Page 1

MAINTENANCE/REPAIR

Important Points!

Continuous Level Transmitters

Regular maintenance of the total system is recommended to assure sustained optimum performance. These devices are

not field repairable and should be returned to the factory if recalibration or other service is required. After first obtaining a

Returned Goods Authorization (RGA) number , send the unit freight prepaid to the following. Please include a clear description of the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City , IN 46360

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and Dwyer product catalog

and instruction bulletin. Failure to observe this warning could

result in serious injuries or damages.

For hazardous area applications involving such things as (but

not limited to) ignitable mixtures, combustible dust and

flammable materials, use an appropriate explosion-proof

enclosure or intrinsically safe interface device.

The pressure and temperature limitations shown on the

individual catalog pages and drawings for the specified flow

switches must not be exceeded. These pressures and

temperatures take into consideration possible system surge

pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical

to the life and operation of Dwyer products. Take care in the

proper selection of materials of construction, particularly wetted

materials.

Life expectancy of switch contacts varies with applications.

Contact Dwyer if life cycle testing is required.

Ambient temperature changes do affect switch set points,

since the specific gravity of a liquid can vary with temperature.

Dwyer Products have been designed to resist shock and

vibration; however, shock and vibration should be minimized.

Filter liquid media containing particulate and/or debris to

ensure the proper operation of our products.

Electrical entries and mounting points in an enclosed tank

may require liquid/vapor sealing.

Dwyer Products must not be field-repaired.

Physical damage sustained by the product may render it

unserviceable.

Series CLT

Designed for continuous liquid level sensing, Dwyer transmitters are considered "components".

Operating Principle

The CLT Series utilizes reed switch/magnet technology. A

magnet-equipped float rises or lowers with corresponding

liquid level. The magnetic field generated from the float

actuates a series of reed switches mounted within a sealed

hollow tube. The series of reed switches is combined with

resistors to form a voltage divider.

When a regulated DC voltage is applied to an CLT, the

resulting voltage output is directly proportional to liquid level.

