Page 1

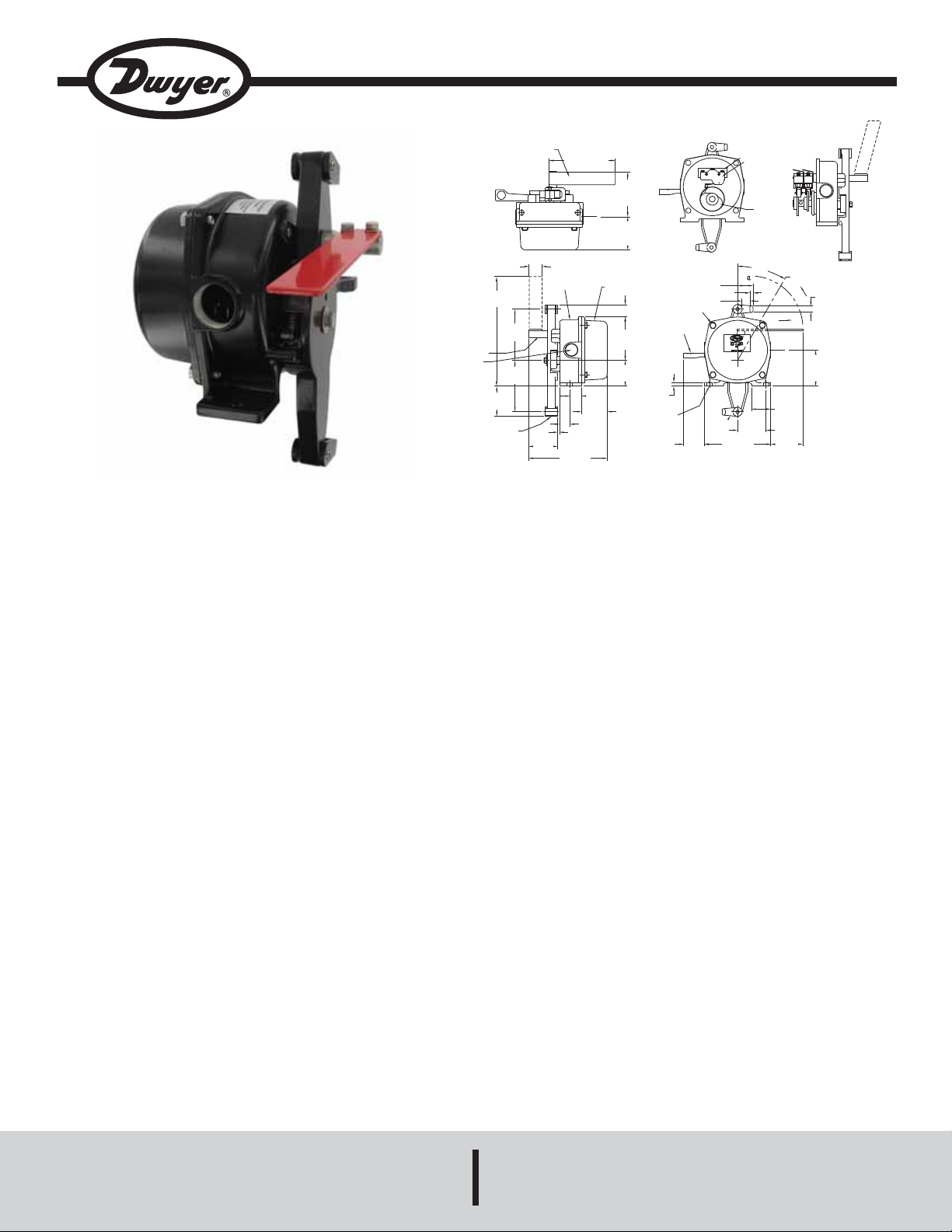

Series CPS Cable Pull Switch

OPERATION-INDICATING

PLATE

INSIDE VIEW

CAMS

INSULATORS

MICROSWITCHES

5-1/8

[130.18]

3-7/16

[87.31]

2-9/16

[65.09]

1-1/8

[28.58]

19/32

[15.03]

COVER BOLTS

4X M10

RESETTING

LEVER

63/64

[25]

CASE

COVER

61/64

[24.21]

3-23/64

[85.33]

