Page 1

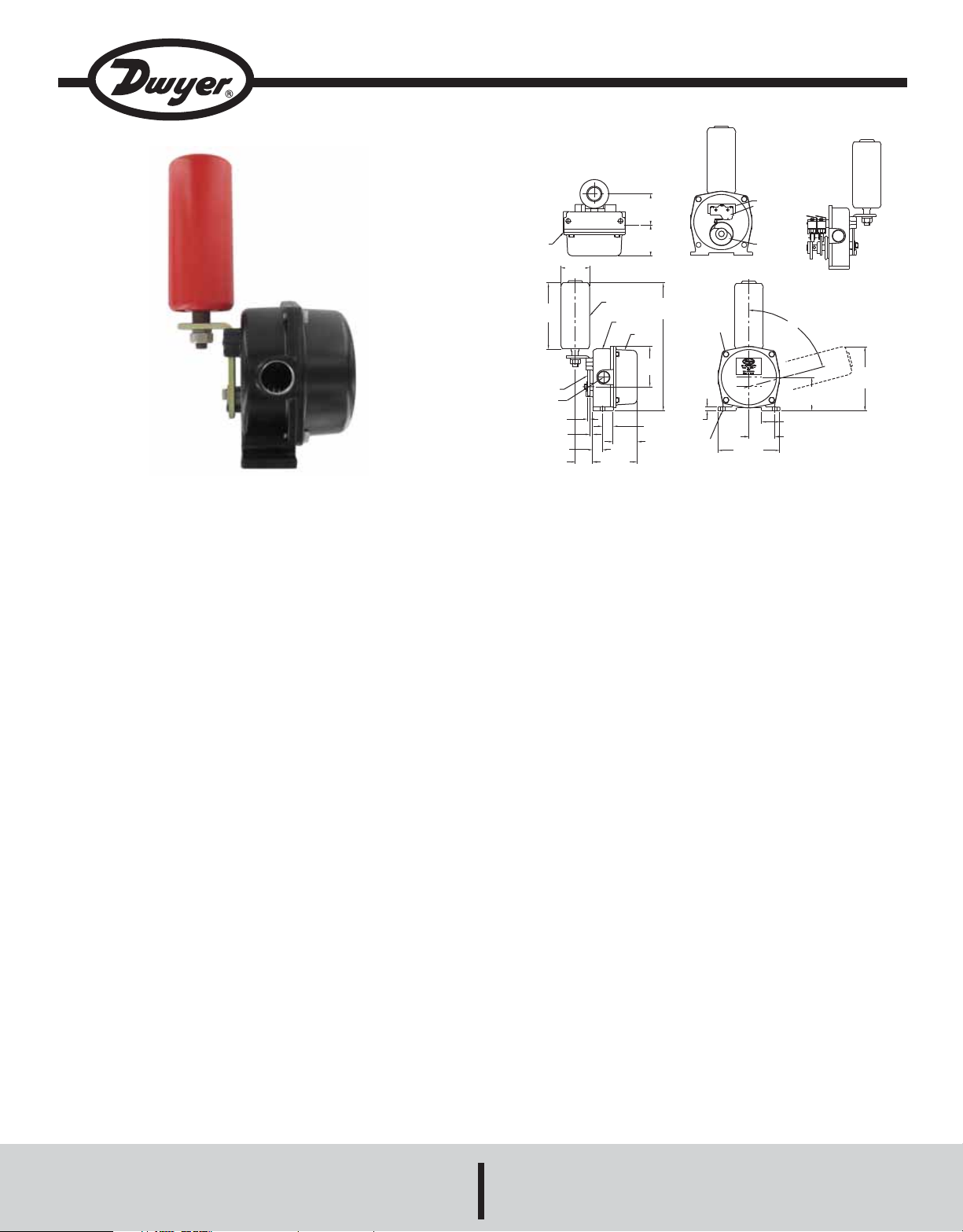

Series CBAS Belt Alignment Switch

Specifications - Installation and Operating Instructions

Bulletin PC-CBAS

The Series CBAS is a rugged and reliable conveyor belt align-

ment switch. The compact die cast aluminum housing is designed for easy installation. The switch cover allows for simple

access to wiring terminals and CAM adjustments. Belt alignment

switches are typically used in pairs with one switch on each side

of the conveyor belt mounted near the first and/or last pulley of a

conveyor. Each series CBAS is equipped with two micro switches, allowing one actuation angle for small belt deviations and a

second actuation angle for extreme belt deviations. The actuation angles are factory set at 20 degrees and 35 degrees, each

actuation angle can be easily adjusted in the field to fit any application.

