mechanical pressure

i

ages. The DigiMag

g

ability to be field-programmed to select pressure, air velocity or flow operation. The

®

DigiMag

applications where a set point can be input where the display will blink when the

filter is dirty, alerting the user that a maintenance action needs to occur.

Programming the Series DM-1200 is easy using the menu key to access 4

simplified menus which provide access to: Security level; engineering units; Kfactor for use with various Pitot tubes and flow sensors, circular or rectangular duct

size for volumetric flow operation; filter set point; view peak and valley process

readings; digital damping for smoothing erratic process applications; display

update to conserve battery life; zero and span field calibration.

The Series DM-1200 DigiMag

possesses a full-scale accuracy of 1% on ranges down to 2˝ w.c. and 2% accuracy

down to the very low ranges of 1˝ to 0.25˝ w.c. DigiMag

Pressure Gages offer power versatility by working with 9-24 VDC line power or

simply 9V battery power. If using line power and connecting the 9V battery, the

battery will act as a back-up if line power is lost or interrupted.

Digital Differential Pressure Gages have an added feature for filter

®

®

igital Differential Pressure and Air Flow Gage

D

igital Gages are more versatile than analog gages with their

D

®

Digital Differential Pressure and Air Flow Gage

®

Digital Differential

PECIFICATIONS

S

ervice: Air and non-combustible, compatible gases.

S

etted Materials: Consult factory.

W

Housing Materials: Glass filled plastic.

Accuracy: ±1% F.S. including linearity, hysteresis and repeatability; ±2% F.S. for

ranges 1˝ w.c. and below.

Temperature Limits: 0 to 140°F (-18 to 60°C).

Compensated Temperature Limits: 32 to 122°F (0 to 50°C).

Long Term Stability: ±1% F.S. per year.

Thermal Effect: ±0.05% F.S./°F typ.; ±0.10% F.S./°F for ranges 1˝ w.c. and

below.

Display: 4-digit LCD (Digits: 0.60˝H x 0.33˝W).

Display Update: Selectable for 1 second to 10 minutes or update only from

button push.

Pressure Limits: 5˝ w.c. and lower = 2 psi (13.7 kPa) 10˝ w.c. and higher = 11

psi (75 kPa).

Power Requirements: 9V battery or external power supply 9-24 VDC. Battery

included but not connected.

Type of Battery: 9V alkaline battery (Duracell

Battery Service Life: Battery life depending on the Display Update setting: 150

hours (typical) if Display Update = 1 second; 9 months (typical) if Display Update

= 10 minutes; 1.5 years (typical) if Display Update is disabled. Battery may last

up to four times longer when using lithium-based battery ULTRALIFE U9VL-J.

Current Consumption: 5 mA maximum.

Electrical Connections: Removable terminal block for 16 to 26 AWG.

Electrical Entry: Cable gland for 0.114 to 0.250˝ (2.9 to 6.4 mm) diameter cable.

Process Connections: 3/16˝ I.D. tubing (5 mm I.D.), maximum O.D. 3/8˝ tubing.

Enclosure Rating: NEMA 4X (IP66).

Weight: 1.18 lb (535 g).

Size: 5˝ (127 mm) O.D. front face.

Agency Approvals: CE, EN 61326-1 [Immunity Test Requirement for Industrial

Environments] with the following SPEC:

IEC61000-3-2

IEC61000-3-3

IEC61000-4-2

IEC61000-4-3

IEC61000-4-4

IEC61000-4-5

IEC61000-4-6

IEC61000-4-11

®

Duracell

is a registered trademark of The Gillette Company.

®

PC 1604 or equivalent).

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

NSTALLATION

I

ounting

M

vertical position required. That is the position in which all standard models are

A

alibrated at the factory. Provide a 4-9/16˝ diameter opening in panel. Insert gage

c

and secure in place with provided screws and adapters.

Included Accessories:

ounting lugs –3

M

-20 x 2-1/2 screws –3

6

-20 x 3/8 screws – 3 (mounting hole depth is 3/8˝ [9.53])

4

able gland –1

C

PERATING INSTRUCTIONS

O

Key Functions

IGURE 1

F

Pressure Connections

Two integral tubing connections are provided on the back of the gage. They are

sized to fit 3/16˝ (4.8 mm) I.D. x 5/16˝ (7.9 mm) O.D. flexible PVC tubing. To

easure single positive pressure, connect tubing to the + port and vent the – port

m

o atmosphere. To measure single negative pressure (vacuum), connect tubing to

t

he – port and vent the + port to atmosphere. To measure differential pressure,

t

connect higher pressure to the + port and lower pressure to the – port. Be sure the

pressure rating of the tubing exceeds that of the operating ranges.

