Page 1

Bulletin AQ-CDW2

4

-37/64

[

116.40]

1

-1/16

[

27.11]

3

-13/64

[

81.40]

2

-23/64

[

60.06]

BACK COVER

COVER LOCKING HOLE

1-1/16

[27.11]

3-13/64

[81.40]

2

-23/64

[

60.06]

B

ACK COVER

COVER LOCKING HOLE

3

-13/32

[

86.41]

3-1/4

[82.55]

1-3/16

[30.10]

1-3/16

[30.10]

F

OR MODELS

W

ITH LCD DISPLAY

F

OR MODELS

W

ITH LCD DISPLAY

Series CDW2 Wall Mount Carbon Dioxide Transmitter

Installation and Operating Instructions

hown with Optional LCD Display

S

The Series CDW2 Wall Mount Carbon Dioxide Transmitters monitor ambient

carbon dioxide conditions for variable air volume (VAV) on demand ventilation

ystems. Universal current/voltage temperature and humidity outputs are also

s

vailable to reduce the number of instruments mounted on the wall. The Non-

a

ispersive Infrared (NDIR) sensor continuously updates the calibration through a

D

roprietary logic feature which limits the amount of error due to drift. A duct mount

p

nd a heated outside air enclosure are available enabling the CDW2 to be used in

a

ifferent environments.

d

WARNING

Before performing service or maintenance on the systems, turn

OFF the main power switches to the unit. Electric shock can

cause personal injury. Please read and follow the wiring instructions precisely;

incorrect wiring may cause permanent damage to the product.

WARNING

The Series CDW2 products have two terminal pins that are

connected inside the sensor to a common/ground pin: pins 2

and 7 on the I/O terminal block and pin 2 on the power block. Do NOT connect

positive 24 VAC power line to pin 2 of the power block.

CAUTION

The Series CDW2 are 3-wire or 4-wire type configurations only.

Wiring the CDW2 as a 2-wire device will irreparably damage the

sensors and void the warranty.

NOTICE

The Series CDW2 contains a passive thermistor which is

electrically isolated from the other circuitry and should be wired

independently from the active inputs(Temperature, RH, CO

share a common ground.

). The active inputs all

2

MOUNTING

Push the tabs on the case to separate the case into its front and rear sections.

Mount the rear section of the case to the wall or junction box with the supplied

screws. Mount controller on the base by aligning the top clips and securing the

bottom clips. Secure the CDW2 with the supplied set screw.

Standard Style European Style

PECIFICATIONS

S

ange: CO

R

R

0 to 2000 PPM;

:

2

elative Humidity: 0 to 99%;

Active Temperature: 32 to 122°F (0 to 50°C).

Accuracy: CO

RH: ± 2.5% (20 to 80% RH) / 3.5% (<20% and >80%);

: ±30 PPM or 3% of reading, whichever is greater;

2

Active Temperature: ± 1.5°F @ 72°F (0.8°C @ 22°C);

hermistor: ± 1.9°F @ 60 to 95°F (1°C @ 15 to 35°C).

T

emperature Dependence: ±0.11% FS per °F (0.2% per °C).

T

ressure Dependence: 0.135% of reading per mm Hg.

P

Response Time: Signal updates every 5 seconds.

Warm Up Time: < 2 min (operational), 10 min (max. accuracy).

Temperature Limits:

Ambient: 32 to 122°F (0 to 50°C);

Storage: -40 to 158°F (-40 to 70°C).

Power Requirements: 18 to 30 VAC RMS 50/60 Hz, 18 to 42 VDC, polarity

protected.

Sensor: CO

RH: Capacitive polymer sensor

: Non-dispersive infrared sensor (NDIR) with ABC logic

2

Temperature: 10 kΩ Type II thermistor, 10 kΩ type III Thermistor, 3 kΩ

Thermistor, 20 kΩ Thermistor, PT100RTD, PT1000 RTD.

Weight: 7.2 oz (204 g).

Agency Approvals: CE, RoHS.

POWER SUPPLY REQUIREMENTS

The transmitter can be powered with either 18 to 42 VDC or 18 to 30 VAC. DC

power is polarity protected. AC power must be at a frequency between 50 and 60

Hz.