APPLICATIONS

• Conventional Belt Conveyors

• Ship Loading/Unloading Systems

• Stacker/Reclaim Conveyors

• Apron Feeder Conveyors

• Tripper or Shuttle Conveyors

• Crane, Shovel, or Drag Line Limit Switch

• Heavy Duty Limit Switch

INSULATORS

MICROSWITCHES

CAMS

INSIDE VIEW

2X 2-11/64

[55.17]

5-1/8

[130.18]

75°

2X 1-1/2

[38.1]

5-49/64

[70.25]

5-21/64

[135.33]

0-RING

5-9/16

[141.29]

LEVER

2X 3/4˝ NPT

3/16

[4.76]

1/4

[6.35]

51/64

[20.24]

ø2-3/8

[ø60.33]

1-15/32

[37.31]

TOUCH

PULLEY

1-63/64

[50.4]

3-43/64

[93.27]

CASE

2-9/16

[65.09]

2-9/16

[65.09]

10-9/16

[268.29]

COVER

3-11/32

[84.93]

29/32

[25.02]

2X 13/32 [10.32]

MOUNTING HOLES

COVER BOLTS

4X M10

9/32

[7.14]

SPECIFICATIONS

Temperature Limits: -4 to 140°F (-20 to 60°C).

Enclosure: Die cast aluminum.

Enclosure Rating: NEMA 6 (IP 67).

Switch Type: 2 SPDT.

Electrical Rating: 10 amp @ 125/250 VAC; 1/2 amp @ 125

VDC.

Electrical Connection: 3 screw type, common, normally open,

normally closed.

Electrical Conduit: Two 3/4" female NPT.

Activation Angles: 20 degrees and 35 degrees (adjustable).

Activation Force: 0.8 to 1.2 pounds.

Control Type: Automatic reset.