1-31/32

[50]

29/32

[23.02]

1-31/32

[50]

51/64

[20.24]

6-1/16

[153.99]

1/8

[3.18]

LEVER

2-21/64

[59.13]

3-15/16

[100.01]

2X 3/4˝

NPT

SHAFT

3-15/16

[100.01]

8-7/16

[214.31]

2-15/64

[5.95]

PULLING DIRECTION

1/4

[6.35]

30°

LOCK POSITION

31/64

[12.3]

2-49/64

[70.25]

2X 2-11/64

[55.17]

2-9/16

[65.09]

2X 1-1/2

[38.1]

5-1/8

[130.18]

1-37/64

[40.08]

9/32

[7.14]

ø13/32 [10.32]

MOUNTING HOLES

SHACKLES

OPERATING DIRECTION

Specifications - Installation and Operating Instructions

Bulletin PC-CPS-1

The Series CPS Cable Pull Switch is designed to provide a

switching system to isolate the power to the conveyor system or

other similar process equipment in event of a shut-down condition. A steel wire is placed along the side of the conveyor and attached to the cable pull switch. When the cable is pulled at any

point along the conveyor it will trip the cable pull switch causing

the conveyor to shut down. To restart the conveyor the CPS

must be manually reset. The series CPS has a universal design

for bi-directional activation and utilizes a highly visible red flag to

indicate the switch status. The compact design makes it ideal for

easy installation.

SPECIFICATIONS

Temperature Limits: -4 to 140°F (-20 to 60°C).

Enclosure: Die cast aluminum.

Enclosure Rating: NEMA 6 (IP 67).

Switch Type: 2 SPDT.

Electrical Rating: 10 amp @ 125/250 VAC; 1/2 amp @ 125

VDC.

Electrical Connection: 3 screw type, common, normally open,

normally closed.

Electrical Conduit: Two 3/4˝ female NPT.

Activation Angles: 30 degrees.

Activation Force: 11 +/- 2.25 pounds.

APPLICATIONS

• Conventional Belt Conveyors

Control Type: Manual reset.

Weight: 6.4 pounds.