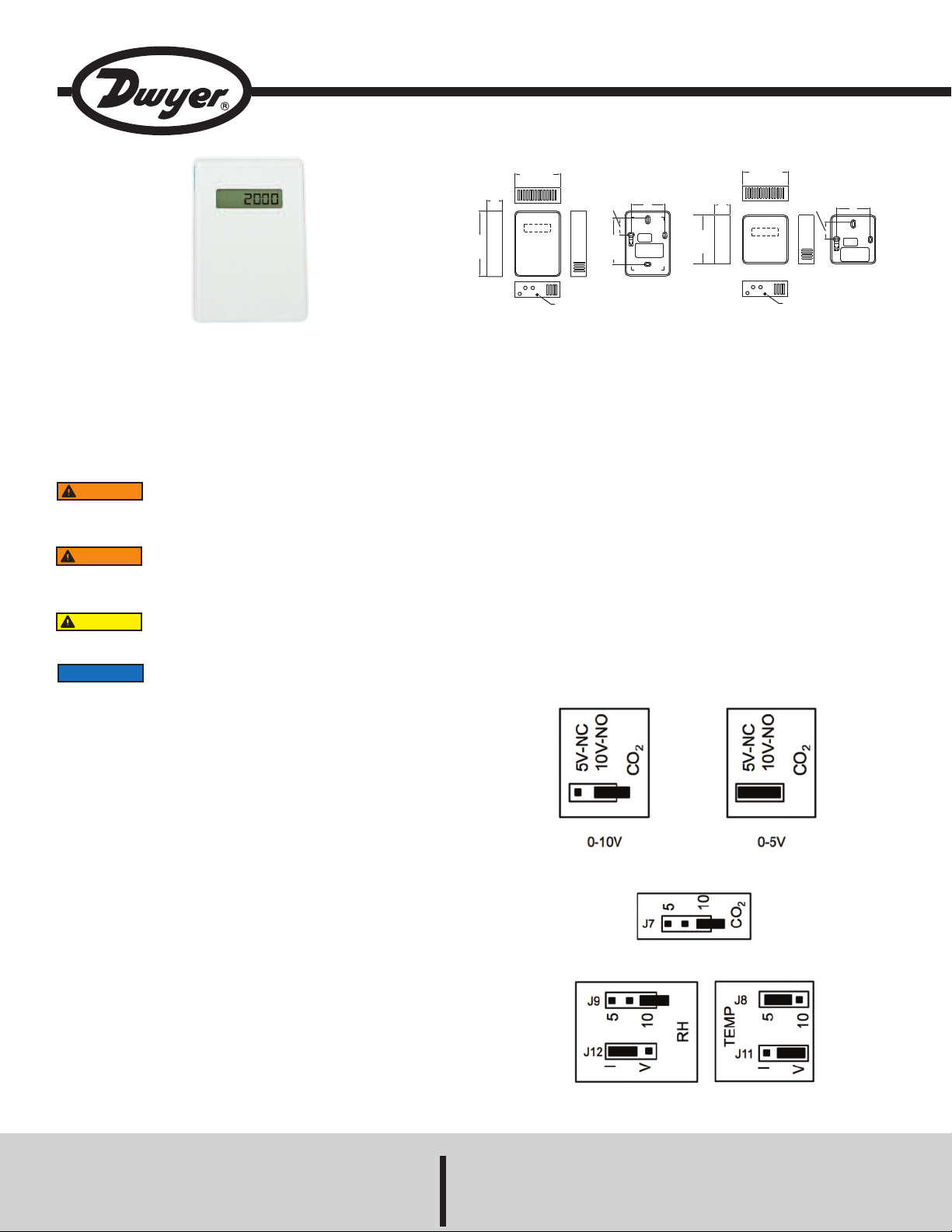

Figure 1: Jumper settings for CO2output on non-display units (J3)

Selection of Current and Voltage Outputs

Prior to wiring, verify that the current/voltage selections jumpers are set to the

desired output type. For voltage output selection, the output can be 0 to 5 or 0 to

10 VDC.

Figure 2: Jumper settings for display units. CO2is set for a 4 to 20 mA and

to 10V output , humidity is set for a 4 to 20 mA output, temperature is set to

0 to 5V output. (NOTE: Jumper names)

Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

IRING

W

he CDW2 series has two basic configurations. The first provides three active outputs

T

relative humidity, temperature, CO

(

onfiguration provides only the CO

c

power requirements and wiring for the two configurations are identical. The

recommended wire gauge is 18 to 22 AWG (1.0 to 0.75 metric).