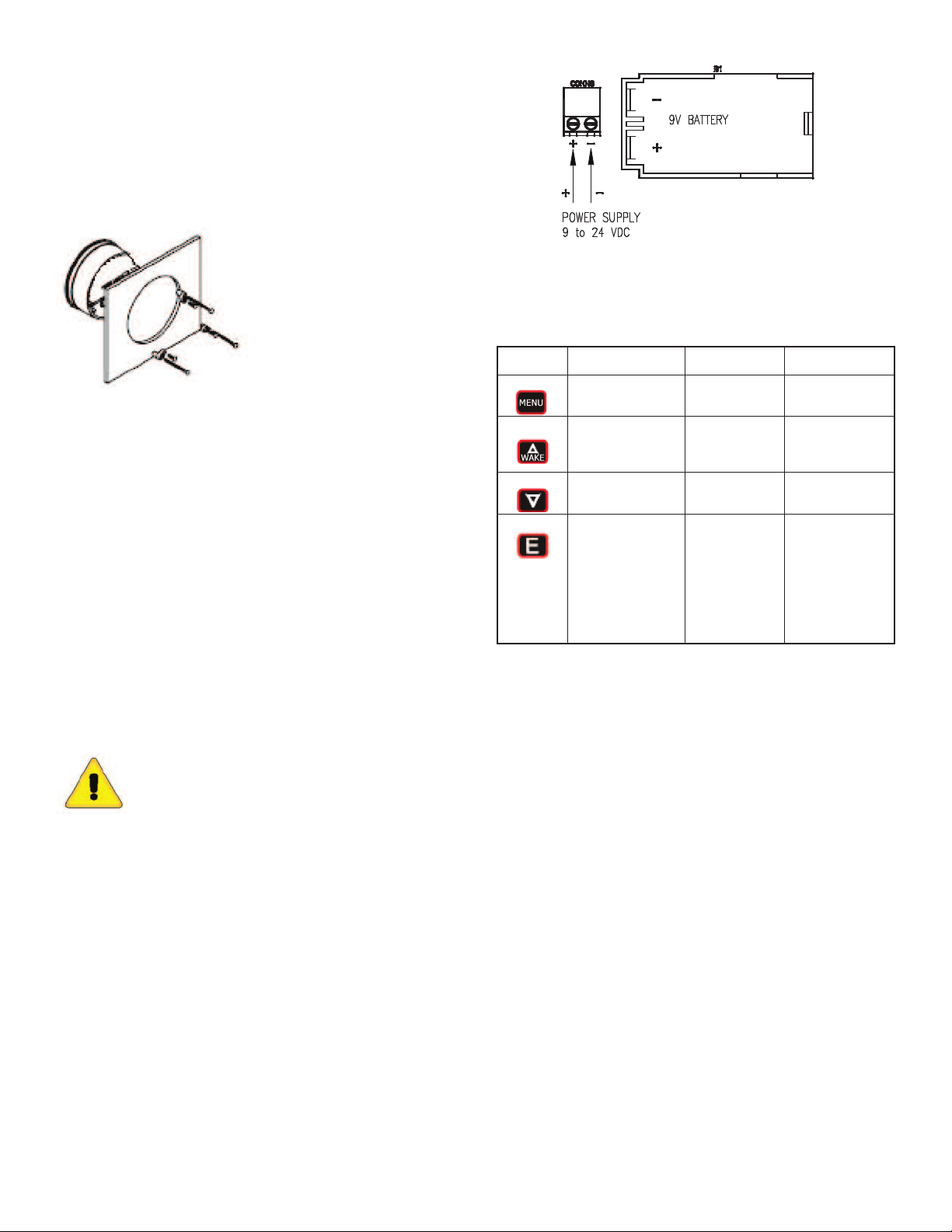

Electrical Connections

A 9V battery or an external power supply 9-24 VDC can be used to power the unit.

If both battery and external power supply are connected, the battery will work as

back up power.

Battery Installation

The unit is shipped with a separate 9V alkaline battery. Remove the unit’s top back

cover then connect the 9V battery to the battery holder as shown in Figure 1.

External Power Supply Installation

Remove the unit’s back cover then connect the external power supply to the

terminal block as shown in Figure 1.