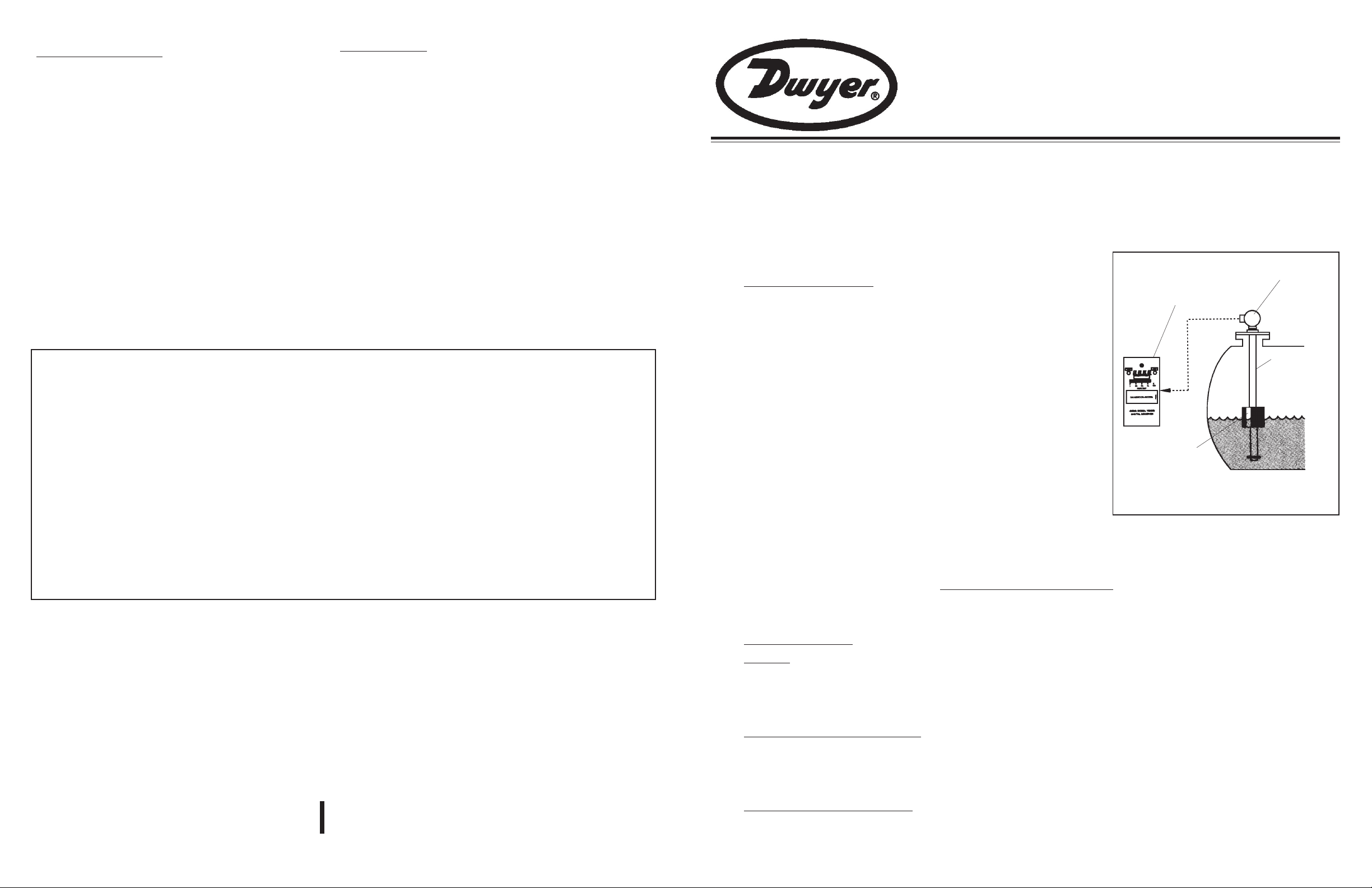

Installation / Mounting

Units operate normally in any attitude, from vertical to a 30° inclination, up or down.

Meter

(Optional)

Float

Junction

Box

Sealed

Hollow

Tube

DWYER INSTRUMENTS,INC.

P .O.BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Thread Treatment

Sealing: When threading metal threads into a metal coupling , pipe sealant or Teflon tape is

recommended. Due to potential compatibility problems, when sealing plastic threaded units, a

compatible pipe sealant such as "No More Leaks" from Permatex is recommended.

Tightening (Plastic to Metal): When threading a plastic sensor into a metal coupling, the installer should use a suitable wrench and tighten the threads 1 to 1-1/2 additional turns past handtight. Over-torquing of the threads will result in damage to the plastic mounting plug.

Tightening (Metal to Metal): When threading a metal sensor into a metal coupling, the installer

should use a suitable wrench and tighten the threads 1-1/2 turns past hand-tight.