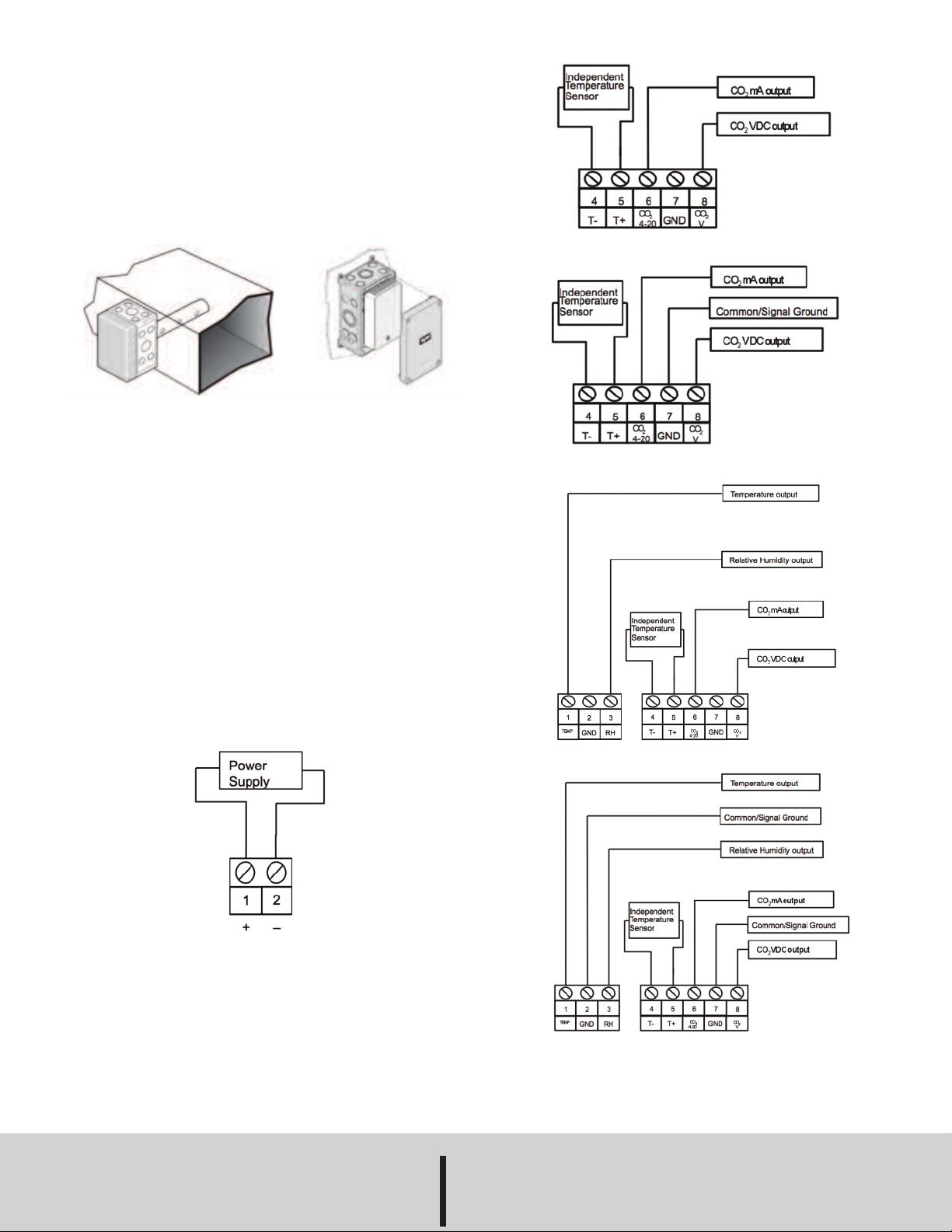

CCESSORIES

A

odel 1508 Duct Mount Enclosure – The CDW2 series can be installed in a model

M

508 duct mount enclosure.

1

odel 1552 Outside Air Enclosure – This NEMA-3R weatherproof enclosure

M

includes thermostat and allows installation of the sensor in environments with

temperatures down to -40°F (-40°C).

Figure 8: Duct mount enclosure (left), outside air enclosure (right)

Calibration

he Series CDW2 is factory set with the proprietary logic function activated. The logic

T

unction allows the sensor to continuously recalibrate itself when the indoor

f

oncentrations drop to levels similar to outside air conditions when the building is

c

unoccupied. The building must be unoccupied for a minimum of 4 hours or more for

this self calibration to be effective. The logic allows the sensor to maintain its

calibration over the life of the sensor. If the building is occupied 24 hours a day or

there is significant sources of CO

should be turned off.

and an independent thermistor. The other

)

2

utputs and an independent thermistor. The

o

2

while the building is unoccupied, the logic function

2

igure 4: 3-wire configuration for use with models CDW2-2W4XX

F

igure 5: 4-wire configuration for use with models CDW2-2W4XX

F

MAINTENANCE/REPAIR

Upon final installation of the Series CDW2, no routine maintenance is required. The

Series CDW2 is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

WIRING DIAGRAMS

Figure 3: Power block terminal connection. For use on all models.

(See Power Supply Requirements)

Figure 6: 3-wire configuration for use with models CDW2-2W4XX-LCD

Figure 7: 4-wire configuration for use with models CDW2-2W4XX-LCD

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 3/13 FR# R6-444001-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...