CAUTION: POWER MUST BE OFF WHILE WIRING

CONNECTIONS ARE BEING MADE. DO NOT EXCEED

SPECIFIED SUPPLY VOLTAGE RATINGS. PERMANENT

DAMAGE NOT COVERED BY WARRANTY WILL RESULT.

enu

M

Up Arrow

own Arrow

D

Enter

Home Position

Function

llows access to the

A

enus

m

Displays pressure

readings instantly

(rAtE KEY MODE only)

Displays full scale

range of unit

Main Menu

Function

eturn to home

R

osition

p

Sequences through

menus

equences through

S

enus

m

Enter into SUB

MENU

ub Menu

S

unction

F

eturn to previous

R

menu

Increments a value

Decrements a value

hanges a value or

C

setting. Press

ENTER and display

will blink. Adjust with

UP or DOWN

arrows. Press

ENTER to store.

Display will stop

blinking.

Page 3

enu Map

M

Page 4

AIN MENU PROGRAMMING INSTRUCTIONS

M

Upper Right Display Reads MENU)

(

ecurity Menu

S

SECr-MENU

:

Lock out access to all menus or lock out access to all menus except Auto-Zero

function (Auto-ZERO).

peration Menu

O

elect the measurement type – pressure, velocity or flow and corresponding

S

ngineering units.

e

OPEr-MENU

:

Display Menu: diS-MENU

Monitor and adjust display related settings: Filter type, filter point, dampening,

display update, peak and valley.

dvanced Menu

A

erform auto-zero or full-scale calibration.

P

AdU-MENU

:

VAILABLE VELOCITY RANGES

A

nput Range

I

FPM Range

n w.c.

i

0 - 0.25

0 - 0.50

0 - 1.00

- 2.00

0

- 5.00

0

- 10.0

0

- 15.0

0

0 - 25.0

0 - 50.0

LO (Flow) SUB MENU:

F

or flow measurements, the following units are available:

F

LO – SCFM: Flow – Standard cubic feet per minute

F

FLO –M

S

0 - 2002

0 - 2832

0 - 4004

- 5663

0

- 8954

0

- 12.66 x 1K

0

- 15.51 x 1K

0

0 - 20.02 x 1K

0 - 28.32 x 1K

3

H: Flow – Cubic meters per hour

/S Range

M

0 - 10.17

0 - 14.39

0 - 20.35

- 28.77

0

- 45.48

0

- 64.33

0

- 78.76

0

0 - 101.7

0 - 143.9

SECURITY MENU

: SECr-MENU

With the gage reading pressure (home position), press and hold the MENU key

ntil the SECr-MENU is displayed. Press the E key to show the security SUB

u

ENU SECr–0001. When the security SUB MENU is selected, the present

M

ecurity level is displayed in the upper right hand display. To change the security

s

level, adjust the number displayed to the number shown in the following table for

the desired security level.

ecurity Level

S

Displayed

1

2

ccess

A

All menus access

All menus locked except

assword Value

P

o Enter

t

0

1

90

the Auto-zero function

ll menus locked

3

A

111

The password values shown in the table cannot be altered, so retain a copy of

these pages for future reference.

OPERATION MENU

: OPEr-MENU

With the gage reading a numerical value (home position), press and hold the

MENU key until the SECr-MENU is displayed. Press the q key to show the OPErMENU. Press the E key to show the Operation SUB MENUS.

The Operation SUB MENUS are:

PrES – Pressure UEL – Velocity FLO – Flow

FLOr – Flow range KFAC – K Factor ArEA – Area

DIA – Diameter XDIM – X Dimension YDIM – Y Dimension

If the instrument is set for Velocity, the OPEr MENU will have an additional KFAC

SUB MENU. If the instrument is set for Flow, the OPEr MENU will have additional

KFAC and ArEA SUB MENUS. These will be discussed under Velocity and Flow.

NOTE: When scrolling through the OPEr SUB MENUS, the measurement type

the unit is currently set for will show the units in the upper right display. The

other measurement types will have a blank upper right display (see below).

FLOr (Flow range) SUB MENU:

The following flow ranges are available:

LOr – HI: Flow range – High: 999.9 x 1K

F

LOr – MED: Flow range – Medium: 99.99 x 1K

F

LOr – LO: Flow range – Low: 9999

F

able 1: FLOr = LO

T

aximum Duct Size (English)

M

Max Duct Size

sq ft

4.994

.531

3

.497

2

1.766

1.117

0.789

0.644

0.499

0.353

Max Duct Size

sq ft

49.94

35.31

24.97

17.66

11.17

7.898

6.446

4.994

3.530

.50

.00

SCFM

Range

9999

999

9

999

9

9999

9999

9999

9999

9999

9999

SCFM

Range

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

Range

in w.c.