Page 2

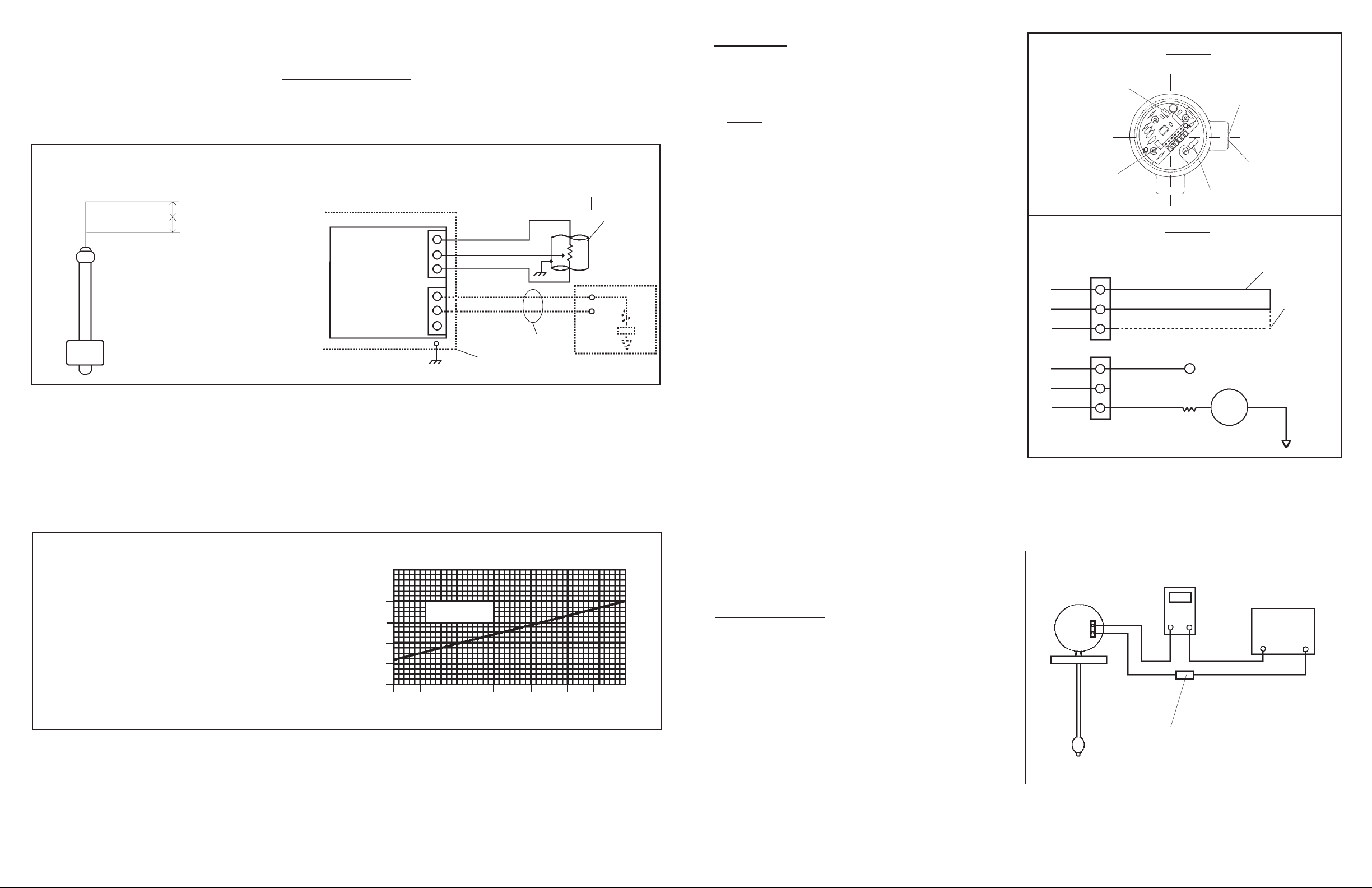

Wiring Diagrams

Note: For hazardous area applications, use an appropriate intrinsically safe interface device.

Wiring Diagram

Analog Output (Proportional Voltage)

Red

Black

White

Input: 10 - 30 VDC

Output: Proportional

Voltage

4-20 mA Tank Level Transmitter

Wiring Diagram

(4-20mA Output)

1

3

2

4

5

6

Red

Wht

Blk

Junction

Box

Process

Control

Loop

Transmitter

+VA

Voltage

Source

or

Simulator

R

L

Calibration

The signal conditioner on your CLT has been Factoryset. You do not need to calibrate.

Steps:

Calibration should be performed with the probe

A.

disconnected from the signal conditioner. Turn

off power to loop. Disconnect the red, black and

white wires from terminals 1, 2, and 3.

Adjust both the null and span potentiometers at

B.

approximately mid-range. (Figure 1)

Wire as shown per Figure 2, connecting a jumper

C.

wire in place of the black and white probe wires.

Connect an ammeter in series to monitor loop

current. Apply power to loop. Adjust null pot for

4mA.

Remove power from loop. Reposition the jumper

D.

wire in place of red and white probe wires.

Reapply power and with the span pot, set the

output current to 20mA.

Repeat Steps C and D for final adjustment.

E.

If power is maintained during jumper connections,

F.

current level may increase to 36mA. This is

normal. Current will return to regular readings

when connections are made.

Figure 1

Span

Potentiometer

Null

Potentiometer

Figure 2

Using 300 Ohm Resistor

Red

White

Black

Brown

Wht/Blk

Orange

1

3

2

5

6

4

R

Loop

Customer Wiring

(See Wiring Diagram)

1/2" Trade Size

Ground Terminal

(both Ports)

Place Jumper

Here for 20 mA

Output

Place Jumper

Here for 4 mA

Output

+V (Typically 24V)

Ammeter

_

+

Excitation Required for Transmitters

Using 4-20 mA Signal Conditioners

The minimum excitation required for operation of

transmitters with 4-20 mA, DC signal converters

(See Chart) can be determined for a given total loop

resistance from the graph shown. (Total loop resistance = the sum of the DC termination resistance plus

loop resistance.) For optimum operation, which is a

function of source voltage (+VA) and total loop resistance, the source voltage value used should be above

the minimum load line for the related loop resistance.

Minimum Excitation Required For Loop Resistance

40

30

20

10

DC Source Voltage

0

0 200 400 600 800 1000 1200

RL (Ohms) Termination Plus DC Loop Resistance

Area

of Operation

Troubleshooting

Verify proper wiring, power supply, and loop resistance. If

transmitter is not functioning properly, isolate the transmitter

from the system and wire per Figure 3. Meter should read

4mA with float at bottom and 20mA with float on top of

transmitter. If unit is still not operating properly, please

consult Factory for further troubleshooting details.

+24V

Return

Figure 3

4.12

AMMETER

COM

mA

Power Supply

(24 VDC)

+

Choose loop resistance (RL)

to match application

_

Loading...

Loading...