Weight: 6.4 pounds.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

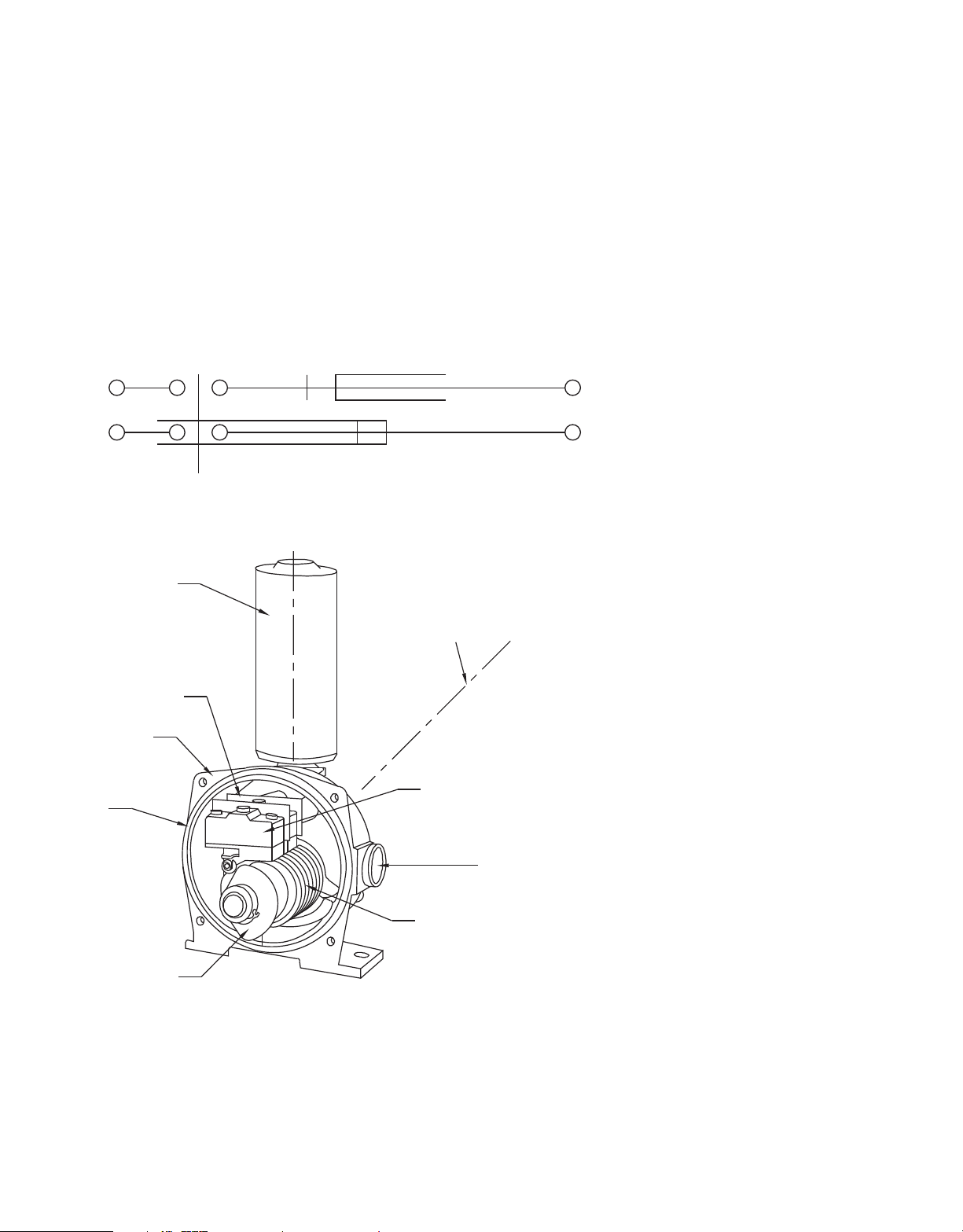

Operation Principle

The CBAS is typically installed in pairs on both sides of the belt

and positioned 1-6 feet from the head or tail pulley.

The touch roller is deflected by the deviation of the conveyor belt

from a vertical position to 75 degrees, and when the deviation is

restored, a spring will return the touch roller to the vertical

position when the belt is realigned. Cams are preset to turn on

or off the micro switches when the touch roller is deflected. When

the touch roller deviates 20 degrees the first micro switch will

change state, and when the touch roller is deviated 35 degrees

the second micro switch will change state.

Detection (Standard 1C X 2 Output)

TERMINAL NO. TERMINAL NO. TERMINAL NO.

0°

1

3

18˝ 20˝(ON)

2

5

4

* Switching frequency: 20 times/min.

• Number of contact: 1C x 2 output.

TOUCH ROLLER

INSULATING PLATES

CASING

PACKING

33°

35°(OFF)

MAX. SLANT ANGLE 75°

MICROSWITCHES

6

3/4˝ FNPT CONNECTION

CAMS

SPRING

Fig. 1 Construction of CBAS

Page 3

INSTALLATION

The mounting base should be fitted so that the CBAS touch roller

is 1-3 inches from the outside edge of the conveyor belt. The top

of the idler should be aligned 6.25” from the base of the CBAS.

A typical installations is shown in Fig. 2.

TOP OF IDLER

TOUCH ROLLER

6.25˝

MOUNTING BASE

CONVEYOR BELT

FRAME OF BELT CONVEYOR

IDLER

Fig. 2 Example of Installation of CBAS

Wiring

The Belt Alignment Switch has 2 SPDT relays that can be

accessed by removing the cover. The independent relays can be

used to control two separate circuits or allow a signal when there

is a slight belt shift and a server belt shift.

OPEN

20°

CLOSED

CLOSED

OPEN

35°

MICROSWITCH OPERATING POSITION

MICROSWITCH OPERATING POSITION

TOUCH ROLLER

MAXIMUM ANGLE

SHAFT

CAM

Fig. 3 Micro-switch Operating Positions

TOUCH ROLLER

Page 4

TERMINAL SCREW

ROLLER LEVEL

COM-1, 4

NO- 3, 6

NC- 2, 5

DEACTIVATEDACTIVATED

Fig. 4 Operation of Micro swtich

ADJUSTMENT

The Belt Sway Switch is adjusted to 20° and 35° at the factory.

If the angle of activation must be adjusted, the following steps

must be taken. Loosen the setscrew using an allen wrench as

shown in Fig 5 so that the cam can be moved. Rotate the cam to

the desired angle, and tighten the setscrew. Move the touch

roller to confirm that the micro switches activate at the desired

angle.

MAINTENANCE/REPAIR

Upon final installation of the Series CBAS, no routine

maintenance is required. The Series CBAS is not field

serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on

our website. Contact customer service to receive a Return

Goods Authorization number before shipping the product back

for repair. Be sure to include a brief description of the problem

plus any additional application notes.

MULTISWITCH

TIGHTEN

ROTATE

Fig. 5 Adjustment of Cam

ALLEN WRENCH

LOOSEN

SET SCREW

CAM

©Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 3/11 FR# R4-443727-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...