0.25

0

1

2.00

5.00

10.0

15.0

25.0

50.0

Table 3: FLOr = MED

Maximum Duct Size (English)

Range

in w.c.

0.25

0.50

1.00

2.00

5.00

10.0

15.0

25.0

50.0

T

M

Table 4: FLOr = MED

Maximum Duct Size (Metric)

able 2: FLOr = LO

aximum Duct Size (Metric)

Range

in w.c.

0.25

.50

0

.00

1

2.00

5.00

10.0

15.0

25.0

50.0

Range

in w.c.

0.25

0.50

1.00

2.00

5.00

10.0

15.0

25.0

50.0

3

M

/hr

Range

9999

999

9

999

9

9999

9999

9999

9999

9999

9999

3

M

/hr

Range

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

99.99x1K

Max Duct Size

M

0.273

.193

0

.136

0

0.096

0.061

0.043

0.035

0.027

0.019

Max Duct Size

M

2.731

1.930

1.364

0.965

0.610

0.431

0.352

0.273

0.193

2

2

UEL (Velocity) SUB MENU:

For velocity measurement, the following units are available:

UEL-SFPM: Velocity – Standard feet per minute

UEL-M/S: Velocity – Meters per second

NOTE: Air velocity and flow readings are based upon standard dry air

conditions with an ambient temperature of 70°F and a barometric pressure of

29.92 INHG.

Table 5: FLOr = HI

Maximum Duct Size (English)

Range

in w.c.

0.25

0.50

1.00

2.00

5.00

10.0

15.0

25.0

50.0

SCFM

Range

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

Max Duct Size

sq ft

499.4

353.1

249.7

176.6

111.7

78.98

64.46

49.94

35.30

Table 6: FLOr = HI

Maximum Duct Size (Metric)

Range

in w.c.

0.25

0.50

1.00

2.00

5.00

10.0

15.0

25.0

50.0

3

M

/hr

Range

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

999.9x1K

Max Duct Size

2

M

27.31

19.30

13.64

9.654

6.107

4.317

3.526

2.731

1.931

Page 5

FAC (K Factor) SUB MENU:

K

.00-KFAC: K Factor = 1.00

1

K factor becomes accessible if the instrument is set for Velocity or Flow. When the

®

DigiMag

is used with a Pitot tube, the manufacturer may specify a K factor. The

adjustment range is 0.01 to 2.00. The factory setting is 1.

rEA (Area), DIA (Diameter), XDIM (X dimension) and YDIM (Y dimension)

A

UB MENUS:

S

These SUB MENUS become accessible if the instrument is set for Flow. When

measuring flow, the area of the duct must be specified. Tables 1 to 6 show the input

range vs. maximum flow and duct size. For a rectangular duct the maximum size

s specified by the X, Y dimensions. For a circular duct the maximum size is

i

pecified by the diameter. X, Y and circular dimensions are entered in feet with

s

.001 foot resolution for FLOr = LO, 0.01 foot resolution for FLOr = MED and 0.1

0

foot resolution for FLOr = HI, or entered in millimeters with 1 millimeter resolution.

ArEA – Area, select CIR for a circular duct or RECT for a rectangular duct. If a

circular duct is selected the DIA SUB MENU will be activated. If a rectangular duct

s selected, the XDIM and YDIM SUB MENUS will be activated.

i

IA – Diameter, enter the diameter of a duct

D

XDIM – Enter the “X” dimension of a duct

YDIM – Enter the “Y” dimension of a duct

ISPLAY UPDATE SETTING

D

ith the LCD reading rAtE – NORM, press the E key; the display will blink. Press

W

he q key to change the display update rate then press the E key to save the

t

esired display update rate.

d

rAtE – NORM: Display update = Normal (1 second).

The gage reads the process pressure and updates the LCD every second.

AtE – 10: Display update = 10 minutes.

r

he gage reads the process pressure and updates the LCD every 10 minutes.

T

rAtE – KEY (On-Touch mode): Display update is disabled.