• Ship Loading/Unloading Systems

• Stacker/Reclaim Conveyors

• Apron Feeder Conveyors

• Tripper or Shuttle Conveyors

• Bucket Elevators

• Horizontal Feed Systems

Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

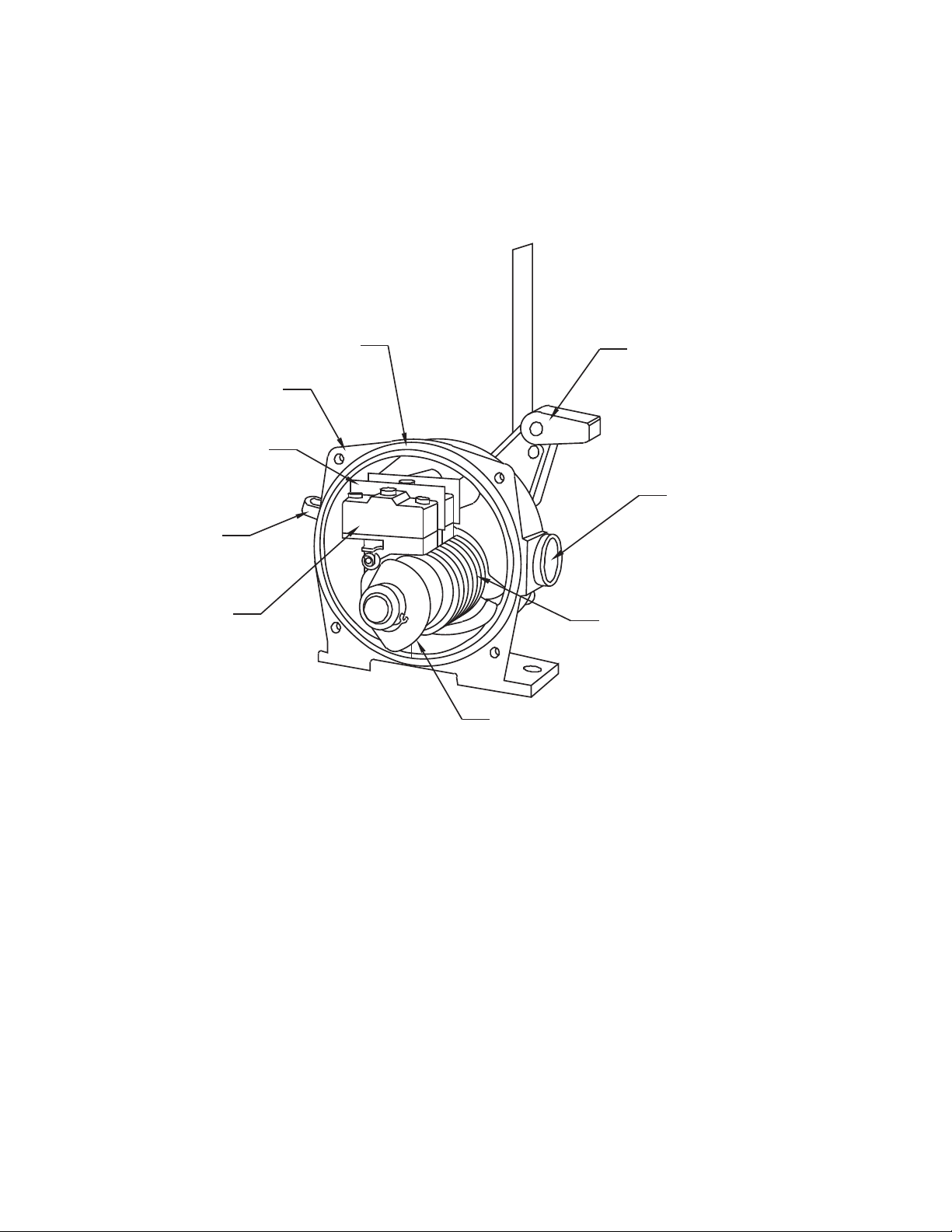

Operation Principle

The CPS is designed to provide a switching system to isolate the

power to conveyor system and other equivalent process

equipment in a shutdown condition. The cable pull switch is

actuated by a steel wire, which is placed along-side the

conveyor. By pulling on the cable at any point, the CPS will

activate when the operating lever rotates 30 degrees clockwise,

automatically locking the switches. The CPS can be reset by

pressing down on the reset lever.

INSULATING PAPER

RESETTING LEVER

MICROSWITCH

CASING

PACKING

OPERATING LEVER

3/4˝ FNPT CONDUIT CONNECTION

SPRING

CAM

Page 3

Installation

Eye bolts should be prepared before installation, and should be

spaced according to the cable length (Figure 2). A single pull

cord up to 50 feet should have an eye bolt mounted every 10

feet. When using a single pull cord up to 75 feet there should be

an eyebolt every 3 feet. The maximum length of cable between

CPS is 75 feet (Note: Variations in temperature will cause cable

to expand and contract). The ideal cord is a steel cable 0.25

inches in diameter. Figure 3 is a typical installation of a CPS.

CONVEYOR BELT FRAME

CABLE

Fig. 2 Installation of Eye Bolts

EYE BOLTS

FRAME OF BELT

CONVEYOR

CABLE

MOUNTING

BASE

6˝

WIRE CUP

4.5˝

8.25˝

Fig. 3 Typical Installation of CPS

Page 4

Wiring

The Cable Pull Switch has 2 SPDT relays that can be accessed

by removing the cover. The independent relays can be used to

control two separate circuits such as a motor starter and a signal

light.

TERMINAL SCREW

ROLLER LEVEL

COM-1, 4

NO- 3, 6

NC- 2, 5

DEACTIVATEDACTIVATED

Adjustment

The cams are set at the factory to trip the microswitches when

the operating arm is rotated 30 degrees clockwise. Cams can be

adjusted by loosening the set screw.

MAINTENANCE

Clean excessive amount of dust when it accumulates on the

operating lever. Occasionally check to see if the CPS is working

normally by pulling the cable. After the CPS is installed check the

housing cover to ensure it is tight, water and dust can enter

between the cover and casing if it not tightened correctly causing

the switch to malfunction. The CPS is not field serviceable and

should be returned if any repair is needed (field repair should not

be attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes.

Contact customer service to receive a returns good authorization

number before shipping.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# R4-443727-50

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...