The gage reads the process pressure and updates the LCD whenever the p key

is pressed. If the p key is released, the LCD will hold and display the last pressure

eading.

r

OTES:

N

1. Depending on the Display Update setting, the battery life is shown below:

-150 hours (typical) if Display Update is set for “Normal” 1 second update. rAtE-

NORM

-1 year (typical) if Display Update is set for 10 minutes. rAtE-10

2 years (typical) if Display Update is disabled. rAtE-KEY

-

. If the Display Update is set for 10 minutes or disabled (On-Touch mode), the

2

rocess pressure value can be read instantly by pressing and holding the p key

p

on the front panel. Also the LCD will automatically show “ALAr” if the filter point has

been exceeded.

PEAK AND VALLEY SETTING

00.0 – PEAK: Peak value = 100.0

1

he peak feature stores the highest pressure reading the instrument has measured

T

ince the last reset or power up. At power up PEAK is reset to the present pressure

s

reading. To manually reset the PEAK value, press the E key while in the PEAK

SUB MENU.

DISPLAY MENU: diS – MENU

With the gage reading a numerical value (home position), press and hold the

MENU key until the SECr-MENU is displayed. Press the q key until the LCD

shows diS – MENU. Press the E key to show the Display SUB MENUS.

FILTER TYPE SETTING

With the LCD reading FILt – OFF, press the E key; the display will blink. Press the

q key to change the filter type then press the E key to save the desired filter type.

FILt – OFF: Filter type = OFF. The filter function is disabled.

FILt – HIGH: Filter type = HIGH. The display blinks when pressure is greater than

the filter point.

FILt – LOW: Filter type - LOW. The display blinks when pressure is less than the

filter point.

FILTER POINT SETTING

With the LCD reading 0.00 – SPPT, press the E key; the display will blink. Press

the p or q key to change the filter point then press the E key to save the desired

filter point.

0.00 – SPPT: Filter point = 0.00. The filter point may be set to anywhere within the

range of the instrument.

DAMPING SETTING

With the LCD reading 1 – DAMP, press the E key; the display will blink. Press the

p or q key to change the damping level then press the E key to save the desired

damping level.

1 – DAMP: Damping level = 1. The damping level can be adjusted from 1 to 15.

Damping stabilizes the display from instabilities due to things such as vibration and

excessive pressure fluctuations. The damping function adjusts the amount of

readings that are averaged for each display update.

0.0 – VALY: Valley value = 0.0

The valley feature stores the lowest pressure reading the instrument has measured

since the last reset or power up. At power up VALY is reset to the present pressure

reading. To manually reset the VALY value, press the E key while in the VALY SUB

MENU.

ADVANCED MENU: AdU – MENU

With the gage reading pressure (home position), press and hold the MENU key

until the SECr-MENU is displayed. Press the q key until the display shows the

AdU – MENU. Press the E key to show the advanced function SUB MENUS.

Auto ZERO: auto-zero

NOTE: For accurate calibration, DO NOT apply any pressure when

performing this function.

With the display reading Auto ZERO, release pressure to Zero then press the E

key; the display will blink. Press the E key again to complete the Auto-zero.

CAL – SPAN: full-scale calibration

With the display reading CAL – SPAN, apply full-scale pressure then press the E

key; the display will blink. Press the E key again to save the full-scale calibration

or press the MENU key to cancel the calibration.

MAINTENANCE

Upon final installation of the Series DM-1200 DigiMag

®

Digital Differential Pressure

Gage, no routine maintenance is required. A periodic check of the system is recommended. The Series DM-1200 is not field serviceable and should be returned if repair

is needed (field repair should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant application notes. Contact

customer service to receive a return good authorization number before shipping.

Page 6

3-5/64

[78.27]

STANDARD MOUNTING HOLE

DIMENSION FOR DIGIMAG GAUGE

Ø4-9/16 [115.89]

1

[25.44]

2X30°

2xØ13/32 [10.32]

THRU HOLES FOR

PRESSURE PORTS

1-51/64 [45.72]

3-15/32 [88.12]

(3) SURFACE MOUNTING

HOLE LOCATIONS

13/32 [10.16]

Ø5/8 [15.88]

THRU HOLE FOR

CONDUIT CONNECTION

OUTSIDE DIAMETER

OF A-286 FLANGE

1-1/4 [31.75]

(3) FLANGE MOUNTING

HOLE LOCATIONS

Ø5-17/32 [140.49]

BOLT CIRCLE

MOUNTING HOLE DIMENSION

FOR A-286 FLANGE

Ø5-1/8 [130.18]

Mounting Template

©Copyright 2014 Dwyer Instruments, Inc Printed in U.S.A. 1/14 FR# 19-443779-50 Rev.2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...